Unit 4 indutrial safety

- 1. Prepared and presented by N. Ganesha Pandian Assistant professor Madurai school of management Madurai

- 2. Contents Causes of Accidents Prevention of accidents Safety Provisions Industrial Health and Hygiene –Importance Problems Occupational Hazards Diseases Psychological problems Counselling Statutory Provisions.

- 3. Introduction Industrial safety must be an integral part of any industrial undertaking; it must be built in at the design stage, in production planning and in operator training The aim must be to make every individual in industry have more regard not only for his own personal safety, but also for the safety of others

- 4. Features of safety organization Factors that govern plant safety effectiveness included choice of equipment, procedures and materials, budgets, the selection of personnel the kind of leadership provided and the work habits of the individual When a safety specialist is employed to direct the plant safety programme his function usually is to assist line managers to control the safety of their operations

- 5. Contd… A. Management participation safety programme (Declaration of company safety policy) B. Supervisory responsibility for employee safety (each member of supervisory staff is held responsible for safety) C. Assignment of staff functions to safety personnel D. Provisions for safe working conditions building and equipment Facilities must be available for strong and displaying samples of safety equipment, posters, safe practice reference, equipment catalogs and for the necessary records, files and charts of the department

- 6. Accident prevention programme There are certain basic steps in safety programme, on which based on fundamental principles in the following order. 1. Obtain co-operation of plant manager 2. Obtain co-operation of other heads of departments 3. Analyze accident records 4. Hold meetings of operation executives 5. Organize education (Information on safety) Role of safety director is very important and appointed in a concern to ensure workers safety

- 7. Statutory safety provisions The statutory safety provisions as applicable to factories in India are found in (sec21-40) of factories Act 1948 Sec 21: Fencing of machinery Sec 22: Work on or near machinery in motion Sec 23: Employment of young persons on dangerous machines Sec 24: self acting machines Sec25 : Casing of new machinery Sec26: Prohibition of employment of women and children near cotton openers

- 8. Contd… Sec27 : Hoists and lifts Sec28 : Lifting machines, chains, ropes and lifting tackles Sec29 : Revolving machinery Sec30 : Pressure plant Sec31 : Floors, stains and means of access Sec32 : pits, sumps, openings in floors etc., Sec33 : Excessive weights Sec34 : Protection of eyes Sec35 : Precautions against dangerous fumes, gases and etc.,

- 9. Contd… Sec36 : Precautions regarding the use of portable electric light Sec37 : Explosive or inflammable dust, gas and etc., Sec38 : Precautions in case of fire Sec39 : Power to require specifications of defective parts or tests of stability Sec40 : Safety of buildings and machinery Sec40A : Maintenance of buildings sec40B : safety officers Sec41 : Powers to make rule to supplement this chapter

- 10. Workers’ health Statutory health measures: The factories act 1948 comprises 11 chapters and 120 sections with a schedule listing notifiable disease. (sec11 to 20) of factories act 1948 list the following health measures to be provided for its workers Sec11: Cleanliness Every factory shall be kept clean and free from effluent arising from drain, privy or other Sec12 : Disposal of wastes and effluents Effective arrangements shall be made in every factory for the treatment of wastes and effluents due to the manufacturing process carries on therein, so as to render them innocuous and for their disposal

- 11. Contd…Sec13 : Ventilation and temperature Effective and suitable provision shall be made in every factory for securing and maintaining in every workroom Sec14 : Dust and fume If any exhaust appliance is necessary for this purpose, it shall be applied as near as possible to the point of origin of the dust, fume or other impurity Sec15 : Artificial humidification In any factory in which the humidity of the air is artificially increased Sec16 : Overcrowding No room in any factory shall be overcrowded to an extent injurious to the health of the workers employed therein Sec17 : Lighting In every part of a factory where workers are working or passing there shall be provided and maintained sufficient and suitable lighting, natural or artificial or both

