Dsine MCCB

Dsine MCCB

Uploaded by

ryreddyCopyright:

Available Formats

Dsine MCCB

Dsine MCCB

Uploaded by

ryreddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Dsine MCCB

Dsine MCCB

Uploaded by

ryreddyCopyright:

Available Formats

L&T SWITCHGEAR

SAFE & SURE

Moulded Case Circuit Breakers

Introduction

Larsen & Toubro infuses engineering with imagination. The Company offers a wide range of advanced solutions in the field of Engineering, Construction, Electrical & Automation, Machinery and Information Technology. L&T Switchgear, a part of the Electrical & Automation business, is India's largest manufacturer of low voltage switchgear, with the scale, sophistication and range to meet global benchmarks. With over five decades of experience in this field, the Company today enjoys a leadership position in the Indian market with a growing international presence. It offers a complete range of products including powergear, controlgear, industrial automation, building electricals & automation, reactive power management, energy meters, and protective relays. These products conform to Indian and International Standards. The range, a new generation of MCCBs, stands out due to its state-of-the-art design, contemporary user-friendly features, wide choice of protective releases, ergonomics, aesthetics and compactness. The range complies with the latest standards like IEC 60947-2, EN 60947-2 & IS 13947-2.The products conform to international standards, carry markings and are & CB certified. The range is specially designed for tropical conditions, ensuring reliable performance at high ambient and humid environments. The range is designed to meet the changing needs of users after extensive analysis and user feedback. The range can satisfy the most demanding system requirements. The range, complimented by a wide range of accessories, offer total solution to customer applications ensuring operational safety, reliability and versatility.

Switchgear Factory, Mumbai

Contents

Range Protection Releases State-of-the-art technology Accessories Technical Data Time - Current Characteristic Curves Overall Dimensions

1 2 5 7 11 13 16

DN0

DN1

DN2

DN3

DN4

The Complete Range

Features From 20 A to 1250 A 3 Pole & 4 Pole Choice of 36kA/50kA/70kA breaking capacities. With protection releases in Microprocessor, Thermal-Magnetic and only Magnetic MCCBs for motor backup protection MCCBs for distribution and SD versions Manual, rotary or motorised versions Wide range of internal and external accessories

DN0

Rated Current Release Rated Current Release Rated Current Release Rated Current Release Rated Current Release 20, 25, 32, 40, 50, 63, 80, 100 A Thermal-Magnetic

DN1

100, 125, 160, 200, 250 A Thermal-Magnetic

DN2

32, 40, 50, 63, 80, 100, 125, 160, 200, 250 A Thermal-Magnetic 40, 63, 100, 160, 250 A Microprocessor

DN3

320, 400, 500, 630 A Thermal-Magnetic 160, 250, 400, 630 A Microprocessor

DN4

800, 1000, 1250 A Microprocessor

Breaking Capacities

Breaking capacity 36kA 50kA 70kA Old Type Designation S (35kA) H L New Type Designation D N S

Note : Since there is no change in the constructional aspect of the MCCBs, the product Certification with old designation remain valid with new type designation.

Protection Releases

Thermal-Magnetic Release

Features of Thermal-Magnetic Release

Adjustable

overload settings short circuit settings True RMS sensing No contact with live parts Adjustable

Protection DN0 & DN1 Overload Short circuit Earth fault 80% - 100% In 9 In (fixed) External Settings DN2 & DN3 80% - 100% In 6 - 10 In External

Microprocessor Release

6 1 2 3 4 5

Features of RC10 Microprocessor Release Overload protection with inverse time delay j Short circuit protection with selectable time delay k Instantaneous over ride protection Earth fault protection with selectable time delay l Neutral protection with selectable time delay m Push to trip button n Port for release testing and thermal memory bypass o Power ON LED p Self powered protections True RMS sensing

RC10

Rated Current In (A)

From 40 to 1250 A

Overload (Phase)

Current setting, Ir (Ir = XIn) Time delay, tr (Inverse) Protection mode OFF, 0.4 to 1.0 in steps of 0.1 10 sec at 6Ir ON / OFF

Overload (Neutral)

Current setting, Ir (Ir = XIn) Protection mode 0.5,0.75 & 1.00 Ir Inverse 10 sec at 6 Ir / Fixed 200ms ON / OFF

Short Circuit

Current setting, Is (Is =XIr) Time delay, ts Protection mode 1.5, 4 & 6Ir, 8Ir Inst. / 100 msec ON / OFF

Instantaneous Over ride

Current setting, Ip DN2-8In, DN3-400-12In, DN3-630-8In, DN4-8In

Earth Fault

Current setting, Ig Time delay, tg Protection mode 0.2 to 0.5In steps of 0.1 100 / 200 msec ON / OFF

Protection Releases

Microprocessor Release

Features of RC20 - Communication Capable

Communication Power

using RS 485 on LED Backlit LCD display Scroll buttons Push to trip button All features of RC10 release are incorporated Metering for current parameters Protection against unbalanced load / single phasing I2t protection Neutral protection load protection Cold User friendly navigation system Self powered MODBUS RTU protocol

RC20

Rated Current In (A) From 160 to 630 A

Overload (Phase)

Current setting (A), Ir (Ir = xIn) Time delay, tr (s) (Inverse) Protection mode Preset trip alarm setting Thermal memory

0.4 to 1.0 in steps of 0.1 3, 6, 10, 15, 30 at 6Ir ON / OFF 0.8 to 1.0Ir in steps of 0.05 ON / OFF

Overload (Neutral)

Current setting (A), Ir Protection mode

50%, 100%, 150% Ir ON / OFF

Short Circuit

Current setting (A), Is Time delay (ms), ts Protection mode Preset trip alarm setting Cold load pickup

1.5, 4, 6, 8Ir

For It OFF 20 to 200 in steps of 20 For It ON 60 to 200 in steps of 20 ON / OFF 0.8 to 1.0 times Is in steps of 0.05 Is Enable / Disable

Instantaneous

Instantaneous Protection mode Cold load pickup

1.5 to 8In in steps of 0.5In / Ir ON / OFF Enable / Disable

Instantaneous Over ride

Current setting (A), Ip

DN2-8In, DN3-400-12In, DN3-630-8In, DN4-8In

Earth Fault

Current setting (A), Ig Time delay (ms), tg Preset trip alarm setting Protection mode Cold load pickup

0.2 to 0.5In steps of 0.1In 0.1, 0.2, 0.5, 1, 3 sec. 0.8 to 1.0 Ig in steps of 0.05 ON / OFF Enable / Disable

