SEVPL Brochure

Uploaded by

Naveen AnandCopyright:

Available Formats

SEVPL Brochure

Uploaded by

Naveen AnandOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SEVPL Brochure

Uploaded by

Naveen AnandCopyright:

Available Formats

SRI ENERGY VALVES PVT. LTD.

Oil Field Drilling & Production Equipment

GATE VALVES CHOKES CHECK VALVES

WELL HEADS X MAS TREES SSVS

FLOWHEADS MANIFOLDS SUBSEA EQUIPMENT

ISO-1300

Q1-1100

TS-0981

6A-1165

TUV-104 07 1669

Excellence in extremes

Sri Energy Valves (SEV) is a leading provider of oilfield equipment, systems and services to worldwide oil and gas industries. Sri Energy is located in a state of the art facility in Trichy, India. Our team of highly skilled technicians, machinists and engineers enable us to offer best in class service globally. Sri Energy manufactures a complete line of Valves, Flowheads, Choke and Kill Manifolds, Standpipe Manifolds, Chokes, Cross-Over Connectors, Top Connectors, Tees and Crosses, Adapter and Spacer Spools, Flanged Connectors, Threaded Connectors, Other End Connectors at PSL 1, 2, 3 and 3G, Bull plugs adhering to API6A standards. Products can be supplied to NACE MR0175 specifications in pressure ratings ranging from 2,000 psi to 20,000 psi and temperatures from 500 F to 3500 F. A winning combination of technical excellence and world class facilities enables Sri Energy Valves to offer quality products to its customers. It is the goal of Sri Energy Valves to provide our valued customers with innovative solutions with a level of service that exceeds the industry standard. Strong Engineering expertise enables us to custom build equipment to the users specification. We take pride in our ability to service our customers as quick as possible and strive to offer quality products in a timely manner.

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type) Manual

This type of gate valve is best suited for all kinds of manifolds, Christmas trees, etc. Size: 1-13/16 7-1/16 Pressure Rating: 2,000 psi 15,000 psi Construction: Forged body and bonnet. Type: Manual, hydraulic or pneumatic End Connection: Flanged end, weld neck, hub end or any other end connection as requested Design Features: Bi-directional, metal to metal seal between gate and seat Advantages: Easy maintenance as the parts can be taken out for service while the body is on line. Interchangeable with CIW valve parts. Good lubrication and venting system helps the valve with easy operation.

SEVPL

B A

Working Pressures (psi) Size & Bore (Inches) A (Inches) B (Inches) C (Inches) D (Inches) Weight (lbs) 2 1/16 14 5/8 5 5/8 13 14 180 3000 2 9/16 16 5/8 6 1/2 N/A 14 249 3 1/8 17 1/8 7 3/8 4 1/16 20 1/8 9 1/8 2 1/16 14 5/8 5 5/8 5000 2 9/16 16 5/8 6 1/2 3 1/8 18 5/8 7 3/8 4 1/16 21 5/8 9 1/8 1 13/16 18 1/4 5 3/4 15 1/8 14 270 2 1/16 20 1/2 5 7/8 15 1/8 18 275 10,000 2 9/16 22 1/4 6 13/16 15 13/16 18 485 3 1/16 24 3/8 8 1/16 4 1/16 26 3/8 10 1/16 1 13/16 18 5 7/8 15,000 2 1/16 19 6 1/8 15 1/8 18 350 2 9/16 21 7 5/16 3 1/16 23 9/16 9 1/4

16 13/16 18 7/16 14 282 18 450

15 1/8 15 15/16 16 13/16 18 7/16 14 182 14 255 18 360 18 545

16 7/8 19 11/16 15 1/8 22 680 22 1057 18 275

17 3/16 20 15/16 18 800 22 1065

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type) Manual

PARTS LIST FOR MANUAL VALVES 1. Handwheel 2. Bearing Cap 3. Grease fitting Alemite 4. O-Ring 5. Bearing Race 6. Bearing Thrust 7. O-Ring (Stem Adapter) 8. Stem Adapter 9. Stem Pin 10. Packing Gland 11. Packing Stem 12. Hex Nut 13. Stud 14. Bonnet 15. Check valve 16. Grease fitting (Body) 17. Bonnet Gasket 18. Auto Clave Plug 19. Operating Stem 20. Gate 21. Retainer Plate 22. Seat 23. Seal, Seat & Body Bushing 24. Alignment Pin 25. Body 26. Name Plate 27. Gate Guide 28. Body Bushing 29. Bolt W/Nut

