0 ratings0% found this document useful (0 votes)

Plate 1

Uploaded by

Mary Jane Saño1) Prestressing involves applying internal stresses that counteract stresses from service loads. It squeezes materials like books or concrete beams to improve load capacity.

2) The steps of prestressing include tensioning steel strands in a beam form to a high stress before the concrete is poured. After the concrete gains strength, the strands are cut, compressing the beam and creating a negative bending moment to counteract positive moments from loads.

3) This document describes prestressing as squeezing materials like books or concrete beams to improve load capacity and discusses the steps of prestressing including tensioning strands before pouring concrete and cutting the strands afterwards to compress the beam.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

Plate 1

Uploaded by

Mary Jane Saño0 ratings0% found this document useful (0 votes)

1) Prestressing involves applying internal stresses that counteract stresses from service loads. It squeezes materials like books or concrete beams to improve load capacity.

2) The steps of prestressing include tensioning steel strands in a beam form to a high stress before the concrete is poured. After the concrete gains strength, the strands are cut, compressing the beam and creating a negative bending moment to counteract positive moments from loads.

3) This document describes prestressing as squeezing materials like books or concrete beams to improve load capacity and discusses the steps of prestressing including tensioning strands before pouring concrete and cutting the strands afterwards to compress the beam.

Original Description:

asd

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

1) Prestressing involves applying internal stresses that counteract stresses from service loads. It squeezes materials like books or concrete beams to improve load capacity.

2) The steps of prestressing include tensioning steel strands in a beam form to a high stress before the concrete is poured. After the concrete gains strength, the strands are cut, compressing the beam and creating a negative bending moment to counteract positive moments from loads.

3) This document describes prestressing as squeezing materials like books or concrete beams to improve load capacity and discusses the steps of prestressing including tensioning strands before pouring concrete and cutting the strands afterwards to compress the beam.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

Plate 1

Uploaded by

Mary Jane Saño1) Prestressing involves applying internal stresses that counteract stresses from service loads. It squeezes materials like books or concrete beams to improve load capacity.

2) The steps of prestressing include tensioning steel strands in a beam form to a high stress before the concrete is poured. After the concrete gains strength, the strands are cut, compressing the beam and creating a negative bending moment to counteract positive moments from loads.

3) This document describes prestressing as squeezing materials like books or concrete beams to improve load capacity and discusses the steps of prestressing including tensioning strands before pouring concrete and cutting the strands afterwards to compress the beam.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1/ 3

STEPS IN PRESTRESSING

Prestressing can be dened as the imposition of internal stresses

into a structure that are of opposite character to those that will be cause

by the service or working loads. A common method used to describe

prestressing as shown in Figure, where a row of books has been squeeze

together by a persons hands. The resulting beam can carry a

downward load as long as the compressive stress from squeezing at the

bottom of the beam is greater than the tensile stress there from the

moment produced by the weight of the books and the superimposed

loads. Such a beam has no tensile strength and, thus, no moment

resistance until it is squeeze together or prestressed.

PRESTRESSING

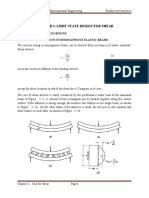

SEQUENCE SHOWING EFFECT OF PRESTRESSING FORCE AT

DIFFERENT STAGES.

STEPS IN PRESTRESSING

It is assumed that the following steps have been taken:

1. Steel strands (represented by the dashed lines) were placed in the

lower part of the beam form.

2. The strands were tensioned to a very high stress.

3. The concrete was placed in the form and allowed to gain sufcient

strength for the prestressed strands to be cut.

4. The strands were cut.

The cut strands tend to resume their original length, thus

compressing the lower part of the beam and causing a negative bending

moment. The positive moment caused by the beam weight and any

superimposed gravity loads is directly opposed by the negative moment.

Another way of explaining this is to say that a compression stress has

been produced in the bottom of the beam opposite in character to the

tensile stress that is caused there by the working loads.

REFERENCE

STEPS IN PRESTRESSING

Design of Reinforced Concrete (Eight Edition)

By: Jack C.

McCormack

Rusell H. Brown

You might also like

- Parts Lists: Gas Fired Steamers MODELS: SX-34GCR, SX-55GCR, SX-34GCR-RH, SX-55GCR-RH Red LobsterNo ratings yetParts Lists: Gas Fired Steamers MODELS: SX-34GCR, SX-55GCR, SX-34GCR-RH, SX-55GCR-RH Red Lobster13 pages

- 6.1 Flexural Analysis (Uncraked Beam Section)No ratings yet6.1 Flexural Analysis (Uncraked Beam Section)30 pages

- force (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)No ratings yetforce (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)11 pages

- MODULE 1 Introduction and Simple Stresses 2No ratings yetMODULE 1 Introduction and Simple Stresses 210 pages

- CE 308 - Lec 9 - Flexural Analysis and Design of BeamsNo ratings yetCE 308 - Lec 9 - Flexural Analysis and Design of Beams62 pages

- An Explanation of The Mechanism and Benefits of Shot PeeningNo ratings yetAn Explanation of The Mechanism and Benefits of Shot Peening4 pages