- 12. Contd… Sec18 : Drinking water In every factory effective arrangements shall be made to provide and maintain at suitable points conveniently situated for all workers employed therein a sufficient supply of wholesome drinking water Sec19 : Latrines and urinals In every factory, sufficient latrine and urinal accommodation of prescribed conveniently suited and accessible to workers at all times while they are at factory Sec 20 : Spit toons In every factory there shall be provided a sufficient no. of spit toons in convenient places and they shall be maintained in a clean and hygienic condition

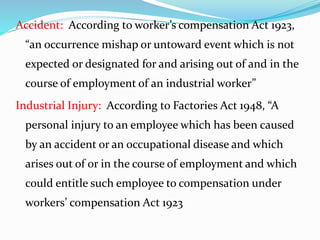

- 13. Accident: According to worker’s compensation Act 1923, “an occurrence mishap or untoward event which is not expected or designated for and arising out of and in the course of employment of an industrial worker” Industrial Injury: According to Factories Act 1948, “A personal injury to an employee which has been caused by an accident or an occupational disease and which arises out of or in the course of employment and which could entitle such employee to compensation under workers’ compensation Act 1923

- 14. Hazardous processes The schedule- Part A Hazardous occupation Any occupation concerned with :- 1. Transport of passengers, goods or mails by railways; 2. Cinder packing, clearing of an ash pit or building operation in the railway premises 3. Work in a catering establishment at a railway station, involving the movement of a vendor or any other employee of the establishment from one platform to another and etc., 4. Work relating to the construction of a station or with any other work where such work is done in close proximity to or between the railway lines 5. A port authority within the limits of any port 6. Work relating to selling of crackers and fireworks in shops with temporary licenses

- 15. 7. Abattoirs /Slaughter house 8. Foundries 9. Automobile workshops and garages 10. Handling of toxic or inflammable substances or explosives 11. Handloom and power loom industry 12. Mines (underground and underwater) and collieries 13. Plastic units and fiberglass workshops 14. Domestic workers or servants and 15. Dhabas (roadside eateries), restaurants, hotels, motels, tea shops , resorts, spas or other recreational centres

- 16. Part – B Industries wherein the manufacturing process are hazardous 1. Beedi – Making 2. Carpet weaving 3. Cement manufacturing, including bagging of cement 4. Cloth printing, dying and weaving 5. Manufacture of matches, explosives and fireworks 6. Mica – Cutting and splitting 7. Shellac manufacture 8. Soap manufacture 9. Tanning 10. Wool – cleaning 11. Building and construction industry 12. Manufacture of slate pencils

- 17. 13. Manufacture of products from agate 14. Manufacturing products using toxic metals and substances such as lead, mercury, manganese, chromium, cadmium, benzene, pesticides and asbestos 15. “Hazardous process” as defined in sec 2(cb) and “dangerous operations” as noticed in rules made under sec 87 of the factories act 1948(63 of 1948) 16. Printing as defined in section 2(k)(vi) of the factories Act, 1948(63 of 1948) 17. Cashew and cashew nut de scaling and processing 18. Soldering process in electronic industry 19. “Agarbatti” manufacturing 20. Automobile repairs and maintenance including processes incidental thereto namely welding, latte work and painting

- 18. 21. Brick kilns and roof tiles units 22. Cotton ginning and processing and production of hosiery goods 23. Detergent manufacturing 24. Fabrication workshops (ferrous and non-ferrous) 25. Gem cutting and polishing 26. Handling of chromites and manganese ores 27. Jute textile manufacture and Coir making 28. Lime Kilns and manufacture of lime 29. Lock making 30. Manufacturing process having exposure to lead 31. Manufacture of cement pipes, cement products and other related work

- 19. 32. Manufacture of glass and glassware 33. Manufacture of dye and dyestuff 34. Manufacturing or handling of pesticides and insecticides 35. manufacture, processing and handling of corrosive and toxic substances 36. Manufacturing of burning coal and coal briquettes 37. Manufacturing of sports goods involving chemicals and leather 38. Molding and processing of fiber glass and plastic 39. Oil expelling and refinery 40. Paper making 41. Potteries and ceramic industries 42. Polishing, moulding, cutting, welding and manufacturing of brass goods in all forms

