Linear Screen Sizing

Linear Screen Sizing

Uploaded by

HARIPRASADCopyright:

Available Formats

Linear Screen Sizing

Linear Screen Sizing

Uploaded by

HARIPRASADOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Linear Screen Sizing

Linear Screen Sizing

Uploaded by

HARIPRASADCopyright:

Available Formats

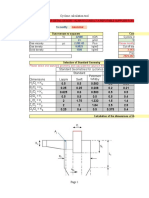

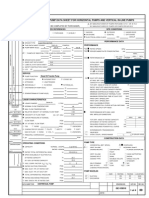

ANNEXURE - I

TECHNICAL DATA SHEET FOR LINEAR SCREEN FOR 10 MTPA EXPANSION OF GUA ORE MINES CRUSHING, BENEFICIATION AND PELLET PLANT

Doc. No. O14060-M-GMS-003

Equipment No. GSB01, GSB51

Requirement as per TPD

Page 1 of 4

A.

1

GENERAL DATA

APPLICATION

2

3

4

5

6

7

8

9

10

INSTALLATION

OPERATION

OPERATING HOUR PER DAY

OPERATING DAY PER YEAR

AVAILABILITY

MATERIAL HANDLED

QUANTITY

OPERATING TEMPERATURE

SITE CONDITION

B.

1

2

3

FEED AND DISCHARGE ARRANGEMENT

C.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

FEED MATERIAL AND OPERATING PARAMETERS

FRESH SOLID FEED (NOMINAL)

TPH

FRESH SOLID FEED (MAX)

TPH

% SOLID IN FEED SLURRY (NOMINAL)

% w/w

% SOLID IN FEED SLURRY (MAX)

% w/w

D.

1

2

3

4

5

6

UTILITY REQUIREMENT

WASH WATER QUANTITY

WASH WATER PRESSURE

WASH WATER QUALITY

INSTRUMENT AIR QUANTITY

INSTRUMENT AIR PRESSURE

COMPRESSED AIR QUANTITY

UNIT

Trash removal before HGMS

Hr/Day

days

%

No(s)

Deg C

OVERFLOW TO

UNDERFLOW TO

Storage sump, via pipe/launder

SG OF SOLIDS

WATER FLOW RATE (MAX)

SLURRY FLOW RATE (NOMINAL)

SLURRY FLOW RATE (MAX)

SLURRY DENSITY

FEED SLURRY PRESUURE

FEED PARTICLE SIZE

SEPARATION SIZE (NOTE 1)

FEED SLURRY TEMPERATURE

m3/hr

m3/hr

m3/hr

m3/hr

t/m3

bar

micron

micron

Deg C

SLURRY pH

DESIGN FACTOR (NOTE 2)

Indoor

Continuous

24

320

>95

Iron Ore Slurry

2

Ambient

Refer clause 3.0.0 of GCS

LIMS, Via pipe/launder

Trash bin, via chute

FEED FROM

WATER FLOW RATE (NOMINAL)

BIDDER's Response

m3/hr

mwc

Nm3/hr

bar(G)

Nm3/hr

211.0

240.0

30.0

30.0

4.0

492.3

560.0

545.1

620.0

1.29

Atm (gravity flow)

Refer Annexure-IA

710

Ambient

~7-8

10%

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

TECHNICAL DATA SHEET FOR LINEAR SCREEN FOR 10 MTPA EXPANSION OF GUA ORE MINES CRUSHING, BENEFICIATION AND PELLET PLANT

Doc. No. O14060-M-GMS-003

Equipment No. GSB01, GSB51

Requirement as per TPD

7

E.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Page 2 of 4

COMPRESSED AIR PRESSURE

bar(G)

