Compresses Air Table

Compresses Air Table

Uploaded by

Anonymous BJ9omOCopyright:

Available Formats

Compresses Air Table

Compresses Air Table

Uploaded by

Anonymous BJ9omOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Compresses Air Table

Compresses Air Table

Uploaded by

Anonymous BJ9omOCopyright:

Available Formats

High efficiency filters Replaceable element, typical filtration to 0.01um, oil to 0.

01 mg/m3 Activated carbon filters Designed for oil removal to <0.01 mg/m3 General purpose filters Replaceable element, typical filtration to 1um, oil to 0.1 mg/m3 Refrigerant Low energy and capital cost provide pressure dewpoints to +3oC

Correct Pipe Sizing The maximum design velocity for main distribution pipework is 6m/s For short branch lines the velocity can be up to 15m/s Pressure drop across distribution system should be less than 0.2 bar Consider low friction aluminium or plastic piping systems

Points to consider when dealing with piping: Horizontal lengths of distribution piping should be sloped slightly downwards, with provision for moisture drainage. When designing a compressed air system, it is often a good practice to add 30% to the expected air flow (to add for future potential system expansion), and then select the pipe diameter having the lowest pressure

drop.

If possible it is good practice to loop the distribution piping in order to allow for air to travel in multiple directions, as illustrated in Figure 17. A single loop of pipe can reduce pressure differential by 75% compared to a single pipe of similar size. Multiple loops can further enhance the flow of air.

The size of an air receiver can be calculated as follows:

reciprocating compressors the rule of thumb for sizing a primary air receiver, has been from 1 gallon per cfm to 3 gallons per cfm of compressor capacity Primary air receivers As a rule of thumb, for load/unload operated lubricated screw compressors, the receiver volume should be 5 to 10 US gallons (20-40 liters) per trim compressor scfm output. Other factors come into play when sizing, such as the type of air compressor method of capacity control and compressor starting delays. Secondary receivers Generally a receiver of about 110 US gallons (415 l) will store 1 cubic foot of compressed air per psi. Required receiver size for any application is simply the cubic feet required multiplied by 110, and then divided by the pressure range. Example 2 - Determining Size of Air Receiver A clamp using 2 cfm needs a check valve protected storage receiver to maintain at least 85 psi for 2 minutes in a system that normally operates at 100 psi. Cubic feet required = 2 cfm 2 minutes = 4 cubic feet Pressure (psi) range during even = 100 - - 85 = 15 Storage receiver required 4 110/15 = 29 gallons (US) Example 3 - Transient Load Receiver Sizing A large transient sand blasting operation requiring 100 cfm occurs for 1 minute every 10 minutes. The blaster needs 80 psi and the system pressure is 100 psi. Without a secondary receiver, the main air system must supply this full flow, often with a significant pressure differential across the system. The alternative is to use a secondary storage receiver with the inlet

restricted by an orifice or needle valve. 100 cfm x 1 minute = 100 cubic feet Pressure (psi) range = 20 Storage receiver required = 100 cubic feet 110/20 psi= 550 gallons (US) This receiver could be filled over 10 minutes at a rate of 10 cfm which would reduce the previous system pressure differential by a factor of 100. Facilities having large fluctuations in air demand, or having insufficient air pressure (usually at the end of the line), should evaluate the need for one or more air receivers strategically located in the air distribution system.

1 gallon for each ACFM (Actual Cubic Feet per Minute), or 4 gallons per compressor hp (horse power)

ons per cfm of

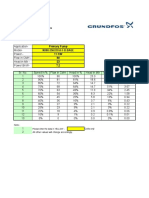

Resistance of Pipe Fittings in Equivalent Lengths (in metres)

Compressed Air System

Question: A 23 metre pipe with an inner diameter of 80 mm shall lead a flow of 140 l/s. The pipe is routed with 8 elbows that all have a bend diameter equal to the inner diameter. How great will the pressure drop across the pipe be if the absolute initial pressure is 8 bar(a)? 8 x 1.3 + 23 = 33.4 meters

You might also like

- Sizing of Air ReceiverDocument6 pagesSizing of Air Receiverraghu_mn100% (2)

- Compressed Air Distribution SystemsDocument5 pagesCompressed Air Distribution SystemsVarrit VejpongsaNo ratings yet

- Compressed Air CalculationDocument7 pagesCompressed Air Calculationlutfi awnNo ratings yet

- Foam CalculationsDocument8 pagesFoam CalculationsAnonymous BJ9omO86% (7)

