Unit I.pdf

- 1. PRODUCTION PLANNING & CONTROL (PPC) Course Instructor Dr. Vivek Sheel Rajput Assistant Professor Department of Mechanical Engineering

- 2. Production is an organized activity of converting raw materials into useful products. But before starting the actual production process planning is done: • To anticipate possible difficulties. • To decide in advance – how the production processes be carried out in a best & economical way to satisfy customers. Quantity, Quality, Time, and Price—encompass the production system.

- 3. Only planning of production is not sufficient. The management must take all possible steps to see that plans developed by the planning department are properly adhered to and the standard sets are attained. In order to achieve it, control over production process is exercised.

- 4. Definition: PPC may be defined as the direction and co-ordination of the firms materials and physical facilities towards the attainment of pre-specified production goals in the most efficient and economical way. Objective: Therefore, the ultimate objective of production planning and control is to produce products of • right quality • in right quantity • at right time By using the best and least expensive methods/procedure.

- 5. OBJECTIVES OF PRODUCTION PLANNING • To determine the requirements of men, material and equipment. • Arranging production schedules according to the needs of marketing demand. • Arranging various inputs at a right time and in right quantity. Making most economical use of various inputs. • To achieve coordination among various departments relating to production. • To make all arrangements to remove possible obstacles in the way of smooth production. • To achieve economy in production cost and time. • To operate plant at planned level of efficiency. • Making efforts to achieve production targets in time.

- 6. Elements of production planning and control:

- 7. Materials Raw materials, as well as standard finished parts and semifinished products, must be available when required, to ensure that each production operation will start on time. Duties include the specifications of materials (both with respect to dimensions and quality), quantities and availability, delivery date, standardization and reduction of variety, procurement and inspection. This function also covers the procurement of semifinished products from subcontractors.

- 8. Methods The purpose of this function is to analyze possible methods of manufacture and to try define the best method compatible with a given set of circumstances and facility. This analysis covers both the general study and selection of production processes for the manufacture of components or assemblies and the detailed development and specifications of methods of application. Such a study results in determining the sequence of operations and the division of the product into assemblies and subassemblies, modified by the limitations of existing layout and work flow.

- 9. Machines and equipment Methods of manufacture have to be related to available production facilities, coupled with a detailed study of equipment replacement policy. Maintenance, policy, procedure, and schedules are also functions connected with managerial responsibility for equipment, since the whole problem of breakdowns and reserves can be seriously reflected in halts in production. Tool management, as well as problems both of design and economy of jigs and fixtures constitutes the duties of production planning and control.

- 10. In short, routing determines ‘What’, ‘How much’, ‘With which’, ‘How’ and ‘Where’ to produce. Production planning and control ensures that raw materials are transformed into finished goods using the best route possible. Eliminating useless steps or excessive motion through the shop floor are the main objective of this component. Routing Routing is the first step in production planning and control. Routing can be defined as the process of deciding the path (route) of work and the sequence of operations. Routing fixes in advance: ➢ The quantity and quality of the product. ➢ The men, machines, materials, etc. to be used. ➢ The type, number and sequence of manufacturing operations, and the place of production.

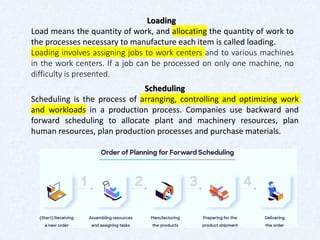

- 11. Loading Load means the quantity of work, and allocating the quantity of work to the processes necessary to manufacture each item is called loading. Loading involves assigning jobs to work centers and to various machines in the work centers. If a job can be processed on only one machine, no difficulty is presented. Scheduling Scheduling is the process of arranging, controlling and optimizing work and workloads in a production process. Companies use backward and forward scheduling to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials.

- 12. Dispatching - This phase of production planning in control involves the execution of the production schedule. It involves the release of materials, components, and tools to the machine operators so that production can begin. As one can imagine, this is where the importance of production planning and control is highlighted. If there are any delays in procuring materials or inefficient routing or processes, production will be hindered. Expediting - This step is also called Follow-Up and involves checking the progress of production. It also involves the follow up of materials, work in progress, and assembly. In this step, manufacturers should identify bottlenecks in the production process and work to remedy them to ensure that the production plan is executed as planned.

- 13. Evaluation One of the most important steps in production planning and control, and any process in general, is to evaluate it. This portion helps identify areas where productivity is still lacking and where improvements could be made. Managers can then focus on these areas and determine what needs to be changed and then implement strategies to improve those areas. Inspection Inspection is the most common method of attaining standardization, uniformity and quality of workmanship. It is the cost art of controlling the production quality after comparison with the established standards and specifications. It is the function of quality control. These in-process inspection procedures take place at any stage of production to ensure the product quality is being met before they are finalized and continue to the next stage. Identifying a misstep at an early stage in production gives the ability to reset the issue and save time and resources in the long run.