By Bidder

mm

mm

mm

m2

mm

m/s

micron

By Bidder

By Bidder

By Bidder

2

4.1

4

9

2

0

By Bidder

mm

By Bidder

mm

By Bidder

mm

By Bidder

mm

By Bidder

mm

By Bidder

mm

By Bidder

mm

mm

mm

mm

mm

mm

mm

mm

By Bidder

6

6

400

12.7

By Bidder

By Bidder

By Bidder

mm

By Bidder

mm

mm

mm

By Bidder

By Bidder

By Bidder

mm

By Bidder

mm

By Bidder

mm

By Bidder

RPM

By

By

By

By

CONSTRUCTION AND DIMENSIONS

MAKE

MODEL

TYPE

OVERALL WIDTH

OVERALL LENGTH

OVERALL HEIGHT

SCREENING AREA

SCREEN CLOTH WIDTH

SCREEN CLOTH SPEED

SCREEN CLOTH APERTURE

FEED PIPE/LAUNDER END

DIMENSION

FEED PIPE/LAUNDER

THICKNESS

FEED PIPE/LAUNDER LINER

THICKNESS

OVERFLOW DISCHARGE CHUTE

END DIMENSION

OVERFLOW DISCHARGE CHUTE

THICKNESS

OVERFLOW DISCHARGE CHUTE

LINER THICKNESS

UNDERPAN END DIMENSION

UNDERPAN THICKNESS

UNDERPAN LINER THICKNESS

HEAD PULLEY DIAMETER

SHELL THICKNESS OF HEAD

PULLEY

TAIL PULLEY DIAMETER

SHELL THICKNESS OF TAIL

PULLEY

TENSIONING PULLEY DIAMETER

SHELL THICKNESS OF

TENSIONING PULLEY

BEND PULLEY DIAMETER

SHELL THICKNESS OF BEND

PULLEY

CLOTH ROLLER DIAMETER

SHELL THICKNESS OF CLOTH

ROLLER

RETURN ROLLER DIEMETER

SHELL THICKNESS OF RETURN

ROLLER

DRIVE PULLEY SPEED

GEAR TYPE

GEAR BOX MAKE

GEAR BOX MODEL

BIDDER's Response

Bidder

Bidder

Bidder

Bidder

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

TECHNICAL DATA SHEET FOR LINEAR SCREEN FOR 10 MTPA EXPANSION OF GUA ORE MINES CRUSHING, BENEFICIATION AND PELLET PLANT

Doc. No. O14060-M-GMS-003

Equipment No. GSB01, GSB51

Requirement as per TPD

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

F.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 3 of 4

GEAR BOX RATING

GEAR BOX RATIO

COUPLING TYPE/MAKE (INPUT)

COUPLING TYPE/MAKE

(OUTPUT)

COUPLING GUARD THICKNESS

BEARING TYPE/MAKE AT HEAD

PULLEY

BEARING TYPE/MAKE AT TAIL

PULLEY

BEARING TYPE/MAKE AT

TENSIONING PULLEY

BEARING TYPE/MAKE AT BEND

PULLEY

BEARING TYPE/MAKE AT CLOTH

ROLLER

BEARING TYPE/MAKE AT

RETURN ROLLER

BEARING LIFE

TORQUE ARM

TRACKING UNIT DETAILS

LUBRICATION TYPE

LUBRICANT QUANTITY

FIRST FILL OF LUBRICANTS

MATERIAL OF CONSTRUCTION

SCREEN FRAME

FEED BOX

LINER FOR FEED BOX

DISTRIBUTION PLATES

LINER FOR DISTRIBUTION

PLATE

OVERFLOW DISCHARGE CHUTE

LINER FOR OVERFLOW

DISCHARGE CHUTE

UNDER PAN

LINER FOR UNDERPAN

CLUTCH

DRIP TRAY

HEAD PULLEY

TAIL PULLEY

TENSIONING PULLEY

BEND PULLEY

CLOTH ROLLER

RETURN ROLLER

SHAFTS

SCREEN CLOTH

CLUTCH TENSIONER

kW

mm

By

By

By

By

By

BIDDER's Response

Bidder

Bidder

Bidder

Bidder

Bidder

By Bidder

By Bidder

By Bidder

By Bidder

By Bidder

By Bidder

HRS

Yes/No

ltr

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

By Bidder

By

By

By

By

By

By

By

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

TECHNICAL DATA SHEET FOR LINEAR SCREEN FOR 10 MTPA EXPANSION OF GUA ORE MINES CRUSHING, BENEFICIATION AND PELLET PLANT

Doc. No. O14060-M-GMS-003

Equipment No. GSB01, GSB51

Requirement as per TPD

21

22

23

24

25

26

27

SPRAY BAR

SPRAY NOZZLE

SPILLAGE LAUNDER

LINER FOR SPILLAGE LAUNDER

GEAR

DRIVE BASE FRAME

FASTENERS

G.

