4 Load & Load Combination

Uploaded by

Anonymous b9fkTYfEoR4 Load & Load Combination

Uploaded by

Anonymous b9fkTYfEoRDesign of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.

Santha Kumar

7.4 Loads and Load combinations

7.4.1 Loads on bridges

The following are the various loads to be considered for the purpose of

computing stresses, wherever they are applicable.

· Dead load

· Live load

· Impact load

· Longitudinal force

· Thermal force

· Wind load

· Seismic load

· Racking force

· Forces due to curvature.

· Forces on parapets

· Frictional resistance of expansion bearings

· Erection forces

Dead load – The dead load is the weight of the structure and any permanent

load fixed thereon. The dead load is initially assumed and checked after design is

completed.

Live load – Bridge design standards specify the design loads, which are

meant to reflect the worst loading that can be caused on the bridge by traffic,

permitted and expected to pass over it. In India, the Railway Board specifies the

standard design loadings for railway bridges in bridge rules. For the highway

bridges, the Indian Road Congress has specified standard design loadings in

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

IRC section II. The following few pages brief about the loadings to be considered.

For more details, the reader is referred to the particular standard.

Railway bridges: Railway bridges including combined rail and road bridges

are to be designed for railway standard loading given in bridge rules. The

standards of loading are given for:

· Broad gauge - Main line and branch line

· Metre gauge - Main line, branch line and Standard C

· Narrow gauge - H class, A class main line and B class branch line

The actual loads consist of axle load from engine and bogies. The actual

standard loads have been expressed in bridge rules as equivalent uniformly

distributed loads (EUDL) in tables to simplify the analysis. These equivalent UDL

values depend upon the span length. However, in case of rigid frame, cantilever

and suspension bridges, it is necessary for the designer to proceed from the

basic wheel loads. In order to have a uniform gauge throughout the country, it is

advantageous to design railway bridges to Broad gauge main line standard

loading. The EUDLs for bending moment and shear force for broad gauge main

line loading can be obtained by the following formulae, which have been obtained

from regression analysis:

For bending moment:

EUDL in kN = 317.97 + 70.83l + 0.0188l2 ≥ 449.2 kN (7.1)

For shear force:

EUDL in kN = 435.58 + 75.15l + 0.0002l2 ≥ 449.2 kN (7.2)

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Note that, l is the effective span for bending moment and the loaded

length for the maximum effect in the member under consideration for shear. 'l '

should be in metres. The formulae given here are not applicable for spans less

than or equal to 8 m with ballast cushion. For the other standard design loading

the reader can refer to Bridge rules.

Highway bridges: In India, highway bridges are designed in accordance with

IRC bridge code. IRC: 6 - 1966 – Section II gives the specifications for the

various loads and stresses to be considered in bridge design. There are three

types of standard loadings for which the bridges are designed namely, IRC class

AA loading, IRC class A loading and IRC class B loading.

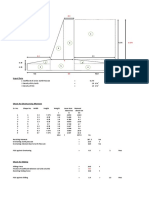

Fig.7.10 IRC AA loading

IRC class AA loading consists of either a tracked vehicle of 70 tonnes or a

wheeled vehicle of 40 tonnes with dimensions as shown in Fig. 7.10. The units in

the figure are mm for length and tonnes for load. Normally, bridges on national

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

highways and state highways are designed for these loadings. Bridges designed

for class AA should be checked for IRC class A loading also, since under certain

conditions, larger stresses may be obtained under class A loading. Sometimes

class 70 R loading given in the Appendix - I of IRC: 6 - 1966 - Section II can be

used for IRC class AA loading. Class 70R loading is not discussed further here.

Class A loading consists of a wheel load train composed of a driving

vehicle and two trailers of specified axle spacings. This loading is normally

adopted on all roads on which permanent bridges are constructed. Class B

loading is adopted for temporary structures and for bridges in specified areas.

For class A and class B loadings, reader is referred to IRC: 6 - 1966 – Section II.

