VERIS Accelabar Flow Meter

- 1. 1 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. VERIS ACCELABAR® SUPERIOR FLOW MEASUREMENT ACCURACY Mead O'Brien | www.meadobrien.com | (800) 892-2769

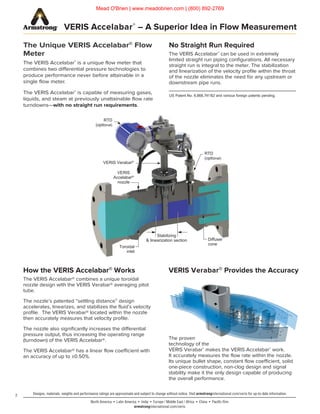

- 2. 2 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. VERIS Accelabar® – A Superior Idea in Flow Measurement The Unique VERIS Accelabar® Flow Meter The VERIS Accelabar® is a unique flow meter that combines two differential pressure technologies to produce performance never before attainable in a single flow meter. The VERIS Accelabar® is capable of measuring gases, liquids, and steam at previously unattainable flow rate turndowns—with no straight run requirements. How the VERIS Accelabar® Works The VERIS Accelabar® combines a unique toroidal nozzle design with the VERIS Verabar® averaging pitot tube. The nozzle’s patented “settling distance” design accelerates, linearizes, and stabilizes the fluid’s velocity profile. The VERIS Verabar® located within the nozzle then accurately measures that velocity profile. The nozzle also significantly increases the differential pressure output, thus increasing the operating range (turndown) of the VERIS Accelabar®. The VERIS Accelabar® has a linear flow coefficient with an accuracy of up to ±0.50%. No Straight Run Required The VERIS Accelabar® can be used in extremely limited straight run piping configurations. All necessary straight run is integral to the meter. The stabilization and linearization of the velocity profile within the throat of the nozzle eliminates the need for any upstream or downstream pipe runs. US Patent No. 6,868,741 B2 and various foreign patents pending. VERIS Verabar® Provides the Accuracy The proven technology of the VERIS Verabar® makes the VERIS Accelabar® work. It accurately measures the flow rate within the nozzle. Its unique bullet shape, constant flow coefficient, solid one-piece construction, non-clog design and signal stability make it the only design capable of producing the overall performance. VERIS Verabar® RTD (optional) Stabilizing & linearization section Toroidal inlet Diffuser cone VERIS Accelabar® nozzle RTD (optional) Mead O'Brien | www.meadobrien.com | (800) 892-2769

- 3. 3 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. VERIS Accelabar® – Test Data Verified Accuracy and Flow Coefficients Empirical test data from an independent laboratory verified the VERIS Accelabar’s flow coefficient (K) as constant and independent of Reynolds Number. The flow coefficient remained within a ±0.5% error band regardless of upstream flow disturbances, thus validating the assertion: zero straight run required. Results Comparing the two tests shown below reveals that K values remain within ±0.5% of each other and within ±0.5% of the predicted value. This holds true regardless of upstream piping configurations that skew and distort the fluid’s flow profile. Baseline Test at CEESI (NIST Traceable Flow Lab) 2” SCH 80 pipe Date 11-9-2009 No Straight Run—Two Elbows Out of Plane—Test 2” SCH 80 pipe Date 11-9-2009 Mead O'Brien | www.meadobrien.com | (800) 892-2769

