111111111111111111111111111111111111111111111111111111111111111111111111111

US006387829Bl

(12)

(54)

(75)

(73)

United States Patent

(10)

Usenko et al.

(45)

SEPARATION PROCESS FOR SILICON-ONINSUIATOR WAFER FABRICATION

5,250,460

5,374,564

5,710,057

5,994,207

6,013,567

6,221,774

Inventors: Alexander Yuri Usenko, Murray Hill;

William Ned Carr, Montclair, both of

NJ (US)

Assignee: Silicon Wafer Technologies, Inc.,

Newark, NJ (US)

( * ) Notice:

Subject to any disclaimer, the term of this

patent is extended or adjusted under 35

U.s.c. 154(b) by 0 days.

(21)

Appl. No.: 09/543,998

(22)

Filed:

(60)

Related U.S. Application Data

Provisional application No. 60/139,851, filed on Jun. 18,

(51)

(52)

(58)

Int. CI?

U.S. CI

Field of Search

Apr. 6, 2000

1999.

(56)

HOiL 21/425; HOlL 21/265

438/977; 438/120

438/15, 977, 120

References Cited

U.S. PATENT DOCUMENTS

4,846,931 A

7/1989 Gmitter

Patent No.:

US 6,387,829 Bl

Date of Patent:

May 14,2002

A

A

A

A

A

B1

*

*

10/1993

12/1994

1/1998

11/1999

1/2000

4/2001

Yamagata

Brnel

Kenney

Henley et al.

Henley

Malik

438/515

438/690

* cited by examiner

Primary Examiner-Amir Zarabian

Assistant Examiner-Beth E. Owens

(74) Attorney, Agent, or Firm-DeMont & Breyer, LLC

(57)

ABSTRACT

A process for manufacturing a silicon-an-insulator wafer

from a silicon wafer assembly. The assembly is made of two

wafers. One of the wafers contains a fragile layer. The

fragile layer is a layer containing a high amount of hydrogen. An amount of energy from an energy source is applied

to the assembly to separate the assembly along the fragile

layer thus forming a silicon-on-insulator wafer and a leftover wafer. The energy source is selected from the group

consisting of: ultrasound, infrared, hydrostatic pressure,

hydrodynamic pressure, or mechanical energy. The amount

of energy is chosen to be sufficient to transform the fragile

layer into a quasi-continuous gaseous layer. Under separation the hydrogen-enriched layer transforms into layer consisting of hydrogen platelets and hydrogen microbubbles.

13 Claims, 9 Drawing Sheets

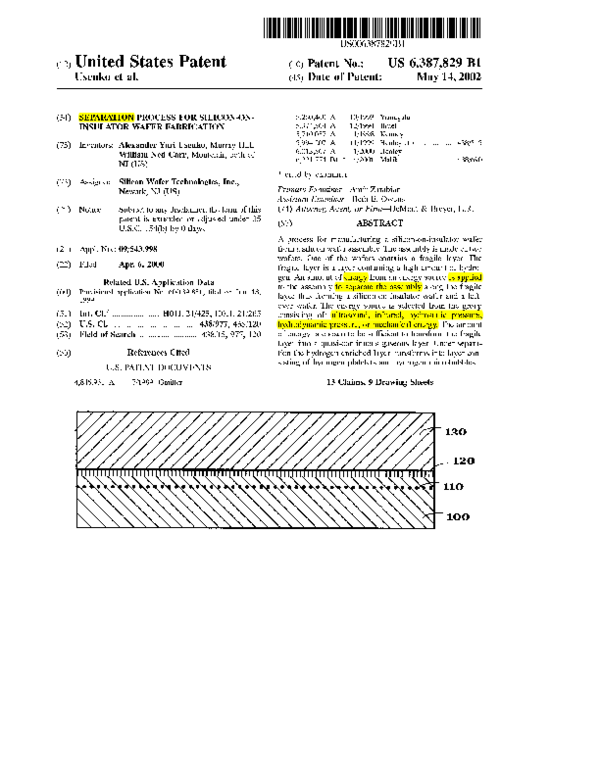

1::\0

120

110

100

�u.s. Patent

US 6,387,829 Bl

Sheet 1 of 9

May 14,2002

c

Fig.

