0 ratings0% found this document useful (0 votes)

81 viewsAttribute Gage R & R Effectiveness: Date: Name: Product: Process

This document summarizes the results of a study evaluating the reliability of three operators conducting visual inspections of wiring harnesses. Each operator inspected 30 samples and indicated whether they passed or failed. Their responses were compared to the known condition of the samples and to each other. The percentage of matches between each operator and the known condition was over 90% for all operators. When comparing the operators to each other, they agreed on their assessments for most but not all samples. The overall effectiveness of the inspection process, as measured by the percentage of matches to the known condition across all operators, was 93.33%.

Uploaded by

shuklahouseCopyright

© © All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0 ratings0% found this document useful (0 votes)

81 viewsAttribute Gage R & R Effectiveness: Date: Name: Product: Process

This document summarizes the results of a study evaluating the reliability of three operators conducting visual inspections of wiring harnesses. Each operator inspected 30 samples and indicated whether they passed or failed. Their responses were compared to the known condition of the samples and to each other. The percentage of matches between each operator and the known condition was over 90% for all operators. When comparing the operators to each other, they agreed on their assessments for most but not all samples. The overall effectiveness of the inspection process, as measured by the percentage of matches to the known condition across all operators, was 93.33%.

Uploaded by

shuklahouseCopyright

© © All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

You are on page 1/ 1

Data Entry

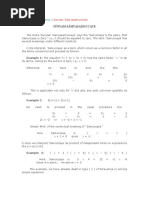

Attribute Gage R & R Effectiveness

SCORING REPORT

DATE: 18.03.2008

Attribute Legend NAME: Rajeev Kumar

1 pass PRODUCT: Wiring Harness

2 fail PROCESS: Visual Inspection

Known Population Operator #1 Operator #2 Operator #3 Y/N Y/N

Sample # Attribute Try #1 Try #2 Try #1 Try #2 Try #1 Try #2 Agree Agree

1 pass pass pass pass pass pass pass Y Y

2 pass pass pass pass pass pass pass Y Y

3 fail fail fail fail pass fail fail N N

4 fail fail fail fail fail fail fail Y Y

5 fail fail fail fail fail fail fail Y Y

6 pass pass pass pass pass pass pass Y Y

7 pass fail fail fail fail fail fail Y N

8 pass pass pass pass pass pass pass Y Y

9 fail pass pass pass pass pass pass Y N

10 fail pass pass fail fail fail fail N N

11 pass pass pass pass pass pass pass Y Y

12 pass pass pass pass pass pass pass Y Y

13 fail fail fail fail fail fail fail Y Y

14 fail fail fail fail fail fail fail Y Y

15 fail fail fail fail fail fail fail Y Y

16 pass pass pass pass pass pass pass Y Y

17 pass pass pass pass pass pass pass Y Y

18 pass pass pass pass pass pass pass Y Y

19 pass pass pass pass pass pass pass Y Y

20 fail fail fail fail fail fail fail Y Y

21 fail fail fail fail fail fail fail Y Y

22 fail fail fail fail fail fail fail Y Y

23 pass pass pass pass pass pass pass Y Y

24 pass pass pass pass pass pass pass Y Y

25 pass pass pass pass pass pass pass Y Y

26 pass pass pass pass pass pass pass Y Y

27 pass pass pass pass pass pass pass Y Y

28 pass pass pass pass pass pass pass Y Y

29 pass pass pass pass pass pass pass Y Y

30 fail fail fail fail fail fail fail Y Y

% APPRAISER SCORE

(1)

-> 100.00% 96.67% 100.00%

% SCORE VS. ATTRIBUTE

(2)

-> 90.00% 90.00% 93.33%

SCREEN % EFFECTIVE SCORE

(3)

-> 93.33%

SCREEN % EFFECTIVE SCORE vs. ATTRIBUTE

(4)

-> 86.67%

Note:

(1) If % Appraiser Score is less than 100% training needs to occur, focus on specific areas

(2) % Score vs. Attribute is an error against known population as deemed by experts

(3) 100% is the target for Screen % Effectiveness Score

(4) Sceen % Effective vs. Attribute is an error against a known population as deemed by the experts

