0 ratings0% found this document useful (0 votes)

48 viewsSupranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Uploaded by

Gogo PSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Uploaded by

Gogo P0 ratings0% found this document useful (0 votes)

48 views1 pageSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Original Description:

112

Original Title

121

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Supranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

48 views1 pageSupranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant Steels

Uploaded by

Gogo PSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

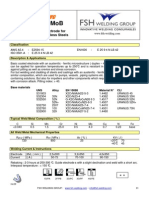

SUPRANOX RS 347

Keep dry and avoid condensation.

Re-drying not generally required.

If necessary: 350-370 C for 1 hour, 3 times max.

AWS A5.4: E 347-16

EN 1600: E 19 9Nb R 12

GOST 10052-75: 08X20H10 2 similar

AC; DC+

2,0 30-60 11,1 6,6 300

2,5 50-80 18,7 11,2 300

3,2 60-120 35,0 21,0 350

4,0 100-140 52,5 31,5 350

5,0 130-180 82,6 49,5 350

Packaging data

Classification

Weld metal weight

per electrode (g)

Diameter

(mm)

Current

(A)

Electrode

average weight (g)

MMA Electrodes

All-weld metal Mechanical Properties

As Welded 550 350 30 48 -

Impact Energy

ISO - V (J)

Heat Treatment

Tensile

Strength

N/mm

2

Yield

Strength

N/mm

2

Elongation

A5 (%)

20C

Hardness

1.4541 (X6CrNiTi18-10); 1.4301 (X4CrNi18-10); 1.4550 (X6CrNiNb18-10);

AISI 347 - 321

Length

(mm)

Current condition and welding position Storage and redrying

PA PB PC PF PE

Analysis of all-weld metal (Typical values in %)

C Ferrite

0.05 5-10 0.80 0.60 0.025 0.020 19 10 - 0.50 - -

Mn Si P S Cr Ni Mo Nb Cu N

Stainless and Heat resistant steels

Materials

Semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. The Nb+Ta in

the weld metal is due to the Ti sublimation at the liquidus temperature of the weld pool. The weld metal mechanical

properties are excellent at high temperatures. Excellent weldability with a spatter free arc, self-releasing slag results in a

very smooth bead appearance. Efficiency 100%. Packed in Gaspack system.

MMI

TV

Approvals Grades

see Appendix, Classification Society Approvals, for details pag. 521

121

You might also like

- Freshwater Fish Compatibility ChartDocument1 pageFreshwater Fish Compatibility ChartGogo PNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- 235 oerlikon inertfil 310Document1 page235 oerlikon inertfil 310stefavaNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Citomangan: MMA Electrodes HardfacingDocument1 pageCitomangan: MMA Electrodes Hardfacingcinthia8yasmin8sulcaNo ratings yet

- E8018 B8Document1 pageE8018 B8Issac GeorgeNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- AWS A5.9 ER347 BS EN ISO 14343-A-W (19 9 NB) BS EN ISO 14343-B-SS347 JIS Z3321 Y347 GB/T 4241 H08Cr20Ni10NbDocument1 pageAWS A5.9 ER347 BS EN ISO 14343-A-W (19 9 NB) BS EN ISO 14343-B-SS347 JIS Z3321 Y347 GB/T 4241 H08Cr20Ni10NbImmalatulhusnaNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Wire Thermanit CSiDocument1 pageWire Thermanit CSiviphemantNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- 02112015000000B - Boehler FOX DCMS KB - CeDocument1 page02112015000000B - Boehler FOX DCMS KB - CeHamdi HamdiNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- MIP Bohler Welding Austria 364Document1 pageMIP Bohler Welding Austria 364c131508No ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Metrode Cryogenic ER316 B-38Document5 pagesMetrode Cryogenic ER316 B-38Claudia MmsNo ratings yet

- Cast Iron - Ni Cast 55Document1 pageCast Iron - Ni Cast 55Takul ThongyooNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocument1 pageInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Metrode Cryogenic 308lcf B-37Document5 pagesMetrode Cryogenic 308lcf B-37Claudia MmsNo ratings yet

- Boehler Mig DMO IGDocument1 pageBoehler Mig DMO IGदिनेश कुशवाहाNo ratings yet

- Advanced Welding TechnologyDocument60 pagesAdvanced Welding TechnologySwati AgarwalNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- 18042016000000T - Thermanit X - Solid WireDocument2 pages18042016000000T - Thermanit X - Solid WireMadhusudan YeoleNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Electrodes Hilchrome 308rDocument1 pageElectrodes Hilchrome 308rManu NistorNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- S-23804-Eng - 22 12 HTDocument2 pagesS-23804-Eng - 22 12 HTbiliboi5No ratings yet

- CERTILAS EN Edition2023 316Document1 pageCERTILAS EN Edition2023 316Alireza KhodabandehNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Mission Concepts and TimelinesDocument8 pagesMission Concepts and TimelinesGogo PNo ratings yet

- NCycleDocument2 pagesNCycleGogo PNo ratings yet

- Goldfish: Starting Out WithDocument16 pagesGoldfish: Starting Out WithGogo PNo ratings yet

- Goldfish VarietiesDocument5 pagesGoldfish VarietiesGogo PNo ratings yet

- AswDocument40 pagesAswGogo P100% (2)

- Black Moor GoldfishDocument11 pagesBlack Moor GoldfishGogo PNo ratings yet

- Goldfish: Carassius AuratusDocument2 pagesGoldfish: Carassius AuratusGogo PNo ratings yet

- Elezović - Linearna AlgebraDocument104 pagesElezović - Linearna AlgebraGogo P100% (1)

- Optimum GoldfishDocument5 pagesOptimum GoldfishGogo PNo ratings yet

- AsDocument7 pagesAsGogo P0% (1)

- 78 PDFDocument1 page78 PDFGogo PNo ratings yet

- Passive Voice. Volunteer Exercise. Change From Active To PassiveDocument2 pagesPassive Voice. Volunteer Exercise. Change From Active To PassiveGogo PNo ratings yet

- 10 InterfaceDocument11 pages10 InterfaceGogo PNo ratings yet

- Selectarc Selectarc Selectarc Selectarc: Inox 2509mobDocument1 pageSelectarc Selectarc Selectarc Selectarc: Inox 2509mobGogo PNo ratings yet

- Fizika 1 Reklama 2011Document1,030 pagesFizika 1 Reklama 2011Gogo PNo ratings yet

- Passive and Active VoiceDocument4 pagesPassive and Active VoiceGogo PNo ratings yet

- 2.61 Internal Combustion Engines: Mit OpencoursewareDocument2 pages2.61 Internal Combustion Engines: Mit OpencoursewareGogo PNo ratings yet

- 2.61 Internal Combustion Engines: Mit OpencoursewareDocument2 pages2.61 Internal Combustion Engines: Mit OpencoursewareGogo PNo ratings yet