1

2

3

4

5

ELECTRICAL AND INSTRUMENTATION

DRIVE MOTOR TYPE/MAKE

FRAME SIZE

DRIVE MOTOR SPEED

RPM

DRIVE MOTOR RATED POWER

kW

DRIVE MOTOR CONSUMED

kW

POWER

POWER CONSUMPTION AT

kW

DRIVE COUPLING (MAX)

DRIVE MOTOR PROTECTION

DRIVE MOTOR INSULATION

LOAD GD^2 VALUE AT MOTOR

kgf-m2

SHAFT

NO LOAD GD^2 VALUE AT

kgf-m2

MOTOR SHAFT

DIRECTION OF ROTATION OF

MOTOR (VIEWED FROM

COUPLING TO MOTOR)

UPS POWER REQUIREMENT

VA

FOR INSTRUMENTATION

6

7

8

9

10

11

12

H.

1

2

WEIGHT DATA

TOTAL WEIGHT

OF THEPART

EQUIPM

WEIGHT

OF HEAVIEST

OF

THE EQUIPMENT FOR

MAINTENANCE

I.

1

OTHERS

LIST

OF MAKES FOR ALL

BOUGHT OUT ITEMS

ENCLOSED

By

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

By

By

By

By

Bidder

Bidder

Bidder

Bidder

BIDDER's Response

By Bidder

By Bidder

By Bidder

By Bidder

By Bidder

By Bidder

Clockwise/ Counter clockwise

By Bidder

Kg

By Bidder

Kg

By Bidder

Yes / No

By Bidder

NOTE:1) Bidder to size the screen area suitably to accommodate 500 microns separation size.

2) Bidder to consider suitable design factor to ensure smooth operation at rated capacity.

Page 4 of 4

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

You might also like

- Code of EthicsDocument1 pageCode of EthicsEdelman100% (4)

- Spurious OVERWNG LOCK Inop Sys Displayed On Ecam: Engineering SupportDocument3 pagesSpurious OVERWNG LOCK Inop Sys Displayed On Ecam: Engineering Supportjontis jasoliya100% (2)

- Biotech q1 Mod1Document32 pagesBiotech q1 Mod1Jem Culianan33% (3)

- Media Charge TrajectoriesDocument9 pagesMedia Charge Trajectoriessnarf273100% (1)

- Test Cyclone ExcelDocument16 pagesTest Cyclone Excelvivek mishraNo ratings yet

- Ball Mill Capacity Dimensions PAUL O ABBEDocument2 pagesBall Mill Capacity Dimensions PAUL O ABBEaghilifNo ratings yet

- #1equipment DesignDocument19 pages#1equipment DesignRhea MambaNo ratings yet

- Kemix Interstage Screen BrochureDocument8 pagesKemix Interstage Screen BrochureFernandim SoaresNo ratings yet

- Filter PressDocument2 pagesFilter Presskamod.rai528No ratings yet

- Dryer Output CalculationDocument1 pageDryer Output CalculationSatish DaveNo ratings yet

- Impeller PerformanceAug17 FRDocument10 pagesImpeller PerformanceAug17 FRSteve WanNo ratings yet

- B-901 Mixer Impellers LTN 12Document5 pagesB-901 Mixer Impellers LTN 12Abidin RahmanNo ratings yet

- Cyclones in Milling A Black Box ApproachDocument65 pagesCyclones in Milling A Black Box ApproachJakesNo ratings yet

- Comex Air ClassifierDocument8 pagesComex Air ClassifierFiroj AlamNo ratings yet

- CalcDocument2 pagesCalcbasavaraju535100% (1)

- Moly-Cop Tools: Mineral Slurry Characterization Extensive PropertiesDocument2 pagesMoly-Cop Tools: Mineral Slurry Characterization Extensive PropertiesAnonymous TsKN7XZBNo ratings yet

- Fertilizer Rotary Drum Granulator MachineDocument2 pagesFertilizer Rotary Drum Granulator Machineluna leNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- Ball Mill DesignDocument3 pagesBall Mill DesignDoaa BadarnehNo ratings yet

- Energy Used in GrindingDocument10 pagesEnergy Used in GrindingGordon Webb0% (1)

- 02 Mechanical-Design ESDocument36 pages02 Mechanical-Design ESJessica Andrea Tafur DiazNo ratings yet

- E 31.xxx - Roots BlowerDocument1 pageE 31.xxx - Roots BlowerPhượng NguyễnNo ratings yet

- Apron Feeder Data SheetDocument1 pageApron Feeder Data SheetPat AuffretNo ratings yet

- Cyclosim SingleDocument12 pagesCyclosim SingleAch_The_KingNo ratings yet

- Mediacharge TrajectoriesDocument8 pagesMediacharge TrajectoriesRolando QuispeNo ratings yet