- 20. 43. Processes in agriculture 44. Saw mill –all processes 45. Sericulture processing 46. Skinning, dyeing and processes for manufacturing of leather and leather products 47. Stone breaking and stone crushing 48. Tobacco processing including manufacturing 49. Tyre making, repairing, re-treading and graphite benefaction 50. Utensils making, polishing and metal buffing 51. ‘Zari’ making 52. Electroplating 53. Graphite powdering and incidental processing 54. Ginding or glazing of metals 55. Diamond cutting and polishing 56. Extraction of slate from mines 57. Rag picking and scavenging

- 21. List of industries involving hazardous processes as defined U/S 2(cb) of the factories Act, 1948 1. Ferrous metallurgical industries 1.1 Integrated iron and steel 1.2 Ferrous-alloys 1.3 special steels 2. Non-ferrous metallurgical industries 2.1 primary metallurgical industries namely zinc, lead, copper, manganese and aluminum 3. Foundries (ferrous and non-ferrous) 3.1 castings and forging including, cleaning or smoothening, roughening by sand and shot blasting 4. Coal (including coke) industries 4.1 Coal, lignite, coke and etc., 4.2 fuel gases

- 22. 5. Power generating industries 6. Pulp and paper(including paper products) 7. Fertilizer industries 7.1 nitrogenous 7.2 phospahtic 7.3 mixed 8. Cement industries 9. Petroleum industries 10. petro-chemical industries 11. Drugs and pharmaceutical industries 12. Fermentation industries 13. Rubber industries

- 23. 14. Leather tanning industries 15. Paints and pigments industries 16. Electroplating industries 17. Chemical industries 18. Synthetic resin and plastics 19. Man-made fiber industry 20. Manufacture and repair industry 21. Glass and ceramics 22. Insecticides, fungicides, herbicides and other pesticides industry 23. Grinding and glaxing of metals 24. Manufacture, handling and processing of asbestos 25. Extraction of oils and fats from vegetable and animals sources

- 24. 26. Manufacture, handling and use of benzene and substances containing benzene 27. Manufacturing processes and operations involving carbon disulphide 28. Dyes and Dye stuff including their intermediates 29. Highly inflammable liquids and gases

- 25. Statutory requirements for hazardous manufacturing process In a factory manufacturing process of hazardous nature is carried on, the factory shall compulsorily comply with (sec41A to 41H) of the factories Act 1948 1. The state government may for purpose of advising it to consider applications for grant of permission for the initial location of a factory, appoint a site appraisal committee 2. Site appraisal committee consists of the chief inspector of the chairman who shall be its chairman 3. And other representatives from central board for the prevention an control of pollution 4. They shall examine an application for the establishment of a factory involving hazardous process and make its recommendation to the state government with in a period of 90 days 5. They shall have power to call for any information

- 26. Sec 41B: Compulsory disclosure of information by the occupier The occupier of every factory involving a hazardous process shall disclose in the manner prescribed all information regarding dangers, including health hazards and the measures to overcome such hazards arising from the exposure to or handling of the materials or substance in the manufacture, transportation, storage and other process to the workers employed in the factory is situate and general public in vicinity

- 27. Sec 41C: Specific responsibility of the occupier in relation to hazardous processes Every occupier of a factory involving any hazardous process shall- (a) maintain accurate and up to date health records or, as the case may be, medical records, of the workers in the factory who are exposed to any chemical, toxic or any other harmful substances which are manufactured, stored , handled or transported and such records shall be accessible to the workers subject to such conditions as may be prescribed

- 28. Sec 41D: Power of central government to appoint inquiry committee The central government may, in the event of the occurrence of an extra ordinary situation involving a factory engaged in a hazardous process, appoint an inquiry committee to inquire into the standards of health and safety observed in the factory with a view to finding out the causes of any failure or neglect in the adoption of any measures or standards prescribed for the health and safety of the workers employed in the factory or the general public affected