Foot Bridges and Footpath on Bridges – The live load due to pedestrian

traffic should be treated as uniformly distributed over the pathway. For the design

of footbridges or footpaths on railway bridges, the live load including dynamic

effects should be taken as 5.0 kN/m2 of the footpath area. For the design of foot-

path on a road bridges or road-rail bridges, the live load including dynamic

effects may be taken as 4.25 kN/m2 except that, where crowd loading is likely,

this may be increased to 5.0 kN/m2.

The live load on footpath for the purpose of designing the main girders has

to be taken as follows according to bridge rules:

(i) For effective spans of 7.5 m or less - 4.25 kN/m2

(ii) The intensity of load is reduced linearly from 4.25 kN/m2 for a span of 7.5 m

to 3.0 kN/m2 for a span of 30m

(iii) For effective spans over 30 m, the UDL may be calculated as given below:

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

1 ⎛ 400 ⎞ ⎛ 17 − W ⎞

P= ⎜13.3 + ⎟⎜ ⎟ kN / m

2

(7.3)

100 ⎝ l ⎠ ⎝ 1.4 ⎠

Where, P = Live load in kN/m2

l = Effective span of the bridge in m.

W = Width of the foot path in m.

Where foot-paths are provided on a combined rail-road bridge, the load on

foot-path for purpose of designing the main girders should be taken as 2.0

kN/m2.

Impact load

Fig 7.11 Impact percentage curve for highway bridges for IRC class A and

IRC class B loadings

The dynamic effect caused due to vertical oscillation and periodical

shifting of the live load from one wheel to another when the locomotive is moving

is known as impact load. The impact load is determined as a product of impact

factor, I, and the live load. The impact factors are specified by different

authorities for different types of bridges. The impact factors for different bridges

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

for different types of moving loads are given in the table 7.1. Fig.7.11 shows

impact percentage curve for highway bridges for class AA loading. Note that, in

the above table l is loaded length in m and B is spacing of main girders in m.

Longitudinal forces – Longitudinal forces are set up between vehicles and

bridge deck when the former accelerate or brake. The magnitude of the force F,

is given by

W δV

F= (7.4)

g δt

Where, W – weight of the vehicle

g – acceleration due to gravity

δV – change in velocity in time d t

This loading is taken to act at a level 1.20 m above the road surface. No

increase in vertical force for dynamic effect should be made along with

longitudinal forces. The possibility of more than one vehicle braking at the same

time on a multi-lane bridge should also be considered.

Table 7.1: Impact factors for different bridges

BRIDGE LOADING IMPACT FACTOR (I)

Railway Broad gauge (a) Single track

bridgesaccording and Meter

to bridge rules gauge

(b) Main girder of double track

with two girders

(c) Intermediate main girder of

multiple track spans

(d) Outside main girders of Specified in (a) or (b)

multiple track spans whichever applies

(e) Cross girders carrying two

or more tracks

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Broad gauge

Rails with ordinary fish plate

joints and supported directly

on sleepers or transverse

steel troughing

Meter gauge

Narrow gauge

IRC class AA (i) Spans less than 9 m.

loading (a) Tracked vehicle 0.25 for spans up to 5

mand linearly reducing

to 0.10 to spans of 9m

(b) Wheeled vehicle 0.25

0.10

(ii) Spans 9 m or more

Highway bridges 0.25 for spans up to 23

(a) Tracked vehicle

according to IRC mand in accordance

regulations with the curve

(b) Wheeled vehicle

indicated inFig .11 for

spans in excess of 23

m

IRC class A

loading and IRC Spans between 3 m and45 m

class B loading In accordance with the

curve indicated inFig

.11 for all spans

No separate impact

Foot bridges

allowance is made

Thermal forces – The free expansion or contraction of a structure due to

changes in temperature may be restrained by its form of construction. Where any

portion of the structure is not free to expand or contract under the variation of

temperature, allowance should be made for the stresses resulting from this

condition. The coefficient of thermal expansion or contraction for steel is 11.7 x