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type F & FC) Manual

2 1/16" 5,000psi F&FC Model 2 1/16" 10,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE) 2 1/16" 15,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE)

2 1/16

SL No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Description Hand Wheel Bearing Cap Grease Fitting Alemite O - Ring Bearing Race Bearing Thrust O - Ring (Stem Adapter) Stem Adapter Stem Pin Packing Gland Packing Stem Hex Nut Stud Bonnet Check Valve Grease Fitting Body Bonnet Gasket Auto Clave Plug Operating Stem Gate Retainer Plate Seat Seal-seat & Body Bushing Alignment Pin Body Name Plate Gate Guide Body Bushing Bolt W/nut Qty. Reqd. 1 1 2 2 4 2 1 1 1 1 1 8 8 1 1 1 1 1 1 1 2 2 4 2 1 1 2 2 1

Regular Trim (AA)

Super Trim (DD)

Part Number LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 07 TS - 0740 LAC 2005-14-1 N/A GT - 040 LAC 2005-17-1 N/A LAC 2005-19-1 LAC 2005-20-1 LAC 2005-21 LAC 2005-22 PM - 1006 PM - 1007 LAC 2005-25-1 PM - 1008 PM - 1010-1 LAC 2005-28-1 PM - 1011 LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 07 TS - 0740 LAC 2005-14-2 N/A GT - 040 LAC 2005-17-2 N/A LAC 2005-19-2 LAC 2005-20-2 LAC 2005-21 LAC 2005-22 PM - 1006 PM - 1007 LAC 2005-25-2 PM - 1008 PM - 1010-1 LAC 2005 - 28-1 PM - 1011 LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 11 TS - 1152 LAC 2010-14-2 CK - 020 GT - 040 LAC 2010-17-2 AP - 3750 LAC 2005-19-2 LAC 2005-20-2 LAC 2005-21 LAC 2005-22 PM - 1006 N/A LAC 2010-25-2 PM - 1008 PM - 1010-1 LAC 2005 - 28-1 PM - 1011 LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 11 TS - 1152 LAC 2010-14-2 CK - 021 GT - 041 LAC 2010-17-2 AP - 3750 LAC 2005-19-2 LAC 2005-20-3 LAC 2005-21 LAC 2005 - 22 PM - 1006 N/A LAC 2010-25-2 PM - 1008 PM - 1010-1 LAC 2005-28-2 PM - 1011 LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 12 TS - 1252 LAC 2015-14-2 CK - 020 GT - 040 LAC 2010-17-2 AF - 3750 LAC 2005-19-2 LAC 2005-20-2 LAC 2005-21 LAC 2005 - 22 PM - 1006 N/A LAC 2015-25-2 PM - 1008 PM - 1010-1 LAC 2005 - 28-1 PM - 1011 LAC 2005 -1-14 LAC 2005 - 2 GT - 010 SB-3399 PM - 1002 PM - 1003 SB - 2229 LAC 2005 - 8 LAC 2005 - 9 LAC 2005 - 10 PM - 1004 SN - 12 TS - 1152 LAC 2015-14-3 CK - 021 GT - 041 LAC 2010-17-2 AF - 3750 LAC 2005-19-2 LAC 2005-20-3 LAC 2005-21 LAC 2005 - 22 PM - 1006 N/A LAC 2015-25-3 PM - 1008 PM - 1010-1 LAC 2005-28-2 PM - 1011

FOR FF & HH TRIM AVAILABLE UPON REQUEST

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type F & FC) Manual

3 1/8 & 3 1/16

SL No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Description Hand Wheel Bearing Cap Grease Fitting Alemite O - Ring Bearing Race Bearing Thrust O - Ring (Stem Adapter) Stem Adapter Stem Pin Packing Gland Packing Stem Hex Nut Stud Bonnet Check Valve Grease Fitting Body Bonnet Gasket Auto Clave Plug Operating Stem Gate Retainer Plate Seat Seal-seat & Body Bushing Alignment Pin Body Name Plate Gate Guide Body Bushing Bolt W/nut Qty. Reqd. 1 1 2 2 4 2 1 1 1 1 1 8 8 1 1 1 1 1 1 1 2 2 4 2 1 1 2 2 1

