Timber

- 1. Timber

- 2. Introduction • Timber Is one of the oldest material of Construction. Parts of the trees were the first to be used by man for shelter even before he entered the age of civilization. • From the prehistoric times till date, timber has been used in a variety of ways in building construction, bridge construction, in tunnels and many other engineering activities.

- 3. Introduction

- 4. Introduction Among many Qualities of timber the following may be mentioned. • It is a natural material and a renewable resource, with proper planning, trees can form in-exhaustable source of construction materials. • It has quite satisfactory engineering properties Thus, it has better strength than concrete and steel. • Interestingly it is better fire resistant than steel or reinforced concrete. Steel on heating softens, whereas in timber, as a structural member heat travels from outside to inside at a slow rate and an inner unburnt part of timber beam may stay intact without collapsing if designed with a good factor of safety. • It is easily workable, any convenient shape can be given to timber • It is durable. If used with care and caution, timber parts can stay faithfully for centuries.

- 6. Growth of Wood • There are two ways in which trees grow up the endogenous growth and the exogenous growth. • In the endogenous growth, a plant grows by addition of new cells only at the end of the previous year’s plant height. Such a tree obviously grow upward without becoming thicker and broader. They remain, thin, slender, and knotted, Examples are Bamboo, Palms, and Yuccas. Endogenous trees are practically useless as a structural timber.

- 8. Growth of Wood • In the exogenous growth, the plant grows by the addition of a new layer of cell all around those grown in the previous year. This process naturally result in increasing in the height as well as diameter of the plant. Result is a big, tall, fat type of tree. • Almost all the structural timber is derived from the tree having exogenous growth, among them we can mention, pines, deodar, walnut , teak, mango, shishum, spruce, etc.

- 10. Exogenous Growth

- 11. Structure Of Exogenous Wood • The structure of exogenous wood may be conveniently studied under three headings, the Wood element and the arrangement of these elements. • (a) Wood Element • The fundamental element in all types of wood tissue is a cell. It is microscopic to sub-microscopic structure of different shapes and sizes. • An outer wall called the cell wall is made up of lignin, starch and glucose. It is the cell wall that is most important from engineering point of view.

- 12. Structure Of Exogenous Wood

- 13. Structure Of Exogenous Wood

- 14. Structure of Exogenous wood • Within the (inner) cell wall is enclosed the cell cavity (also called lumen) it is filled with sap in the living cell. • Since the wood tissue consist of thousands of such cells the adjacent cell walls are separated by thin layers of tissue called middle lamella. • The primary type of cell of wood tissue are: • Tracheids: These consist of very thin, submicroscopic, human hair like cell which run vertically in the tree the trachids form the principal cell of the soft wood group.

- 15. Structure of Exogenous wood

- 16. Structure of Exogenous wood • Vessels These are also longitudinal cell similar to trachids, but they differ in two main aspect their wall are comparatively thick and strong; and are open at ends when they make up the tissue of a tree the wood is called a hardwood. • The Storage cell • These form the so called medullar rays that are developed radially and connect the outermost layer of the longitudinal cell with the inner layers they are also referred as Parenchyma. • In a living tree, growth is achieved by the natural process of cell division in a special layer of cell called cambium which is located just under the skin of tree

- 17. Structure of Exogenous wood

- 18. Structure of Exogenous wood • Arrangement of wood element • The wood element namely the trachids, vessel and rays are arranged in a definite manner to give rise to a typical structure of wood. • 1) Bark • It is the outer most zone of wood structure which can be described as skin of the tree. It is hard, rough and thick in some trees. In some trees it may be soft and smooth.

- 19. Bark

- 20. The Cambium • The Cambium • In the living tree, there is always present just inside, the inner bark a delicate layer of special cells, this layer is called cambium. It is in this layer the process of growth takes place by cell division. • In old and cut trees, the cambium is no longer distinguished from the rest of wood.