10-6 / oC

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Wind load – Wind load on a bridge may act

· Horizontally, transverse to the direction of span

· Horizontally, along the direction of span

· Vertically upwards, causing uplift

· Wind load on vehicles

Wind load effect is not generally significant in short-span bridges; for

medium spans, the design of sub-structure is affected by wind loading; the super

structure design is affected by wind only in long spans. For the purpose of the

design, wind loadings are adopted from the maps and tables given in IS: 875

(Part III). A wind load of 2.40 kN/m2 is adopted for the unloaded span of the

railway, highway and footbridges. In case of structures with opening the effect of

drag around edges of members has to be considered.

Racking force – This is a lateral force produced due to the lateral movement

of rolling stocks in railway bridges. Lateral bracing of the loaded deck of railway

spans shall be designed to resist, in addition to the wind and centrifugal loads, a

lateral load due to racking force of 6.0 kN/m treated as moving load. This lateral

load need not be taken into account when calculating stresses in chords or

flanges of main girders.

Forces on parapets - Railings or parapets shall have a minimum height

above the adjacent roadway or footway surface of 1.0 m less one half the

horizontal width of the top rail or top of the parapet. They shall be designed to

resist a lateral horizontal force and a vertical force each of 1.50 kN/m applied

simultaneously at the top of the railing or parapet.

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Seismic load – If a bridge is situated in an earthquake prone region, the

earthquake or seismic forces are given due consideration in structural design.

Earthquakes cause vertical and horizontal forces in the structure that will be

proportional to the weight of the structure. Both horizontal and vertical

components have to be taken into account for design of bridge structures.

IS:1893 – 1984 may be referred to for the actual design loads.

Forces due to curvature - When a track or traffic lane on a bridge is curved

allowance for centrifugal action of the moving load should be made in designing

the members of the bridge. All the tracks and lanes on the structure being

considered are assumed as occupied by the moving load.

This force is given by the following formula:

W V2

C= (7.5)

12.7 R

Where, C - Centrifugal force in kN/m

W - Equivalent distributed live load in kN/m

V - Maximum speed in km/hour

R - Radius of curvature in m

Erection forces – There are different techniques that are used for

construction of railway bridges, such as launching, pushing, cantilever method,

lift and place. In composite construction the composite action is mobilised only

after concrete hardens and prior to that steel section has to carry dead and

construction live loads. Depending upon the technique adopted the stresses in

the members of the bridge structure would vary. Such erection stresses should

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

be accounted for in design. This may be critical, especially in the case of erection

technologies used in large span bridges.

7.4.2 Load combinations

Stresses for design should be calculated for the most sever combinations

of loads and forces. Four load combinations are generally considered important

for checking for adequacy of the bridge. These are given in Table 7.2 and are

also specified in IS 1915 - 1961.

Table 7.2: Load combinations

SNo Load combination Loads

Dead load, live load, impact load and

1 Stresses due to normal loads

centrifugal force

Normal load as in (1) + wind load, other lateral

Stresses due to normal loads +

2 loads, longitudinal forces and temperature

occasional loads

stresses

3 Stresses due to loads during erection -

Stresses due to normal loads +

Loads as in (2) + with seismic load instead of

4 occasional loads + Extra-ordinary loads

wind

like seismic excluding wind load

Indian Institute of Technology Madras

You might also like

- IRC 112 RC Design Guide For Civil - 2016 - Draft100% (1)IRC 112 RC Design Guide For Civil - 2016 - Draft20 pages

- Reinforced Concrete Road Bridges: Prof. Nirjhar DhangNo ratings yetReinforced Concrete Road Bridges: Prof. Nirjhar Dhang110 pages

- S - 301 PIER DWG PILE DETAIL WAL TYPE-PILE FDN - PDF 2 of 2No ratings yetS - 301 PIER DWG PILE DETAIL WAL TYPE-PILE FDN - PDF 2 of 21 page