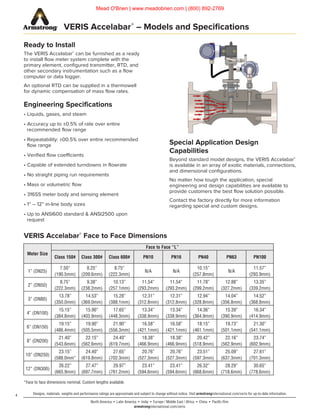

- 4. 4 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. VERIS Accelabar® – Models and Specifications Ready to Install The VERIS Accelabar® can be furnished as a ready to install flow meter system complete with the primary element, configured transmitter, RTD, and other secondary instrumentation such as a flow computer or data logger. An optional RTD can be supplied in a thermowell for dynamic compensation of mass flow rates. Engineering Specifications • Liquids, gases, and steam • Accuracy up to ±0.5% of rate over entire recommended flow range • Repeatability: ±00.5% over entire recommended flow range • Verified flow coefficients • Capable of extended turndowns in flowrate • No straight piping run requirements • Mass or volumetric flow • 316SS meter body and sensing element • 1” – 12” in-line body sizes • Up to ANSI600 standard & ANSI2500 upon request *Face to face dimensions nominal. Custom lengths available. Meter Size Face to Face “L” Class 150# Class 300# Class 600# PN10 PN16 PN40 PN63 PN100 1” (DN25) 7.50” (190.5mm) 8.25” (209.6mm) 8.75” (222.3mm) N/A N/A 10.15” (257.8mm) N/A 11.57” (293.9mm) 2” (DN50) 8.75” (222.3mm) 9.38” (238.2mm) 10.13” (257.1mm) 11.54” (293.2mm) 11.54” (293.2mm) 11.78” (299.2mm) 12.88” (327.2mm) 13.35” (339.2mm) 3” (DN80) 13.78” (350.0mm) 14.53” (369.0mm) 15.28” (388.1mm) 12.31” (312.8mm) 12.31” (312.8mm) 12.94” (328.8mm) 14.04” (356.8mm) 14.52” (368.8mm) 4” (DN100) 15.15” (384.8mm) 15.90” (403.9mm) 17.65” (448.3mm) 13.34” (338.9mm) 13.34” (338.9mm) 14.36” (364.9mm) 15.39” (390.9mm) 16.34” (414.9mm) 6” (DN150) 19.15” (486.4mm) 19.90” (505.5mm) 21.90” (556.3mm) 16.58” (421.1mm) 16.58” (421.1mm) 18.15” (461.1mm) 19.73” (501.1mm) 21.30” (541.1mm) 8” (DN200) 21.40” (543.6mm) 22.15” (562.6mm) 24.40” (619.7mm) 18.38” (466.9mm) 18.38” (466.9mm) 20.42” (518.9mm) 22.16” (562.9mm) 23.74” (602.9mm) 10” (DN250) 23.15” (588.0mm” 24.40” (619.8mm) 27.65” (702.3mm) 20.76” (527.3mm) 20.76” (527.3mm) 23.51” (597.3mm) 25.09” (637.3mm) 27.61” (701.3mm) 12” (DN300) 26.22” (665.9mm) 27.47” (697.7mm) 29.97” (761.2mm) 23.41” (594.6mm) 23.41” (594.6mm) 26.32” (668.6mm) 28.29” (718.6mm) 30.65” (778.6mm) Special Application Design Capabilities Beyond standard model designs, the VERIS Accelabar® is available in an array of exotic materials, connections, and dimensional configurations. No matter how tough the application, special engineering and design capabilities are available to provide customers the best flow solution possible. Contact the factory directly for more information regarding special and custom designs. VERIS Accelabar® Face to Face Dimensions Mead O'Brien | www.meadobrien.com | (800) 892-2769

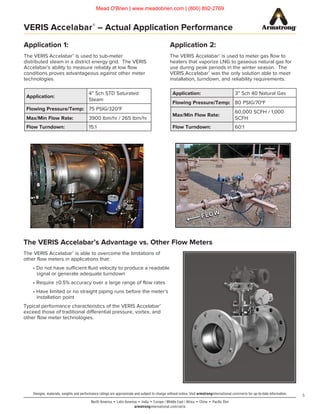

- 5. 5 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. VERIS Accelabar® – Actual Application Performance Application 1: The VERIS Accelabar® is used to sub-meter distributed steam in a district energy grid. The VERIS Accelabar’s ability to measure reliably at low flow conditions proves advantageous against other meter technologies. Application 2: The VERIS Accelabar® is used to meter gas flow to heaters that vaporize LNG to gaseous natural gas for use during peak periods in the winter season. The VERIS Accelabar® was the only solution able to meet installation, turndown, and reliability requirements. Application: 4” Sch STD Saturated Steam Flowing Pressure/Temp: 75 PSIG/320°F Max/Min Flow Rate: 3900 lbm/hr / 265 lbm/hr Flow Turndown: 15:1 Application: 3” Sch 40 Natural Gas Flowing Pressure/Temp: 80 PSIG/70°F Max/Min Flow Rate: 60,000 SCFH / 1,000 SCFH Flow Turndown: 60:1 The VERIS Accelabar’s Advantage vs. Other Flow Meters The VERIS Accelabar® is able to overcome the limitations of other flow meters in applications that: • Do not have sufficient fluid velocity to produce a readable signal or generate adequate turndown • Require ±0.5% accuracy over a large range of flow rates • Have limited or no straight piping runs before the meter’s installation point Typical performance characteristics of the VERIS Accelabar® exceed those of traditional differential pressure, vortex, and other flow meter technologies. Mead O'Brien | www.meadobrien.com | (800) 892-2769

