Change Language :

The history of igus - from Cologne's backyard out into the world

2024

€1,136 billion

Sales

4,600

Employees worldwide

31

Locations and 50 dealers:

Represented in over 80 countries

188,000

Customers

243,000

Products from stock

800

Injection moulding machines

2023

igusGO app: Discover optimisation potential in just a few seconds thanks to AI

How can we quickly and easily illustrate what is possible with our motion plastics? This question gave rise to our app igusGO which we released in September 2023. With the help of artificial intelligence, we analyse machines and applications and present optimisation options in a matter of seconds. Simply upload a photo of your application and the igusGO AI will show you which motion plastics products will help to make your machine lubrication-free and thus improve the technology and also save costs.

2022

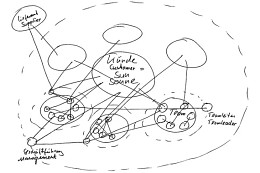

iguverse - the industrial metaverse from igus

At the IAA Transportation in Hanover in September 2022, visitors were able to take a first look at the beginnings of the igus metaverse. The iguverse is a virtual reality for sales and engineering in the industry. In this digital parallel universe, you can implement machines and systems faster and more efficiently and save time, costs and resources in the development, optimisation and maintenance of products.

2022

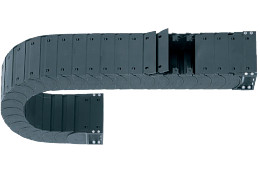

chainge platform: industrial plastic recycling for everyone

In 2019, we launched our plastic energy chain recycling program. Since then, customers have been able to send us worn-out energy chains. We weigh the material and issue a voucher for it. What is special about the program is that we take back not only our own energy supply systems, but those of other manufacturers as well if the chains are made of plastic. We shred the material or send it to external recycling services. But then we thought: There is still more to do. Since 2022, there is our chainge recycling platform. We want to facilitate recycling in industry and promote the circular economy. To this end, we offer recycled material (recyclate) through our marketplace.

2021

igus:bike - A new bike for a new future

Company owner Frank Blase has long dreamed of manufacturing a no-lubrication product from rust-free plastics for moving not industry, but end users. As is so often the case, the idea was prompted by a coincidence: he noticed rusting, high-maintenance rental bicycles at a seaside holiday resort. Could motion plastics help? In 2021, igus worked with MTRL, a Dutch start-up, to design a bicycle made of plastic. igus:bike.With moving parts from igus, the developers are charting new territory. Rim brake, freewheel, planetary gearbox, pulley, wheel bearing, crankset – all are made of igus high-performance plastic.

2021

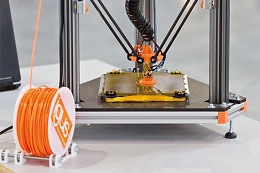

FastLine: Individual injection moulded plain bearings delivered in seven days

When market demand for a product is high, manufacturers and their suppliers are called for. Customised parts, such as plain bearings in special shapes, have to be delivered quickly and easily. But it is not unusual for the production of special parts by injection moulding to take several weeks. With the FastLine service lubrication-free plastic bearings in special dimensions are delivered within a few days at cost-effective part prices.

1965

The first product: a valve cone for Pierburg

And Günter Blase received that enquiry from Pierburg. Their complicated part turned out to be a valve plug for a carburettor. In 1965, no one would have thought of using plastic to make the small component, let alone injection-moulding it. The manufacturing process was simply too complicated. For Günter Blase, this was no reason to lose heart. He went into his double garage and experimented until the first perfect plastic valve cone came out of the injection-moulding machine.

1964

Every beginning is difficult

"Give me your most difficult part, and I will find a solution," Günter Blase told Pierburg. He had to take a risk in order to win over the company, which was his very first customer. There were two children at home who needed to be cared for. Money was in short supply. He had just set up igus with his wife and still had to buy his first injection moulding machine. The order from Pierburg was a critical one.

1964

Foundation of igus GmbH on 15th October

igus in motion

From the very beginning, life at igus was captured on film.The video shows a compilation of old recordings and Günter Blase interview excerpts.

This provides a little insight into the early years and shows how Günter Blase got into plastic and what was important to him from the start: the customers and the advantages igus products can give them!