AVR Comparision

AVR Comparision

Uploaded by

Grupos GeradoresCopyright:

Available Formats

AVR Comparision

AVR Comparision

Uploaded by

Grupos GeradoresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

AVR Comparision

AVR Comparision

Uploaded by

Grupos GeradoresCopyright:

Available Formats

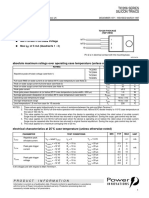

A V R COMPARISION CHART

SX 460 SX 440 SX 421 MX 341 MX 321

Used on m/cs from 30-200 KVA, UC frame machine.

Used on m/cs from 210-650 KVA, HC4 & HC5 frame machines.

Used on m/cs from 210-650 KVA HC4 & HC5 frame machines.

Used on m/cs from 30-650 KVA I.e. UC22,27 & HC4, HC5 frame m/cs with PMG as optional. 2 phase sensing. Terminal 7,8 sensing I/p from main stator & Power input from PMG to AVR. Power - Connect P2 , P3 from PMG to P2 , P3 of AVR respectively. Sensing - Connect 7 & 8 from main Stator to 3 & 2 of AVR respectively. AVR DC output X, XX OR F1 F2 to Exciter Stator ( I.e. +ve, - ve ).

Used on m/cs from 725 KVA & above I.e. HC6 & HC7 frame machines. 3 phase sensing terminals 6,7,8 from Isolation Transformer Secondary & power input from PMG. Power - Connect P2, P3, P4 from PMG to P2, P3, P4 of AVR respectively.

2 phase sensing. Terminal 7,8 from main stator are, Power & sensing input for AVR. Power - Connect 7 , 8 from main stator to 7 , 8 of AVR. Sensing - Connect 7, 8 from main stator to 7, 8 of AVR. AVR DC output X, XX OR F1 F2, to Exciter Stator ( I.e. +ve, - ve ) respectively. Used with SELF EXCITED, non PMG machine. Excitation Interruption link, K1, K2, not provided.

2 phase sensing. Terminal 7,8 sensing & power input from main stator of m/c to AVR. Power - Connect 7 & 8 from main stator to P3 & P2 of AVR. respectively. Sensing - Connect 7 & 8 from main stator to 3 & 2 of AVR respectively.

3 phase sensing. Terminals 6, 7,8 sensing & power input from main Stator of m/c to AVR. Power - Connect 6, 7, 8 from main Stator to P4, P3, P2 of AVR respectively. Sensing - Connect 6, 7, 8 from main stator to, 6, 7, 8 of AVR terminals respectively. AVR DC output X, XX OR F1 F2 to Exciter Stator ( I.e. +ve, - ve )

Sensing - Connect 6, 7, 8 from Isolation Transformer secondary to 6, 7, 8 of AVR respectively. AVR DC output X, XX OR F1 F2 to Exciter Stator ( I.e. +ve, - ve )

AVR DC output X, XX OR F1 F2 to Exciter Stator ( I.e. +ve, - ve ) Used with SELF EXCITED MACHINE WITHOUT PMG. Excitation interruption link K1, K2 provided. ( Always short externally )

Used with SELF EXCITED MACHINE WITHOUT PMG. Excitation interruption link K1, K2 NO EXTERNAL SHORT LINK. K1, K2 control thru B0, B1 coil supply control. During High excitation, coil at B0, B1 activates & opens link at K1 , K2 thus interrupts excitation.

Used with SEPARATELY EXCITED MACHINE WITH PMG. Excitation interruption link K1, K2 provided. ( Always short externally )

Used with SEPARATELY EXCITED MACHINE WITH PMG. Excitation interruption link K1, K2 NO EXTERNAL SHORT LINK. K1, K2 control thru B0, B1 coil supply control. During High excitation, coil at B0, B1 activates & opens link at K1 , K2 thus interrupts excitation. Stability selection Frame UC 22, HC 4,5 ( Under 90 KW ) - Link AC ( 90 KW to 550 KW ) - Link BC Frame UC 27, HC 6,7( Above 550 KW ) - Link AB. Frequency selection 4 Pole 50 HZ - LINK 4 Pole 60 HZ - LINK 6 Pole 50 HZ 6 Pole 60 HZ - LINK

Stability selection - N. A.