- Cummins Engine Room Ventilation RequirementDocument3 pagesCummins Engine Room Ventilation RequirementAnonymous BJ9omONo ratings yet

- Compressed Air SystemsDocument4 pagesCompressed Air Systemsshameer_sanju1049100% (1)

- Sizing Air Receiver TankDocument3 pagesSizing Air Receiver TankDennis DanielNo ratings yet

- Compressor-Performance Evaluation PDFDocument4 pagesCompressor-Performance Evaluation PDFAlvin Smith100% (2)

- Tech Specification VSDDocument9 pagesTech Specification VSDDony SaputraNo ratings yet

- CompressorsDocument6 pagesCompressorsErmiyas MistreNo ratings yet

- WET AIR TO DRY AIR Types of Dryers.......................................Document8 pagesWET AIR TO DRY AIR Types of Dryers.......................................HARKULVINDER SINGH100% (1)

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- Velocity of Compressed AirDocument1 pageVelocity of Compressed AirLucky Karunia Setyawan PratamaNo ratings yet

- NPSH Calculating It PDFDocument6 pagesNPSH Calculating It PDFSanthosh ThekkethottiyilNo ratings yet

- Losses in PipesDocument43 pagesLosses in PipesSomnath Swamy100% (1)

- M 377 ContentDocument33 pagesM 377 Contenttamilradha821No ratings yet

- Air Compressor SizingDocument11 pagesAir Compressor Sizingalquin08No ratings yet

- Cooling Water Sump Model Studies Through CFD AnalysisDocument6 pagesCooling Water Sump Model Studies Through CFD AnalysisvijayasarathiNo ratings yet

- Louver and Pump SizeDocument1 pageLouver and Pump SizeShabeer HamzaNo ratings yet

- Fuel Gas Pipe SizingDocument12 pagesFuel Gas Pipe Sizingvarun guptaNo ratings yet

- Class Example Pump Sizing-Module 5 - Sep28Document6 pagesClass Example Pump Sizing-Module 5 - Sep28Stefan De Beer50% (2)

- Compressed Air Supply: Training NotesDocument22 pagesCompressed Air Supply: Training Notesardianalim100% (1)

- Condensate PumpsDocument1 pageCondensate Pumpstricky11100% (1)

- 4.6 Fans and BlowersDocument6 pages4.6 Fans and Blowerssrimant1984No ratings yet

- Vacuum Pump SizingDocument1 pageVacuum Pump SizingAhmad Saiful AnwarNo ratings yet

- Static Pressure Calculation in The Air DuctsDocument2 pagesStatic Pressure Calculation in The Air Ductsmeeng2014No ratings yet

- Compressed Air SystemDocument29 pagesCompressed Air SystemPrathmesh GujaratiNo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (2)

- Air Compressor ReportDocument51 pagesAir Compressor Reportvinay muley100% (1)

- STC (Buffer Tank 25KL) - Calc PDFDocument4 pagesSTC (Buffer Tank 25KL) - Calc PDFAvril Rindra T PNo ratings yet

- Compressor and Compressed Air SystemDocument34 pagesCompressor and Compressed Air Systemrashm006ranjanNo ratings yet

- Afinity Law - CalculationsDocument1 pageAfinity Law - CalculationsShivraj SawantNo ratings yet

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocument4 pagesOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2No ratings yet

- Duct Sizing & Fan Static Calculation - Week 3Document49 pagesDuct Sizing & Fan Static Calculation - Week 3slow_bbNo ratings yet

- Compressed Air HandbookDocument96 pagesCompressed Air Handbookfralalli100% (1)

- Pipe Sizing ASHRAEDocument2 pagesPipe Sizing ASHRAEooop33No ratings yet

- Relief Valve SizingDocument3 pagesRelief Valve SizingcutefrenzyNo ratings yet

- Pressure Relief Damper: Type ARK2Document14 pagesPressure Relief Damper: Type ARK2vvlad34No ratings yet

- Rightsizing Compressed Air SystemDocument6 pagesRightsizing Compressed Air SystemRahul ChandrawarNo ratings yet

- 06 PB Air Quality and Tunnel Ventilation DesignDocument12 pages06 PB Air Quality and Tunnel Ventilation Designp0486No ratings yet

- Air Receivers Tech TipDocument3 pagesAir Receivers Tech TipOthman Mat Yaman100% (1)