Protection Releases

Additional Features of RC20

Current Unbalance Current setting (A) xIn Time delay (s) Protection mode Cold load pickup Temperature Rise Alarm / Trip Metering Current Display Communication* Protocol Link used Event records Trip history Trip counter record MODBUS RTU RS 485 Pickup, Trip, Alarm upto 128 records-volatile memory Last 5 trips records - non volatile memory Counts for total number of trips Phase, Neutral and Earth Backlit LCD At 80C / At 100C 10% to 100% In in steps of 5% 1 to 10 in steps of 0.5 ON / OFF Enable / Disable

Only Magnetic release (for Motor backup protection)

magnetic Only

Frame Type Current Range (A) Poles Icu(kA) @ 415V AC, 50Hz

250 A DN2-250M 100-250

400 A DN3-400M 320-400 3P only 50

630 A DN3-630M 500-630

with instantaneous protection upto 10In protection for complete starter upto 50kA Type 2 charts available for DOL & Star/delta starters Fault level

Frame

250 A

400 A

630 A DN3-630SD 500-630 3/4 6

Switch Disconnector version (without protection release) Can be used as switching or Isolator devices Higher withstand capacities Wide range of accessories for remote operation

Type Current Range (A) Poles Icw (kA) for 1sec.

DN2-250SD DN3-400SD 100-250 3/4 3.6 320-400 3/4 6

* To establish communication with computer every MCCB with RC20 will require a communication module.

State-of-the-art technology

Faster

tripping

The unique speed contact system accelerates the opening of contacts during short circuit. This ensures faster tripping an ultimate current limiting feature. The result-very low let-through, cut-off current and fault clearing time

Mechanical

Anti-reclosing

This unique feature ensures that under short circuit conditions, the contacts open and latch even before the release gives a trip command to the mechanism. This avoids contact re-closing and bounce

Low

watt loss The entire current carrying path is optimally designed to achieve very low watt loss

Positive

Isolation

The MCCB knob indicates the true position of the contacts

Double

U im p : 8k V U e : 4 15V, 5 0 / 6 0Hz. CAT: A I cu : 50 kA,I cs :100%I cu

EN 60947-2 IS 13947-2 IEC 60947-2

Insulation

DN3-630N

The internal accessories are housed in insulated casings to ensure first level of insulation. When the front cover is opened for the fixing of internal accessories, the MCCB is totally insulated ensuring the double insulation

Marking

Extra Grip on Handle

CE Marking ensures use of superior engineering plastic, meeting all requirements of flammability and glow wire testing path is optimally designed to achieve very low watt loss

State-of-the-art technology

Common

Internal accessories

V 0 H z. U imp : 8k U e : 4 1 5 V, 5 0 /6 I cu C AT: A I cu : 50 k A ,I cs :100% 2

EN 60 947I E C 609 47-2 IS 1394 7- 2

The internal accessories remain same across DN0 / DN1 & DN2 / DN3 / DN4* and they are easy to install snap fit type

DN3-630N

0 Hz. U im p :8kV U e :41 5 V, 5 0/6 CAT: A cu I cu :70kA, I cs :100%I

I S 1 3 94 7 -2 -2 I EC 6 0 94 7

DN2-250S

2 EN 6 09 4 7-

LINE

No load

line bias Either side of MCCB terminal can be used as load or line

U i m p :8 k V U e :415V, 50/60Hz. CAT:A cu I cu :70 k A,I cs :100%I

2 IS 139472 I E C 60 9 47-

DN2-250S

-2 EN 60947

LOAD

Terminal

finger proofing

Front terminal plates conceal the terminals to prevent human contact thus achieving complete finger proofing

Release

shrouding

Release is shrouded from the front thus preventing tampering by unauthorized person

Safer

release adjustments No live parts are in contact during release adjustments

Common

front adjustments for protection release

Overload & short circuit setting can be adjusted from front using a common knob for all the poles

Visibility

Push to trip button and release ratings are visible even when release plate is fitted

* Except under voltage release.

Accessories

Internal Accessories

Range of MCCBs are offered with snap-fit type, easily installable internal accessories. There is no need to open main cover and no live parts are accessed during installation. TAC, Aux+TAC to be fitted in the right cavity & under voltage release to be fitted in left cavity.

Auxiliary Contact

List of Internal Accessories

U i mp : 8 k V U e :41 5 V, 50/60Hz. CAT:A cu I c u : 7 0kA,I cs :100%I

z. U im p :8kV U e :41 5 V, 50/60H 100 % I c uCAT:A I c u : 7 0kA,I c s :

DN2-250S

DN2-250S

2 IS 13947-

IE C 6 0947-2

-2 EN 60947

Auxiliary Auxiliary

Contact 1 C/O Contact 2 C/O Trip Alarm Contact Auxiliary & Trip Alarm Contact Shunt Release Under Voltage Release

IS 13947-2

IEC 60947-2

-2 EN 6 0947

MCCB with mid cover opened & Internal accessories fitted

External Accessories

Extended Rotary Handle (Panel Mounted) ROM mounts directly on MCCB without removal of mid cover ON/OFF/TRIP indication Clear Clear view of MCCB rating label with ROM mounted Direct access to push to trip button with ROM mounted IP 54 degree of protection with extended rotary handle Unique coupling to allow +3mm tolerance Door interlock in ON position, with defeat facility Door interlock in OFF condition with padlock feature Auto restoration of door interlock External keylock for mechanical interlocking

U imp: 8 k V 5 0 / 6 0 H z. U e : 4 1 5V, I C AT: A ,I :100% c u I cu : 50kA c s EN 6 0947-2

IS 139 4 7-2 IEC 6 0947-2

DN3-630N

Extended Rotary Handle: Panel Mounted

Panel Door Mounted Key lock (To be used along with extended rotary handles)

Rotary Operating Mechanism

U : 8kV 50 /60 Hz . U e : 41 5 V, I C AT: A ,I :100 % cu I c u : 50kA cs E N 60947-2

im p

DN3-630N

The rotary operating mechanism (ROM) for Direct & Extended versions.

MCCBs are available in

IS 13947-2

IEC 60947-2

Direct rotary handle (MCCB mounted) These versions are available for the entire family of MCCBs.