- 29. Sec 41E: Emergency standards The emergency standards laid down under sub-section shall, until they are incorporated in the rules made under this Act, be enforceable and have the same effect as if they had been incorporated in the rules made under this Act. Sec 41F: Permissible limits of exposure of chemicals and toxic substances The maximum permissible threshold limits of exposure of chemicals and toxic substances in manufacturing processes (whether hazardous or otherwise) in any factory shall be of the value indicated

- 30. Sec 41F : Workers’ participation in management The occupier shall, in every factory where a hazardous process take place, or where hazardous substances are used or handled, set up a safety committee consisting of equal number of representatives of workers and management to promote co-operation between workers and the management in maintaining proper safety and health at work Sec 41G : Rights of workers to warn about imminent danger

- 31. Occupational hazards Every occupation has its own hazards, one should take adequate and proper precautions to save him/ her Companies should look into safety of their workers before hand to have proper safety and precautionary measures against occupational hazards is the fundamental right of all workers The constitution of India, as a part of the fundamental rights has laid down that the state shall direct its policy towards protection of childhood and youth against exploitation

- 32. They shall not be employed to work in any factory or mine or engaged in any hazardous employment Construction and chemical work, automobile repairing and Gem polishing are some of industries affect the physical and mental health of children So there is a serious concern of the government and society about those children who are working in such hazardous occupations

- 33. Match and firecracker industry in Sivakasi, Tamil Nadu In and around Sivakasi, TN there are approximately 2700 match workers and 200 fire factories employing more than 2 lacs workers According to UNICEF (united nations children's fund) 1986, there are 45,269 children working in this industry Children are employed in various process of match making factory. Major processes are frame filling, wax dipping, head filling, drying, box farming, side painting, band rolling and etc., They are exposed to various chemical hazards mainly potassium chlorate, commercial sulphur, glue, black and red manganese, red phosphorus, antimony glass powder etc.,

- 34. Occupational health problems In the long run, due to synergistic effect of above mentioned chemicals in the presence of excessive heat and lack of ventilation and improper ergonomic condition, the major occupational health problem which can be expected are many Common acute occupational illness observed are allergic skin diseases, allergic lung disorders and irritation of eyes with lacrimation, photophobia and conjunctivitis Long working hours may induce psychological problems can’t be ruled out

- 35. Gem polishing industry, Jaipur; Rajasthan Gem polishing Industry is located mainly in Jaipur, the capital of Rajasthan where there are 60,000 persons are employed in this industry Out of total work force nearly 20% are children, many of the children complain frequent injuries, fissures and cracks of their hands and fingers, especially tip of fingers

- 36. Hand made carpet weaving industry, Mizpur and Bhadoi, UP The art of carpet making has spread from Kashmir to the southern tip of India By approx, out of total workers 80%, 15%, 5% are in UP (96,000 children out of 2,40,000 total employees) Rajasthan (12,000 children out of 30,000 total employees) and J&K (6000 out of 15,000 employees)respectively Workers/children are subject to skeletal deformities, ergonomic problems, eye sight problems due to exposure to toxic chemicals

- 37. Mental health problems The very fine work requiring a high degree of skill and constant attention leads in some cases to nervous illness manifesting itself in hand trembling and sometimes mental troubles

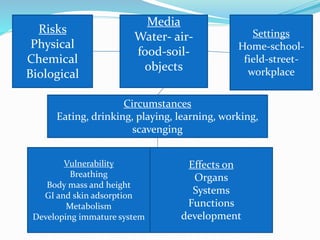

- 38. Risks Physical Chemical Biological Media Water- air- food-soil- objects Settings Home-school- field-street- workplace Circumstances Eating, drinking, playing, learning, working, scavenging Vulnerability Breathing Body mass and height GI and skin adsorption Metabolism Developing immature system Effects on Organs Systems Functions development

- 39. Notifiable diseases The factories act further declares certain diseases which are particularly attributable to such industry or the manufacturing process carried out in that particular industry, sec89&90 of Act specify them as: Sec 89: Notice of certain diseases Where any worker in a factory contracts any disease specified in the Third schedule, the manager of the factory shall send notice thereof to such authorities, and in such form and within such time as may be prescribed The central government may by notification in the official Gazette, add to or alter the Third schedule and any such addition or alteration shall have effect as if had been made by this Act