L

L

セ

セ⦅

セ

セ

セ

セ

Mcセ

L

セ

セ⦅

セ

1.

Prior Art

__;r

Fig.

__;r

Fig. 3. Prior Art

:::l-

Fig. 4. Prior Art

__;r

2.

Prior Art

�u.s. Patent

セQPV

VPQセ|

May 14,2002

Sheet 2 of 9

US 6,387,829 Bl

601

rIO

L-----------------J

-----------------

60.1

Fig.5. Prior art

/,00

10

EXPANDING

CLEAVE

FRONT

Fig.6. Prior art

�u.s. Patent

[3

May 14,2002

Sheet 3 of 9

NfM M M M M セ

Fig. 7. Prior Art

Fig. 8. Prior Art

US 6,387,829 Bl

�u.s. Patent

May 14,2002

Sheet 4 of 9

US 6,387,829 Bl

Fig.9A

1:10

120

110

100

Fig.9B

セQPP

Fig.9C

�u.s.

Patent

May 14,2002

Sheet 5 of 9

.........•.•...••.•..........•.••...............

Fig. to

US 6,387,829 Bl

�u.s.

Patent

Sheet 6 of 9

May 14,2002

Fig.

11

US 6,387,829 Bl

�u.s.

Patent

Sheet 7 of 9

May 14,2002

121

120

Fig.l2A

Fig.12B

US 6,387,829 Bl

�u.s.

Patent

May 14,2002

Sheet 8 of 9

US 6,387,829 Bl

35

Fig.13A

Fig.13B

�u.s. Patent

May 14,2002

Sheet 9 of 9

Fig.l4A

14.2

l.p

140

Fig.14B

US 6,387,829 Bl

�US 6,387,829 Bl

1

2

patents on the ELTRAN process of fabrication of siliconon-insulator wafers. In this technique the film separation is

obtained by etching off a sacrificial layer comprised of

porous silicon.

This application claims priority from the provisional

patent application entitled "Separation Process For Silicon- 5

Still another variation of the epitaxial lift-off process for

On-Insulator Wafer" and, filed Jun. 18, 1999 and assigned

film separation is described by Kenney in U.S. Pat. No.

application No. 60/139,851, the disclosure of which is

5,710,057 [5]. In this technique an etchant distribution is

hereby incorporated incus entirety for all purposes.

facilitated by capillary action in trenches preformed in the

seed substrate.

BACKGROUND OF THE INVENTION

10

A disadvantage of the Bruel [lJ technique is that the

The present invention relates to the manufacture of

roughness of the as-cut surface requires polishing (e.g.,

silicon-on-insulator substrates. More particularly, the invenCMP) to smooth the surface. This polishing affects the

tion provides a technique for separating (cleaving) a subthickness uniformity of the device layer across the wafer.

strate as part of the fabrication process of silicon-onThus, the polishing process, while improving local

insulator wafers for semiconductor integrated circuits and 15 roughness, simultaneously increases thickness variations.

microelectromechanical systems.

Another disadvantage of the Bruel process [1 J is that the

assembly sometimes cleaves along an undesired plane. The

Delamination of thin films (micron range thickness) from

solids such as a single crystal is a processing step that is

desired plane is along the peak density of the implanted

useful for variety of technologies, including semiconductor

hydrogen. The undesirable plane is at a prebonded interface

processing technology. Prior art includes separation methods 20 between wafers of the assembly. Defective silicon-oninsulator wafers are the result.

as (1) ion cut with thermal initiation (Bruel), (2) ion cut with

jet initiation (Henley), and (3) variations of sacrificial layer

A disadvantage ofthe epitaxial lift-off technique [3J is that

etching (Gmitter, Yonehara, Kenney).

the area of delaminated film is limited to about 1 square inch,

The separation technique through a hydrogen-rich layer 25 that is much less that typical silicon wafer size (4-12 inches

was described by Bruel, U.S. Pat. No. 5,374,564 [1]. This

in diameter). So the process is not applicable to mainstream

technique is a part of Bruel's process [lJ used to fabricate

semiconductor processing.