Accessories

Mechanical Interlocking Schemes

1. Mechanical Interlocking Kit: Two MCCBs can be interlocked using base plate mechanism, in side-by-side configuration. Features For 3 Pole For DN2 & 4 Pole versions & DN3 frames Site fittable

: 8 kV 0 /6 0H z . U imp U e : 4 1 5 V, 5 T: A :10 0 %I cu CA I cu : 50 k A,I cs 2 E N 60 9 47 -2 I EC 60 9 47 IS 1 3 947-2

DN3-630N

: 8k V 0/ 60 H z . U imp A U e : 41 5V, 5 :1 0 0% I cu CAT: I cu : 50kA,I cs 2 E N 6 09 47 -2 I EC 60 9 47 IS 1 3 94 7 - 2

DN3-630N

MIL with Base Plate

2. Mechanical Interlocking using Key locks: For mechanical interlocking through Extended Rotary operating mechanism, a panel mounted key lock is available. The selection of the key lock as per the following details,

2 l/C 2 I/C and 1 B/C 3 I/C and 2 B/C

Any 1 type of lock for both MCCBs Lock 1 and Lock 2 for I/C and Lock 12 for B/C Locks 1, 2, 3 for I/Cs and Locks 12, 23 for B/Cs

Key Lock Selection

I/C1 I/C2 I/C3

Lock 1

Lock 2

Lock 3

Incommers (I/C)

Bus couplers (B/C) Lock 12 B/C1

Type of lock 1 2 3 12 23

Lock 23

B/C2

Exclusively operable by Key Nos. 1 2 3 1, 2 & 12 2, 3 & 23

Accessories

External Neutral CTs

Features

on Add Reliable

accessory for 3P MCCB solution for Earth / Neutral fault protection for 3 Phase 4 wire system

Stored Energy Electrical Operating Mechanism

Features OFF & Charged/Discharged indication ON / Foolproof mounting Selector switch for Auto/Manual operation Padlock facility for locking in OFF position(3 nos locks) Resetting time < 250msec & Closing time< 90 msec Higher mechanical & electrical endurance Back up fuse for extended motor protection Easy access to the protection setting on MCCB True indication for ON/OFF & Trip

DN3 SE EOM data sheet Operating voltage (V AC) Operating voltage (%) Closing time (ms) Opening time (ms) Power consumption (VA) Life / No. of operations Door cut out (mmXmm) IP protection, on the front Operating frequency Min. control impulse time (ms) 240 85-110% 90 250 500 5000 96X96 IP30 1/min 200

Accessories

Automatic Source Transfer Switch Controller AuXC-1000

448 448

LINE 1 LINE 2

L1 L2 L3 Hz L1 L2 L3 Hz ON OFF ON WITHDRAWN TRIP ON ON OFF TRIP

AUTO TRANSFER CONTROLLER

AuXC-1000

ALARM TEST

TEST

The AuXC-1000 controller brings simplicity and flexibility to an auto source transfer system. It has been developed to control and supervise the automatic or manual transfer of a utility load from a principal power supply source to a stand-by. It sets a new benchmark in Auto source transfer switch controller technology. It includes all the necessary features to supervise and control power supply sources, composed by energy distribution systems or generating sets, and the relative transfer equipment, such as contactors, motorized moulded case circuit breakers and air circuit breakers.

AUTO

MANUAL

WITHDRAWN OFF/RESET

LOAD

A01 LOW BATTERY VOLTAGE A02 HIGH BATTERY VOLTAGE A03 LINE 1 SWITCH FAULT A04 LINE 2 SWITCH FAULT A05 LINE 1 WRONG PHASE SEQ. A06 LINE 2 WRONG PHASE SEQ. A07 LOAD NOT POWERED T. OUT A08 GENERATOR NOT READY A09 EMERGENCY STOP

The automatic transfer takes place through AuXC-1000 whenever conditions predefined by the user take place, for example: Power supply source not respecting programmed limits need to have a very reliable power source The need to use the most economical power source The Some of the key features of this controller are: display for monitoring the system voltage and frequency and for Front onsite controller programming Six programmable inputs and five programmable outputs Front test feature to simulate the operation of the diesel generator set Status indication through 22 LEDs Flush mounting arrangement Communication capable The AuXC-1000 controller is compatible with U-Power range of Air circuit breakers, range of MCCBs and MCX range of contactors.

+

AuXc-1000 MIL with Base Plate & EOM

10

Technical Data

TESTED

Frame Type Current Range (A) Poles Impulse withstand Voltage (kV) Rated Operational Voltage (V) (MAX) Rated Insulation Voltage (V) Utilisation Category Standard 230 / 240 V 400 / 415 V IEC-60947-2 500 V Icu (kA) 550 V 600 V 690 V 250 V DC (3P in series) 500 V DC (3P in series) L/ R<15msec Ics as % lcu Life span Mechanical Electrical @1.0 In Operating Frequency (Hz) Total Opening Time Finger-proof Terminals Ambient Temperature Storage Temperature Mounting Positions Dimensions (W x D x H) 3-Pole 3 mm 4-Pole Weight (kg) (3/4 Pole) Auxiliary Contact

A C C E S S O R I E S

100 A DN0-100 D 3/4 6 600 690 A IEC / EN / IS 65 36 10 8 5 15 5 50% 30000 4000

250 A DN1-250 N 3/4 6 600 690 A IEC / EN / IS 65 50 10 8 5 15 10 50% 10000 3000 65 36 25 18 16 10 15 5 100% D

250 A DN2-250 N 3/4 8 690 750 A IEC / EN / IS 70 50 36 25 18 15 25 10 100% 25000 10000 50 / 60 <10 msec Yes -5 to 55 C -350 to 700 C

0 0

400 A DN3-400 S D N 63, 160, 250, 320, 400 3/4 8 690 750 A IEC / EN / IS 100 70 42 36 22 20 36 20 100% 65 36 25 15 12 8 15 5 100% 70 50 36 20 18 15 25 10 100% 15000 4000 100 70 42 25 22 20 36 20 100% 65 36 25 15 12 8 15 5 100% S D

630 A DN3-630 N 3/4 8 690 750 A IEC / EN / IS 70 50 36 20 18 10 25 10 100% 15000 2000 100 70 42 25 22 15 36 16 100% 70 50 25 20 16 10 100% S N 63, 160, 250, 320, 400, 630 A

800 / 1000 / 1250 A DN4-1250 S 800, 1000, 1250 3/4 8 690 750 A IEC / EN / IS 100 70 36 25 20 18 100% 8000 750 <20 msec

