Sa 516

Sa 516

Uploaded by

Vipul ShahCopyright:

Available Formats

Sa 516

Sa 516

Uploaded by

Vipul ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Sa 516

Sa 516

Uploaded by

Vipul ShahCopyright:

Available Formats

(Identical with ASTM Specification A 516/A 516M-90.

Scope 1.1 This specification covers carbon steel plates intended primarily for service in welded pressure vessels where improved notch toughness is important.

1. 1.2 Plates under this specification are available in four grades having different strength levels as follows:

Grade U.S. [SI] 55 60 65 70 [380] [415] [450] [485] Tensile Strength, ksi [ m a ] 55-75 60-80 65-85 70-90 [380-5151 [415-5501 [450-5851 [485-620]

Referenced Documents 2.1 ASTM Standards: A 20lA 20M Specification for General Requirements for Steel Plates for Pressure Vessels A 435lA 435M Specification for Straight-Beam Ultrasonic Examination of Steel Plates A 577lA 577M Specification for Ultrasonic Angle-Beam Examination of Steel Plates A 578lA 578M Specification for Straight-Beam Ultrasonic Examination of Plain and Clad Steel Plates for Special Applications

2.

1.3 The maximum thickness of plates is limited only by the capacity of the composition to meet the specified mechanical property requirements; however, current practice normally limits the maximum thickness of plates furnished under this specification as follows:

Grade U.S. [SI] 55 60 65 70 [380] [415] [450] [485] Maximum Thickness, in. [mm] 12 [305] 8 [205] 8 [205] 8 [205]

General Requirements and Ordering formation 3.1 Material supplied to this material specification shall conform to Specification A 2011: 20M. These requirements outline the testing and retesting methods and procedures, permissible variations in dimensions, and mass, quality and repair of defects, marking, loading, etc.

3. 3.2 Specification A 20lA 20M also establishes the rules for the ordering information that should be complied with when purchasing material to this specification. 3.3 In addition the basic requirements of this specification, certain supplementary requirements are available when additional control, testing, or examination is required to meet end use requirements. These include: 3.3.1 Vacuum treatment, 3.3.2 Additional or special tension testing, 3.3.3 Impact testing, and 3.3.4 Nondestructive examination.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

2004 SECTION I1

3.4 The purchaser is referred to the listed supplementary requirements in this specification and to the detailed requirements in Specification A 20lA 20M. 3.5 If the requirements of this specification are in conflict with the requirements of Specification A 20lA 20M, the requirements of this specification shall prevail.

5.3 When notch-toughness tests are required on plates in. [40 mm] and under in thickness, the plates shall be nomalized unless otherwise specified by the purchaser. 5.4 If approved by the purchaser, cooling rates faster than those obtained by cooling in air are permissible for improvement of the toughness, provided the plates are subsequently tempered in the temperature range 1100 to 1300F [595 to 705OCI.

4.

Manufacture 4.1 Steelimkiizg Practice -The steel shall be killed and shall conform to the fine a~istenitic grain size requirement of Specification A 20lA 20M.

6.

5.

eat Treatment 5.1 Plates 1.50 in. [40 nun] and under in thiclcness are normally supplied in the as-rolled condition. The plates may be ordered normalized or stress relieved, or both.

Chemical Requirements 6.1 The steel shall conform to the chemical requirements shown in Table 1 unless otherwise modified in accordance with Supplementary Requirement S 17, Vacuum Carbon-Deoxidized Steel, in Specification A 20lA 20M.

7.

5.2 Plates over 1.50 in. [40 mm] in thickness shall be normalized.

Mechanical Requirements 7.1 Telzsioiz Test Reqzliremeizts -The material as represented by the tension-test specimens shall confom to the requirements shown in Table 2.