silicon-on-insulator wafers. The technique uses thermal

A disadvantage of etch-stop based separation techniques

treating of a wafer assembly that includes a hydrogen[3,4,5J is the difficulty in obtaining a uniform layer thickness

implanted wafer. The annealing temperature used is above 30 for large areas. Since the etchant etches silicon in addition to

that at which ion implantation takes place. Typical annealing

the sacrificial layer, there is a tendency to reduce the

temperatures are in range from 400 to 500 0 C. Under

thickness at the thin film silicon near the outer perimeter of

annealing the implanted hydrogen begins to diffuse inside of

the wafer. The result is a separated thin film of decreasing

the wafer. Hydrogen coagulates into precipitates that serve

thickness along radii toward the wafer perimeter.

as nuclei for subsequent structure transfonnations. Then flat 35

Adisadvantage of the side jet technique [2J is that plasma

platelets consisting of hydrogen are formed from the nuclei.

immersion ion implantation dose needed in the process is

The platelets are arranged along <100> silicon crystallo10" 8 cm- 2 . Such a high dose severely deteriorates the quality

graphic planes. The platelets have top and bottom silicon

of the delaminated layer.

<100> surfaces with dangling bonds terminated by hydrogen. Next, bigger platelets continue to grow in expense of 40

SUMMARY OF THE INVENTION

smaller platelets according to the Ostvald ripening mechaA technique is detailed for forming a silicon film from a

nism. Finally, the continuous hydrogen layer is formed along

donor silicon substrate with <100> or <111> surface orienthe plane of the maximum implanted hydrogen. Following

tations.

annealing, the former single wafer is separated into two

45

A The technique utilizes a step of forming a hydrogen-rich

thinner wafers.

layer in a donor substrate at a selected depth underneath the

Another technique to delaminate a top layer from a silicon

surface where the hydrogen atoms have a relatively high

wafer using the buried hydrogen-rich layer is described by

concentration to define a donor substrate material above the

Henley in U.S. Pat. No. 6,013,567 [2]. The wafer is cleaved

selected depth. The hydrogen-rich layer may be obtained by

along the hydrogen-rich plane using a pressurized fluid jet

applied initially to the edge of the wafer. The cleavage 50 implanting hydrogen ions through a surface into the donor

wafer.

initiates at the edge due to the jet action and the cleavage

To initiate separation of thus prepared wafer, an energy

wave then propagates through the substrate to release a thin

source is applied to the substrate. The source is selected from

film of material from the substrate.

the group consisting of ultrasound, hydrostatic pressure,

Still another technique to selectively peel a film from a

single crystal is described by Gmitter in U.S. Pat. No. 55 hydrodynamic pressure, infrared light, mechanical, or combination thereof. Said energy source is applied in such a way

4,846,931 [3]. The technique is usually referred as epitaxial

that energy is deposited preferentially in the hydrogen-rich

lift-off. In this technique an epitaxial film is released from a

layer.

single crystal substrate upon which it is grown. The technique comprises (a) providing a thin release layer (1000 A)

The application of said energy source coagulates hydrobetween the film to be grown and the substrate; (b) growing 60 gen into nuclei having platelet shapes oriented along crysthe epitaxial film(s); (c) applying a polymeric support layer

tallographic cleavage planes, that is usually the <100> plane.

which is under tension over the film; and (d) selectively

The platelets then form a continuous layer thus releasing the

etching the release layer, the tension in the support layer

adjacent silicon film.

causing the edges of the film to curve upward as the release

For said ultrasound and infrared energy cases, choosing

layer is etched away.

65 preferable parameters means the wavelength is chosen

smaller than said donor substrate material thickness

A variation of the epitaxial lift-of process is described by

Yamagata in U.S. Pat. No. 5,250,460 [4J and subsequent

(typically less than 10 micrometers).

