Art - 'S TEMA Designations

Art - 'S TEMA Designations

Uploaded by

muhammad_asim_10Copyright:

Available Formats

Art - 'S TEMA Designations

Art - 'S TEMA Designations

Uploaded by

muhammad_asim_10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Art - 'S TEMA Designations

Art - 'S TEMA Designations

Uploaded by

muhammad_asim_10Copyright:

Available Formats

Art Montemayor

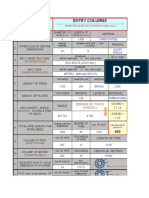

DESIGNACIONES TEMA

Front End Stationary Head Shell Type

September 30, 2005 Rev: 0

Rear End Stationary Head

Channel and removable cover

One-pass shell

Fixed tubesheet; like "A" Stationary head.

Bonnet (Integral Cover)

2-pass shell with longitudinal baffle

Fixed tubesheet; like "B"

stationary head.

C Channel integral with tubesheet

& removable cover. Shown: Removable Tube Bundle

Split Flow Shell

Fixed tubesheet; like "C" stationary head.

N Channel integral with tubesheet

& removable cover.

Double split flow

Outside, packed floating head

Special, high-pressure closure

Divided shell flow

Floating head with backing device (split-ring)

Page 1 of 4

FileName: 139904612.xls.ms_office WorkSheet: Designaciones TEMA

Art Montemayor

September 30, 2005 Rev: 0

K

Other popular rear end head types employed:

Kettle type of reboiler

Pull-through floating head

U-tube bundle design

W Packed floating tubesheet with

lantern ring

Some examples of the TEMA designation for Heat Exchangers are shown below:

BEM

Front bonnet (Intergral Cover), with one-Pass Shell and a Fixed Tubesheet rear Bonnet

Fixed tubesheet heat exchanger. This is a very popular version as the heads can be removed to clean the inside of the tubes. The front head piping must be unbolted to allow the removal of the front head, if this is undesired this can be avoided by applying a type A front head. In that case only the cover needs to be removed. It is not possible to clean the outside surface of the tubes as these are fixed inside the shell. Chemical cleaning can be used in the shell side. Shown is a version with one shell pass and two tube passes. This is probably the least expensive of the shell-and-tube designs.

Page 2 of 4

FileName: 139904612.xls.ms_office WorkSheet: Designaciones TEMA

Art Montemayor

September 30, 2005 Rev: 0

BEM

This is the same type of heat exchanger as shown above, except it has but with one tube pass

AEM

Channel with Removable Cover, One Pass Shell, Fixed Tubesheet Bonnet

This is almost the same type of heat exchanger as the first BEM, the removable cover allows the inside of the tubes to be inspected and cleaned without unbolting the piping. However, as can be expected, the tradeoff is that this convenient feature makes it more expensive.

The maintenance feature of having a removable tube bundles requires an exchanger as the following:

AES

Channel and Removable Cover, One Pass Shell, Floating Head with Backing Device

A floating head heat exchanger is excellent for applications where the difference in temperature between the hot and cold fluid causes unacceptable stresses, in the axial direction, between the shell and tubes. The floating head can move, i.e. it provides the ability to allow tube expansion in the axial direction. Note that the bundle can not be pulled from the front end. For maintenance both the front and rear end head, including the backing device, must be disassembled. If pulling from the front head is required a type AET should be selected. However, it is wise and prudent to be aware of the inherent trade-offs in this design. Note that the tube-side fluid can leak through the internal floating head cover gasket and mix (or contaminate) the shell-side fluid. It is very difficult -and sometimes impossible to mitigate or compensate for the internal bolts tightening the internal bonnet to remain under constant, steady torque. Hot fluid temperatures make the bolts expand and the result is a reduction in bolt torque and subsequent leaks through the bonnet gasket. Additionally, it is a common and expected occurance for maintenance crews to find the internal bolts badly rusted or corroded to the point where they have to be burned or sawed off in order to extract the "removable" tube bundle. The chemical engineer has other options to apply when requiring mechanical expansion of a heat exchanger tube bundle. Various rear head design also exist that allow for tube bundle expansion. Among these are the popular (and inexpensive) "U" tube bundle design. A "P" and "W" rear head design will also contribute this feature without the hazard of internal mixing (or contamination) of the two fluids.