- Effect of Varying Slab Depth of The Skew CulvertNo ratings yetEffect of Varying Slab Depth of The Skew Culvert12 pages

- Implication of IRC 112 - 2011 On RCC Bridge DesignNo ratings yetImplication of IRC 112 - 2011 On RCC Bridge Design8 pages

- Theory of Elasticity: Subject Code (ST102)100% (1)Theory of Elasticity: Subject Code (ST102)20 pages

- Response of A High-Speed Train Bridge Under The ExNo ratings yetResponse of A High-Speed Train Bridge Under The Ex7 pages

- Isolated Footing-Check For Base PressureNo ratings yetIsolated Footing-Check For Base Pressure5 pages

- Steel Connections-Lacing-Bridge BearingNo ratings yetSteel Connections-Lacing-Bridge Bearing11 pages

- InnoVatIVe Solution For Box Abutments of Flyovers inNo ratings yetInnoVatIVe Solution For Box Abutments of Flyovers in8 pages

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)No ratings yetSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)5 pages

- Proof Load Testing For Bridge Assessment and Upgrading PDFNo ratings yetProof Load Testing For Bridge Assessment and Upgrading PDF13 pages

- Vdocuments - MX - Bef Analogy For Concrete Box Girder Analysis of Bridges SummaryNo ratings yetVdocuments - MX - Bef Analogy For Concrete Box Girder Analysis of Bridges Summary8 pages

- Tutorial 4 A Ar RC CH H B BR Ri Id DG Ge eNo ratings yetTutorial 4 A Ar RC CH H B BR Ri Id DG Ge e48 pages

- Article 2 Detail Design of PSC I-Girder Bridge Deck-Girder Superstructure in AASHTO-LRFDNo ratings yetArticle 2 Detail Design of PSC I-Girder Bridge Deck-Girder Superstructure in AASHTO-LRFD177 pages

- Lecture 9 - DR Lakshmy Parameswaran On Chapter7 of IRC114No ratings yetLecture 9 - DR Lakshmy Parameswaran On Chapter7 of IRC11469 pages

- A Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC AbutmentsNo ratings yetA Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC Abutments3 pages

- Static and Dynamic Analysis of Tee Beam Bridge DeckNo ratings yetStatic and Dynamic Analysis of Tee Beam Bridge Deck4 pages

- All Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingNo ratings yetAll Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A Loading6 pages

- Analysis of T-Beam Bridge Using Finite Element MethodNo ratings yetAnalysis of T-Beam Bridge Using Finite Element Method7 pages

- Analysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011No ratings yetAnalysis and Design of Prestressed Deck Slab Bridge With IRC 112-20116 pages

- Table: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly GlobalzNo ratings yetTable: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly Globalz6 pages

- Analytical and Experimental Evaluation of Stiffness Parameters of Voided Concrete Slab Bridge 4No ratings yetAnalytical and Experimental Evaluation of Stiffness Parameters of Voided Concrete Slab Bridge 485 pages

- QUOTATION FOR JAMMU PROJECT - DC-IPL - UpdatedNo ratings yetQUOTATION FOR JAMMU PROJECT - DC-IPL - Updated2 pages

- SECTION at CH - 452+190 SECTION at CH - 452+180: Manomav Engineers Pvt. Ltd. MeplNo ratings yetSECTION at CH - 452+190 SECTION at CH - 452+180: Manomav Engineers Pvt. Ltd. Mepl1 page

- SECTION at CH - 452+220 SECTION at CH - 452+230: Manomav Engineers Pvt. Ltd. MeplNo ratings yetSECTION at CH - 452+220 SECTION at CH - 452+230: Manomav Engineers Pvt. Ltd. Mepl1 page

- Plum Wall Details Plan: N 3365450 N 3365460 N 3365470 N 3365520No ratings yetPlum Wall Details Plan: N 3365450 N 3365460 N 3365470 N 33655201 page