20, 25, 32, 40, 50, 63, 80 & 100 A 100, 125, 160, 200, 250 A

32, 40, 50, 63, 100, 125, 160, 200 & 250 A

Vertical and 900 in both directions 75 x 60 x 130 100 x 60 x 130 1 / 1.25 1C/O or 2C/O 1C/O or 2C/O 1C/O + 1C/O 240 / 415 V AC 50 / 60 Hz 240 V AC 50 Hz P 105 x 60 x 165 140 x 60 x 165 1.45 / 1.8 1C/O or 2 C/O 1C/O or 2 C/O 1C/O + 1 C/O 240 / 415 V AC 50 / 60 Hz 240 V AC 50 Hz P 105 x 96 x 179 140 x 96 x 179 2.5 / 3.3 1C/O or 2C/O 1C/O 1C/O + 1C/O 110 / 415 V AC 50 / 60 Hz, 110 / 220 V DC 220 - 240 V AC 50 Hz P P P P P P 140 x 111.5 x 266 183.5 x 111.5 x 266 5.5 / 7.2 1C/O or 2C/O 1C/O 1C/O + 1C/O 110 / 415 V AC 50 / 60 Hz,110 / 220 V DC 220 - 240 V AC 50 Hz P 140 x 111.5 x 266 183.5 x 111.5 x 266 6 / 7.8 1C/O or 2C/O 1C/O 1C/O + 1C/O 110 / 415 V AC 50 / 60 Hz,110 / 220 V DC 220 - 240 V AC 50 Hz P 278 x 143 x 370 278 x 143 x 370 15 / 16 1C/O or 2C/O 1C/O 1C/O + 1C/O 110 / 415 V AC 50 / 60 Hz, 110 / 220 V DC 220 - 240 V AC 50 Hz P x x P P P

Trip Alarm Contact Internal Auxiliary & Trip Alarm Contact Shunt Release $ Under Voltage Release Rotary Operating Mechanism Electrical Operating Mechanism Earth Fault Release External Mechanical Interlock Spreader Links Key lock Pad lock through ROM

x x Available with external GF module with TM release x P x

# P

P P Available with external GF module with TM release and Inbuilt protection with Microprocessor release P P P P P P P P

x P x P

$ : NO of control contactor to be connected in series for 220V DC application. Any Note: l two internal accessories can be mounted at a time lspecial application like capacitor switching, DC please contact nearest branch office For lmotor application, use M series MCCBs (DN2M, DN3M) For * Available on request. # Direct Pad locking available

11

12

Time - Current Characteristic Curves

Thermal-Magnetic Release DN0-100

10000 10000

DN1-250

1000

1000

100 Time in Seconds Time in Seconds 2 4 6 8

100

10

10

1 1

0.1 0.1

0.01 0.01 1 10 20 1 10 Multiples of Current 100

Multiples of Current

DN2-160/250

10000 10000

DN3-400/630

1000

1000

100

100

Time in Seconds

Time in Seconds

10

10

0.1

0.1

0.01 1 2 4 6 8 10 2 4 6 8 100 2

0.01 2 1 4 6 8 4 6 8 2 10 100 Multiples of Current 2

Multiples of Current

13

Time - Current Characteristic Curves

Microprocessor Release-RC10 DN2-250A

10000 10000

DN3-400A

1000

1000

100 Time in Seconds Time in Seconds 100% In 0.1 40% In

100

10

10

0.1

100% In

40% In

0.01 2 1 4 6 8 10

Multiples of Current

0.01 2 4 1 2 4 6 8 10

Multiples of Current

DN3-630A

10000 10000

DN4-1250A

1000

1000

100

100

Time in Seconds

10

Time in Seconds

10

100% In 0.1

40% In 0.1

100% In

40% In

0.01 2 1 4 6 8 10

Multiples of Current

0.01 2 4 1 2 4 6 8 2 4 10 Multiples of Current

14

Time - Current Characteristic Curves

Microprocessor Release-RC20 DN2-250A

10000 10000

DN3-400A

1000

30 sec 15 sec 10 sec 6 sec 3 sec

1000

30 sec 15 sec 10 sec 6 sec 3 sec

100 Time in Seconds Time in Seconds 100% In 0.1 40% In

100

10

10

0.1

100% In

40% In

0.01 2 1 4 6 8 10

Multiples of Current

0.01 2 4 1 2 4 6 8 10

Multiples of Current

DN3-630A

10000 10000

DN4-1250A

1000

30 sec 15 sec 10 sec 6 sec 3 sec

1000

30 sec 15 sec 10 sec 6 sec 3 sec

100

100

Time in Seconds

10

Time in Seconds

10

100% In 0.1

40% In 0.1

100% In

40% In

0.01 2 1 4 6 8 2 4 10 Multiples of Current

0.01 2 1 4 6 8 10

Multiples of Current

15

Overall Dimensions

DN0-100 MCCB

100 (4 pole) 12.5 25 6.9 9 25 25 62.5 61.5 38 116.4 130 60 85 Suitable for 35 x 7.5 Top Hat Rail Mounting 25.5 25 M3-2.4 3P CM97785OOOO 4P CM97921OOOO 86.1 60 20 2 130 20 20

75 (3 pole) 58 45

N s

2.25 48.5 52 29.5 76 25 112 Recommended CAT number for DN0 spreaders Cut-out 1 46 39 or Cut-out 2

Note : Spreaders are available as spare

Mounting & Door Cutout Details

DN0-100 with Spreader Links

92 35 35 35 127 35 35

194.2

116.4

130

172.2

N s

30.2

35

35 127

35

22 Note : Spreaders are available as spare. It is recommended to use spreader links for enhancing termination capacity All dimension are in mm

11

16

Overall Dimensions

DN1-250 MCCB

60 35 35 35 18 Mounting Panel 35 35 17.5

165

145

126

35

35 105(3P)

64.5

For Four Pole

140(4P) 93.7

DN1-250 with Spreader Links

18 18 35 35 4

38

54

54 197

54

257

221

Spreader Link 4P MCCB Hardware

4 54.5 72 54.5 72 18

Spreader Link 3P MCCB

17

126

All dimension are in mm

Overall Dimensions

DN2-250 MCCB

120 97.5 8 17.5 17.5 28.6 35 35

72.7

61

ON TRIP OFF

163

179

45

43 35 35 105 A 140 35 17.5 86

43

Mounting & Door Cut-out Details

Terminal width = 25.5.mm

DN2-250 3P with Spreader Links

28.6 18 35 4

DN2-250 4P with Spreader Links

54.5 54.5 54.5 18 N ON TRIP OFF Wider gap

20

46.5 4 A = 198.5 Rating Dimension (A) 26 25.5 26.25 28 = 3P ST98053OOOO 4P 38

275

38

10

ON TRIP OFF

239

54.5 = 144

54.5 =

35

125-250A TM 63-100A TM 32-50A RC breakers Note : Spreaders are available as spare. It is recommended to use spreader links for enhancing termination capacity. All dimension are in mm