Stability selection Frame UC 22, HC 4,5 - Link BC ( 90 KW - 550 KW ) Frame UC 27, HC 6,7 - Link A,B ( Over 550 KW )

Stability selection Under 40 KW 40 KW - 90 KW 90 KW - 550 KW Over 550 KW

- Link B D - Link A C - Link B C - Link A B

Stability selection Frame UC 22, HC 4,5 - Link BC ( 90 KW - 550 KW ) Frame UC 27, HC 6,7 - Link A,B ( Over 550 KW )

Frequency selection 50 HZ - LINK C - 50. 60 HZ - LINK C - 60.

Frequency selection 50 HZ - LINK C - 50 60 HZ - LINK C - 60

Frequency selection 50 HZ - LINK C - 50 60 HZ - LINK C - 60

Frequency selection 4 Pole 50 HZ - LINK 4 Pole 60 HZ - LINK 6 Pole 50 HZ 6 Pole 60 HZ -

- 2 , 3. -1,3 - NO LINK - Link 1 , 2.

- 2 , 3. -1,3 - NO LINK - 1 , 2.

External Hand Trimmer for,REMOTE VOLTAGE ADJUSTMENT. No Trimmer - Link 1 , 2. For Trimmer - Remove Link at 1,2 & connect trimmer here. TRIMMER - 1 K Ohm / 1 Watt.

External Hand Trimmer for,REMOTE VOLTAGE ADJUSTMENT No Trimmer - Link 1 , 2. For Trimmer - Remove Link at 1 , 2 & connect Trimmer here. TRIMMER - 1 K Ohm / 1 Watt

External Hand Trimmer for,REMOTE VOLTAGE ADJUSTMENT No Trimmer - Link 1 , 2. For Trimmer - Remove Link at 1 , 2 & connect Trimmer here. TRIMMER - 1 K Ohm / 1 Watt

External Hand Trimmer REMOTE VOLTAGE ADJUSTMENT No Trimmer - Link 1 , 2. For Trimmer - Remove Link at 1 , 2 & connect Trimmer here. TRIMMER - 4.7 or 5 K Ohm / 1 Watt

External Hand Trimmer REMOTE VOLTAGE ADJUSTMENT No Trimmer - Link 1 , 2. For Trimmer - Remove Link at 1, 2 & connect Trimmer here. TRIMMER - 4.7 or 5 K Ohm / 1 Watt

AVR input selection 220 / 240 V input - No Link. High Voltage. 110 / 120 V input - Link 3 , 4. Low Voltage. For 415V output machine, NO LINK AT 3,4 IS REQUIRED. NOT SUITABLE FOR PARALLEL OPERATION.

AVR input selection Link 2 - 3, 4 - 5, 6 - 7 at AVR.

AVR input selection - N. A.

AVR input selection,Link 2 - 3, 4 - 5, 6 - 7 at AVR.

AVR input selection - N. A.

Terminals for Parallel Operation with Grid. Terminals A1, A2 used only in parallel operation with grid. Wires from Power Factor Controller need to be connected to A1, A2. NORMALLY KEEP OPEN. Parallel operation :S1 , S2 terminals of Droop CT provided at W phase of machine need to be connected at S1 , S2 terminals of AVR respectively. S1, S2 terminal of AVR are of Voltage Droop. Terminals A1, A2 used only in parallel operation with grid. Wires from Power Factor Controller need to be connected to A1, A2. NORMALLY KEEP OPEN. Parallel operation :S1 , S2 terminals of Droop CT provided at W phase of machine need to be connected at S1 , S2 terminals of AVR respectively. S1, S2 terminal of AVR are of Voltage Droop. Terminals A1, A2 used only in parallel operation with grid. Wires from Power Factor Controller need to be connected to A1, A2. NORMALLY KEEP OPEN. Parallel operation :S1 , S2 terminals of Droop CT provided at W phase of machine need to be connected at S1 , S2 terminals of AVR respectively. S1, S2 terminal of AVR are of Voltage Droop. ( S1 - S2 ) - U / ( S1 - S2 ) - V / ( S1 - S2 ) W & A1, A2

NORMALLY KEEP OPEN. Parallel operation :S1 , S2 terminals of Droop CT provided at W phase of machine need to be connected at S1 , S2 terminals of AVR respectively. S1, S2 terminal of AVR are of Voltage Droop.

Over Voltage Protection - N. A.

