100%(3)100% found this document useful (3 votes)

2008 7 8

Uploaded by

Peps RenIn this issue of GEARS, we'll take one apart, and see what really makes this unit work. The only way to reach any of the internal components is by first removing the pump assembly. Right behind the pump is the front planetary and three sets of clutches.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

2008 7 8

Uploaded by

Peps Ren100%(3)100% found this document useful (3 votes)

In this issue of GEARS, we'll take one apart, and see what really makes this unit work. The only way to reach any of the internal components is by first removing the pump assembly. Right behind the pump is the front planetary and three sets of clutches.

Original Title

2008_7_8

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

In this issue of GEARS, we'll take one apart, and see what really makes this unit work. The only way to reach any of the internal components is by first removing the pump assembly. Right behind the pump is the front planetary and three sets of clutches.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(3)100% found this document useful (3 votes)

2008 7 8

Uploaded by

Peps RenIn this issue of GEARS, we'll take one apart, and see what really makes this unit work. The only way to reach any of the internal components is by first removing the pump assembly. Right behind the pump is the front planetary and three sets of clutches.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 8

GEARSJuly200

A Look Inside the 6-Speed Volkswagen Automatic; Part 2

by David Skora

A Look Insi de

the 6-Speed

Vol kswagen

Automati c; PArt 2

I

n the last issue of GEARS we went

over the theory of VWs 09G and

09M 6-speed automatic transmis-

sion. In this issue, well take one apart,

and see what really makes this unit

work.

Start by removing the external sen-

sors, switches and oil cooler. Since this

is probably your first time with one of

these units, mark the wiring connec-

tors and solenoids before removing the

valve body. That way youll be sure to

get it back together properly.

After splitting the case, all youll

see is part of the differential and the

front of the pump assembly; the rest of

the transmission is still mounted inside

the main part of the case. The only way

to reach any of the internal components

is by first removing the pump. As soon

as you have the pump removed, notice

that the stator is splined to the sun gear

in the front planetary. This is typical

for units with the Leppeletier planetary

design.

Right behind the pump is the front

planetary and three sets of clutches.

The K3 is on top; its applied in 3

rd

,

5

th

and Reverse (Figure 1). The next

clutch is the K1, which is applied in 1

st

through 4

th

. The third clutch is the B1;

its on for 2

nd

and 6

th

gears. Some of

these clutches including the drums,

B1 return spring cage, and planetary

must be tilted to work them free of

Figure 1

Figure 2

GEARS July 2008

the differential gear.

The B1 clutch drum is secured to

the center support: Instead of splining

it to the case, they used a simple snap

ring to lock several tabs down into

detents machined into the sprag sup-

port. After removing the snap ring, tilt

the B1 clutch assembly and take it out.

Now you can remove the differential

and intermediate (transfer) gears.

With the B1 support shell removed,

bend back the locking tabs on the bolts

that hold the center support in the case.

Pry up on the center support until you

can grab onto it. The sprag and center

support will come out together.

Next, reach in and pull out the

Ravigneaux planetary assembly.

Typically the sun gear will stay behind;

youll see it sitting on the K2 drum.

Grab the output shaft and remove the

K2 clutch drum assembly with sun

gear. The K2 clutch is applied for 4

th

through 6

th

gear.

The only clutch left is the B2,

which applies for reverse and engine

braking in manual 1. The apply piston

Figure 3

Figure 4

10 GEARSJuly2008

A Look Inside the 6-Speed Volkswagen Automatic; Part 2

Figure 5

for the B2 clutch is the last piece you

can remove, by carefully applying air

pressure from the valve body side of

the case.

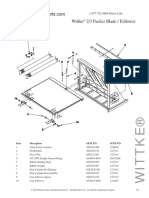

Look over the clutches assemblies

and planetaries. All clutch packs appear

very common. The exploded views of

the clutches and gear assemblies might

help you put one back together if you

get a transmission in a box (Figures

2 to 5).

Here are the most productive steps

for reassembling the unit.

Install the B2 piston and return

spring assembly into the case.

Install the B2 clutches and the

K2 clutch-and-drum assembly

(Figure 6).

Install the sun gear shaft (not

shown).