Recommended CAT number for DN2 spreaders

CM92007OOOO

157

18

Overall Dimensions

DN3-400/630 MCCB

43.5 43.5 = =

183.4

16

140

234

ON

142

136.8

82.7

OFF

43.5 43.5 43.5

26.5

121 = =

Mounting & Door Cut-out Details

Terminal width = 28mm

DN3-400/630 3P with Spreader Links

165 62.5 62.5

DN3-400/630 4P with Spreader Links

177.8

224.5 62 60.5 62

22

78

TRIP

224

111.5

Wider gap

A

13 F

142

ON TRIP OFF

TRIP OFF

43.5 43.5 40 43.5

26.5

234

ON

266

5 142

23

Wider gap 22.5

Type A B C D E Note : Spreaders are available as spare. It is recommended to use spreader links for enhancing termination capacity. F

DN3-400 DN3-630 39 37 45 324 370 13 41 38 55 344 390 11 Recommended CAT numbers for DN3 spreaders Rating 400A 630A 3P ST98065OOOO ST98054OOOO 4P ST98066OOOO CM92004OOOO All dimension are in mm

19

Overall Dimensions

DN4-800/1000/1250 MCCB

143 4 POLE 68 20 68 68 85 57 C 109.5 132.5 326 105 68 68 195 182

24

330

179.5 278

DN4-800 MCCB with Spreader Links

A A A 15

DN4-1000/1250 MCCB with Spreader Links

A Wider gap

28

85

370

46

- 46 (N version) 42 (S version)

DN4-800/1000/1250 MCCB

195 143 15 46

85

107

510

510

15

60 B

Dimensions Type 800A 1000/1250/1600A

24

60 B

24

15

85

370

46

Recommended CAT numbers for DN4 spreaders A 88 80 B 324 300 C 6 20 Rating 800A 1000A /1250A 3P ST90361OOOO ST98055OOOO 4P ST90362OOOO ST98058OOOO

Note : Spreaders are available as spare. It is recommended to use spreader links for enhancing termination capacity. All dimension are in mm

105

132.5

20

ROM Door cut-out details

Direct ROM door cut-out detail

L5

N

L2

L1

L3

L4

L1 = Mounting Depth L2/L3 = Panel Cut-out L4/L5 = Breaker Mounting Refer

Type DN0 DN1 DN2 DN3

L1 96.5 96.5 122 146

L2 58 73 96 121

L3 52 52 63 87

L4 43.5 56.5 53 78

L5 37 54 66 82

Extended ROM door cut-out detail

L2

50 L3 76

45

L1=Minimum Panel Depth suggested

L = Length of Shaft Required for Panel Depth L1 Total Length of Shaft =275mm

Refer Panel Cut Details

TYPE DN0 DN1 DN2 DN3 DN4 L1 169 169 202 233 302 L L1 - 119 L1 - 119 L1 - 152 L1 - 183 L1 - 252 L2 7.5 24.5 27 39 69

Refer Panel Cut Details

L3 69.5 81.7 84 122 170

All dimension are in mm

21

Overall Dimensions

MCCB with EOM (Stored Energy)

DN3

264

43.5 Mounting holes for MCCB

256

=

Door

94 Door cut out 224

94

62.1

45

49

Cat. No. CM98130OOOO

Panel Mounted Key Lock

72 48.5 2 Holes, 4.2 76 50 450 50

136

68

Cut-out for Handle Assembly 12

58

52 29 Cut-out for Panel Mounted Key Lock 2.2

All dimension are in mm

68

22

Overall Dimensions

DN2 MIL Kit

372 141 141

10 Mounting Holes 36

209

141

141

Holes for Breaker Mounting

DN3 MIL Kit

239

10 Mounting Holes 436 161 161 56

316

346

161

161

Holes for Breaker Mounting

266 All dimension are in mm

23

179

Overall Dimensions

External Neutral CTs DN2 / DN3

K L

B C F D A Bottom Side Bottom Side

A DN2 250A DN3 400A DN3 630A 93 93.5 93.5

B 59 58 58

C 47 46 46

D 81 81.5 81.5

E 35 40 40

F 10.2 13 10.5

G 77 63.5 63.5 Adaptor Terminal

H DN2 250A DN3 400A DN3 630A 153 153.5 173.5

J 189 199.5 219.5

K 26 39 39

L 4 5 5

M 55 60 60 ON TRIP

Note: Adapter Terminals shown are not available with product. kindly refer accessories data for ordering separately. Circuit Breaker shown for reference only. Bottom Side

OFF

>M

All dimension are in mm

24

Overall Dimensions

External Neutral CTs DN4

H M N

DN4 800A 1000/1250A

A 132 132

B 88.5 88.5

C 73.5 73.5

D 117 117

E 60 60

F 12.5 12.5

G 92 92

DN4 800A 1000/1250A

H 24 24

J 302 302

K 272 272

L 80 80

M 73.5 73.5

N 6 20 N

Note: Adapter Terminals shown are not available with product. kindly refer accessories data for ordering separately. Circuit Breaker shown for reference only.

Special Note: Adapter Terminals for DN4 range of product are not symmetrical. Kindly insure proper orientation in assembly as shown in figure below.