Over Voltage Protection - N. A.

Over Voltage Protection :Connect E0 , E1 of AVR to terminals 7 & 8 at Isolation Transformer.

Over Voltage Protection - N. A.

Over Voltage Protection :Connect E0 , E1 of AVR to terminals 7 & 8 at Isolation Transformer.

AVR SETTING POTS & ADJUSTMENT PROCEDURES. POTS RAMP AVR TYPE MX 321 PURPOSE To control time taken by generator to build up voltage from initial to rated.

STABILITY

SX 460 SX 440 SX 421 MX 341 MX 321

To prevent voltage hunting ( fluctuation ) I.e. to provide damping effect.

VOLTS

SX 460 SX 440 MX 341

To adjust generator output voltage.

OVER VOLTAGE

SX 421 MX 321

Over Voltage Protection. To remove generator excitation in event of loss of AVR sensing input. SX 421 - Priovides only tripping signal for overvoltage Additional tripping circuit need to provide. MX 321 - It has internal de excitation system & also provides signal to use for tripping external circuit as Circuit Breaker. Incorrect setting LED will glow.

EXCITATION MX 341 TRIP MX 321 Only for m/cs with PMG

AVR detects high excitation & removes it after predetermined time 8 - 10 sec.

I ' LIMIT

To set maximum short circuit current capacity.

UFRO

SX 460 SX 440 SX 421 MX 341 MX 321

To set under Frequency Roll Off Point. All AVR's are incorporated with under speed protection Incorrect setting - LED will remain permanently ON. when generator is ON LOAD.

DIP

SX 421 MX 341 MX 321 MX 321

Adjusts slope of voltage /speed ( HZ ) characteristic below the knee point.

DWELL

To maintain time delay between recovery of voltage and speed. Dwell time delay is to reduce generator KW below available engine KW to allow improved speed recovery.

PROCEDURE

Standard Ramp time - 3 sec. can be reduced to - 1 sec. can be increased to - 8 second

- Factory set. - Fully anticlockwise. - Fully clockwise.

* Clockwise rotation of the pot increases damping effect and vice versa.

Clockwise rotation of the pot increases output voltage and vice versa.

Correct setting is 240 V across AVR terminal E1& E0. * Run the DG set on No Load at 1500 RPM. * Turn overvoltage pot fully clockwise. * Set output voltage of machine to 480 V with Volts pot. * Turn Overvoltage pot slowly anticlockwise. * At one point output voltage will collapse. This is correct point of setting. * Now turn Volts pot anticlockwise and stop DG set. * Restart DG set & run to 1500 RPM on no load. * Set output voltage of machine to 415 V with Volts pot. * Now overvoltage setting is set. * Now max. Overvoltage limit is 480 V.

Correct setting 70 V + 5 % DC between AVR terminals X, XX ( + , - ). LED will remain permanently ON during Excitation Trip. PMG being separate source for excitation supply, it can deliver max excitation during large overload or shortcircuit. This may cause to overvoltage and burn the winding. Hence to protect winding, Excitation trip protection is provided.

* Put generator off. * Remove short link at K1, K2 of AVR & connect 5A switch there. * Turn I limit pot fully anticlockwise. * Short all main stator winding at terminals & put clamp on Ammeter there. * Switch at K1, K2 keep open and start the generating set. * Close across K1, K2 & turn I limit clockwise until required current limit observed on the clamp on meter.

* As soon as required current limit reads, open the K1, K2 switch. If current collapses during procedure, * Shut down set & open K1, K2 switch. * Restart set for 10 min with K1, K2 open to cool generator winding. Running set for cooling without K1, K2 open may lead to damage the set.

Clockwise rotation reduces speed ( Frequency ) setting of KNEE POINT and LED becomes off. LED should on if frequency falls below 47 HZ ( on 50 HZ Generator ) Setting procedure :* Run DG on no load at 1425 RPM. * Turn UFRO pot fully anticlockwise, LED will become off. M/c vtg. Will be 415 V. * Now start turning UFRO pot slowly clockwise. * At one point LED will glow and voltage will drop down slightly. * Turn the UFRO pot slightly anticlockwise and LED will become off. * Again turn UFRO pot clockwise and LED will glow. * Now increase speed of engine to 1435 - 1440 RPM & LED will become off. * Now UFRO is set at 47.5 HZ. NOTE : for MX 341 & MX 321 if LED is glowing & no output voltage is present checkup with Excitation Trip and / or Overvoltage setting.