- Datasheet ClarifierDocument1 pageDatasheet ClarifierMuhammad GhaziNo ratings yet

- Balance de HidrociclonDocument13 pagesBalance de HidrociclonFlavioCesarChirmeSisaNo ratings yet

- Flexibond Agitator ModificationDocument26 pagesFlexibond Agitator ModificationGLENDA CASINONo ratings yet

- NX PID Designer Fact SheetDocument4 pagesNX PID Designer Fact SheetBoopeshkumar NNo ratings yet

- Product Catalog: Advance Glass Reactor SystemDocument10 pagesProduct Catalog: Advance Glass Reactor SystemRafique AjmeriNo ratings yet

- Lemper SR P1Document22 pagesLemper SR P1khansaNo ratings yet

- SAGParam RecycleDocument123 pagesSAGParam RecycleFederico Hirsch EspinozaNo ratings yet

- Cascade Air Separator KVT enDocument6 pagesCascade Air Separator KVT enkamjulajayNo ratings yet

- Delkor Apic JigDocument6 pagesDelkor Apic JigruzmirNo ratings yet

- Ex Reactor DesignDocument10 pagesEx Reactor DesignNugraha Weedhee ANo ratings yet

- Thickener Design and Theory ProblemsDocument9 pagesThickener Design and Theory ProblemsRodrigo GarcíaNo ratings yet

- En8 EquDocument6 pagesEn8 EquPrapa KaranNo ratings yet

- Cyclosim SingleDocument9 pagesCyclosim SinglehadryanaNo ratings yet

- Size ReductionDocument24 pagesSize ReductionKarynne Bernardine Gerona SiclotNo ratings yet

- Data Sheet For Rotary Calciner - TEPLDocument2 pagesData Sheet For Rotary Calciner - TEPLpuneet gehlotNo ratings yet

- Darcy Friction Factor CalculatorDocument2 pagesDarcy Friction Factor CalculatormayureshNo ratings yet

- Size Thick Flange Dia Flange Thick R.F Dia Hole Size Hole P.C.DDocument2 pagesSize Thick Flange Dia Flange Thick R.F Dia Hole Size Hole P.C.DPrathmesh GujaratiNo ratings yet

- Balance 2013 - Presa RelavesDocument18 pagesBalance 2013 - Presa Relavesmikmad86No ratings yet

- Design of Boiler Forced Draft FanDocument2 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Ribbon BlenderDocument16 pagesRibbon BlenderamitNo ratings yet

- Quick Calculations - For Sizing Boiler To Heat Water: S.P. Thermal Systems IncDocument8 pagesQuick Calculations - For Sizing Boiler To Heat Water: S.P. Thermal Systems IncKimou ThebestNo ratings yet

- Cyclone Design Calculation Tool SimplifiedDocument6 pagesCyclone Design Calculation Tool Simplifieddad100% (1)

- Pump System Hinsom Bore PumpDocument78 pagesPump System Hinsom Bore Pumpsaroat moongwattanaNo ratings yet

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- ENGRDocument36 pagesENGRjherryNo ratings yet

- PWOG HZL 6033 PR CAL 002 - Cooling Water Supply and Return ConfigurationDocument3 pagesPWOG HZL 6033 PR CAL 002 - Cooling Water Supply and Return ConfigurationpavanNo ratings yet

- Kurva Distribusi Ukuran: (-) (+) CM Inch No. Rata - Rata ApertureDocument33 pagesKurva Distribusi Ukuran: (-) (+) CM Inch No. Rata - Rata ApertureNuraini YenniNo ratings yet

- CrushBal ClosedDocument10 pagesCrushBal ClosedAldo PabloNo ratings yet

- Perhitungan Rotary DryerDocument4 pagesPerhitungan Rotary DryerDella Ayu MeitasariNo ratings yet

- The Lurgi Pelletizing Process:: A Combined Updraft-Downdraft TechniqueDocument5 pagesThe Lurgi Pelletizing Process:: A Combined Updraft-Downdraft TechniqueaminbasharatiNo ratings yet

- HydroCyclone Design Equations and Sizing Parameters For Calculations 1Document4 pagesHydroCyclone Design Equations and Sizing Parameters For Calculations 1سعيد الهاديNo ratings yet

- Dorr Watersediment MLDocument12 pagesDorr Watersediment MLsenkuttuvanNo ratings yet