3 1/8" 5,000psi F&FC Model Regular Trim (AA) Super Trim (DD)

3 1/16" 10,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE)

3 1/16" 15,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE)

Part Number LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -11 TS -1145 LAC 3005-14-1 N/A GT - 040 LAC 3005-17-1 N/A LAC 3005-19-1 LAC 3005-20-1 LAC 3005-21 LAC 3005-22 PM - 1006 PM - 1007 LAC 3005-25-1 PM - 1008 PM -1010-3 LAC 3005-28-1 PM - 1011 LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -11 TS -1145 LAC 3005-14-2 N/A GT - 040 LAC 3005-17-2 N/A LAC 3005-19-2 LAC 3005-20-2 LAC 3005-21 LAC 3005-22 PM - 1006 PM - 1007 LAC 3005-25-2 PM - 1008 PM -1010-3 LAC 3005-28-1 PM - 1011 LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -13 TS -1366 LAC 3010-14-2 CK - 020 GT - 040 LAC 3010-17-2 AP - 3750 LAC 3005-19-2 LAC 3005-20-2 LAC 3005-21 LAC 3005-22 PM - 1006 N/A LAC 3010-25-2 PM - 1008 PM -1010-3 LAC 3005-28-1 PM - 1011 LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -13 TS -1366 LAC 3010-14-2 CK - 021 GT - 041 LAC 3010-17-2 AP - 3750 LAC 3005-19-2 LAC 3005-20-3 LAC 3005-21 LAC 3005-22 PM - 1006 N/A LAC 3010-25-2 PM - 1008 PM -1010-3 LAC 3005-28-1 PM - 1011 LAC 3005-1-18 LAC 3015-2 GT -010 SB -3399 PM -1002-1 PM -1003-2 SB -2229 LAC 3015-8 LAC 3015-9 LAC 3015-10 PM -1004 SN TS LAC 3015-14-2 CK - 020 GT - 040 LAC 3015-17-2 AF - 3750 LAC 3015-19-2 LAC 3015-20-2 LAC 3015-21 LAC 3015 - 22 PM - 1006 N/A LAC 3015-25-2 PM - 1008 PM -1010-4 LAC 3015 - 28-1 PM - 1011 LAC 3005-1-18 LAC 3015-2 GT -010 SB -3399 PM -1002-1 PM -1003-2 SB -2229 LAC 3015-8 LAC 3015-9 LAC 3015-10 PM -1004 SN TS LAC 3015-14-3 CK - 021 GT - 041 LAC 3015-17-2 AF - 3750 LAC 3015-19-2 LAC 3015-20-3 LAC 3015-21 LAC 3015 - 22 PM - 1006 N/A LAC 3015-25-3 PM - 1008 PM -1010-4 LAC 3015 - 28-1 PM - 1011

FOR FF & HH TRIM AVAILABLE UPON REQUEST

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type F & FC) Manual

4 1/16" 5,000psi F&FC Model 4 1/16" 10,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE) 4 1/16" 15,000psi F&FC Model Super Trim (DD) Stainless Steel Trim (EE)

4 1/16

SL No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Description Hand Wheel Bearing Cap Grease Fitting Alemite O - Ring Bearing Race Bearing Thrust O - Ring (Stem Adapter) Stem Adapter Stem Pin Packing Gland Packing Stem Hex Nut Stud Bonnet Check Valve Grease Fitting Body Bonnet Gasket Auto Clave Plug Operating Stem Gate Retainer Plate Seat Seal-seat & Body Bushing Alignment Pin Body Name Plate Gate Guide Body Bushing Bolt W/nut Qty. Reqd. 1 1 2 2 4 2 1 1 1 1 1 8 8 1 1 1 1 1 1 1 2 2 4 2 1 1 2 2 1

Regular Trim (AA)

Super Trim (DD)