FileName: 139904612.xls.ms_office WorkSheet: Designaciones TEMA

Page 3 of 4

Art Montemayor

Also, be aware that any TEMA shell and tube design with a removable tube bundle feature has - by nature - a larger shell diameter (& increased cost) due to the need to be able to pull the rear tubesheet the length of the exchanger's shell. A larger diameter shell can sometimes also present problems in a lower Reynolds number (yielding a lower heat transfer) and internal by-passing of the shell fluid around the baffles (this also reduces the effective heat transferred. All these effects eventually lead to a bigger heat exchanger (more area and more tubes) in order to do a heat transfer operation.

September 30, 2005 Rev: 0

Longitudinal Baffles - their application and inherent problems

The employment of longitudinal baffles in heat exchangers - such as the "F", "G", and "H" shell types - can often resolve both heat transfer and fluid flow problems within the shell and tube exchanger used. Their application can significantly increase the shell-side Reynolds Number and lead to more efficient shell-side heat transfer coefficients with a subsequent increase in heat transfer. Additionally, these type of baffles permit the engineer to incorporate counter-flow heat transfer. True counter-current heat transfer is as efficient a heat transfer configuration as an engineer can obtain. In some heat recovery applications, this is highly sought. By splitting the shell-side flow, some applications can actually have a significant reduction in shell-side pressure drop. This is especially true in partial vacuum process operations where a minimum of pressure drop can be tolerated. However, the application of longitudinal baffles should be always carefully scrutinized and used sparingly. There are, as would be expected, some very important trade-offs involved in the application of longitudinal baffles. Firstly, if a longitudinal baffle is a process necessity, the baffle should be seal-welded against the inner shell wall in order to ensure that there will be no internal, by-pass leakage. This positive step negates the possibility of having a removable tube bundle. Additionally, the welding necessity requires a minimum shell diameter and this winds up being applicable only to relatively large streams. By the basic need to establish effective shell-side flow around a longitudinal baffle, one has to accept the obvious fact that a minimum of shell-side clearances can be tolerated. Once having said and applied these facts, one then has to also accept that the required, small baffle clearances mean extraordinary fabrication techniques and resultant super-human maintenance efforts to extract a removable tube bundle. In far too many actual field cases, it has been found that the removable tube bundle with a longitudinal baffle is a non-practical device. Field results have shown that in most cases the tube bundle has resulted in being destroyed in order to remove it. This extraordinary and desperate maintenance act labels such a design as non-practical.

Page 4 of 4

FileName: 139904612.xls.ms_office WorkSheet: Designaciones TEMA

You might also like

- Chapter 4 - Aircraft GalleyDocument40 pagesChapter 4 - Aircraft GalleyDamon Leong71% (7)

- Heat ExchangerDocument420 pagesHeat ExchangerRavindra S. Jivani75% (4)

- TEMA Shell & Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell & Bundle Entrance and Exit Areasnagtummala100% (3)

- AW 450 KwicknotesDocument36 pagesAW 450 KwicknotesNuman2100% (6)

- Exchanger DesignDocument17 pagesExchanger DesignRamesh mudunuriNo ratings yet

- Separator Sizing SpreadsheetDocument10 pagesSeparator Sizing SpreadsheetEmmanuel ByensitaNo ratings yet

- Exchangers: Repairing Cracks in Refinery HeatDocument4 pagesExchangers: Repairing Cracks in Refinery Heatramadoss_alwar7307No ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic Levelsudoku100% (1)

- Refinery Process ChartDocument16 pagesRefinery Process ChartUsman AshrafNo ratings yet

- Mechanical Design of Shell and TubeDocument21 pagesMechanical Design of Shell and TubeMahesh ewRRpuqQrcNo ratings yet

- Fractionation Column CalcDocument20 pagesFractionation Column CalcCHANADASNo ratings yet

- Catastrophicheatexchangerfailures Handout1Document18 pagesCatastrophicheatexchangerfailures Handout1edgardiaz5519No ratings yet

- Hair Pin Heat Exchanger - BaherDocument11 pagesHair Pin Heat Exchanger - BahersbmmlaNo ratings yet

- Surface AreaDocument10 pagesSurface AreasudjonoNo ratings yet

- 14 Shell & Tube ExchangerDocument9 pages14 Shell & Tube ExchangerEdwin AldrinNo ratings yet

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDocument5 pagesFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakNo ratings yet