SEPARATION PROCESS FOR SILICON-ONINSUIATOR WAFER FABRICATION

�US 6,387,829 Bl

3

4

separation of a thin film from a single crystal silicon wafer

Advantage of the present invention is the technique adds

previously implanted with proton particles or with hydrogen

flexibility for creating customized silicon-on-insulator based

ions. The implanted wafer can be covered with thermally

microstructures and integrated circuits. Also the technique

grown silicon dioxide layer 105 (FIG. 9) before the implanrises the yield of silicon layer transfer as the hydrogen

platelet coagulation along the interface of prebonded silicon 5 tation stage. FIG. 9A is a simplified cross-sectional view of

the initial oxidized and wafer 100 implanted with protons

wafers is suppressed. Also the technique improves a surface

200 that form a hydrogen-rich layer 110 and a thin film to be

roughness of the silicon-on-insulator wafers obtained.

separated 120. FIG. 9B is a simplified cross-sectional view

diagram of the wafer 100 with a stiffener wafer 130 attached.

BRIEF DESCRIPTION OF THE DRAWINGS

This is an ioitial structure to be separated. FIG. 9C shows the

FIGS. 1 through 4 show prior art that is related to 10 final step of the separation process when the top assembly

consisting of stiffener wafer 130 and separated thin film 120

heat-caused separation [1].

is completely detached from initial implanted substrate 100.

FIG. 1 shows the concentration profile of the hydrogen

The process is used for the manufacture of silicon-onions as a function of the penetration depth.

insulator wafers from regular silicon wafers that are preFIG. 2 shows the monocrystalline semiconductor wafer 15 implanted with ions. The wafer undergoes an energy load

exposed to a bombardment of H+ ions and within which has

that transforms the pre-implanted layer into of a layer 110 of

appeared a gas microbubble layer produced by the implanted

gaseous microbubbles in the wafer. The wafer can be than

particles.

easy separated into two wafers along the layer of

FIG. 3 shows the semiconductor wafer of FIG. 2 and

microbubbles. In the FIG. 9A the implantation 200 occurs

20 through an upper surface of the wafer 100 that is substancovered with a stiffener.

tially parallel to a main crystallographic plane of the

FIG. 4 shows the cross-section view of assembly of the

substrate, for example the <100> plane. The implanted

semiconductor wafer and the stiffener wafer shown in FIG.

specie is preferably protons.

3 at the end ofthe separation phase, when cleaving has taken

The implantation allows for the formation of a layer of

place between the film and the substrate mass.

gaseous microblisters 110 within the volume of the wafer at

FIGS. 5 through 8 shows previous art that is related to 25 a depth approximately equal to the average ion penetration

jet-caused separation [2].

depth. This layer of microblisters delimits a surface layer

FIG. 5 is a simplified cross-sectional view of an implanted

120 within wafer 100, which will form the top part 120 of

substrate 10 using selective positioning of cleave energy

silicon-on-insulator wafer 140 in FIG. 9C. In particular, it

601.

30 should be noted that during ion implantation the wafer is

FIG. 6 illustrates the controlled-propagating cleave with

preferably kept at a temperature below the temperature at

which the atoms of the implanted gas can move away by

successive impulses 701, 705, 709 to initiate and then

propagate a cleariog process 700.

thermal diffusion from the crystaL

For all preferred embodiments described below, an

FIG. 7 shows a cross-sectional view of a pressurized fluid

jet from a fluid nozzle to perform a controlled cleaving 35 amount of energy from an energy source is applied to the

wafer assembly FIG. 9B. After applying the amount of

process.

energy a continuous hydrogen layer is formed at the place of

FIG. 8 shows a cross-sectional view of a pressurized fluid

the hydrogen-rich layer 110 thereby releasing silicon-onsource 607.

insulator wafer 150 (FIG. 9C) from byproduct wafer 100

FIG. 9 shows a cross-sectional view that illustrates the

40 (FIG. 9C.)

separation process due to present invention.

Preferred Embodiment 1: Separating with Ultrasound

FIG. 10 illustrates the first preferred embodiment of the

Energy Load

separation process due to the present invention where an

FIG. 10 shows the preferred embodiment utilizing ultraultrasound load is used.

sound as the activation energy for separation. The ultrasound

FIG. 11 illustrates the second preferred embodiment of 45 energy load is applied to the wafer assembly FIG. 9C

the separation process due to the present invention where a

through either the top or bottom surface.

hydrostatic pressure load is used.