Part Number LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -12 TS -1252 LAC 4005-14-1 N/A GT - 040 LAC 4005-17-1 N/A LAC 4005-19-1 LAC 4005-20-1 LAC 4005-21 LAC 4005-22 PM -1006-5 PM - 1007 LAC 4005-25-1 PM - 1008 PM -1010-3 LAC 4005-28-1 PM - 1011 LAC 3005-1-18 LAC 2005-2 GT -010 SB -3399 PM -1002 PM -1003 SB -2229 LAC 2005-8 LAC 2005-9 LAC 2005-10 PM -1004 SN -12 TS -1252 LAC 4005-14-2 N/A GT - 040 LAC 4005-17-2 N/A LAC 4005-19-2 LAC 4005-20-2 LAC 4005-21 LAC 4005-22 PM -1006-5 PM - 1007 LAC 4005-25-2 PM - 1008 PM -1010-3 LAC 4005-28-1 PM - 1011 LAC 4005-1-22 LAC 4010-2 GT -010 SB -3449 PM -1002 PM -1003 SB -2249 LAC 4010-8 LAC 4010-9 LAC 4010-10 PM -1004-2 SN -15 TS -1576 LAC 4010-14-2 CK - 020 GT - 040 LAC 4010-17-2 AP - 3750 LAC 4010-19-2 LAC 4010-20-2 LAC 4010-21 LAC 4010-22 PM -1006-5 N/A LAC 4010-25-2 PM - 1008 PM -1010-6 LAC 4010-28-1 PM - 1011 LAC 4005-1-22 LAC 4010-2 GT -010 SB -3449 PM -1002 PM -1003 SB -2249 LAC 4010-8 LAC 4010-9 LAC 4010-10 PM -1004-2 SN -15 TS -1366 LAC 4010-14-2 CK - 021 GT - 041 LAC 4010-17-2 AP - 3750 LAC 4010-19-2 LAC 4010-20-3 LAC 4010-21 LAC 4010-22 PM -1006-5 N/A LAC 4010-25-2 PM - 1008 PM -1010-6 LAC 4010-28-1 PM - 1011 LAC 4005-1-22 LAC 4015-2 GT -010 SB PM -1002-1 PM -1003-2 SB LAC 4015-8 LAC 4015-9 LAC 4015-10 PM -1004-3 SN TS -1576 LAC 4015-14-2 CK - 020 GT - 040 LAC 4015-17-2 AF - 3750 LAC 4015-19-2 LAC 4015-20-2 LAC 4015-21 LAC 4015 - 22 PM N/A LAC 4015-25-2 PM - 1008 PM LAC 4015 - 28-1 PM - 1011 LAC 4005-1-22 LAC 4015-2 GT -010 SB PM -1002-1 PM -1003-2 SB LAC 4015-8 LAC 4015-9 LAC 4015-10 PM -1004-3 SN TS LAC 4015-14-3 CK - 021 GT - 041 LAC 4015-17-2 AF - 3750 LAC 4015-19-2 LAC 4015-20-3 LAC 4015-21 LAC 4015 - 22 PM N/A LAC 4015-25-3 PM - 1008 PM LAC 4015 - 28-1 PM - 1011

FOR FF & HH TRIM AVAILABLE UPON REQUEST

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type) Hydraulic

Design Features: Built with manual override to close of the manually Body has a bottom preparation for installing tail rod and stem protector Tail rod acts as a means for balancing the pressure

PARTS LIST FOR HYDRAULIC GATE VALVES 1. Handwheel 2. O-Ring 3. Adjusting Nut 4. O-Ring 5. Locking Screw 6. Cylinder Head Nut 7. Set Screw 8. Blind Cylinder Head 9. Cylinder Head Stud 10. Cylinder 11. Centering Pin 12. Set Screw 13. Piston Lock Nut 14. Piston 15. O-Ring 16. O-Ring 17. Gland 18. Stem Packing 19. Lower Cylinder Head 20. Relief Valve 21. Bonnet Nut 22. Bonnet 23. Grease Fitting 24. Valve Check 25. Bonnet Gasket 26. Stem 27. Gate 28. Retainer Plate 29. Seat Ring 30. Seal, Seat & Body Bushing 31. Body Bushing 32. Pin 33. Lower Stem 34. Bonnet Stud 35. Auto Clave Plug 36. Name Plate 37. Pipe Plug 38. Body 39. Body Extension 40. Grease Zert 41. Stem Protector 42. Bolt W/Nut

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type) Hydraulic

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type) Hadraulic

D

SEVPL

Working Pressure (psi)