Install the Ravigneaux plan-

etary assembly without the

sprag. Rocking the assembly

should help align all the fric-

tion plates.

Install L/R sprag with the

plastic washer with double

rows of grooves facing up

(Figure 7).

Figure 6

Figure 7

Install the B2 clutches

and the K2 clutch-and-

drum assembly

(Figure 6).

Install L/R sprag with

the plastic washer with

double rows of grooves

facing up (Figure 7).

Randy says: I have discovered a new respect for every clutch, steel

and electronic component Raybestos produces. There is an incredible

sense of pride and confidence everywhere within Raybestos.

My congratulations to a fantastic company of dedicated folks who

make the Made in the USA label the most powerful on the planet.

Electronic Components Benefits

Sensors: Superior reliability

and durability compared to

off-shore and OE; eliminate

limp mode comebacks

Solenoids: Corrosion resistant

and durable under the most

severe operating conditions;

reduce risk of solenoid failure

964 East Market St., Crawfordsville, IN 47933 Toll Free: 800-729-7763 Fax: 765-364-4576 Email: raypt@raybestospowertrain.com

RAYbestos plcd508.indd 19 5/1/08 10:13:51 AM

12 GEARSJuly2008

A Look Inside the 6-Speed Volkswagen Automatic; Part 2

IMPORTANT: The planet must

rotate counterclockwise when

installed.

Install the center support and

tighten the bolts (Figure 8 and

9).

Install the intermediate (trans-

fer) gear and differential as an

assembly into case followed

by the B1 clutch with drum

onto sprag support and secure

it with the snap ring (Figure

10).

Install the K1 clutches and

steels plus the cushion dish

plate (facing down) on top of

the clutch stack (Figure 11).

Install the intermediate

(transfer) gear and

differential as an

assembly into case

followed by the B1

clutch with drum

onto sprag support

and secure it with the

snap ring.

Figure 10

Figure 8 Figure 9

Figure 11

T. 419.499.25O2 F. 419.499.28O4 www.TransTec.com Nilan, 0H 4484O

Mork and Mindy are long gone, along with $2.00

movie tickets and gas at 70 cents a gallon. But

TransTec

transmission kits have grown to become

the leading brand requested by transmission profes-

sionals. In fact, more TransTec

kits are installed than

all other kits combined.

Wed like to thank our customers, representatives,

suppliers and associates for their faithfulness and

support throughout the past 30 years.

These years have been very good to us. We cant

wait to see what the future holds.

A Division of Freudenberg-NOK

Mork & Mindy

was a good year.

1978

was aTVfavorite

70 cents a

gallon

Gas was

A movie ticket cost

$

2

TransTec

kits were introduced

14 GEARSJuly2008

A Look Inside the 6-Speed Volkswagen Automatic; Part 2

Installthedrivehub.

Install the K3 clutch pack,

which consist of 5 frictions

and5steels.

Rock the front planetary

assembly to install it into the

clutch packs until theres no

moreplay(Figure12).

Install the B1 apply/return

springassembly(Figure13).

Install the pump assembly

(Figure14).

Air-checktheclutches(Figure

15).

Thesearemeasuredspecifications,

andmaynotbetheactualOEMrecom-

mendedvalues.

After you have all the clutches

installed,performanairchecktomake

sureallclutchesaresealedproperly.

Thats all there is to it; not a par-

ticularly difficult transmission, once

you become familiar with its inner

workings. Special thanks to Whatever

It Takes for supplying the 09G trans-

mission used to research and take the

picturesforthisarticle.

Clutch Friction/Steel Inches mm

K1 5/5 0.050 1.27

K2 3/3 0.020 0.50

K3 3/3 0.015-0.018 0.38-0.45

B1 4/4 Plus cushion 0.020 0.50

B2 6/6 0.070 1.77

Input Shaft Endplay 0.003-0.010 0.08-0.25

Figure 12

Figure 14

Figure 13

Figure 15

COrrection

Cause

Smooth Apply & Control

COMPLAINT

TCC concerns, Engine stall upon engagement

SECONDARY COMPLAINTs Premature lockup Shuttle or loss of lockup Overheating Loss of cooler flow

Solve common TCC concerns with the

Sonnax TCC control valve and plunger assembly for the JF506E.