PART A - FERROUS MATERIAL SPECIFICATIONS

TABLE 1 CHEMICAL REQUIREMENTS

Composition, % Elements Carbon, maxA: 1 in. C12.5 m m l and under ', Over in. to 2 in. C12.5 to 50 mml, incl Over 2 in. to 4 in. C50 to 100 mml, incl Over 4 to 8 in. C l O O to 200 mml, incl Over 8 in. C200 m m l Manganese: yz in. C12.51 and under: Heat analysisR Product analysisR Over in. C12.51: Heat analysis Product analysis Phosphorus, maxA Sulfur, maxA Silicon: Heat analysis Product analysis

A

Grade 5 5 [Grade 3801

Grade 6 0 [Grade 4151

Grade 65 [Grade 4501

Grade 7 0 [Grade 4851

0.18 0.20 0.22 0.24 0.26

0.21 0.23 0.25 0.27 0.27

0.24 0.26 0.28 0.29 0.29

0.27 0.28 0.30 0.31 0.31

0.60-0.90 0.55-0.98 0.60-1.20 0.55-1.30 0.035 0.035 0.15-0.40 0.13-0.45

0.60-0.90 0.55-0.98 0.85-1.20 0.79-1.30 0.035 0.035 0.15-0.40 0.13-0.45

0.85-1.20 0.79-1.30 0.85-1.20 0.79-1.30 0.035 0.035 0.15-0.40 0.13-0.45

0.85-1.20 0.79-1.30 0.85-1.20 0.79-1.30 0.035 0.035 0.15-0.40 0.13-0.45

Applies to both heat and product analyses. 'Grade 60 plates 1/, in. C12.5 rnml and under in thickness may have 0.85-1.20% nese on product analysis.

manganese on heat analysis, and 0.79-1.30%

manga-

TABLE 2 TENSILE REQUIREMENTS

Grade

Tensile strength, ltsi CM Pal Yield strength, min,' ltsi C Pal M Elongation in 8 in. C200 mml, min, % Elongation in 2 in. C50 mml, min, %

A

55-75 C380-5151 30 C2051 23A 27A

60-80 C415-5501 32 C2201 21A 25A

65-85 C450-5851 35 C2401 19A 23A

70-90 C485-6201 3 8 C2601 17~ 21A

See Specification A 20/A 20M. 'Determined by either the 0.2% offset method or the 0.5% extension-under-load method.

2004 SECTION I1

Supplementary requirelnents shall not apply unless specified in the order. A list of standardized supplementary requireinents for use at the option of the pmchaser is included in ASTM Specification A 20/A 20M. Several of those considered suitable for use with this specification are listed below by title. Other tests may be perfor~nedby agreement between the s~lpplier and the purchaser.

S2.

Product Analysis,

SS. Ultrasonic Examination in accordance with Specification A 435lA 435M, agnetic Particle Examination,

Mechanical Test S4.1 Additional Tension Test,

S11. Ultrasonic Examination in accorda~~ce with cation A 577lA 577M, S12. Ultrasonic Examination Specification A 578lA 57

S5. S6. S7.

Charpy V-Notch Eu m Drop-Weight Test, High-Temperature Tension Test,

S17. Vacuum Carbon-Deoxidize

You might also like

- CE 200L Report 3Document13 pagesCE 200L Report 3Hayden Chappelear-Robbins100% (1)

- U1CDocument4 pagesU1CAdriana HernandezNo ratings yet

- ASTM A270-98ae1Document5 pagesASTM A270-98ae1NadhiraNo ratings yet

- B 171Document7 pagesB 171manuel flores100% (1)

- Asme Section Ii A Sa-426 PDFDocument6 pagesAsme Section Ii A Sa-426 PDFAnonymous GhPzn1xNo ratings yet

- Astm A694Document3 pagesAstm A694Muhammad Awais0% (1)

- Ground Bearing SlabDocument33 pagesGround Bearing Slabliverpoolengineer100% (8)

- Astm A285 1978Document5 pagesAstm A285 1978Juan Manuel Cruz MárquezNo ratings yet

- Asme Section II A Sa-302 Sa-302mDocument4 pagesAsme Section II A Sa-302 Sa-302mAnonymous GhPzn1xNo ratings yet

- A203 - 17 Standard Specification For Pressure Vessel Plates, Alloy Steel, NickelDocument3 pagesA203 - 17 Standard Specification For Pressure Vessel Plates, Alloy Steel, Nickelalucard3750% (1)

- Astm B705Document4 pagesAstm B705Maram NasraweenNo ratings yet

- Astm A285-1996 PDFDocument2 pagesAstm A285-1996 PDFMohammed TariqNo ratings yet

- Astm B423Document4 pagesAstm B423pritam sarkarNo ratings yet

- Astm G 8Document8 pagesAstm G 8luisafer26No ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- Astm A537-A537m-95-2000Document4 pagesAstm A537-A537m-95-2000NadhiraNo ratings yet