>L

G F

All dimension are in mm

25

Electrical Standard Products (ESP) Branch Offices:

REGISTERED OFFICE AND HEAD OFFICE L&T House, Ballard Estate P. O. Box 278 Mumbai 400 001 Tel: 022-67525656 Fax: 022-67525858 Website: www.Larsentoubro.com ELECTRICAL STANDARD PRODUCTS (ESP) 501, Sakar Complex I Opp. Gandhigram Rly. Station Ashram Road Ahmedabad 380 009 Tel: 079-66304006-11 Fax: 079-66304025 e-mail: esp-ahm@LNTEBG.com 38, Cubbon Road, P. O. Box 5098 Bangalore 560 001 Tel: 080-25020100/25020324 Fax: 080-25580525 e-mail: esp-blr@LNTEBG.com 131/1, Zone II Maharana Pratap Nagar Bhopal 462 011 Tel: 0755-4098721/7/ 8 / 9 Fax: 0755-2769264 e-mail: esp-bho@LNTEBG.com Plot No. 559, Annapurna Complex Lewis Road Bhubaneswar 751 014 Tel: 0674-6451342, 2436696 Fax: 0674-2537309 e-mail: esp-bbi@LNTEBG.com SCO 32, Sector 26-D Madhya Marg, P. O. Box 14 Chandigarh 160 026 Tel: 0172-4646840, 4646853 Fax: 0172-4646802 e-mail: esp-chd@LNTEBG.com 10, Club House Road, Annasalai Chennai 600 002 Tel: 044-28462072 / 4 / 5 / 2109 Fax: 044-28462102 / 3 e-mail: esp-maa1@lntebg.com 67, Appuswamy Road Post Bag 7156 Opp. Nirmala College Coimbatore 641 045 Tel: 0422-2588120 / 1 / 5 Fax: 0422-2588148 e-mail: esp-cbe@LNTEBG.com L&T House, Group MIG-5 Padmanabhpur Durg 491 001 Tel: 0788-2213833 / 14 / 21 / 29 Fax: 0788-2213820 e-mail: esp-durg@LNTEBG.com Khairasol, Degaul Avenue Durgapur 713 212 Tel: 2559848, 2559849, 2559844 Fax: 0343-2553614 e-mail: esp-dgp@LNTEBG.com Milanpur Road, Bamuni Maidan Guwahati 781 021 Tel: 0361-2550562 / 65 Fax: 0361-2551308 e-mail: hazrasudipto@LNTEBG.com II Floor, Vasantha Chambers 5-10-173, Fateh Maidan Road Hyderabad 500004 Tel: 040-66720250 Fax: 040-23296468 e-mail: esp-hyd@LNTEBG.com D-24, Prithvi Raj Road, C-Scheme Jaipur 302 001 Tel: 0141-2385915 / 16 / 17 / 18 Fax: 0141-2373280 e-mail: esp-jai@LNTEBG.com Akashdeep Plaza, 2nd Floor P. O. Golmuri Jamshedpur 831 003 Jharkhand Tel: 0657-2312205 / 38 Fax: 0657-2341250 e-mail: esp-jam@LNTEBG.com Skybright Bldg; M. G. Road Ravipuram Junction, Ernakulam Kochi 682 016 Tel: 0484-4409420 / 4 / 5 / 7 Fax: 0484-4409426 e-mail: esp-cok@LNTEBG.com 3-B, Shakespeare Sarani Kolkata 700 071 Tel: 033-44002572 / 3 / 4 Fax: 033-22821025/7587 e-mail: esp-ccu@LNTEBG.com A28, Indira Nagar, Faizabad Road Lucknow 226 016 Tel: 0522-2312904 / 5 / 6 Fax: 0522-2311671 e-mail: esp-Lko@LNTEBG.com No: 73, Karpaga Nagar, 8th Street K. Pudur Madurai 625007 Tel: 0452-2537404, 2521068 Fax: 0452-2537552 e-mail: esp-mdu@LNTEBG.com EBG North Wing Office-Level 2 Gate 7, Powai Campus Mumbai 400 072 Tel: 022-67052874 / 2737 / 1156 Fax: 022-67051112 e-mail: esp-bom@LNTEBG.com 12, Shivaji Nagar North Ambazari Road Nagpur 440 010 Tel: 0712-2260012/3 Fax: 0712-2260020/30 e-mail: esp-nag@LNTEBG.com 32, Shivaji Marg P. O. Box 6223 New Delhi 110 015 Tel: 011-41419514 / 5 / 6 Fax: 011-41419600 e-mail: esp-del@LNTEBG.com L&T House P. O. Box 119 191/1, Dhole Patil Road Pune 411 001 Tel: 020-26135048/26164048 Fax: 020-26124910, 26135048 e-mail: esp-pnq@LNTEBG.com 3rd Floor Vishwakarma Chambers Majura Gate, Ring Road Surat 395 002 Tel: 0261-2473726 Fax: 0261-2477078 e-mail: esp-sur@LNTEBG.com Radhadaya Complex Old Padra Road Near Charotar Society Vadodara 390 075 Tel: 0265-6613610 / 1 / 2 Fax: 0265-2336184 e-mail: esp-bar@LNTEBG.com 48-8-16, Dwarakanagar Visakhapatnam 530 016 Tel: 0891-6620411-2 / 3 Fax: 0891-6620416 e-mail: esp-viz@LNTEBG.com

Product improvement is a continuous process. For the latest information and special applications, please contact any of our offices listed here.

Electrical Standard Products Larsen & Toubro Limited Powai Campus, Mumbai 400 072 Customer Interaction Center (CIC) BSNL / MTNL (toll free) : 1800 233 5858 Reliance (toll free) : 1800 200 5858 Tel : 022 6774 5858 Fax : 022 6774 5859 E-mail : cic@LNTEBG.com Website : www.LNTEBG.com SP 50290 R4 160112

You might also like

- Modern Digital and Analog Communications Systems - B P Lathi Solutions ManualDocument155 pagesModern Digital and Analog Communications Systems - B P Lathi Solutions Manualsandy_00991% (89)

- ACB ManualDocument42 pagesACB Manual4usangeetNo ratings yet

- Let Thru and I2tDocument2 pagesLet Thru and I2trajinipre-1No ratings yet

- FFTK Report GeneratorDocument21 pagesFFTK Report GeneratorAbdel Hernandez CardonaNo ratings yet

- Ashida 2010 Compact CatalogueDocument4 pagesAshida 2010 Compact Catalogueqaisar_shafi100% (1)

- Air Circuit Breakers - AH TypeDocument12 pagesAir Circuit Breakers - AH TypeSanjay JoshiNo ratings yet

- PLDT Customer User GuideDocument11 pagesPLDT Customer User GuideLindsay MarquezNo ratings yet

- Static Timing Analysis in VLSI CircuitsDocument16 pagesStatic Timing Analysis in VLSI CircuitseeshgargNo ratings yet

- mc61c PDFDocument32 pagesmc61c PDFashishchugh44No ratings yet

- 11kw 220v 1450rpm Afs225x Datasheet Jop DCDocument6 pages11kw 220v 1450rpm Afs225x Datasheet Jop DCcherif yahyaouiNo ratings yet

- ASHIDA Numerical OC/EF ASHIDA Numerical OC/EF Protection RelayDocument8 pagesASHIDA Numerical OC/EF ASHIDA Numerical OC/EF Protection RelayVishwanath TodurkarNo ratings yet