- 40. Sec 90: Power to direct enquiry into cases of accident or disease The state government may, if it considers it expedient so to do, appoint a competent person to inquire into the causes of any accident occurring in a factory or into any case where a disease specified in the Third schedule has been, or is suspended to have been, contracted in a factory, and may also appoint one or more persons possessing legal or special knowledge to act as assessors in such inquiry

- 41. Sec 91: Power to take samples An inspector may at any time during the normal working hours of a factory, after informing the occupier or manager of the factory, take in the manner hereinafter provided a sufficient sample of any substance used or intended to be used in the factory Sec 91A: Safety and occupational health surveys For the purpose of facilitating surveys under sub-section: Every worker shall, if so required by the person conducting the survey present himself to undergo such medical examination as may be considered necessary by such person and furnish all information in his possession and relevant to the survey

- 42. List of Notifiable diseases 1. Lead poisoning including poisoning by any preparation or compound of lead 2. Lead tetra ethyl poisoning 3. Phosphorus poisoning 4. Mercury poisoning 5. Manganese poisoning The third schedule of the Act lists the following diseases as Notifiable diseases. The third schedule (sec89&90) 6. Arsenic poisoning 7. Poisoning by nitrous fumes 8. Carbon di sulphide poisoning 9. Benzene poisoning 10, Chrome poisoning

- 43. 19. Toxic jaundice 20. Oil acne or dermatitis 21. Byssionosis 22. Asbestosis 23. Occupational or contract dermatitis 24. Berillium poisonong 25. Carbon mono oxide 26. Coal miner’s pneumoconiosis 27. Phosgene poisoning 28. Occupational cancer 29. Iso cynates poisoning 30. Toxic Nephratitis 11. Anthrax 12. Silicosis 13. Poisoning by halogens and derivatives 14. Pathological manifestations 15. Radium or other radio active substances 16. X-rays 17. Cancer of skin 18.Toxic anemia

- 44. Psychological counseling The counseling process is a planned, structured dialogue between a counselor and a client It is a co-operative process in which a trained professional helps a person called the client to identify sources of difficulties or concerns that he/ she is experiencing Together they develop ways to deal with and overcome these problems so that person has new skills and increased understanding of themselves and others

- 45. Counseling process Step 1: Relationship building Step 2: Problem Assessment Step 3: Goal setting Step 4: Counseling intervention Step 5: Evaluation, termination or referral

- 46. Qualities of counselor 1. Interpersonal relationship 2. Personal adjustment 3. Health and personal appearance 4. Leadership 5. Philosophy of life 6. High sense of morality

- 47. Techniques of counseling 1. Prescriptive counseling 2. Non-directive counseling 3. Directive counseling

- 48. Counseling methodology Counseling psychologists participate in a range of activities including teaching, research, psychotherapeutic and counseling practice, career development, assessment, supervision and consultation They employ a variety of methods closely tied to theory and research to help individuals, groups and organizations function optimally as well as mediate dysfunction/ issues Counseling psychology also consult with organizations seeking to enhance their effectiveness or the well being of their members

- 49. Exam point of view Part-A Define “Industrial safety”? What is meant by psychological problem? What is the importance of hygiene in industries? Write a note on significance of industrial safety for employees? What is mean by “Industrial health”? Define “Counselling”? Write the need for social assistance? Define “Accidents”? What are the implications of statutory provisions? What is works committee? What is occupational disease? Define “psychology”? What are hygiene factors? What are the causes of accidents in factory? What is occupational hazard?

- 50. Part-B Enlist the causes of industrial accidents and mention the safety measures to be taken to prevent the same? How and to what extent occupational hazard can be minimized and employees to be compensated adequately for health risks? Psychological issues of employees and measures taken to prevent adverse impact on overall health of employees. Factors motivating the industrial health and hygiene Essentials and different methods of counselling? Various statutory measures available for the industrial safety in India. Occupational hazards and occupational disease. Legal provisions regarding employee health under the factories Act 1948