what is process piping

- 1. Process Piping By: Varun Patel, B.E- Mechanical, PMP® Source: Piping Component G_FORDHAM 1

- 3. What is Process Piping ? • Pipe: Pressure tight cylinder used to transport material mainly liquid and gas. It is also used to transport slurry, powered, metal pallets etc.. 3

- 4. What is Process Piping ? • Pipe Fittings/Pipe Component: − Mechanical elements suitable for joining or assembly into pressure-tight fluid-containing piping systems. Components include pipe, tubing, fittings, flanges, gaskets, bolting, valves, and devices such as expansion joints, flexible joints, pressure hoses, traps, strainers, in-line portions of instruments, and separators. 4

- 5. What is Process Piping ? • Piping: − Assembly of piping components used to convey, distribute, mix, separate, discharge, meter, control, or stop fluid flows. • Piping Systems: − Interconnected piping subject to the same sets of design conditions. 5

- 6. What is Process Piping ? • Process: − A series of activities performed in particular ordered to convert raw material into an useful product • Process Piping is interconnected piping used in process industries to convert raw material in to useful products. 6

- 7. What is Process Piping ? • A Piping under the purview of ASME Code - B31.3 is Process Piping • A Process Piping Systems are design as per the guidelines given in ASME B31.3 7

- 8. ASME B31.3 Process Fluid Service • Category D Fluid Service − The fluid is nonflammable, nontoxic, and not damaging to human tissue. − The design pressure does not exceed 150 psig (1035 kPa). − The design temperature is between -29°C and 186°C. • Category M Fluid Service − a fluid service in which the potential for personnel exposure is judged to be significant and in which a single exposure to a very small quantity of a toxic fluid, caused by leakage, can produce serious irreversible harm to persons on breathing or bodily contact, even when prompt restorative measures are taken 8

- 9. Types of ASME B31.3 Process Fluid • High Pressure Fluid Service − High pressure fluids are those in which the Owner has specified that the pressures will be in excess of that allowed by the ASME B16.5 PN420 (Class 2500) rating for the specified design temperature and material group. • Normal Fluid Service − Everything else that does not cover under Category D, Category M and High Pressure fluid service. − ASME B31.3 covers most of the process fluid in this Category − Gauge 9

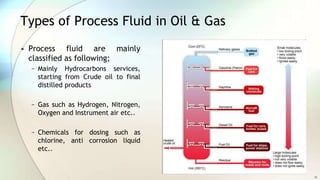

- 10. Types of Process Fluid in Oil & Gas • Process fluid are mainly classified as following; − Mainly Hydrocarbons services, starting from Crude oil to final distilled products − Gas such as Hydrogen, Nitrogen, Oxygen and Instrument air etc.. − Chemicals for dosing such as chlorine, anti corrosion liquid etc.. 10

- 11. Property of Process fluid use in Oil & Gas •Flammable •Corrosive •Explosives •Volatile •Reactive •Hazardous to human health 11

- 12. Material for process fluids • To handle different kind of process fluids in different physical and chemical environments we need different kind of piping materials. • Material that are able to withstand under various design condition are chosen from based on many process parameters. • Lets learn about these types of material in next lecture 12

- 13. What we have learned? • Pipe • Pipe fittings / components • Piping / Piping System • Process Piping 13

- 14. To learn more about pipe and pipe fittings take my online course at 90% discount click on https://www.udemy.com/process-pipe-fittings-for-oil-gas- career/?couponCode=FB10 How to be an Expert in Pipe & Fittings for Oil & Gas career 14 Click hear to Enrolled Now