For the separation, the implanted wafer is subjected to a

sensitizing load for a given time, chosen such that the

FIG. 12 illustrates the third preferred embodiment of the

hydrogen in the substrate which was introduced by the

separation process due to the present invention where infra50 hydrogen implantation is partly released from its attachred laser scanning is used.

ments to the defects (which were generated by the hydrogen

FIG. 13 illustrates the forth preferred embodiment of the

trap-inducing implantation) and as well by the hydrogen

separation process due to the present invention where a

implaimplantation itself. This treatment causes the formawater jet is used.

tion and growth of hydrogen filled microcracks at a depth

FIG. 14 illustrates the fifth preferred embodiment of the 55

close to the maximum in the concentration depth profile of

separation process due to the present invention where

implanted hydrogen. This step must not cause hydrogen

mechanical structures are used.

induced surface blisters, which would prevent subsequent

bonding of the first substrate to a second substrate.

DETAILED DESCRIPTION OF THE

At the end of energy activation the implanted hydrogen in

PREFERRED EMBODIMENTS

60 the substrate is fully released from chemical bonding to the

The present invention provides a technique for removing

defects. These defects were generated by the hydrogen

a thin film of material from a substrate while maintainiog the

trap-inducing implantation as well as by the hydrogen

structural integrity of both separated parts. Said thin film of

implantation itself, to cause growth, overlapping and coamaterial is prebonded to a stiffener, for example, an oxidized

lescence of hydrogen-filled microcracks, which split the

silicon wafer thus forming silicon-on-insulator wafer.

65 monocrystalline thin layer from the rest of the first substrate

The embodiments which will now be described in conthereby allowing the transferrance of the thin monocrystalline layer to the second substrate.

junction with the above drawings FIGS. 9 to 14, relate to the

�US 6,387,829 Bl

5

6

promoting hydrogen movement with formation of platelets

Ultrasound waves propagated through the bulk of a solid

94 (FIG. 10) affect the properties of point and extended

the similar way as it happens under heat treatment. The

defects. This processing is referred to as the process of

difference with the thermal treatment caused separation

ultrasound treatment. Ultrasound vibrations applied to a

described by Bruel is that the separation front is single and

semiconductor with a power density W, exceeding some 5 it propagates through the entire wafer. Finally it leaves

smoother surfaces after the separation as compared to a

threshold value, W rh are able either to generate Frenkel pairs

or to force the dissociation of complex centers composed of

multiple separation front case. Steps on the surface after

two or more point defects. The value ofW th was found to be

separation appear mostly at places where the two separation

of the order of 10 W/cm 3 . In the opposite case, i.e. when

fronts meet. Typical laser processing characteristics are:

W<W rh , a different effect related to the interaction of point 10 beam cross-section diameter 1 millimeter, laser pulse repetidefects and extended lattice defects has been found in single

tive rate 100 Hz, pulse duration 70 nanoseconds, horizontal

crystals. This effect of ultrasound is an enhancement of

scanning speed 50 mm/sec, energy per pulse 0.01 Joule,

gettering by sinks (dislocations, grain boundaries,

vertical scanning step 0.5 millimeters. In the case of using

precipitates) of both intrinsic and extrinsic point defects. The

the neodymium laser (wavelength 1.06 micrometer), the

ultrasound vibrations can reduce the energy barrier for the 15 silicon absorption coefficient is 50 cm- 1 for single crystal

silicon, and more than 103 cm- 1 for amorphous silicon. The

diffusion of defects as well as the barrier for their capture by

hydrogen-rich region has about the same absorption coeffisinks. The present invention uses the effect of the enhancecient as the amorphous silicon, so silicon bulk remains

ment of gettering by sinks, i.e. when W<Wrh"

In the preferred embodiment, ultrasound vibrations were

almost unheated, while the hydrogen-rich region melts at

generated in the wafer using a circular 100 mm diameter and 20 laser pulse energies higher than about 1 Joule/cm 2 . Pulsed

3 millimeter thickness piezoelectric transducer PZT-5A.