- Heat Exchanger Data SheetDocument1 pageHeat Exchanger Data SheetomarcastillogalindoNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- Fired HeatersDocument17 pagesFired Heaterssteepa22100% (1)

- التكسر لاستيل 304 في المبادلاتDocument11 pagesالتكسر لاستيل 304 في المبادلاتFarouq AliNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)ramesh pokhrelNo ratings yet

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Chapter 2 FiretubeDocument18 pagesChapter 2 FiretubeWael Abdel-MageedNo ratings yet

- Perforated Plate 8Document9 pagesPerforated Plate 8Milind Kshirsagar100% (1)

- Revised PPT SG HXDocument44 pagesRevised PPT SG HXskgbondNo ratings yet

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis Vino100% (1)

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- C06 006 Process Calculation (02V 6010) RevEDocument6 pagesC06 006 Process Calculation (02V 6010) RevEAlphaEcc EngineeringTeamNo ratings yet

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Industrial Electric HeatersDocument12 pagesIndustrial Electric Heatersmayukhguha88No ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Presentationlu 180126221936 PDFDocument20 pagesPresentationlu 180126221936 PDFhaptoorNo ratings yet

- Heat Excganger Detail DesignDocument45 pagesHeat Excganger Detail Designoverlord5555No ratings yet

- Pressure Vessel Design Excel Sheet Basic Designing Non Critical PDocument1 pagePressure Vessel Design Excel Sheet Basic Designing Non Critical PKaramYassNo ratings yet

- Process Heat TransferDocument327 pagesProcess Heat TransferMartin ZaballaNo ratings yet

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocument8 pages503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14No ratings yet

- Summary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDocument41 pagesSummary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDHAVAL PANCHALNo ratings yet

- Api 571-1Document11 pagesApi 571-1alkhiat100% (2)

- An Introduction To fouGBPing in Fired Heaters Part 2Document7 pagesAn Introduction To fouGBPing in Fired Heaters Part 2oswaldoNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Hydrogen Crack 1Document17 pagesHydrogen Crack 1muraliNo ratings yet

- Wall ThicknessDocument6 pagesWall ThicknessKrishant Krishant KrishantNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Validated SheetDocument12 pagesValidated SheetrohitkushNo ratings yet

- The Optimal Engineering Design For Natural Gas Dehydration Process by TEGDocument5 pagesThe Optimal Engineering Design For Natural Gas Dehydration Process by TEGijsretNo ratings yet

- Plate and Frame Heat Exchanger IOMDocument28 pagesPlate and Frame Heat Exchanger IOMFlorian_AngererNo ratings yet

- Grand Prix Engg.: Tag No. 90-EH-02Document6 pagesGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNo ratings yet

- Api 571-1Document11 pagesApi 571-1Raghavan100% (1)

- PipingDocument54 pagesPipingakhilsyam21No ratings yet

- Excel Work Book For Heat ExchangersDocument88 pagesExcel Work Book For Heat ExchangersHedi temimiNo ratings yet

- ASME BPVC VIII MinT CalculationsDocument2 pagesASME BPVC VIII MinT CalculationsSbuZikalalaNo ratings yet

- Vessels Internals 2008 05 TFMDocument20 pagesVessels Internals 2008 05 TFMjannick86100% (1)

- Working Principle of Shell and Tube Heat ExchangerDocument8 pagesWorking Principle of Shell and Tube Heat ExchangersanjayNo ratings yet

- Overview of Heat Exchanger Design-R5Document59 pagesOverview of Heat Exchanger Design-R5soubhadra nagNo ratings yet

- Separator All Oil and Gas SpreadsheetDocument22 pagesSeparator All Oil and Gas SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- 41-187.0 Natural Gas Processing 0Document12 pages41-187.0 Natural Gas Processing 0Thameem AnsariNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- Binoy's Engg DatasDocument29 pagesBinoy's Engg DatasSreejith GNo ratings yet

- 05_TEMA DesignationsDocument9 pages05_TEMA DesignationsNice OrioleNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- ExchangerDocument17 pagesExchangerJulio Adolfo López PortocarreroNo ratings yet

- Introduction To Process Safety PrinciplesDocument9 pagesIntroduction To Process Safety Principlesmuhammad_asim_10No ratings yet

- Gipp T Safety AuditDocument45 pagesGipp T Safety Auditmuhammad_asim_10No ratings yet

- Piping Design InfoDocument278 pagesPiping Design Infontrkulja@hotmail.comNo ratings yet