- SECTION at CH - 452+200 SECTION at CH - 452+210: Manomav Engineers Pvt. Ltd. MeplNo ratings yetSECTION at CH - 452+200 SECTION at CH - 452+210: Manomav Engineers Pvt. Ltd. Mepl1 page

- SECTION at CH - 452+160 SECTION at CH - 452+170: Manomav Engineers Pvt. Ltd. MeplNo ratings yetSECTION at CH - 452+160 SECTION at CH - 452+170: Manomav Engineers Pvt. Ltd. Mepl1 page

- Reinforced Concrete Road Bridges: Prof. Nirjhar DhangReinforced Concrete Road Bridges: Prof. Nirjhar Dhang

- S - 301 PIER DWG PILE DETAIL WAL TYPE-PILE FDN - PDF 2 of 2S - 301 PIER DWG PILE DETAIL WAL TYPE-PILE FDN - PDF 2 of 2

- Implication of IRC 112 - 2011 On RCC Bridge DesignImplication of IRC 112 - 2011 On RCC Bridge Design

- Response of A High-Speed Train Bridge Under The ExResponse of A High-Speed Train Bridge Under The Ex

- InnoVatIVe Solution For Box Abutments of Flyovers inInnoVatIVe Solution For Box Abutments of Flyovers in

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)

- Proof Load Testing For Bridge Assessment and Upgrading PDFProof Load Testing For Bridge Assessment and Upgrading PDF

- Vdocuments - MX - Bef Analogy For Concrete Box Girder Analysis of Bridges SummaryVdocuments - MX - Bef Analogy For Concrete Box Girder Analysis of Bridges Summary

- Article 2 Detail Design of PSC I-Girder Bridge Deck-Girder Superstructure in AASHTO-LRFDArticle 2 Detail Design of PSC I-Girder Bridge Deck-Girder Superstructure in AASHTO-LRFD

- Lecture 9 - DR Lakshmy Parameswaran On Chapter7 of IRC114Lecture 9 - DR Lakshmy Parameswaran On Chapter7 of IRC114

- A Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC AbutmentsA Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC Abutments

- Static and Dynamic Analysis of Tee Beam Bridge DeckStatic and Dynamic Analysis of Tee Beam Bridge Deck

- All Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingAll Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A Loading

- Analysis of T-Beam Bridge Using Finite Element MethodAnalysis of T-Beam Bridge Using Finite Element Method

- Analysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011Analysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011

- Table: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly GlobalzTable: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly Globalz

- Analytical and Experimental Evaluation of Stiffness Parameters of Voided Concrete Slab Bridge 4Analytical and Experimental Evaluation of Stiffness Parameters of Voided Concrete Slab Bridge 4

- SECTION at CH - 452+190 SECTION at CH - 452+180: Manomav Engineers Pvt. Ltd. MeplSECTION at CH - 452+190 SECTION at CH - 452+180: Manomav Engineers Pvt. Ltd. Mepl

- SECTION at CH - 452+220 SECTION at CH - 452+230: Manomav Engineers Pvt. Ltd. MeplSECTION at CH - 452+220 SECTION at CH - 452+230: Manomav Engineers Pvt. Ltd. Mepl

- Plum Wall Details Plan: N 3365450 N 3365460 N 3365470 N 3365520Plum Wall Details Plan: N 3365450 N 3365460 N 3365470 N 3365520

- SECTION at CH - 452+200 SECTION at CH - 452+210: Manomav Engineers Pvt. Ltd. MeplSECTION at CH - 452+200 SECTION at CH - 452+210: Manomav Engineers Pvt. Ltd. Mepl

- SECTION at CH - 452+160 SECTION at CH - 452+170: Manomav Engineers Pvt. Ltd. MeplSECTION at CH - 452+160 SECTION at CH - 452+170: Manomav Engineers Pvt. Ltd. Mepl