character of the laser processing is also important in this

case. For the nanosecond-range pulse duration the heat

Transducers were driven by a function generator and power

amplifier adjusted to the resonance frequency of the transproduced by the pulse dissipates during the pulse on disducer radial or thickness vibrations. For good acoustic

tances less than 1 micrometer, thus providing an adiabatic

contact, the wafer was pressed against a transducer front 25 mode of the processing. The pulsed laser treatment heats

predominantly the hydrogen-rich layer. In the heated layer

surface with a spring. The ultrasound transducer was operthe implanted interstitial hydrogen forms hydrogen clusters.

ated at resonance of its radial vibrations of 25 kHz. The

wafer assembly can be placed with either the stiffener or the

The clusters are nuclei of hydrogen platelets. Further heating

causes the nuclei of platelets to grow into bigger platelets.

cleavable surface to the transducer. The ultrasound load time

was 5 minutes or more (up to 120 minutes). The amplitude 30 Further, the growing platelets begin to overlap. The part of

of sample vibrations in acoustic contact with the transducer

the wafer assembly with the dense layer of platelets is a

was monitored by a calibrated contact acoustic probe. The

separated part. A border between separated and nonmaximum acoustic strain amplitude on the film surface was

separated parts is a separating front. The front moves

of the order of 10- 5 . The temperature of the sample under

following the scanning laser beam. FIG. 12B shows the

ultrasound load was stabilized at 50° c., and monitored by 35 different geometry of separation with pulsed infrared proa thermocouple attached to the wafer surface.

cessing where the entire wafer is processed in a single pulse.

Preferred Embodiment 2: Separating with Hydrostatic PresThis preferred embodiment is requires the high power laser

of a flash lamp source. The threshold energy for the sepasure Energy Load

ration is about 0.2 Joule/cm 2 , which translates into a 15

FIG. 11 shows the preferred embodiment using a hydrostatic pressure load to cause separation. The wafer assembly 40 Joule/pulse light source requirement for 100 mm diameter

31 is placed into hydrostatic pressure cell 111 and loaded

wafers.

with a pressure higher than 0.2 GPa. In silicon (and other

Preferred Embodiment 4: Separating with Hydrodynamic

Energy Source

diamond or zinc-blend structured materials), the diffusion

FIG. 13 shows the preferred embodiment utilizing a water

constant increases with pressure. This is in contrast with the

situation in close-packed materials in which diffusion dimin- 45 jet source to separate the donor substrate material. The water

jet nozzle 33 is initially aligned to the edge of the wafer

ishes with compression. Pressure cells, which use comassembly 31 to be separated. The wafer assembly consists of

pressed gas, can accommodate wafer size samples. The

implanted wafer 35 with hydrogen layer 36 and stiffener

compressed gas cells create a pressure up to 1.5 Gpa. This

wafer 37 attached to implantation side of the wafer 35. The

pressure is enough to cause separation of the silicon wafers.

Argon 112 is introduced into the cell 111 to approach 50 water jet nozzle moves with a speed of 0.01 to 0.1 cm/sec

hydrostatic conditions.

towards the center of the wafer assembly 31. The wafer

assembly is placed onto a supporting turntable that has a

Preferred Embodiment 3: Separating with Infrared Energy

spherical shaped surface with radius of curvature between 1

Load

and 2 meters. The turntable is made of material that has

FIG. 12 shows the preferred embodiment using an infrared energy source to cause separation. FIG. 12A illustrates 55 adequate rigidity, for example, stainless steel. The turntable

using of neodymium glass laser 120 in scanning mode. Said

is rotating with speed 0.1 to 10 rotations per second. The

laser produces a light beam 121 that is directed normally to

water jet beam trajectory on the wafer assembly 31 forms a

spiral 38 of continuously decreasing radius. The wafer

the surface of the wafer assembly 31 to be separated.