(5) Attribute legend can be what defect codes are needing a score

Page 1

You might also like

- Statistical Process Control: Quality Productivity Management Consultancy (QPMC)No ratings yetStatistical Process Control: Quality Productivity Management Consultancy (QPMC)15 pages

- Lalji Gopinath Ji Industries: Training Need Identification - Associates (2023-24)No ratings yetLalji Gopinath Ji Industries: Training Need Identification - Associates (2023-24)24 pages

- Industrial Posters (Workplace Posters) : Product ListNo ratings yetIndustrial Posters (Workplace Posters) : Product List1 page

- 5 Esa 5 Esa 5 Esa 5 Esa Kaya Kaya Kaya Kaya - Sqala P'Bamqana Sqala P'Bamqana Sqala P'Bamqana Sqala P'Bamqana50% (2)5 Esa 5 Esa 5 Esa 5 Esa Kaya Kaya Kaya Kaya - Sqala P'Bamqana Sqala P'Bamqana Sqala P'Bamqana Sqala P'Bamqana46 pages

- Training PPT For Control Plan Mr. GARV SINGH GOLDYNo ratings yetTraining PPT For Control Plan Mr. GARV SINGH GOLDY13 pages

- Measurement Systems Analysis: Total Quality ManagementNo ratings yetMeasurement Systems Analysis: Total Quality Management17 pages

- FO9 Audit Opening and Closing Meeting - v4.0No ratings yetFO9 Audit Opening and Closing Meeting - v4.04 pages

- 2013 PDCA-AnalysisforQualityandProductivityimprovementNo ratings yet2013 PDCA-AnalysisforQualityandProductivityimprovement18 pages

- Storm QCC: Welcomes You All For Our Second Project Presentation100% (1)Storm QCC: Welcomes You All For Our Second Project Presentation89 pages

- A Bhaskar: Repeatability - Equipment Variation (EV)No ratings yetA Bhaskar: Repeatability - Equipment Variation (EV)2 pages

- A Process Capability Study On CNC Operation by The Application of Statistical Process Control Approach100% (1)A Process Capability Study On CNC Operation by The Application of Statistical Process Control Approach14 pages

- Fabrication of Spark Plug Testing Machine PDF0% (1)Fabrication of Spark Plug Testing Machine PDF2 pages

- Mahindra and Mahindra - Swaraj Tractor Division - Project Semester Presentation100% (2)Mahindra and Mahindra - Swaraj Tractor Division - Project Semester Presentation43 pages

- MSA - Measurement System Analysis & Questions100% (1)MSA - Measurement System Analysis & Questions19 pages

- Production Department: Subros Audit Non-Confirmity PointNo ratings yetProduction Department: Subros Audit Non-Confirmity Point4 pages

- CV - Vikas Zambre (19 Y Exp in QA & MFG)No ratings yetCV - Vikas Zambre (19 Y Exp in QA & MFG)3 pages

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowNo ratings yetProcedure Manual - IMS: Locomotive Workshop, Northern Railway, Lucknow2 pages

- Brochure For World Quality Month 2024-JSLNo ratings yetBrochure For World Quality Month 2024-JSL12 pages

- Attribute Gage R & R Effectiveness: Date: Name: Product: ProcessNo ratings yetAttribute Gage R & R Effectiveness: Date: Name: Product: Process5 pages

- MINITAB Application For: Cause-and-Effect Diagram & Scatter DiagramNo ratings yetMINITAB Application For: Cause-and-Effect Diagram & Scatter Diagram14 pages

- Tests Conducted On Under Water Battery - YaduNo ratings yetTests Conducted On Under Water Battery - Yadu15 pages

- Cyber Crime, Cyber Security in India: Mohammed Amjadh A SNo ratings yetCyber Crime, Cyber Security in India: Mohammed Amjadh A S16 pages

- Solving Every Sudoku Puzzle - Peter NorvigNo ratings yetSolving Every Sudoku Puzzle - Peter Norvig15 pages

- Certificate Acknowledgement List of Figures NomenclatureNo ratings yetCertificate Acknowledgement List of Figures Nomenclature2 pages

- Attribute Measurement Study: A-1 A-2 A-3 B-1 B-2 B-3 C-1 C-2 C-3No ratings yetAttribute Measurement Study: A-1 A-2 A-3 B-1 B-2 B-3 C-1 C-2 C-32 pages