Clockwise adjustment of the pot increases dip in voltage and vice versa.

Clockwise adjustment gives increased recovery time.

You might also like

- Boylestad 11th Edition - SolmanDocument25 pagesBoylestad 11th Edition - Solmankakiks25% (4)

- Cummins 2011 Test On A Kta50Document2 pagesCummins 2011 Test On A Kta50api-252499008No ratings yet

- Generador StamfordDocument8 pagesGenerador StamfordGustavo ZavalaNo ratings yet

- Leroy SomerDocument20 pagesLeroy SomerRobson Souza100% (1)

- Specifications of Avr - SMR (Mosfet)Document4 pagesSpecifications of Avr - SMR (Mosfet)Александр Щеблыкин50% (2)

- Megmeet Mp113 Led Power SupplyDocument12 pagesMegmeet Mp113 Led Power SupplySanja MiticNo ratings yet

- PLC FatekDocument36 pagesPLC FatekM7mud M7mdNo ratings yet

- ADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualDocument10 pagesADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualcarmeniyoNo ratings yet

- Installation and Adjustments Manual Incorporating The Commissioning ProceduresDocument54 pagesInstallation and Adjustments Manual Incorporating The Commissioning ProceduresSimion Cosmin - AlinaNo ratings yet

- 8woodward GoverningDocument58 pages8woodward Governinglilya mohNo ratings yet

- 4001e Control Panel (GB)Document2 pages4001e Control Panel (GB)RameshNo ratings yet

- Oly Changeover SystemsDocument5 pagesOly Changeover SystemsCandiano PopescuNo ratings yet

- A043y701 MX321 enDocument44 pagesA043y701 MX321 enChhoan NhunNo ratings yet

- Deep Sea Electronics: Model 5220 Installation and Configuration InstructionsDocument2 pagesDeep Sea Electronics: Model 5220 Installation and Configuration Instructionsdhani_is100% (1)

- S4L1D-G41 Wdg.311 - Technical Data SheetDocument10 pagesS4L1D-G41 Wdg.311 - Technical Data SheetsarahlawaNo ratings yet

- ComAP Powermanagement Load Reserve Calculation - V3Document4 pagesComAP Powermanagement Load Reserve Calculation - V3Luis JesusNo ratings yet

- PCC2100 S-1409Document8 pagesPCC2100 S-1409Jairo Alirio Cultid InsuastyNo ratings yet

- Three-Phase Synchronous Generator: AVR WT-2Document4 pagesThree-Phase Synchronous Generator: AVR WT-2Isaac SidibeNo ratings yet

- SR489 Setting FileDocument9 pagesSR489 Setting FileVarun Sharma100% (1)

- SX440 SS440 ManualDocument4 pagesSX440 SS440 ManualThijsNo ratings yet

- Installation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDocument32 pagesInstallation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDjebali MouradNo ratings yet

- Wiring Diagramstp7195Document58 pagesWiring Diagramstp7195Eric Aarriaga AlpizarNo ratings yet

- Semiconductor, Diode and Power Supply: Click To Edit Master Subtitle StyleDocument61 pagesSemiconductor, Diode and Power Supply: Click To Edit Master Subtitle StylejgNo ratings yet

- EST To Flash A PowerWizardDocument2 pagesEST To Flash A PowerWizardmahmoud khtaNo ratings yet

- Dse7520 Installation InstDocument2 pagesDse7520 Installation InstRamon Thales DomeniconiNo ratings yet

- Specification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Document34 pagesSpecification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Jan AhmedNo ratings yet

- CDVRDocument21 pagesCDVRYasir AbdooNo ratings yet

- MX321 Wiring - Selco Interface PDFDocument1 pageMX321 Wiring - Selco Interface PDFthaiNo ratings yet

- Digital Avr For Alternators With Shunt, Arep or PMG ExcitationDocument2 pagesDigital Avr For Alternators With Shunt, Arep or PMG ExcitationParinyaNo ratings yet

- NPT10 Avr Sx460.sx440.sa465.sx421Document6 pagesNPT10 Avr Sx460.sx440.sa465.sx421Elver MesaNo ratings yet