- 21. The Cambium

- 22. Wood Wood • It is main zone of tree tissue, It starts from cambium and extend right up to the centre of the tree trunk. It is made up of concentric rings of cells. • The wood zone is further distinguished by heartwood and Sapwood. • The heartwood is made of wood cell lying close to the core of the tree they are older in age and darker in appearance. In heartwood, cell almost become inactive and rigid. They provide strength and support to the tree they contain little or no sap.

- 23. Wood

- 24. Wood • The sapwood is made up of new and light tissue that lies close to the skin or bark. In this zone cells are yet active and alive and full of sap In fact the name sapwood is because of their higher sap content. • The Pit • The innermost cell of heartwood becomes practically inactive and dead with the passage of time. These cells being in centre of the tree, receives little or no sap food in the later years. Hence, they start deteriorating and decay. The older the tree grows, bigger the pit zone becomes in size, this is the reason that older trees do not give sufficient yield of good timber. • The Medullar Rays These are made up of rectangular cells which arise from cambium and spread towards the inner part of the trees.

- 25. The Pit

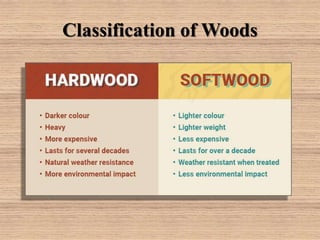

- 26. Classification of Woods • Botanically trees are divided into two main divisions the angiosperms and gymnosperms. In the former, the seed is enclosed within a fruit (mango) or a nut. In the gymnosperms, however the seeds have no such cover, they are naked, Pines are the best example of this group of trees.

- 29. Classification of Woods • In another classification trees are classified as : • The Deciduous Trees • These are characterized with broad, well defined leaves which grow in spring and fall in autumn. Walnut, mango, teak, and oak belong to this group.

- 31. Classification of Woods • The Conifers • These are characterized with needle shaped, very thin leaves which do not fall every year. They fall only when they become old. Such trees are also Commonly called ‘evergreen’ Pines, deodar, kail and fir are some of common conifers

- 32. The Conifers

- 33. Classification of Woods • Trees are sometimes classified as Softwood and Hardwoods. • The Softwoods • Comprise of such trees which yield lightweight timber. They are lighter in shades and show distinct annual rings. They are soft to work and comparatively weaker in strength. But these yields the most commonly used timber for construction purpose. All the conifers yield softwood.

- 35. Classification of Woods • The Hardwoods • Trees which yield dark colored, denser and stronger woods are classed as hardwoods. Most of the deciduous trees are teak, ash, and oak yield hardwoods. In these trees annual ring are faint, The individual cells are thick walled and hence give additional strength and density to the woods.

- 37. Properties of Wood • Most important properties of wood may be discussed under following headings; • Color and Odor • Most trees are characterized with a typical color and odor. Thus Walnut wood is distinguished by its typical brown color. • Similarly, a fresh cut teak wood has golden yellow shade. The softwood like deodar and pine show light color. As regards odor smell quite a few woods are immediately identified by their characteristic smell. Teak wood for example has an aromatic smell. The pine smells of resins. The color and odor, however, may show variations.

- 38. Color and Odor

- 39. Properties of Wood • Specific Gravity • Wood is a very light material, its specific gravity being always less than. Hence wood float on water. Wood show great deal of variation in their specific gravity, Some variety may be as light as 0.3 whereas in others the specific gravity may approach 0.9 this depends on their structure and presence of pores in them.

- 40. Specific Gravity

- 41. Properties of Wood Moisture Content • All woods are porous to some extent. Further all woods are hygroscopic as nature. They gain moisture from the atmosphere depending on moisture content of their cell the humidity in the atmosphere. The natural moisture content can be easily determined by following relation : • Mc= W 1- W 2 x 100 W 2 Where, W1= Weight of the natural wood sample. W 2 = Weight of the same sample when oven dried. Hence Mc values of natural green wood may sometimes be as high as 250 percent. A moisture content of 12 to 15 percent of air seasoned woods is considered quite safe for timber in any construction.