- Compressor Settle-Out CalculationDocument4 pagesCompressor Settle-Out CalculationWickyNo ratings yet

- Friction Factor For Commercial PipesDocument17 pagesFriction Factor For Commercial PipesPriyanka KumariNo ratings yet

- Sheet5-Centrifugal PumpDocument5 pagesSheet5-Centrifugal Pumpyousef mohamedNo ratings yet

- Pumps LectureDocument17 pagesPumps LectureHang U LieNo ratings yet

- Steam Consumption and Line SizingDocument3 pagesSteam Consumption and Line SizingpavanNo ratings yet

- Reciprocating PumpDocument4 pagesReciprocating PumpTejashri Pote100% (1)

- The Weymouth Equation: ParametersDocument3 pagesThe Weymouth Equation: Parametersprateek_bhoirNo ratings yet

- Pump Hydraulic Calculation - Oil Transfer PumpDocument6 pagesPump Hydraulic Calculation - Oil Transfer PumpmuthuglitzNo ratings yet

- Design Data Performance (Dryer) : ClientDocument2 pagesDesign Data Performance (Dryer) : ClientEDUARDONo ratings yet

- Expansion Vessel Calculation SheetDocument2 pagesExpansion Vessel Calculation SheetsmcsamindaNo ratings yet

- Designing Compressed Air SystemsDocument8 pagesDesigning Compressed Air SystemsZaki AnwerNo ratings yet

- Compressor SizeDocument3 pagesCompressor SizeSubhash KumarNo ratings yet

- Gas Compression IIDocument13 pagesGas Compression IIAnuraag MulpuriNo ratings yet

- M 389 ContentDocument52 pagesM 389 ContentokahertaberNo ratings yet

- Compressor Air Intake Quality ImportanceDocument12 pagesCompressor Air Intake Quality Importanceanup_nairNo ratings yet

- Orifice PlateDocument3 pagesOrifice PlateMuhammad MohtashimNo ratings yet

- Wsfu Storey BuildingDocument2 pagesWsfu Storey BuildingfebousNo ratings yet

- Expansion Tank Sizing WorksheetDocument2 pagesExpansion Tank Sizing Worksheetdjsanju69100% (1)

- Calculating Receivers in Compressed Air SystemsDocument4 pagesCalculating Receivers in Compressed Air Systemsdharwin100% (1)

- Sizing The Air ReceiverDocument3 pagesSizing The Air Receivernandhamech25No ratings yet

- Kitchen HoodDocument10 pagesKitchen HoodkumarNo ratings yet

- Cooling Load EstimationDocument69 pagesCooling Load EstimationkarimNo ratings yet

- Pipe Size CalcDocument19 pagesPipe Size Calcnitin_bir100% (3)

- Unit Conversion Sheet - Beta 1Document2 pagesUnit Conversion Sheet - Beta 1Anonymous BJ9omONo ratings yet

- Elite Software - PsyChartDocument5 pagesElite Software - PsyChartsyedkaleem55No ratings yet

- Hvac Control in The New MillenniumDocument388 pagesHvac Control in The New MillenniumPrecisionetica100% (2)

- Additional GraphsDocument20 pagesAdditional GraphsAnonymous BJ9omONo ratings yet

- Basics of PipingDocument102 pagesBasics of PipingDawood Akram100% (4)

- Hazen Williams EquationDocument5 pagesHazen Williams EquationAnonymous BJ9omONo ratings yet

- Q&A PlumbingDocument14 pagesQ&A PlumbingHenry SuarezNo ratings yet

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 pagesTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONo ratings yet

- Pump Head Calculations For Building # 44: Phase # 1Document4 pagesPump Head Calculations For Building # 44: Phase # 1Anonymous BJ9omONo ratings yet

- Exporting HAP Hourly Simulation Data To Spreadsheets.: QB Tip 001Document4 pagesExporting HAP Hourly Simulation Data To Spreadsheets.: QB Tip 001Anonymous BJ9omONo ratings yet

- Water Demand CalculationDocument2 pagesWater Demand Calculationmunim87100% (1)

- Hap Ehelp 007Document6 pagesHap Ehelp 007Anonymous BJ9omONo ratings yet

- Pipe Size CalcDocument19 pagesPipe Size Calcnitin_bir100% (3)

- Total Flow Rate of Building # 43: Crac 3 95.5 (6) 286.5Document2 pagesTotal Flow Rate of Building # 43: Crac 3 95.5 (6) 286.5Anonymous BJ9omONo ratings yet