- Chapter 3 Flexural Analysis (Part 1) (Compatibility Mode)No ratings yetChapter 3 Flexural Analysis (Part 1) (Compatibility Mode)41 pages

- Design. Given A Factored Design Moment, Select A Suitable Cross Section, Including Dimensions, Concrete StrengthNo ratings yetDesign. Given A Factored Design Moment, Select A Suitable Cross Section, Including Dimensions, Concrete Strength15 pages

- 1-s2.0-S0263823116300167-Jonathan D Glassman Plate Buckling 2016No ratings yet1-s2.0-S0263823116300167-Jonathan D Glassman Plate Buckling 201639 pages

- Introduction To Prestressed Concrete PDFNo ratings yetIntroduction To Prestressed Concrete PDF15 pages

- Topic 2-Members Subjected to Axial ForcesNo ratings yetTopic 2-Members Subjected to Axial Forces5 pages

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsNo ratings yetStrength of Materials (15CV 32) : Module 1: Simple Stresses and Strains34 pages

- Structural Design - 1: (Reinforced Concrete)No ratings yetStructural Design - 1: (Reinforced Concrete)6 pages

- Gier, Estiven M. Ultimate Strength Stage (Write-Ups)100% (1)Gier, Estiven M. Ultimate Strength Stage (Write-Ups)3 pages

- Chapter 6 Special Structure: Special Structural Elements Deep Beams and Corbels100% (1)Chapter 6 Special Structure: Special Structural Elements Deep Beams and Corbels14 pages

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- 2.3.15-Eligibility Reqts. For RegistrationNo ratings yet2.3.15-Eligibility Reqts. For Registration5 pages

- Philippine National Railways - South Long Haul Project: China Railway Design Corporation (July 2020 Tianjin)No ratings yetPhilippine National Railways - South Long Haul Project: China Railway Design Corporation (July 2020 Tianjin)1 page

- List of All Ongoing Government & Private Construction Contracts Including Contracts Awarded But Not Yet StartedNo ratings yetList of All Ongoing Government & Private Construction Contracts Including Contracts Awarded But Not Yet Started1 page

- Kim 2012 J. Phys. Conf. Ser. 382 012008 PDFNo ratings yetKim 2012 J. Phys. Conf. Ser. 382 012008 PDF7 pages

- Finite Element Analysis of Universal Joint (Sub)No ratings yetFinite Element Analysis of Universal Joint (Sub)7 pages

- Timeline of Documents: Document Date Remarks Possible DateNo ratings yetTimeline of Documents: Document Date Remarks Possible Date1 page

- Panay Island Map in Region 6 Showing (Aklan, Capiz, Antique, Iloilo)No ratings yetPanay Island Map in Region 6 Showing (Aklan, Capiz, Antique, Iloilo)1 page

- DAY 1 (June 15, 2018) : Duration Site Remarks Date / TimeNo ratings yetDAY 1 (June 15, 2018) : Duration Site Remarks Date / Time1 page

- Panay Island Map in Region 6 Showing (Aklan, Capiz, Antique, Iloilo)No ratings yetPanay Island Map in Region 6 Showing (Aklan, Capiz, Antique, Iloilo)1 page

- Tools & Equipment Canvass Form: Name of Supplier: Name of Supplier Name of SupplierNo ratings yetTools & Equipment Canvass Form: Name of Supplier: Name of Supplier Name of Supplier3 pages

- Sp0793 - Pueblo Viejo PH 1: Pull Wire SwitchNo ratings yetSp0793 - Pueblo Viejo PH 1: Pull Wire Switch1 page

- Gs106-1 - Cement-Mortar Lined Steel Pipe and FittingsNo ratings yetGs106-1 - Cement-Mortar Lined Steel Pipe and Fittings39 pages

- Full Download Mechanics of Fluids Fourth Edition Merle C. Potter PDF DOCX100% (1)Full Download Mechanics of Fluids Fourth Edition Merle C. Potter PDF DOCX61 pages

- AMoS Module Wise Important Questions PDFNo ratings yetAMoS Module Wise Important Questions PDF4 pages

- III B.tech Mechanical Course Structure and SyllabusNo ratings yetIII B.tech Mechanical Course Structure and Syllabus51 pages

- Innovative Ship Design - Ship Motion & Wave LoadNo ratings yetInnovative Ship Design - Ship Motion & Wave Load203 pages

- Grade 7 Shielded Metal Arc Welding (SMAW) Supplementary Learning MaterialNo ratings yetGrade 7 Shielded Metal Arc Welding (SMAW) Supplementary Learning Material11 pages

- Liquefin™ - An Innovative Process To Reduce LNG CostNo ratings yetLiquefin™ - An Innovative Process To Reduce LNG Cost15 pages

- Goh Et Al. (1997) - Analysis of Piles Subjected To Embankment Induced Lateral Soil MovementsNo ratings yetGoh Et Al. (1997) - Analysis of Piles Subjected To Embankment Induced Lateral Soil Movements10 pages

- Annexure 32 - Tool For Design of Sewage Pumping StationNo ratings yetAnnexure 32 - Tool For Design of Sewage Pumping Station1 page