- Sand Washing Plant (Cde) Details SR No Description Cost Total RequiredDocument3 pagesSand Washing Plant (Cde) Details SR No Description Cost Total RequiredKAMAL SINGHNo ratings yet

- Scrubber Catalogue R0!31!10 2017Document8 pagesScrubber Catalogue R0!31!10 2017ÇaPuLcU TosBaANo ratings yet

- GE-103010, Diesel Oil Transfer Pumps, P-202 A, BDocument4 pagesGE-103010, Diesel Oil Transfer Pumps, P-202 A, BMohammed Anwer100% (1)

- GE-103009, Diesel Unloading Pumps, P-201 A, BDocument4 pagesGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerNo ratings yet

- Datasheet Pompa Submersible Rev.0Document5 pagesDatasheet Pompa Submersible Rev.0NasrulSyahruddinNo ratings yet

- Annexure - I: A. General Data UnitDocument4 pagesAnnexure - I: A. General Data UnitHARIPRASADNo ratings yet

- Data ListDocument4 pagesData ListHARIPRASADNo ratings yet

- Design Operation ConditionDocument4 pagesDesign Operation ConditionHARIPRASADNo ratings yet

- DIA (M) HT (M) Dosing (LPH) KW Transfer (LPH) KWDocument1 pageDIA (M) HT (M) Dosing (LPH) KW Transfer (LPH) KWHARIPRASADNo ratings yet

- Duty Application Iron Ore Slurry Type Slurry PumpDocument4 pagesDuty Application Iron Ore Slurry Type Slurry PumpHARIPRASADNo ratings yet

- SOT Date Client M/S Westech Swang: EquipementDocument2 pagesSOT Date Client M/S Westech Swang: EquipementHARIPRASADNo ratings yet

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDocument2 pagesDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNo ratings yet

- Duty Application Iron Ore Slurry Type Slurry PumpDocument4 pagesDuty Application Iron Ore Slurry Type Slurry PumpHARIPRASADNo ratings yet

- SOT Date Client M/S Westech Swang: Equipement 1233 234332434 5665Document2 pagesSOT Date Client M/S Westech Swang: Equipement 1233 234332434 5665HARIPRASADNo ratings yet

- SOT Date Client M/S Westech Swang: EquipementDocument2 pagesSOT Date Client M/S Westech Swang: EquipementHARIPRASADNo ratings yet

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDocument2 pagesDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNo ratings yet

- Truss 09Document2 pagesTruss 09HARIPRASADNo ratings yet

- Annexure - I: Fresh Solid Feed (Nominal)Document4 pagesAnnexure - I: Fresh Solid Feed (Nominal)HARIPRASADNo ratings yet

- OrganicDocument2 pagesOrganicHARIPRASADNo ratings yet

- Pump Data 1Document2 pagesPump Data 1HARIPRASADNo ratings yet

- ChemicalDocument2 pagesChemicalHARIPRASADNo ratings yet

- P Nue Matics 2333Document2 pagesP Nue Matics 2333HARIPRASADNo ratings yet

- Belt Feeder: Annexure - IDocument4 pagesBelt Feeder: Annexure - IHARIPRASADNo ratings yet

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDocument2 pagesDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNo ratings yet

- Design Coa25lDocument1 pageDesign Coa25lHARIPRASADNo ratings yet

- Pnuematics 1Document2 pagesPnuematics 1HARIPRASADNo ratings yet

- SL No Description 1 Planetary Gear Box 2 Motor 3 Bearing 4 Limit Switch 5 Slow Speed Switch 6 Screen ClothDocument2 pagesSL No Description 1 Planetary Gear Box 2 Motor 3 Bearing 4 Limit Switch 5 Slow Speed Switch 6 Screen ClothHARIPRASADNo ratings yet

- Screw Conveyer CalculationDocument2 pagesScrew Conveyer CalculationHARIPRASADNo ratings yet

- Annexure - I: % Solid in Feed Slurry (Nominal)Document1 pageAnnexure - I: % Solid in Feed Slurry (Nominal)HARIPRASADNo ratings yet

- Specific Process Condition During Start-Up/stop/transient Pumping TempratureDocument2 pagesSpecific Process Condition During Start-Up/stop/transient Pumping TempratureHARIPRASADNo ratings yet

- SL No Description: Boughtout ListDocument2 pagesSL No Description: Boughtout ListHARIPRASADNo ratings yet

- Conveyer NewDocument1 pageConveyer NewHARIPRASADNo ratings yet

- Design Operation ConditionDocument4 pagesDesign Operation ConditionHARIPRASADNo ratings yet

