SCIENCE FOR THE CERAMICS INDUSTRY

RHEOLOGICAL PROPERTIES OF SLIPS TREATED WITH BACTERIA

V. V. Baranov, S. N. Vainberg, A. S. Vlasov,

G. Z. Komskii, Yu. V. Nozhnikova, V. P. Skripnik,

V. A. Sidorova, T. N. Solnyshkina,

and O. I. Yashchenko

UDC 666.3.022.66:576.8

The characteristics of the structure of ceramic slips markedly influence the technical

parameters of production and the properties of thegreenware and the finished goods

[i]. It

is established that an effective method of regulating the structure formation of clay dispersions is to introduce a biological r e a g e n t - silicate bacteria [2].

The aim of the present work was to study the action of biological treatment on the rheological properties of slip based on multicomponent bodies used for the production of inside

wallti!es on the continuous lines at the Kishinevsk finishing-materials factory (KZOM).

The

body formula contained the following components (%*): 48 Veselovsk clay VGP, 28 nepheline

syenite, 8 limestone sawdust scrap, 16 tile scrap; on 100%: 1 bentonite and 0.3 sodium tripolyphosphate.

Using the production cycle at KZOM which involves combined wet milling of the materials,

we prepared a slip whose composition contained a suspension of silicate bacteria in amounts

of 0.1% in relation to the dry weight of ~he slip. The slip with the added bacteria was aged,

over a period of 5 days after which, using a previously described method [2] we determined

Pm .kPa

J

-1

2

\

50

I

W, ~

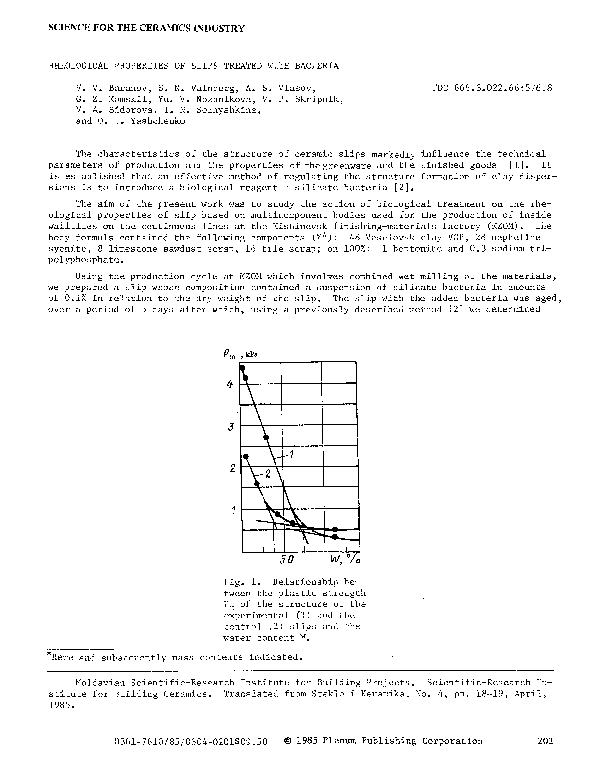

Fig. i. Relationship between the plastic strength

Pm of the structure of the

experimental (i) and the

control (2) slips and the

water content M.

*Here and subsequently mass contents indicated.

Moldavian Scientific-Research Institute for Building Projects.

Scientific-Research Institute for Building Ceramics.

Translated from Steklo i Keramika, No. 4, pp. 18-19, April,

1985.

0361-7610/85/0304-0201509.50

9 1985 Plenum Publishing Corporation

201

�TABLE i

log ~3

Slip

Factors

Modulus of elastic deformation, Pa:

rapid E 0

slow E~

Equilibrium modulus Ep, Pa

Tent. stat. yield pt Pkl, Pa

Max. plastic viscosity q 1,

1-10~Pa-sec

Period of true relaxation 0,sec

Elasticity, ~.

Volarovich plasticity ~-pl,

1.10 -4 sec-1

Tentative deformation capac.

N e, J/cm 3

Structural mechanicfl type

7

:entre1 test

e,I

5 ~ \~

2

It

I

,3'

10

900

600

375

25

6,6

7,5

240

200

0,3

1,5

0,58

3,3

53

133

.!

g

400

900

275

]

?

~ 2

-5

10 2050~050F~

00 800 1000

P, Pa

Fig.

2.

Rheological

for the slip.

curves

its properties.

The checks were carried out on a slip of the same composition but without

the bacteria additions.

The study of the relationship between the plastic strength and the moisture content of

the slips in the moisture concentration range 46-55% (Fig. i) showed that the moisture content corresponding to the formation of a structure in the entire volume of the suspension,

was for the control slip 49%, and for the test slip 52%. In this case the strength of the

structure of the test slip is somewhat lower than for the control, despite the lower content

of solid phase. With a reduction in the moisture content the strength of the structure in

the test slip rapidly increases~ and exceeds that of the control structure.