- 3Ø For 3-10HP Submersible Pump Application Dol Smart ControllerDocument2 pages3Ø For 3-10HP Submersible Pump Application Dol Smart ControllerVishak Theboss100% (1)

- Roboox Ac DriveDocument4 pagesRoboox Ac DrivejaahironlineNo ratings yet

- Siemens 7sj600 Catalog Sip E7Document12 pagesSiemens 7sj600 Catalog Sip E7brunotomeNo ratings yet

- Micom p132 Vol - 1Document794 pagesMicom p132 Vol - 1amdatiNo ratings yet

- AmtechDocument156 pagesAmtechAbhinav GuptaNo ratings yet

- R8563C Kitz 204Document64 pagesR8563C Kitz 204Rinda_Rayna100% (1)

- Application of Multi-Function Motor Protection Relays To Variable Frequency Drive Connected MotorsDocument13 pagesApplication of Multi-Function Motor Protection Relays To Variable Frequency Drive Connected Motorslarry vargas bautistaNo ratings yet

- Scot M3K Scot MXP: Circuit Breaker Time Interval MeterDocument2 pagesScot M3K Scot MXP: Circuit Breaker Time Interval Meterprerna nandNo ratings yet

- Dokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerDocument4 pagesDokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerPAWAN RAJPUTNo ratings yet

- Catalogue For TFM-FR-TZ-TX-B PDFDocument15 pagesCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- P225 PDFDocument12 pagesP225 PDFdave chaudhuryNo ratings yet

- Rishab Delta - Energy - Manual - REV - GDocument57 pagesRishab Delta - Energy - Manual - REV - GSIVA KAVYANo ratings yet

- L&T MN RelaysDocument6 pagesL&T MN RelaysArun Kumar100% (1)

- Ashida ADR141C & ADR214C Fix Type, 4 Element IDMT Relay PDFDocument13 pagesAshida ADR141C & ADR214C Fix Type, 4 Element IDMT Relay PDFachinta singhaNo ratings yet

- Circuit BreakersDocument48 pagesCircuit BreakerspitambervermaNo ratings yet

- Masibus 85XX+ - R3F - 0219 ScannerDocument4 pagesMasibus 85XX+ - R3F - 0219 ScannerchinnathambijNo ratings yet

- Elmeasure Manual Transfer Switch CatalogDocument2 pagesElmeasure Manual Transfer Switch CatalogSEO BDMNo ratings yet

- Neptune Power Analyzer ManualDocument2 pagesNeptune Power Analyzer ManualsanjayNo ratings yet

- Numerical Protection PDFDocument14 pagesNumerical Protection PDFDrashti PatelNo ratings yet

- Vector Surge Relay - MRG20000Document20 pagesVector Surge Relay - MRG20000t_syamprasadNo ratings yet

- Mi COMP111Document8 pagesMi COMP111AONLANo ratings yet

- Crompton GReaves Relay OvercurrentDocument2 pagesCrompton GReaves Relay OvercurrentSuranjana DasNo ratings yet

- MLD Annunciator ManualDocument8 pagesMLD Annunciator Manualpratyusha mohantyNo ratings yet

- ContactorsType MN00 Ac ContactorDocument2 pagesContactorsType MN00 Ac ContactorDivyanshu MittalNo ratings yet

- Prok DVs - ACCL - CatalougeDocument3 pagesProk DVs - ACCL - CatalougekapilNo ratings yet

- Adr241a Do 01 810Document17 pagesAdr241a Do 01 810Vishwanath TodurkarNo ratings yet

- 132 - 33kV Trafo C&R PanelDocument55 pages132 - 33kV Trafo C&R PanelPrashant SoniNo ratings yet

- Basic Parameters in The Operation and Design of Submerged Arc Furnaces, With Particular Reference To Production of High-Silicon AlloysDocument6 pagesBasic Parameters in The Operation and Design of Submerged Arc Furnaces, With Particular Reference To Production of High-Silicon AlloysPrabir Laha100% (1)

- Premier 300Document11 pagesPremier 300Yusuf Khan0% (1)

- Csenexi 250Document16 pagesCsenexi 250EXECUTIVE ENGINEER TESTING DIV. SATARA100% (1)

- Conzerv 6438Document10 pagesConzerv 6438Pur WantoNo ratings yet

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- Star DeltaDocument2 pagesStar DeltaRa ArNo ratings yet

- Schinder CBCTDocument10 pagesSchinder CBCTSunil KumarNo ratings yet

- 1010KVADocument6 pages1010KVAK RameshNo ratings yet

- Coordination Curve DirectDocument2 pagesCoordination Curve DirectBryan SalamatNo ratings yet

- Micom P220 Motor Protection RelayDocument16 pagesMicom P220 Motor Protection RelayAONLANo ratings yet

- Microwarn 9600Document1 pageMicrowarn 9600Pramod B.WankhadeNo ratings yet

- Multi Function Transducer User ManualDocument48 pagesMulti Function Transducer User ManualJoeNo ratings yet

- Iru ProDocument18 pagesIru ProjaikolangaraparambilNo ratings yet

- Powerguard Heavy DutyDocument12 pagesPowerguard Heavy DutyOdion Usunobun Julius100% (1)

- ABB 615 Series Modbus Communication Protocol Manual - LDocument72 pagesABB 615 Series Modbus Communication Protocol Manual - LSayed Younis SadaatNo ratings yet

- ADR131 AmDocument53 pagesADR131 Amapi-3728789100% (2)

- Vmax & VD4 SPARES PARTS LIST Rev-00Document22 pagesVmax & VD4 SPARES PARTS LIST Rev-00Abhishek RaiNo ratings yet

- Mudit MaheshwariDocument57 pagesMudit Maheshwaripulakmandal1No ratings yet

- Controller DetailsDocument7 pagesController DetailsAbdul Moeed0% (1)

- Dsine MCCBDocument27 pagesDsine MCCBKarthikeyanNo ratings yet

- ACB - AH TypeDocument4 pagesACB - AH Type4usangeet50% (2)

- Air Circuit Breakers-AHA TypeDocument8 pagesAir Circuit Breakers-AHA TypeanbarasubalayahoocomNo ratings yet

- EearDocument14 pagesEearOswald NgNo ratings yet

- Info - Mitsubishi LV Acb - Ae-Ss and Ae-ShDocument68 pagesInfo - Mitsubishi LV Acb - Ae-Ss and Ae-ShRyan661213No ratings yet

