Change Language :

Entertainment Rigging Solutions: Reliable, Quiet, and Invisible

Elevate Your Stage with igus® Motion Plastics®

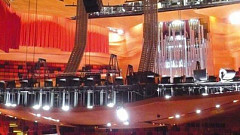

Every stage is unique, which means that each and every component not only has to be powerful, durable and efficient but must also fit together perfectly. Theater and stage construction present special technical challenges. These challenges include high loads, such as those found on crossbeams, stage lighting, stage sets or entire stage platforms, which must move safely and reliably. Furthermore, technical equipment must operate quietly and out of sight, so as not to interfere with the performance. igus® offers energy supply systems, highly flexible cables and plastic bearings that meet these exact requirements. Discover how igus® motion plastics® can optimize your entertainment rigging. Explore our solutions for theater and stage construction that meet the most demanding technical challenges.

Benefits of igus entertainment rigging technology:

- Energy and data cables and hydraulic hoses guided in one system

- Quiet - 32 dB(A) - and low vibration

- Lightweight

- For confined spaces or very high loads

- High speeds and acceleration

- Robust and easy to install

- Simple installation and quick maintenance or repairs

Entertainment rigging, stage rigging and stage lighting solutions

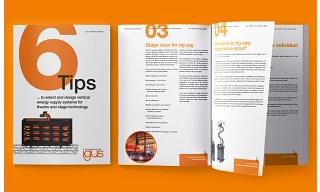

White Paper:

Vertical chain hoists in stage rigging

Like every industry, stage technology has its own requirements regarding machine parts and materials. In this white paper, we would like to give you six tips for selecting and designing vertical energy supply systems for stage technology

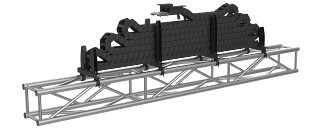

1. Electric chain hoists: Cable drum for e-chains – no slip ring

The e-spool supplies moving stage technology with various media without interruption. The system is used for stage podiums, mobile lighting hoists, and video cubes. The inserted cables are routed through a twisterband so that no slip ring is required, providing a special advantage for transferring data. The length of the reeled-up energy chain is adjusted with a retraction spring for strokes of up to 15 meters and with a motor for strokes of up to 25 meters and more. Placed on the fly walk, in false ceilings above the auditorium, or in the under-stage area, the system works unobtrusively outside of the audience's field of vision.

Design study: Microphone Motor Reeler, 30 meters

- Uninterrupted audio transmission without slip ring

- Cables can be replaced easily

- Easy, space-saving installation, no additional load-bearing element necessary

- No manual work at height

- Manufactured according to DIN EN 17206 and DGUV Principle 315-390

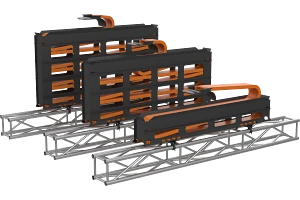

2. Zig-zag system

As an alternative to the e-spool, we offer the zig-zag system – our classic that has proven itself on the stage for many years (at the Royal Opera in London since 1998, for example). With this space-saving system, different media can be guided together without interruption and with no slip rings. The energy chain unfolds during the stage machinery's vertical movement. For upper stage machinery, the zig-zag box is mounted on the tie rod or truss; in under stage machinery, it is mounted on the floor below the podium.

Stage lighting truss systems

Design study: Low-cost zig-zag e-chain®

- More than 50% weight reduction and thus higher payload

- Price reduced by up to 50% compared to the standard zig zag basket

- Lower drive power thanks to weight reduction

3. Two-component heavy-duty plain bearing

Our iglidur Q3E multi-component bearings are the right choice for very high loads such as those in stage lift scissor joints.

Entertainment Rigging Customer Applications

Entertainment Rigging FAQs

Entertainment rigging is the practice of safely suspending and moving equipment, scenery, and performers in theaters, concerts, and film productions. It involves:

- Installing trusses, hoists, and cables

- Ensuring proper load distribution

- Implementing safety measures

- Managing complex control systems

- Coordinating with lighting, sound, design teams

Technology has revolutionized entertainment rigging through:

- Automated rigging systems for precise control

- Computer-aided design for safer layouts

- Load cells for real-time weight monitoring

- Wireless control systems for flexible operation

- Energy-efficient LED lighting reducing power requirements

- Advanced materials for stronger, lighter equipment

Key safety standards for entertainment rigging include:

- ANSI E1.6: Powered Hoist Systems

- ANSI E1.21: Temporary Ground-Supported Overhead Structures

- ANSI E1.47: Entertainment Technology - Recommended Guidelines for Entertainment Rigging System Inspections

- OSHA 1926 Subpart R: Steel Erection

- Local building codes and regulations

An entertainment rigger's primary responsibilities include:

- Designing and implementing rigging plans

- Installing and testing rigging equipment

- Ensuring compliance with safety standards

- Operating rigging systems during performances

- Performing regular equipment inspections and maintenance

- Collaborating with other production departments

- Problem-solving unexpected issues during setup or shows

Common entertainment rigging challenges include:

- Ensuring safety in dynamic environments

- Managing heavy loads in confined spaces

- Coordinating complex cue sequences

- Adapting to diverse venue layouts

- Balancing aesthetic needs with safety requirements

- Staying updated with evolving technology and standards

- Managing tight setup and teardown schedules

Theater vs. Concert Rigging:

- Permanence

- Theater: Often semi-permanent

- Concert: Usually temporary

- Complexity

- Theater: Complex scene changes

- Concert: Focus on lighting/sound

- Load Variability

- Theater: Varies with scenes

- Concert: More consistent

- Speed of Changes

- Theater: Slower, between scenes

- Concert: Rapid, during performance

- Customization

- Theater: Highly customized per show

- Concert: More standardized setups

Sustainability in entertainment rigging is achieved through:

- Energy-efficient LED lighting systems

- Lightweight, durable materials reducing transport emissions

- Reusable and modular rigging components

- Digital design tools minimizing material waste

- Energy-efficient motors and control systems

- Use of renewable energy sources in permanent installations

- Recycling programs for retired equipment

Emerging trends in entertainment rigging include:

- AI-powered rigging control systems

- Augmented reality for rigging design and operation

- Advanced motion capture integration

- 3D-printed custom rigging components

- Increased use of carbon fiber and composite materials

- IoT-enabled equipment for predictive maintenance

- Virtual production techniques influencing rigging needs

Brochure:

Explore Our Brochure for Cutting-Edge Solutions in the Entertainment rigging Industry!

Discover silent, maintenance-free solutions that will keep your shows running smoothly. Download our theater industry catalog now and take the first step towards more reliable, cost-effective stage equipment.

Browse the Engineer's Toolbox

Contact an Expert

Whether you're interested in end-to-end, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!