- 42. Moisture Content

- 43. Properties of Wood Grain • By grain is understood the arrangement and direction of growth of the wood element in the wood. In the normal wood fibers, grow parallel grow parallel to the length of the tree trunk. This type of structure is called a straight grain. • The fiber may be very tightly and closely packed giving rise to a fine-grained texture in wood. In other cases they may be comparatively broad and quite wider. The structure is then termed as coarse grained.

- 44. Grain

- 45. Properties of Wood Shrinkage and Swelling • The newly cut wood looses moisture when subjected to drying naturally or artificially. On drying, the wood undergoes shrinkage. Similarly, dry wood on getting rain soaked or wetted may undergo considerable swelling. • It is known that in the drying process, moisture from the wood is lost first from the cell cavity and then from the cell walls. It is only when the water is lost from the cell wall that the wood start shrinking. • Conversely when dry wood is wetted, the water is first received by cell walls. Only when the wall becomes saturated, water goes to the cell cavities Hence on wetting the swelling starts quickly.

- 47. Strength • The most important fact about strength of timber is that it is not the same in all the directions. This is because wood is anisotropic material (having different structure in different direction) Hence the strength of wood is determined with reference to the direction of grain of wood under load. Hence the strength of wood is determined with reference to direction of grain of the wood under load. Besides grain, many other factors also influence the strength of timber, these are, • Density: Higher the density of timber, greater will be its strength, this is because high density of timber is a result of thicker cell walls. i.e.. greater amount of wood substance per unit volume.

- 48. Strength

- 49. Strength Moisture Content • Higher the moisture Content, lower is the strength of the timber. This is because water in itself has no load bearing capacity. Its increased volume in the cell simply decrease the volume of wood tissue They tend to reduce the strength in an indirect manner. Presence of defects • There may be a number of natural and artificial defects in timber such as cross-grain, knots, and shakes etc. All of them cause a decrease in the strength of the timber

- 50. Strength

- 51. Tensile Strength • Wood is very strong to tensile force acting parallel to grain but very weak when these forces are made to act perpendicular to the grain, thus the tensile strength of some wood ranges from 500 – 2000 kg/cm2 parallel to grain whereas same value lie between 10 – 100 kg/cm2 for the same varieties when tested perpendicular to the grain.

- 52. Tensile Strength

- 53. Transverse or Bending Strength • The most important use of timber as beams is based on the fact that wood has very high bending strength, it may vary from 300 to 900 kN/cm2 or more.

- 54. Defects in Wood • As defect in timber may be defined as any undesirable character natural or artificial that lowers its strength, durability or quality. Defect in timber are generally distinguished as natural defects and artificial defects.

- 55. Defects in Wood

- 56. Natural Defects • This group includes all those defects that are developed in a tree during its growth. Their development. • Therefore, Cannot be generally controlled by man. Most common natural defects are knots, shakes, cross grain, crookedness, rind galls, burr and curl.

- 57. Natural Defects

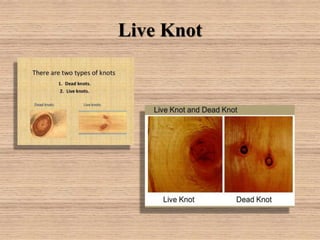

- 58. Natural Defects • Knots • A knot marks the position of growth of a branch of tree. On the cut boards, it is most easily seen by its conspicuous darker appearance and harder character. A knot is essentially a discontinuity in the timber and hence a place of weakness.

- 59. Knots

- 60. Live Knot • Knots show great variation in their size, shape, and stage of development. • Live Knot • It is the part of the branch that becomes completely enclosed within the growing trunk of a tree. In such a knot, there is complete structural continuity between fibers of branch and the main tree.