Scanning begins from the edge of said assembly 31 thus

assembly cleavage begins at the edge of the wafers. The

creating a separation front. The separation front propagates 60 cleaved part propagates inward with the jet and turntable

movements. The wafer assembly separates completely when

following the scanning laser beam. To complete separation,

an entire area of the wafer assembly 31 shoud be scanned.

the jet reaches the center of the wafer assembly 31. The

Said light wavelength should be chosen outside of the

typical water jet characteristics are: nozzle diameter of 1.6

silicon band edge absorption. If the energy of the photons is

millimeter, nozzle exit velocity 27 cm/sec (that gives a

lower than the forbidden gap, the photons are absorbed 65 corresponding Reynolds number Re=430). The nozzle diameter can vary from 0.1 to 2 millimeters, and the nozzle exit

mostly by defects. The hydrogen-rich layer is the defect-rich

and the light energy is absorbed mostly in this layer thus

velocity can vary from 10 to 100 cm/sec for typical wafer

�US 6,387,829 Bl

7

8

energy source selected from the group consisting of

configurations. Under the water jet action the wafer assembly 31 bends, the strain concentrates at the hydrogen-rich

ultrasound, infrared, hydrostatic pressure, hydrodylayer, thus encouraging the hydrogen atom movements

namiic pressure, mechanical, and a combination

inside the silicon. The displaced hydrogen forms platelets

thereof, wherein said amount of energy is sufficient to

the same way as under diffusion activation at elevated 5

transform said hydrogen-rich layer into a continuous

temperatures. The platelets form a continuous hydrogen

hydrogen layer thereby releasing said single-crystalline

layer that separates the wafer assembly 31 into two wafers

silicon layer.

with cleaving along the <100> preferred plane.

2. The process of claim 1, wherein said donor substrate is

Preferred Embodiment 5: Separating with Mechanical Linka silicon wafer.

10

ages and Structure

3. The process of claim 1, wherein said donor substrate

FIG. 14 shows the preferred embodiment applying

comprises single-crystalline silicon.

mechanical linkages and structure. FIG. 14A illustrates the

4. The process of claim 1, wherein said insulator layer

initial position when the wafer assembly 31 is placed onto

comprises

silicon dioxide.

anvil 140 and piston 141 is in its top position. Next, a

5. The process of claim 1, wherein said acceptor substrate

mechanical force 142 is applied to the piston and the piston 15

is single-crystalline silicon.

moves all the way down reaching its bottom position as

6. The process of claim 1, wherein said energy source is

shown on FIG. 14B. With this preferred embodiment the

ultrasound.

wafer assembly 31 bends and gets a shape predetermined by

7. The process of claim 6, wherein said ultrasound is a

said anvil 140 and piston 141. The bend gives the mechanical stress to the wafer and the stress promotes hydrogen 20 self-resonance mode ultrasound with an acoustic strain

amplitude of at least 10- 5 .

movement inside the wafer assembly 31 that has the

8. The process of claim 1, wherein said energy source is

hydrogen-rich layer. If the radii of curvature are chosen

properly, the wafer assembly gets stress that is not enough

an infrared energy source.

to break it in an unintentional place, but enough to separate

9. The process of claim 1, wherein said infrared energy

it along the weakened hydrogen-rich plane. The radii of 25 source provides infrared light that has a wavelength outside

curvature for the assembly is typically from 0.6 to 3 meters.

the silicon band edge absorption.

What is claimed is:

10. The process of claim 1, wherein said hydrostatic

1. A process for manufacturing a silicon-on-insulator

pressure energy source provides a hydrostatic pressure havwafer from a silicon wafer assembly, said process comprising an amplitude of at least 0.2 GPa.

ing the steps of:

30

11. The process of claim 1, wherein said hydrodynamic

providing a wafer assembly comprising a donor substrate

pressure energy source comprises a water jet.

having an insulator layer on a surface and a hydrogen12. The process of claim 1, wherein said mechanical

rich layer at a selected depth below said surface definsource comprises a structure to which a force may be applied

ing a single-crystalline silicon layer above said selected

in order to provide mechanical energy.

depth, and an acceptor substrate bonded to said surface 35

13. The process of claim 12, wherein said mechanical

for accepting said insulator layer and said singleenergy is applied to said structure which has a radius of

crystalline silicon layer above said selected depth, and;

curvature from about 0.6 to 3 meters.

applying to said wafer assembly an amount of energy

directed to a flat surface of said wafer assembly from an

* * * * *

�

Alex Usenko

Alex Usenko