- API 622 Valve Packing For Fugitive EmissionsDocument2 pagesAPI 622 Valve Packing For Fugitive EmissionsHungphamphiNo ratings yet

- Asme B16.34 IntDocument21 pagesAsme B16.34 IntMario TiconaNo ratings yet

- BPVC Code Cases Supplement 6Document34 pagesBPVC Code Cases Supplement 6cilgin cobanNo ratings yet

- F1216 PDFDocument7 pagesF1216 PDFFengki AdaroNo ratings yet

- Astm A106 1999Document13 pagesAstm A106 1999Rolando CastilloNo ratings yet

- Document Centre 440 & 432 & 425Document6 pagesDocument Centre 440 & 432 & 425dian riantiNo ratings yet

- ASTM B363-06a PDFDocument4 pagesASTM B363-06a PDFScribdNo ratings yet

- Astm A1014Document3 pagesAstm A1014Shunmugavel KarpagamNo ratings yet

- Astm D2517 (2000)Document5 pagesAstm D2517 (2000)SANKARAN.KNo ratings yet

- Sfa-5.7Document10 pagesSfa-5.7vannie_yundaNo ratings yet

- ASTM A197 - A 197M - 00 (ReA Pproved 2011)Document4 pagesASTM A197 - A 197M - 00 (ReA Pproved 2011)Heri KurniawanNo ratings yet

- Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationDocument4 pagesPipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationsaerinNo ratings yet

- TH11 - High Temp Expansion Joints Part 1Document7 pagesTH11 - High Temp Expansion Joints Part 1klich77No ratings yet

- SB 111-SB 111MDocument14 pagesSB 111-SB 111MRoberto Faustino FaustinoNo ratings yet

- Astm D2996 17Document4 pagesAstm D2996 17Zakaria MOKARAMNo ratings yet

- ASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceDocument16 pagesASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceKok WaiNo ratings yet

- API Specification 6D 24th Edition Errata 10 20210803Document1 pageAPI Specification 6D 24th Edition Errata 10 20210803ANANDNo ratings yet

- Estimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingDocument3 pagesEstimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingNilton Santillan100% (1)

- Astm A358 PDFDocument3 pagesAstm A358 PDFgaminNo ratings yet

- ASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument18 pagesASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stockfininho555No ratings yet

- C592 13Document9 pagesC592 13Ichwan Ciptadi100% (1)

- ASME BPVC 2021 Section IXDocument6 pagesASME BPVC 2021 Section IXSwarup mishraNo ratings yet

- V B01B0005B-15GB PDFDocument20 pagesV B01B0005B-15GB PDFनिपुण कुमारNo ratings yet

- Asme Section Ii B SB-42Document10 pagesAsme Section Ii B SB-42Monica SuarezNo ratings yet

- Astm 194-2017 PDFDocument13 pagesAstm 194-2017 PDFThiago CurvoNo ratings yet

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNo ratings yet

- Equivalent Valve Forged CastDocument2 pagesEquivalent Valve Forged CastMuthu Kumar RNo ratings yet

- Stainless Steel Grade 304 (UNS S30400)Document4 pagesStainless Steel Grade 304 (UNS S30400)105034412No ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- Astm C547Document7 pagesAstm C547DilaFirizqinaNo ratings yet

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Astm D2239-12-Tubo Plástico Pe (Sidr-Pr)Document7 pagesAstm D2239-12-Tubo Plástico Pe (Sidr-Pr)Marlon TurnerNo ratings yet

- Jis G3466Document9 pagesJis G3466魏雨辰No ratings yet

- A494Document7 pagesA494carlos ruizNo ratings yet

- Astm G39-99-2021Document8 pagesAstm G39-99-2021hashem Al-NasserNo ratings yet

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDocument6 pagesSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesPrad1979No ratings yet

- Polyethylene of Raised Temperature (PE-RT) SDR 9 Tubing: Standard Specification ForDocument7 pagesPolyethylene of Raised Temperature (PE-RT) SDR 9 Tubing: Standard Specification Forastewayb_964354182No ratings yet

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNo ratings yet

- Siteweb900x PDFDocument5 pagesSiteweb900x PDFОлег НикулинNo ratings yet

- Valves: Guidelines On Terminology For and FittingsDocument30 pagesValves: Guidelines On Terminology For and FittingsNatalyaNo ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- A 965/A 965M - 06a Standard Specification For Steel Forgings, Austenitic, For Pressure and High Temperature Parts1Document7 pagesA 965/A 965M - 06a Standard Specification For Steel Forgings, Austenitic, For Pressure and High Temperature Parts1Ivan Iglesias MartinezNo ratings yet