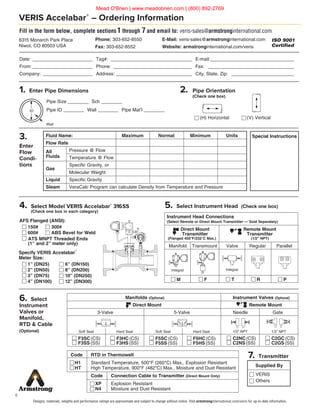

- 6. 6 Specify VERIS Accelabar® Meter Size: 1” (DN25) 2” (DN50) 3” (DN75) 4” (DN100) VERIS Accelabar® – Ordering Information AFS Flanged (ANSI): 150# 300# 600# ABS Bevel for Weld Fill in the form below, complete sections1 through 7 and email to: veris-sales@armstronginternational.com Date:________________________ Tag#: ________________________________ E-mail:_________________________________ From:________________________ Phone: _______________________________ Fax: __________________________________ Company: ____________________ Address:______________________________ City, State, Zip: _________________________ 3. Enter Flow Condi- tions 4. Select Model VERIS Accelabar® 316SS (Check one box in each category) (V) Vertical(H) Horizontal Pipe Size ________ Sch ________ Pipe ID ________ Wall ________ Pipe Mat’l ________ Special Instructions Wall ID Fluid Name: Maximum Normal Minimum Units Flow Rate All Pressure @ Flow Fluids Temperature @ Flow Gas Specific Gravity, or Molecular Weight Liquid Specific Gravity Steam VeraCalc Program can calculate Density from Temperature and Pressure 5. Select Instrument Head (Check one box) 2. Pipe Orientation (Check one box) 1. Enter Pipe Dimensions Supplied By 7. Transmitter Phone: 303-652-8550 E-Mail: veris-sales@armstronginternational.com Fax: 303-652-8552 Website: armstronginternational.com/veris 6315 Monarch Park Place Niwot, CO 80503 USA ISO 9001 Certified 6. Select Instrument Valves or Manifold, RTD Cable (Optional) Code RTD in Thermowell H1 Standard Temperature, 500*F (260*C) Max., Explosion Resistant HT High Temperature, 900*F (482*C) Max., Moisture and Dust Resistant Code Connection Cable to Transmitter (Direct Mount Only) XP Explosion Resistant N4 Moisture and Dust Resistant Manifolds (Optional) Instrument Valves (Optional) Direct Mount Remote Mount 3-Valve 5-Valve Needle Gate Soft Seat Hard Seat Soft Seat Hard Seat 1/2” NPT 1/2” NPT Instrument Head Connections (Select Remote or Direct Mount Transmitter — Sold Separately) Direct Mount Remote Mount Transmitter Transmitter (Flanged 450°F/232°C Max.) (1/2” NPT) Manifold Transmount Valve Regular Parallel M F T R P Integral Integral 6” (DN150) 8” (DN200) 10” (DN250) 12” (DN300) ATS MNPT Threaded Ends (1” and 2” meter only) F3HC (CS) F3HS (SS) F5SC(CS) F5SS(SS) F5HC(CS) F5HS(SS) C2NC(CS) C2NS(SS) C2GC(CS) C2GS(SS) F3SC (CS) F3SS (SS) VERIS Others Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. Mead O'Brien | www.meadobrien.com | (800) 892-2769

- 7. 7 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. Notes Mead O'Brien | www.meadobrien.com | (800) 892-2769

- 8. 8 North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com/veris Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com/veris for up-to-date information. INTELLIGENT SOLUTIONS IN STEAM, AIR AND HOT WATER Armstrong International North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim armstronginternational.com © 2017 Armstrong International, Inc. 479-EN Printed in USA - 2/17 Mead O'Brien | www.meadobrien.com | (800) 892-2769