- 14. Production System refers to that set-up of the organization, which is engaged in producing products. It is an activity in which resources are put together and converted into a product. This process enables adding value to that product. Further, the process takes place as per the policies of the management. •Objective: Because the process of production is an organized activity. So, it takes place with an objective. •Transformation: Conversion of various inputs into outputs takes place in this process. •Feedback: Feedback about activities is necessary. This helps in controlling and improving the performance of the system.

- 15. Classification of Production System

- 16. Intermittent production • The production process takes place at irregular intervals to produce a number of different products with the help of one production line. • Manufacturers use this system to produce low-volume, high-variety products. Job Shop Production • It involves the manufacturing of one or a few products within a predetermined time and cost. • This is because the production takes place as per the specifications of the customer. Therefore, the products in job shop production are high in variety and low in volume. Also, they aim to meet the requirement of the specific order.

- 17. The machines are general purpose. These are set up in different departments. Further, each job has a unique technological requirement. Also, it requires processing on machines in a definite order. Its sub-classification relies on the production of job 1.Only once 2.At irregular intervals 3.At regular intervals Examples: Boutique, Automobile service center, typing shops, etc. Characteristics of Job Shop Production •Multiple varieties of products and low volume. •Machines and facilities are general purposes. •Operators are highly skilled and can perform each job in an effective manner. They take each job as a challenge due to its uniqueness. •There is a huge stock of materials, tools, equipment, and parts. •In-depth planning is important to determine the need of each product, and capacities for each work center, and to order priorities.

- 18. Example of Job Shop Production system

- 20. Batch Production It is that type of production system in which the job passes through functional departments, in lots. These lots are nothing but batches and each lot has a different routing. It involves manufacturing a confined number of products. They are similar and produced in large volumes. These products are produced at periodic intervals and stocked awaiting sales of the batches. Its sub-classification relies on the production of batches: 1.Only once 2.At irregular intervals 3.At regular intervals Examples: Production of tyres and tubes, ready-made garments, pharmaceuticals, and cosmetics.

- 21. Characteristics of Batch Production •The production runs are shorter. •Flexible plant and machinery. •Plant and machinery set up are used to the product in the lot. After that, the setup undergoes a change so as to process the next batch. •Lower lead time and cost.

- 23. Continuous Production Here utilization of machines and resources for producing identical products takes place. It involves the production of large quantities of products, whose demand is high. Mass Production When manufacturing of discrete parts and assemblies takes place by way of a continuous process, it is mass production. The production involves a large volume so as to meet demand. In this, the arrangement of the machine is in a line. There is the standardization of products and processes. Further, the outputs go through the same path. Also, the materials are purchased in bulk. It requires well-researched production planning. Examples: Production of auto parts and industrial products.

- 24. Characteristics of Mass Production ➢ Standardization of sequence of product and process. ➢ Special purpose machines dedicated to higher production capacities and output rates. ➢ Product volume is large. ➢ Cycle time of production is shorter. ➢ Lower in process inventory. ➢ Balanced production lines. ➢ The continuous flow of material components and parts. Also, it does not have any backtracking. ➢ Easy production planning and control. ➢ Automatic material handling. Process Production System Assembly Production System

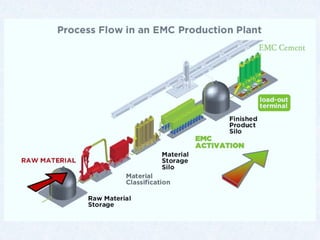

- 26. Flow Production The need for the product forms the basis of plant design. There is no flexibility regarding the use of resources to produce similar products. Due to this characteristic, when there is a decrease in demand, the resources cannot be used to produce other products. Therefore, it is discarded. So we can say that the plant design is specific to that product only. Examples: Cement factory, sugar factory, chemical processing, computer keyboards, and oil refinery Characteristics of Flow Production •Conversion process whereby successive units of output undergo the same operation sequence. •Use of specialized equipment positioned along the production line

- 28. Summary

- 29. Plant layout means the disposition of the various facilities (equipment, material, manpower etc.) and services of the plant within the area of site located. Objectives ➢ Material handling and transportation is minimized and effectively controlled. ➢ Bottlenecks and points of congestions are eliminated (by line balancing) so that the raw material and semi-finished goods move fast from one workstation to other. Workstations are designed suitable and properly. ➢ Suitable spaces are allocated to production centers and service centers. ➢ The movements made by the workers minimized.

- 30. Layout can be classified into the following four categories: a. Process layout b. Product layout c. Group or cellular layout(combination layout) d. Fixed position layout

- 31. Process layout: ➢ It is also known as functional layout. ➢ Here similar machines and services located together Ex. All the lathe machines will be at one place and all milling machines at another place and so on. ➢ This type of layout generally employed for industries engaged in job-shop production and non-repetitive kind of production. ➢ When there variety of products manufactured at low volume we prefer this type of layout. ➢ Ex. furniture manufacturer company, restaurant etc.