- Astm A 515Document5 pagesAstm A 515rameshdatta100% (1)

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceAyoun Ul HaqueNo ratings yet

- Sa 612Document5 pagesSa 612Luis MuñozNo ratings yet

- Asme Section II A-2 Sa-455 Sa-455mDocument4 pagesAsme Section II A-2 Sa-455 Sa-455mAnonymous GhPzn1xNo ratings yet

- Numerical Simulation To Predict Cavitation Inside Diesel Engine Fuel Injector NozzleDocument4 pagesNumerical Simulation To Predict Cavitation Inside Diesel Engine Fuel Injector NozzleBKONo ratings yet

- Quantum University, Roorkee School of Technology: Strength of Materials Lab ManualDocument20 pagesQuantum University, Roorkee School of Technology: Strength of Materials Lab ManualVikash SundriyalNo ratings yet

- Solid SolutionsDocument42 pagesSolid SolutionsrkaruppasamyNo ratings yet

- Prof. Francisco 2010Document5 pagesProf. Francisco 2010Cirilo SantosNo ratings yet

- Document 5Document1 pageDocument 5leoNo ratings yet

- Permeability Determination-2Document37 pagesPermeability Determination-2Naufal FadhlurachmanNo ratings yet

- Inclusions in SteelsDocument31 pagesInclusions in SteelsJatin BangaliNo ratings yet

- Leader in Superabrasive Finishing Systems: Pad Applications We Offer A Full Line of Hyprez® ProductsDocument2 pagesLeader in Superabrasive Finishing Systems: Pad Applications We Offer A Full Line of Hyprez® Productsarmin heidariNo ratings yet

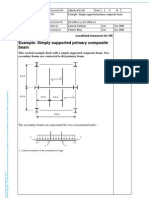

- Example: Simply Supported Primary Composite BeamDocument17 pagesExample: Simply Supported Primary Composite BeamAndrás BurkhardtNo ratings yet

- University of MauritiusDocument8 pagesUniversity of MauritiusKeshav GopaulNo ratings yet

- Is 513 PDFDocument13 pagesIs 513 PDFManeesh Bangale100% (5)

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153Document2 pagesAalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153a1528347No ratings yet

- Lifting Lug AnalysisDocument8 pagesLifting Lug AnalysisTrishul Nath PallayNo ratings yet

- Ductile IronDocument159 pagesDuctile IronPrabhakar KattulaNo ratings yet

- Wire Ropes Data Book PgsDocument6 pagesWire Ropes Data Book Pgssiddharth Gautam100% (2)

- GT 41080 18VV X.X QDocument12 pagesGT 41080 18VV X.X QGiorgio De RossiNo ratings yet

- Optical CommunicationDocument29 pagesOptical Communication9921005047No ratings yet

- 02 - Derivation of Diffusivity Equation - Liquid CartesianDocument5 pages02 - Derivation of Diffusivity Equation - Liquid CartesianHassan AmerNo ratings yet

- ... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak TestDocument5 pages... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak Testmahesh100% (1)

- Alubond Tech - Brochure PDFDocument8 pagesAlubond Tech - Brochure PDFLjubisa TopicNo ratings yet

- 132 KV HANSI-ModelDocument1 page132 KV HANSI-ModelShariq KhanNo ratings yet

- Strength SDocument7 pagesStrength Sabdi dejeneNo ratings yet

- Appraising Stone Column Settlement Prediction Methods Using Finite Element AnalysesDocument20 pagesAppraising Stone Column Settlement Prediction Methods Using Finite Element AnalysesZOUABINo ratings yet

- ADocument5 pagesAKrishna DheerajNo ratings yet

- CEI Extraction of Boundary Layer Characteristics From Fluent ResultsDocument30 pagesCEI Extraction of Boundary Layer Characteristics From Fluent ResultspopodaNo ratings yet

- How Solar Cells Convert Sunlight Into ElectricityDocument4 pagesHow Solar Cells Convert Sunlight Into Electricityapi-434997630No ratings yet

- HMT Unit-1 PDFDocument3 pagesHMT Unit-1 PDFAnkita MishraNo ratings yet