The structural mechanical characteristics [3] of the undamaged structure were determined

with a working moisture content for both slips of 51% (see Table i).

As a result of the bio-treatment the equilibrium modulus of elastic deformation of the

experimental slip increased by 36.3%, the tentative static yield point of the experimental

slip became 2.5 times greater than that of the control.

There was a reduction in the modulus

of slow elastic deformation for the experimental slip by 33.3% which led to a significant increase in the elasticity of the suspension.

The viscosity of the undamaged structure in the experimental slip increased by 13.6%

compared with the viscosity of the control.

There was some reduction in the relaxation

period and an increase in the tentative capacity for deformation of the experimental slip.

The rheological factors for the damaged s t r u c t u r e - the Bingham viscosity n~ and the

tentative dynamic yield p o i n t - were determined by measuring the effective viscosity ~B of

the slip for a high flow rate under different stresses (Fig. 2). It was established that for

the control slip the tentative dynamic yield point Pk2 = 0.7 kPa, the viscosity,of the maximum disturbed structure ~B = 0~

Pa-sec.

For the test slip Pk2 = 0.45 kPa, n B = 0.030

Pa-sec. Thus~ the Bingham viscosity of the slip hardly altered while the yield point was

reduced by 35.7%~

It was established that the Engler fluidity after 30 sec holding for the control slip

equaled 4.5 sec, and for the experimental 3.6 sec, and after 30 min holding the fluidity

levels were respectively 7 and 3.8 sec. The coefficient of thixotropy for the slip was 1.6

and 1.05 respectively.

Analyzing the results obtained we can see the reduction in the critical concentration

of structure formations after the biological processing with a simultaneous reduction in the

critical strength of the structure, which indicates an increase in the dispersion of the particles of the experimental slip~ and at the same time a weakening of the contacts between

them. The increase in the strength factors for the undamaged structure (equilibrium modulus,

tentative static yield point, tentative capacity for deformation, and also the Shvedovsk

viscosity) suggests that as a result of the biological treatment there forms a more highly

developed coagulation structure, distinguished by a high strength.

Such a change in properties is possible under the influence of particle dispersion and also as a result of the increase in the number of contacts in unit volume of suspension.

A reduction in the relaxation

202

�period for the experimental slip indicates an acceleration in it of the stress relaxation,

connected with the increase in the mobility of the particles at the contact sites.

Analysis of the structural-mechanical parameters of the disturbed structure showed that

after bio-treatment there was a significant reduction in the tentative dynamic yield point

Pk2 with a practically unchanged Bingham viscosity.

The reduction in Pk2 causes a significant reduction in the effective viscosity for low stresses, a rise in the mobility of the

test slip and in the Engler fluidity, since this parameter alters with low stresses close to

the yield point. The lower value of Pk2 also causes a reduction in the thickening.

A reduction in Pk2 indicates a reduction in the strength of the contacts between the dispersed particles of slip.

The unchanging nature of the Bingham viscosity factors is connected with the fact that,

at high shear stresses (high flow rate) the strength of the contacts plays a small role,

since the structure of the slip is practically totally destroyed.

A reduction in the thixotropy of the slip is explained by the retardation of the thixotropic restoration of its structure, which may be connected with the influence of the biological surface-activesubstances

formed in the process of the life-activity of the bacteria, their adsorption on the active

sections of the clay particles, and the retardation of the development of new contacts.

Thus, analysis of the changes in the structural mechanical properties of the slip as a

result of biological processing suggests the following changes in its structure.

As a result

of biotreatment there occurs dispersion of the clay particles, and an increase in their concentration, with a simultaneous weakening of the strength of the contacts between them. The

number of contacts in unit volume of suspension increases.

As a result of the mutual influence of the increases in the concentration in unit volume, and the reduction in their strength,

there forms a more highly developed coagulation structure.

In the region of low stresses,

the coagulation structures possess an enhanced strength, and in the region of the high stresses

(region of practically total damage of the structure, flow of slip at high velocities in production units) the new structure is distinguished by a high mobility at low loads, increased

fluidity~ and reduced thixotropy.

]in the slip treated with silicated bacteria it is possible to reduce the content of water

while maintaining the other factors compared with the control slips, and owing to this to

reduce the consumption of fuel in the spray drier.

LITERATURE CITED

i~

2.

3.

S. P. Nechiporenko~ Physicochemical Mechanics of Dispersed Structures in Building Ceramics Technology [in Russian], Naukova Dumka~ Kiev (1968) o

So N. Vainber~, Ao So Vlasov~ and V. Po Skripnik, Steklo i Keram.~ No. 9, (1981).

P. N. Khor'kov~ Go Zo Komskii, Method Recommendations for Controlling the StructuralMechanical and Casting Properties of Ceramic Slips [in Russian], NIISMI, Kiev (1980).

203

�

Simon Vainberg

Simon Vainberg