Automatic Drive P.O. Box 440

Bellows Falls, VT 05101-0440 USA

800-843-2600 802-463-9722 F: 802-463-4059

www.sonnax.com info@sonnax.com

2008 Sonnax Industries, Inc.

TI ME TESTED I NDUSTRY TRUSTED

TM

Visit www.sonnax.comfor more

information about all our products and

tools, and to locate a Sonnax Transmission

Specialties distributor near you.

Wear at the plunger sleeve due to

continuous oscillation of the apply valve

allows premature lockup, overheating

and converter shuttle.

The replacement plunger assembly is

manufactured from highly wear-resistant

materials and restores proper hydraulic

clearance. The redesigned control valve

prevents premature lockup or shuttle.

TCC Control

Valve & Plunger

Assembly

122892-06K

1 Control Valve

1 Plunger Valve & Sleeve Assembly

1 Spring

1 Orifice Plug not shown

Note: This kit also services Jatco FP

series; Ford JF506E, PPH; Jaguar

JF506E, Rover JF506E, FPD; Mazda

JA5A-EL FPF1/FPF2; FPO; Nissan

ZY and VW 09A units.

Also Available:

122892-03K*

1 Oversized PR Valve Kit

122892-10K*

1 TC PR Valve & Sleeve Kit

122892-01K

1 TCC Control Plunger Valve Assy

Note: The 122892-01K is a direct OEM

replacement and cannot be used with

Sonnax modified 122892-06K.

* Tools required

JF506E

Drop-in-place kit requires

no tooling! Provides

short and firmer apply.

TCC Plunger Valve

& Sleeve Assembly

TCC Control Valve

Spring

The OEM design of the control valve enables smooth apply and control of exhaust

release oil. However, if there is any converter or cooler restriction, converter feed is

reduced, which allows the valve to stroke prior to lockup command. This can be

aggravated by wear at the plunger valve sleeve, allowing the oil pressure needed to hold

the control valve in the release position to exhaust instead. The Sonnax assembly

includes a redesigned control valve and plunger valve assembly to prevent premature

TCC apply. The controlled release exhaust reaction spool has been eliminated from

the Sonnax control valve. The plunger valve sleeve has been extended to aid in sealing

this circuit. An orifice plug is included to block the controlled release circuit. These

changes prevent the control valve from stroking prior to lockup command and are

designed to result in a short and firmer TCC apply.

Features & Benefits

Newly designed valve components prevent premature TCC apply.

Parts are been made from highly wear-resistant aluminum materials.

Hard-anodized aluminum valve replaces steel OEM version for better hydraulic clearance

control as fluid temperature changes.

New plunger valve assembly restores proper hydraulic clearances.

A new spring is provided to restore proper holding forces with the newly designed parts.

Salvages castings with wear at the large TCC control valve spool.

Valve Body

TDIFCAD-06-08 5/9/08 11:40 AM Page 1

You might also like

- Critical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-Shift Shown Here100% (1)Critical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-Shift Shown Here4 pages

- AW 6 Speeds: Valve Body Diagnosis: From The SonnaxNo ratings yetAW 6 Speeds: Valve Body Diagnosis: From The Sonnax7 pages

- Technical Bulletin Listing: Transmission # # Pages SubjectNo ratings yetTechnical Bulletin Listing: Transmission # # Pages Subject17 pages

- Diagnostico y Overhaul A41 A40d Toyota TransmisionNo ratings yetDiagnostico y Overhaul A41 A40d Toyota Transmision66 pages

- 307-01 Automatic Transmission 10 Speed - Description and Operation - C Clutch100% (1)307-01 Automatic Transmission 10 Speed - Description and Operation - C Clutch6 pages

- Welcome To Today's Presentation Sponsored byNo ratings yetWelcome To Today's Presentation Sponsored by47 pages

- CUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFNo ratings yetCUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDF403 pages

- Technical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMNo ratings yetTechnical Bulletin #867: A/T Harsh 3-2 Downshift - New TCM3 pages

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFNo ratings yetVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDF68 pages

- Technical Service Information: Automatic Transmission Service Group100% (2)Technical Service Information: Automatic Transmission Service Group2 pages

- A Closer Look at The Toyota A750E Valve Body PDFNo ratings yetA Closer Look at The Toyota A750E Valve Body PDF68 pages