- DSE555 Data SheetDocument4 pagesDSE555 Data SheetFabio JuniorNo ratings yet

- PCC 0500Document4 pagesPCC 0500ywa00No ratings yet

- ECU-9988N Cut Sheet 22JULY08 PDFDocument2 pagesECU-9988N Cut Sheet 22JULY08 PDFJosé David Barrios PadrónNo ratings yet

- Dkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument61 pagesDkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsKhaleel KhanNo ratings yet

- Manual EA20S CaterpillarDocument3 pagesManual EA20S CaterpillarHernán Peñafiel ReaNo ratings yet

- PMG PDFDocument6 pagesPMG PDFrajan_2002eeeNo ratings yet

- L-Series Integrated Speed Control (Manual 26250 Revision H) PDFDocument130 pagesL-Series Integrated Speed Control (Manual 26250 Revision H) PDFkolob008No ratings yet

- Onanps500 PDFDocument67 pagesOnanps500 PDFHector Cabrera100% (1)

- Powercommand Input/Output Expansion Module Aux 101 and Aux 102Document3 pagesPowercommand Input/Output Expansion Module Aux 101 and Aux 102Alberto AraripeNo ratings yet

- AGN 009 - Bearing LifeDocument6 pagesAGN 009 - Bearing LifeariwibowoNo ratings yet

- Oly Changeover SystemsDocument5 pagesOly Changeover SystemsCandiano PopescuNo ratings yet

- R448 Manual From Mac Far Lane GeneratorsDocument14 pagesR448 Manual From Mac Far Lane Generatorstocanh1990No ratings yet

- 1 - Multipart - xF8FF - 2 - PCC3xxx Paralleling Introduction 021606Document8 pages1 - Multipart - xF8FF - 2 - PCC3xxx Paralleling Introduction 021606Rogério LovattoNo ratings yet

- T100 Digital ControlerDocument16 pagesT100 Digital ControlerMIke100% (1)

- EA08A 2000 ManualDocument3 pagesEA08A 2000 ManualFaeistenYweNo ratings yet

- Cummins qxs16 g8Document7 pagesCummins qxs16 g8younis abdurahmanNo ratings yet

- TI New (MTI) AddendumDocument3 pagesTI New (MTI) AddendumBojan KitanovskiNo ratings yet

- Npt35 Avr Ufro ControlDocument11 pagesNpt35 Avr Ufro ControlAbrahan BermudezNo ratings yet

- Avr 20 DatakomDocument2 pagesAvr 20 DatakomMiguel Angel Pavon CarbonellNo ratings yet

- Automatic Gen-Set Controller: Data Sheet Multi-Line 2Document12 pagesAutomatic Gen-Set Controller: Data Sheet Multi-Line 2albertooliveira100% (2)

- Sti Panel (GB) (2004)Document2 pagesSti Panel (GB) (2004)Bojan KitanovskiNo ratings yet

- 0908 0104v1 PDFDocument1,008 pages0908 0104v1 PDFDuy KhaNo ratings yet

- Analogue Control Systems: For Diesel & Gas Engines, Gensets, Combined Heat & Power, Pump DrivesDocument12 pagesAnalogue Control Systems: For Diesel & Gas Engines, Gensets, Combined Heat & Power, Pump Driveslethanhtu0105No ratings yet

- What Is The Difference Between Bus and Mains Mode On The Dse Range of Mains Synchronising ControllersDocument2 pagesWhat Is The Difference Between Bus and Mains Mode On The Dse Range of Mains Synchronising ControllersMaksim PanfilovNo ratings yet

- SX460 ManualDocument4 pagesSX460 ManualJonathan Heyneke100% (1)

- AVC63 7 ManualDocument4 pagesAVC63 7 ManualLuciano PereiraNo ratings yet

- Kohler rsaII BulletinDocument32 pagesKohler rsaII BulletinBrianHazeNo ratings yet

- Service Manual: Detector /sentinel ControlsDocument121 pagesService Manual: Detector /sentinel ControlsAlex100% (1)

- Regulador Marathon Magnamax PM100Document33 pagesRegulador Marathon Magnamax PM100Manuel OteroNo ratings yet

- Electronic Engine Governor Controller Operation ManualDocument7 pagesElectronic Engine Governor Controller Operation ManualVinhNo ratings yet