- Aakash JeeDocument2 pagesAakash JeeryreddyNo ratings yet

- Chandamama Telugu Jul 2006Document68 pagesChandamama Telugu Jul 2006ryreddyNo ratings yet

- Format-Con-5 Draft Connection Offer Letter For Connection To The Inter-State Transmission GridDocument2 pagesFormat-Con-5 Draft Connection Offer Letter For Connection To The Inter-State Transmission GridryreddyNo ratings yet

- Actions Related To Each Dept. For Completing "Format-Con-5" For Signing of Connection AgreementDocument10 pagesActions Related To Each Dept. For Completing "Format-Con-5" For Signing of Connection AgreementryreddyNo ratings yet

- Mitigation of The Transient Recovery Voltage On Generator Circuit Breaker During Generator Fed FaultsDocument4 pagesMitigation of The Transient Recovery Voltage On Generator Circuit Breaker During Generator Fed FaultsryreddyNo ratings yet

- VinPlus InstallationDocument25 pagesVinPlus InstallationryreddyNo ratings yet

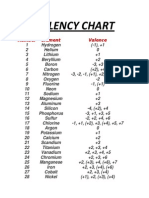

- Valency ChartDocument3 pagesValency Chartryreddy50% (2)

- Type MPB/MPG Test Plug and Universal Test BlockDocument4 pagesType MPB/MPG Test Plug and Universal Test Blockryreddy33% (3)

- 25 Minute YogaDocument6 pages25 Minute YogaryreddyNo ratings yet

- Sub Synchronous ResonanceDocument15 pagesSub Synchronous ResonanceryreddyNo ratings yet

- Weidmuller DRM Relays PDFDocument6 pagesWeidmuller DRM Relays PDFryreddyNo ratings yet

- D Series Datasheet PDFDocument32 pagesD Series Datasheet PDFryreddyNo ratings yet

- Videocon Industries LTD: Key Financial IndicatorsDocument4 pagesVideocon Industries LTD: Key Financial IndicatorsryreddyNo ratings yet

- Transformer Differential ProtectionDocument7 pagesTransformer Differential Protectiondeepak2628No ratings yet

- 70 KvaDocument4 pages70 KvaLeonardusHSijabatNo ratings yet

- Advanced Furnace Cleaning - Kiet Pham - 27072018Document32 pagesAdvanced Furnace Cleaning - Kiet Pham - 27072018chusnuhNo ratings yet

- Mason Industries, Inc.: Position 1 (Floor in Poured Position) Position 2 (Spring & Neoprene Cup Installed)Document1 pageMason Industries, Inc.: Position 1 (Floor in Poured Position) Position 2 (Spring & Neoprene Cup Installed)Mai Tuan AnhNo ratings yet

- Stephan Artec Anaesthesia System 2010 - User ManualDocument32 pagesStephan Artec Anaesthesia System 2010 - User Manualluis100% (1)

- ZS2 Panel ManualDocument40 pagesZS2 Panel Manualsyedfahadraza627No ratings yet

- PQPDocument54 pagesPQPMustafa Liverpool67% (3)

- Contacts Catalog PDFDocument31 pagesContacts Catalog PDFChinmay BornarkarNo ratings yet

- Anna University Exams Nov/Dec 201 9 - Regulation 2017 CE8392 Engineering Geology PART B & PART C Questions For All 5 UnitsDocument2 pagesAnna University Exams Nov/Dec 201 9 - Regulation 2017 CE8392 Engineering Geology PART B & PART C Questions For All 5 UnitsVishnuNo ratings yet

- Melc Science 5Document1 pageMelc Science 5Mariene Patrisabel Ungriano - AndaluzNo ratings yet

- Emteq Arinc 404 and 600 TraysDocument11 pagesEmteq Arinc 404 and 600 TraysLuis CrespoNo ratings yet

- Balance of Line For Milk Powder ProductionDocument36 pagesBalance of Line For Milk Powder ProductionRibwarAbdulrahmanNo ratings yet

- Force and Pressure NotesDocument23 pagesForce and Pressure NotesCodewithRaghav EmailNo ratings yet

- Lab Final SolutionDocument18 pagesLab Final SolutionZeeNo ratings yet

- INCONEL 686 - INCO-WELD 686CPT Application List For IndiaDocument10 pagesINCONEL 686 - INCO-WELD 686CPT Application List For IndiaBhanu Pratap ChoudhuryNo ratings yet

- EUR Doc013 - EUR AOP Limited VisibilityDocument70 pagesEUR Doc013 - EUR AOP Limited VisibilityNguyen Xuan NhuNo ratings yet

- Fabrication of Carbon Nanotube Field-Effect Transistors in Commercial Silicon Manufacturing FacilitiesDocument10 pagesFabrication of Carbon Nanotube Field-Effect Transistors in Commercial Silicon Manufacturing Facilities,/No ratings yet

- US886211Document8 pagesUS886211bob wongNo ratings yet

- Name: Asim Khawaja Roll NO: 16F-8108 Section: D: Problem 1Document5 pagesName: Asim Khawaja Roll NO: 16F-8108 Section: D: Problem 1Mohammad AsimNo ratings yet

- POLYPROPYLENE Updated 281020Document1 pagePOLYPROPYLENE Updated 281020sribachaNo ratings yet

- United States Patent (10) Patent No.: US 6,281,595 B1Document8 pagesUnited States Patent (10) Patent No.: US 6,281,595 B1PaoloPorrasArrietaNo ratings yet

- Damcos BRC 32000: Hydraulic Double-Acting Balanced Rotary Actuator 90 (Quarter-Turn)Document4 pagesDamcos BRC 32000: Hydraulic Double-Acting Balanced Rotary Actuator 90 (Quarter-Turn)Lanceal Tan100% (1)

- RM96 XXDatasheetDocument9 pagesRM96 XXDatasheetspindaarNo ratings yet

- Cse 1st Sem Result PDFDocument3 pagesCse 1st Sem Result PDFrahulyadav957181No ratings yet

- Kanakaiah KDocument5 pagesKanakaiah KKanak YadavNo ratings yet

- ITP For Doors and Windows InstallationDocument1 pageITP For Doors and Windows InstallationravitejaawptNo ratings yet

- Lighting Concepts: ResidentialDocument13 pagesLighting Concepts: ResidentialVasilis KarageorgiouNo ratings yet

- Technical Data Sheet: Toa Roadline PaintDocument4 pagesTechnical Data Sheet: Toa Roadline PaintSiradech SuritNo ratings yet