- 33. Illustrations of Process layout Service or Repair Stations

- 35. Car lifting (Underneath Repair)

- 36. Tyre Repair and Maintenance (Balancing & Alignment)

- 37. Shopping Complex: Different Sections for Different products Grocery Clothing (Female) Clothing (Male) Bags Restaurant Billing

- 38. Clothing Section or Showroom (Female)

- 39. Process Layout at Vermont Teddy Bear Company

- 42. Product layout ➢ It is also known as line (type) layout. ➢ The flow of product will smooth and logical. ➢ When the machines and auxiliary services are located according to the processing sequence we prefer this layout. ➢ It implies that various operations raw material are performed in a sequence and the machines are placed along the product flow line. ➢ The product layout is selected when the volume of production of a product is high such that separate production line to manufacture it can be justified. ➢ Assembly line production or mass production prefer this type layout. ➢ Ex. Assembly of television sets, assembly of computer key-board etc.

- 44. Part moves through a dedicated sequence of operations or in a dedicated order. Three flow lines work together to produce a single or final product. Each line works with a dedicated sequence of operations.

- 45. Product Layout for candy making at Just Born, Inc

- 46. Flow lines for engine assembly or subassembly; Unidirectional Automatic (robotic) flow lines

- 47. Hyundai car assembly line/ Product layout

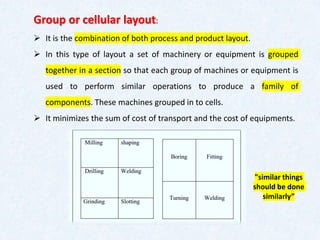

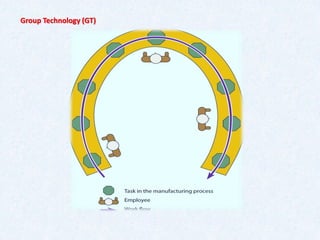

- 50. Group or cellular layout: ➢ It is the combination of both process and product layout. ➢ In this type of layout a set of machinery or equipment is grouped together in a section so that each group of machines or equipment is used to perform similar operations to produce a family of components. These machines grouped in to cells. ➢ It minimizes the sum of cost of transport and the cost of equipments. "similar things should be done similarly”

- 51. Arranging work by function, however, isn’t always efficient. Production lines can back up, inventories can build up, workers can get bored with repetitive jobs, and time can be wasted in transporting goods from one workstation to another. To counter some of these problems, many manufacturers have adopted a cellular layout, in which small teams of workers handle all aspects of building a component, a “family” of components, or even a finished product. Each team works in a small area, or cell, equipped with everything that it needs to function as a self- contained unit. Both product and process layouts arrange work by function.

- 52. ➢ Machines are sometimes configured in a U-shape, with people working inside the U. ➢ Because team members often share duties, they’re trained to perform several different jobs. ➢ Teams monitor both the quantity and the quality of their own output. This arrangement often results in faster completion time, lower inventory levels, improved quality, and better employee morale. ➢ Cellular manufacturing is used by large manufacturers, such as Boeing, Raytheon, and Pratt & Whitney (Chaneski, 1998), as well as by small companies, such as Little Enterprise, which makes components for robots (Modern Machine Shop Magazine, 2001; Little Enterprises, Inc., 2011).

- 54. ➢ GT can be viewed as a role model to obtain the advantages of flow line systems in environments previously ruled by job shop layouts. ➢ The idea is to form groups and to aim at a product-type layout within each group (for a family of parts). ➢ Whenever possible, new parts are designed to be compatible with the processes and tooling of an existing part family. The classical GT cell allows parts to move from any machine to any other machine. Flow is not unidirectional. However, since machines are located in close proximity short and fast transfer is possible.

- 57. Fixed position layout ➢ It is also called static product layout in which the physical characteristics of the product dictate as to which type of machine and men are brought to the product. ➢ This type layout is inherent in ship building, aircraft manufacture and big pressure vessels fabrication. ➢ In other type layout the product moves past stationary production equipment where as in this case men and equipment are moved to the material at one place and the product is completed at the place where the material lies. ➢ In producing large items, manufacturers use fixed-position layout in which the product stays in one place and the workers (and equipment) go to the product.

- 58. This is the arrangement used by General Housing Corporation in constructing modular homes. Each house is constructed at the company’s factory in Bay City, Michigan, according to the customer’s design. Because carpenters, electricians, plumbers, and others work on each building inside the climate-controlled factory, the process can’t be hindered by weather.

- 62. Manufacturing of Ships and Aircrafts

- 64. Exercise As purchasing manager for a company that flies corporate executives around the world, you’re responsible for buying everything from airplanes to onboard snacks. You plan to visit all the plants that make the things you buy: airplanes, passenger seats, TV/DVDs that go in the back of the passenger seats, and the specially designed uniforms (with embroidered company logos) worn by the flight attendants. What type of layout should you expect to find at each facility— process, product, or fixed-position? What will each layout look like? Why is it appropriate for the company’s production process? Could any of these plants switch to a cellular layout? What would this type of layout look like? What would be its advantages?