- Training AvrDocument64 pagesTraining AvrArnold Arung67% (3)

- C6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSDocument5 pagesC6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSsuperteffyNo ratings yet

- DDX719 DDX7049BT DDX419 DDX4049BT DDX319 DDX3049: Instruction ManualDocument88 pagesDDX719 DDX7049BT DDX419 DDX4049BT DDX319 DDX3049: Instruction Manualenzzo molinariNo ratings yet

- ATX Standard DesktopDocument4 pagesATX Standard DesktopAlem GirmaNo ratings yet

- Profibus: What A Fieldbus System Needs To OfferDocument48 pagesProfibus: What A Fieldbus System Needs To OfferSudipto MajumderNo ratings yet

- Etb 10Document2 pagesEtb 10al nakheel electronicsNo ratings yet

- Varis Cable Modem InterfaceDocument2 pagesVaris Cable Modem InterfaceGerard Taip AliagaNo ratings yet

- 888 Manual Ver1.06Document0 pages888 Manual Ver1.06Dota NgNo ratings yet

- STB B860HDocument17 pagesSTB B860HHardiyantoNo ratings yet

- The Effect of Temperature Variations On Solar Cell EfficiencyDocument6 pagesThe Effect of Temperature Variations On Solar Cell EfficiencyVishal FernandesNo ratings yet

- 3GPP TS 36.101: Technical SpecificationDocument31 pages3GPP TS 36.101: Technical SpecificationTerry BacchinNo ratings yet

- Tic206 Series Silicon TriacsDocument6 pagesTic206 Series Silicon TriacsIgorCostaCorreiaNo ratings yet

- Spook BookDocument260 pagesSpook BookAlpha1Decoy86% (29)

- Adonis AM-708EDocument4 pagesAdonis AM-708Ejoe.garcia92No ratings yet

- Laptop Schematics - Learn How To Read Motherboard SchemesDocument3 pagesLaptop Schematics - Learn How To Read Motherboard SchemesMuhammadimran Ali100% (1)

- Systemoverview 05 2017 enDocument492 pagesSystemoverview 05 2017 enkaniappan sakthivelNo ratings yet

- Chapter 5Document49 pagesChapter 5Rishaal ChandraNo ratings yet

- Brochure Orthoralix8500Document8 pagesBrochure Orthoralix8500Medifix Srl50% (2)

- Level 1 and 2 Service ManualDocument68 pagesLevel 1 and 2 Service Manualrivasq1987No ratings yet

- Figure 6-1 Representation of Signed Numbers in Sign-Magnitude FormDocument27 pagesFigure 6-1 Representation of Signed Numbers in Sign-Magnitude FormFx HardsonNo ratings yet

- Training ReportDocument44 pagesTraining Reportshaur20No ratings yet

- Comparing Analog and Digital PotsDocument6 pagesComparing Analog and Digital PotsGerry McMahonNo ratings yet

- HUAWEI Y7 Prime 2018 Quick Start Guide (LDN-L21&LX2, 01, English, Oversea, EMUI8.0, Norma)Document12 pagesHUAWEI Y7 Prime 2018 Quick Start Guide (LDN-L21&LX2, 01, English, Oversea, EMUI8.0, Norma)Wa3d HalabiNo ratings yet

- Airport Icao Iata GCT (Deg) GCD (NM) : Calicut, India Vocl/CcjDocument29 pagesAirport Icao Iata GCT (Deg) GCD (NM) : Calicut, India Vocl/CcjsaurabhNo ratings yet

- Diagnostics Information 2Document64 pagesDiagnostics Information 2Gutavo ExpinozaNo ratings yet

- Poweredge r750 Technical GuideDocument46 pagesPoweredge r750 Technical GuideErnu AnatolieNo ratings yet

- A Hybrid High Efficiency Nine Level Inverter With High DC Voltage Utilization RatioDocument16 pagesA Hybrid High Efficiency Nine Level Inverter With High DC Voltage Utilization RatioRodovarNo ratings yet

- SQEMARINE Bridge Familiarization Checklist 2018 03Document3 pagesSQEMARINE Bridge Familiarization Checklist 2018 03David Nazareth100% (1)

- Wheel Probe Demo 1 NDT 2015 CanadaDocument29 pagesWheel Probe Demo 1 NDT 2015 CanadaRamakrishnan AmbiSubbiah100% (1)