- Conveyer NewDocument1 pageConveyer NewHARIPRASADNo ratings yet

- Screw Conveyer NewDocument1 pageScrew Conveyer NewHARIPRASADNo ratings yet

- SL No Description 1 Planetary Gear BoxDocument2 pagesSL No Description 1 Planetary Gear BoxHARIPRASADNo ratings yet

- VOD ConferenceDocument15 pagesVOD ConferenceCARLOS OSIEL SEBASTIÁN VALDÉSNo ratings yet

- Submerged Arc WeldingDocument2 pagesSubmerged Arc WeldingcalcedaNo ratings yet

- Diagnostic Accuracy of Xpert MTB/RIF On Bronchoscopy Specimens in Patients With Suspected Pulmonary TuberculosisDocument6 pagesDiagnostic Accuracy of Xpert MTB/RIF On Bronchoscopy Specimens in Patients With Suspected Pulmonary TuberculosisMARTIN FRANKLIN HUAYANCA HUANCAHUARENo ratings yet

- W2 Enzymology 1 (Damuni)Document35 pagesW2 Enzymology 1 (Damuni)Jane de VriesNo ratings yet

- Admit CardDocument2 pagesAdmit CardSumit AdwaniNo ratings yet

- Grammar Vocab.-6Document3 pagesGrammar Vocab.-6Melis YeşilyurtNo ratings yet

- Diagnostics in Technical Systems: Interdisciplinary Challenge in Traditional EngineeringDocument9 pagesDiagnostics in Technical Systems: Interdisciplinary Challenge in Traditional EngineeringVelibor KaranovicNo ratings yet

- TI-Nspire Python Programming Guidebook ENDocument60 pagesTI-Nspire Python Programming Guidebook ENgoguNo ratings yet

- Hoàng Writing 2Document4 pagesHoàng Writing 2Ngọc Pe PeNo ratings yet

- The Bretton Wood System-2Document11 pagesThe Bretton Wood System-2Ashwin RacerNo ratings yet

- 606 Educational Measurement and EvaluationDocument3 pages606 Educational Measurement and EvaluationJhie Fortu FabellonNo ratings yet

- Philosophy CODocument2 pagesPhilosophy COAnna VergelNo ratings yet

- Lesson Plan in Health IV JonaDocument8 pagesLesson Plan in Health IV JonaJenelyn Limen100% (1)

- Flat Routing ProtocolsDocument65 pagesFlat Routing ProtocolsNikhil SharmaNo ratings yet

- Lecture Powerpoints: Physics: Principles With Applications, 7 EditionDocument47 pagesLecture Powerpoints: Physics: Principles With Applications, 7 EditionAlbert WalkerNo ratings yet

- Copper Sulphate TitrationDocument29 pagesCopper Sulphate TitrationTeejay Makazhu100% (1)

- Activities Guide and Evaluation Rubric - Unit 2 - Phase 4 - Final Documentation and ConsolidationDocument5 pagesActivities Guide and Evaluation Rubric - Unit 2 - Phase 4 - Final Documentation and ConsolidationSamuel MolinaNo ratings yet

- Semester Project Final Report - 1Document27 pagesSemester Project Final Report - 1Yayachew MandefroNo ratings yet

- Hotline Crossing PPT-!Document10 pagesHotline Crossing PPT-!Rintu Singh MaurayNo ratings yet

- SDG - PHDocument4 pagesSDG - PHBaby CometNo ratings yet

- Best Melodic Dubstep Mix 2013 - YouTubeDocument4 pagesBest Melodic Dubstep Mix 2013 - YouTubeorangotaNo ratings yet

- Bombardier Challenger 300 BrochureDocument3 pagesBombardier Challenger 300 BrochureGourav DasNo ratings yet

- Practical Inorganic ChemistryDocument13 pagesPractical Inorganic ChemistrymuanesabrahemNo ratings yet

- ChemotherapyDocument1 pageChemotherapyGerardLum100% (2)

- CAEEM Impl ENUDocument79 pagesCAEEM Impl ENUdavor.dimeskiNo ratings yet

- Band Gap Studies of Anatase Tio2 NanoparticlesDocument7 pagesBand Gap Studies of Anatase Tio2 Nanoparticlesnarayanan1701_318170No ratings yet

- HDFC Bank Statement PDFDocument1 pageHDFC Bank Statement PDFAli Game You TubeNo ratings yet