- 61. Live Knot

- 62. Dead Knot • Dead Knot • In such a knot, the continuity of the structure is almost lost or is only up to 25 % • An Intergroup Knot • This is a term used when almost three- fourth of the fibers of the knot show continuation with the main tree.

- 63. Knots • Encased Knot • It is a knot surrounded entirely by bark. • Edge Knot • It is seen only in sawn timber, on one edge of cut portion. • Face Knot • Is also seen on cut timber on the face of the board. • Knot of whatever type and shape are always considered to be defect.

- 64. Shakes • After knots shakes are more serious and common defect. In simple language they are also called cracks or fissures. • Shrinkage on aging of the tree • Due to movement caused by wind action in the growing. • Freezing of sap in the cell during its ascent.

- 65. Shakes

- 66. Shakes • Heart Shakes • These are cracks or clefts occurring in the heart wood i.e.. towards the inner regions they indicate beginning of decay of the tree. They become thinner as they extend outward. • Star Shakes • These are also called radial shakes they generally arise in sapwood and extend toward inner region. • Hence, these are wider in the outer regions and become narrows as they pass inwards. Severe temperature difference during different seasons is generally the cause of their development.

- 67. Shakes

- 68. Shakes • Cup Shakes • These are also called ring shakes these are cracks that develop parallel to the annual rings. As such when fully developed they may separate portion of timber longitudinally along the rings. Reasons for development of cup or ring shakes are to be sought in the unequal growth of the timber. The most important effect of shakes on the timber is that the shakes reduces resistance to shear.

- 69. Shakes

- 70. Cross Grain • Cross Grain • As said early, fibers of the wood in a normal tree are usually parallel to the axis of growth, the structure is called straight grained. In some cases however, these fibers are not straight they make angle or slope with the axis of tree, the structure is then called cross- grained. The slope of the grain becomes harmful when it exceeds specific limits.

- 71. Rind Gall • Rind gall i.e. Overgrowth of timber in some parts of a tree may result in some typical defects. Rind galls are quite common. A rind gall is a simple a highly thickened, enlarged wood cover developed over injured part of the tree. It is a defect because it will be removed first of all conversion of tree. • Burr and Curl are generally developed as thickened overgrowth. Such overgrowths commonly result in severe twisting of fibers in the board cut from this portion.

- 72. Rind Gall

- 73. Reaction Wood Reaction Wood • In the growing trees strong winds commonly cause “Shaking” of the standing tree again & again. As a reaction to such shaking action, wood in these trees develops additional strength in those parts where bending action is most severe and often repeated. Within a tree there may be zones of normal wood and also zones of exceptional strong wood.

- 74. Reaction Wood

- 75. Secondary Defects • These include such defects that develop in the timber after its felling and conversion to different sizes. • Checks • These are cracks or clefts developing longitudinally in the logs after their felling. These cracks or checks are often cutting across the annular ring of the log. In most of the cases their origin is due to simple cause of unequal drying. Thus, when a log of wood remain exposed to atmosphere only on one side, the upper side will loose more moisture than the under side. • This will result in shrinkage in the exposed region to such an extent that tensile force sufficient to cause crack or cracks in the wood will be easily developed. These cracks can be avoided by changing the position of the timber log at regular intervals. This will insure Uniform Shrinkage, which will not allow checks to develop.

- 77. Warps • Warping is defined as a deformation in the original plane surface of a board cut from the timber, this is attributed to unequal shrinkage. It is most commonly developed in those boards that are cut from green or “unseasoned” timber. • Warping timber can take many shapes • Box It is a Curvature of the board developed in longitudinal direction. The thin board takes the position of a bow. • Cupping It is a distortion developed transversely, Length of the board remains un affected but the width suffers distortion. • Twisting • It is a complex type of deformation in which one end of the board is so much distorted that it comes to lie over a part of the other edge.

- 78. Warps

- 79. References • Building Construction : Dr B.C. Punmia • Civil Engineering Material : Prof. Singh • Internet Web Sites

- 80. Thanks…