- Flammable and Combustible LiquidsDocument23 pagesFlammable and Combustible Liquidsmuhammad_asim_10No ratings yet

- A Refresher On Pump Cavitation and NPSHDocument10 pagesA Refresher On Pump Cavitation and NPSHmuhammad_asim_10No ratings yet

- Flash PointDocument30 pagesFlash PointAdel SukerNo ratings yet

- Spherical TanksDocument2 pagesSpherical Tanksmuhammad_asim_10No ratings yet

- Slug CatcherDocument16 pagesSlug Catchermuhammad_asim_10No ratings yet

- 1 GuestDocument14 pages1 Guestmuhammad_asim_10No ratings yet

- Pressure Relief Safety ValvesDocument52 pagesPressure Relief Safety Valveswah_ma100% (4)

- Open Ended LabDocument13 pagesOpen Ended Labharis shahNo ratings yet

- Lecture 7 - CIE 551 - Part 1Document19 pagesLecture 7 - CIE 551 - Part 1Emmanuel MwabaNo ratings yet

- Arduino TutorialDocument2 pagesArduino TutorialxxxNo ratings yet

- Me Lab 6Document9 pagesMe Lab 6BensoyNo ratings yet

- Perkins Systems Operation Testing and Adjusting 1106d Industrial EngineDocument8 pagesPerkins Systems Operation Testing and Adjusting 1106d Industrial Enginecarolyn100% (60)

- Service Training: 793D (FDB) Off-Highway TrucksDocument52 pagesService Training: 793D (FDB) Off-Highway TrucksRolando Taco Chise100% (1)

- Cementing Best PracticesDocument11 pagesCementing Best PracticesdanielmcaeNo ratings yet

- Pump Clinic 38Document4 pagesPump Clinic 38fnahas_bhNo ratings yet

- A4 Exam Answer May 2012Document13 pagesA4 Exam Answer May 2012egi100% (1)

- Ch17 Young Freedman2Document14 pagesCh17 Young Freedman2Andrew MerrillNo ratings yet

- JRC200 RC Drilling RigDocument4 pagesJRC200 RC Drilling Righamed ShNo ratings yet

- Ze Fgl16b16-Eng PDFDocument16 pagesZe Fgl16b16-Eng PDFjavivi_75No ratings yet

- Form Service Activity 2020 DraegerDocument57 pagesForm Service Activity 2020 DraegerRenaoval AchillesNo ratings yet

- Stuewe 201708 Catalogue Type-HsdDocument25 pagesStuewe 201708 Catalogue Type-HsdJorge A VilalNo ratings yet

- Design of Airport PavementsDocument23 pagesDesign of Airport PavementsArpita SaxenaNo ratings yet

- PT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Document19 pagesPT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Faturachman Reza100% (1)

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumNo ratings yet

- Intorq Bfk457: Setting The StandardDocument40 pagesIntorq Bfk457: Setting The StandardElton Rodrigues de BritoNo ratings yet

- WISON-APB-1000: Creating Tools That Move Your Business Creating Tools That Move Your BusinessDocument2 pagesWISON-APB-1000: Creating Tools That Move Your Business Creating Tools That Move Your BusinessCarlos MolinaNo ratings yet

- Lecture DC MachinesDocument40 pagesLecture DC MachinesPrathap VuyyuruNo ratings yet

- Autonomous Systems Tutorial 2Document11 pagesAutonomous Systems Tutorial 2Khaled ZakiNo ratings yet

- Application GuideDocument4 pagesApplication GuideBruno MarianoNo ratings yet

- CHEM1120 - ProjectDocument1 pageCHEM1120 - ProjectcemaliNo ratings yet

- Trial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Document3 pagesTrial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Aek JanNo ratings yet

- Mechanical Engineering Objective DS Handa - by EasyEngineering - Net-01 PDFDocument534 pagesMechanical Engineering Objective DS Handa - by EasyEngineering - Net-01 PDFNithin Basava100% (3)

- Integral Motor IOM ManualDocument8 pagesIntegral Motor IOM ManualE.E. / Mayurakshi E & M Division, SuriNo ratings yet

- Centurion EngineDocument132 pagesCenturion EngineMoncef Abd Elaziz DrifNo ratings yet

- Partsbook Reece 101Document103 pagesPartsbook Reece 101Maskusyani100% (2)