- 6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA Presenter100% (2)6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA Presenter42 pages

- 01J Clutch Clearances: Technical Information BulletinNo ratings yet01J Clutch Clearances: Technical Information Bulletin1 page

- WS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USANo ratings yetWS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USA11 pages

- Every Second One in The World Drives Automatic!100% (1)Every Second One in The World Drives Automatic!54 pages

- Discovering the Toyota Prius Hybrid: Your Easy Guide to Eco-Friendly DrivingFrom EverandDiscovering the Toyota Prius Hybrid: Your Easy Guide to Eco-Friendly DrivingNo ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- 43 Aisin Warner 4 AF40 TF80SC AF21 TF81SC Was Ford 4c100% (4)43 Aisin Warner 4 AF40 TF80SC AF21 TF81SC Was Ford 4c8 pages

- Formulir Izin Kerja / Permit To Work: A. Potensi Bahaya / Potential HazardNo ratings yetFormulir Izin Kerja / Permit To Work: A. Potensi Bahaya / Potential Hazard4 pages

- WITTKE - Street Smart Parts-Packer BladeNo ratings yetWITTKE - Street Smart Parts-Packer Blade10 pages

- S1D - Drive Shaft Planet Gear Cardan Water Syst.No ratings yetS1D - Drive Shaft Planet Gear Cardan Water Syst.124 pages

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonNo ratings yet1,322,227. L - Y Patented Nov. 18, Í919.: F. F. Burton7 pages

- Operating and Maintenance Manual: For RKS Plunger ValveNo ratings yetOperating and Maintenance Manual: For RKS Plunger Valve9 pages

- Actuator Instruction Manual - RCEL006-009No ratings yetActuator Instruction Manual - RCEL006-0092 pages

- Demonstrate Communication Skills Level 5No ratings yetDemonstrate Communication Skills Level 57 pages

- Caterpillar Lift Trucks MCFE 2011 SAMPLENo ratings yetCaterpillar Lift Trucks MCFE 2011 SAMPLE11 pages

- GM 6L80 Transmissions: How to Rebuild & ModifyFrom EverandGM 6L80 Transmissions: How to Rebuild & Modify

- Critical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-Shift Shown HereCritical Wear Areas & Vacuum Test Locations: Lower Valve Body - Jaguar ZF6HP26, M-Shift Shown Here

- AW 6 Speeds: Valve Body Diagnosis: From The SonnaxAW 6 Speeds: Valve Body Diagnosis: From The Sonnax

- Technical Bulletin Listing: Transmission # # Pages SubjectTechnical Bulletin Listing: Transmission # # Pages Subject

- Diagnostico y Overhaul A41 A40d Toyota TransmisionDiagnostico y Overhaul A41 A40d Toyota Transmision

- 307-01 Automatic Transmission 10 Speed - Description and Operation - C Clutch307-01 Automatic Transmission 10 Speed - Description and Operation - C Clutch

- CUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFCUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDF

- Technical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMTechnical Bulletin #867: A/T Harsh 3-2 Downshift - New TCM

- Technical Service Information: Automatic Transmission Service GroupTechnical Service Information: Automatic Transmission Service Group

- 6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA Presenter6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA Presenter

- 01J Clutch Clearances: Technical Information Bulletin01J Clutch Clearances: Technical Information Bulletin

- WS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USAWS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USA

- Discovering the Toyota Prius Hybrid: Your Easy Guide to Eco-Friendly DrivingFrom EverandDiscovering the Toyota Prius Hybrid: Your Easy Guide to Eco-Friendly Driving

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity Vehicles

- 43 Aisin Warner 4 AF40 TF80SC AF21 TF81SC Was Ford 4c43 Aisin Warner 4 AF40 TF80SC AF21 TF81SC Was Ford 4c

- Formulir Izin Kerja / Permit To Work: A. Potensi Bahaya / Potential HazardFormulir Izin Kerja / Permit To Work: A. Potensi Bahaya / Potential Hazard

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. Burton1,322,227. L - Y Patented Nov. 18, Í919.: F. F. Burton

- Operating and Maintenance Manual: For RKS Plunger ValveOperating and Maintenance Manual: For RKS Plunger Valve