Size & Bore (Inches) 2 1/16

A (Inches) 14 5/8 16 5/8 18 5/8 21 5/8 28 8 1/4 20 1/2 22 1/2 24 3/8 26 3/8 18 19 21 23 9/16

B (Inches) 14 1/2 15 15/16 17 1/4 19 3/4 25 7/8 14 1/4 14 1/2 15 15/16 17 1/4 19 3/4 14 1/4 14 1/2 15 1/2 20 5/8

C (Inches) 35 3/8 37 7/8 40 3/8 44 7/8 58 3/16 35 3/8 35 3/8 37 7/8 41 3/4 48 7/8 35 3/8 35 3/8 42 1/2 50 1/8

D (Inches) 14 14 18 18 22 18 18 18 22 22 18 18 18 18

5,000

2 9/16 3 1/8 4 1/16 7 1/16 2 1/16 2 9/16 3 1/16 4 1/16 7 1/16 1 13/16

15,000

10,000

2 1/16 2 9/16 3 1/16

SRI ENERGY VALVES

Gate Valve, Model LAC (CIW Type F & FC) Hydraulic

TRIM CHART HYDRAULIC VALVES - MATERIAL

TRIM AA DD EE FF BODY Carbon Alloy Steel Carbon Alloy Steel Carbon Alloy Steel Stainless Steel BONNET Carbon Alloy Steel Carbon Alloy Steel Carbon Alloy Steel Stainless Steel BODY EXTENSION Carbon Alloy Steel Carbon Alloy Steel Carbon Alloy Steel Stainless Steel LOWER STEM Stainless Steel Stainless Steel Stainless Steel Stainless Steel GATE Carbon Alloy Steel Carbon Alloy Steel Stainless Steel Stainless Steel STEM Stainless Steel Stainless Steel Stainless Steel Stainless Steel

10

SRI ENERGY VALVES

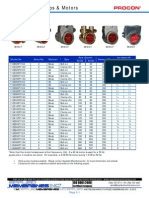

Choke, Model S-H2, Adjustable

1. Body 2. Bonnet Assembly 3. Bonnet 4. Bonnet Extension 5. Set Screw W/Nylon Tip 6. Wing Nut 7. Seal Ring & Back up Ring 8. Seat 9. Gasket Seat 10. Hex Nut 11. Bleeder Plug 12. Lock Washer 13. Stem 14. Packing Assembly 15. Stem Sleeve 16. Retainer Ring 17. Nut Bushing 18. Bonnet Nut 19. Thumb Screw 20. Set Screw W/Nylon Tip 21. Rod Wiper 22. Set Screw 23. Housing Indicator 24. Indicator 25. Handwheel 26. Grease Fitting 27. Hex Bolt 28. Lock Washer 29. Retainer Ring

11

SRI ENERGY VALVES

Choke, Model S-H2, Adjustable

Size: Pressure Rating: Construction: Design Features: 2-1/16 to 4-1/16 5,000 psi to 15,000 psi Forged body and bonnet. Built to suit H2S service and temperatures up to 2500 F Can be supplied to elevated temperatures and special trims

SEVPL

FLANGE SIZE CWP 2 1/16 2 9/16 / 3 1/8 2 9/16 / 3 1/8 2 9/16 / 3 1/8 4 1/16 2 9/16 / 3 1/16 4 1/16

PRESSURE 5,000 API 3,000 API 5,000 API 10,000 API 10,000 API 15,000 API 5,000 API

A 8.00 11.38 11.38 11.75 11.50 11.75 11.38

B 6.87 8.88 8.88 10.38 9.94 10.38 9.88

C 21.50 30.00 30.00 30.25 30.12 30.06 30.13

12

SRI ENERGY VALVES

Choke, Model S-H2, Positive

1. Body 2. Bonnet 3. Wing nut 4. Bean 5. Gasket, Seat 6. Liner 7. Bleeder plug 8. Hex bolt 9. O-Ring & Back up ring 10. Retainer Ring

13

SRI ENERGY VALVES

Choke, Model S-H2, Positive

SEVPL

FLANGE SIZE CWP 2 1/16 2 9/16 / 3 1/8 2 9/16 / 3 1/8 2 9/16 / 3 1/8 4 1/16 2 9/16 / 3 1/16 4 1/16

PRESSURE 5,000 API 3,000 API 5,000 API 10,000 API 10,000 API 15,000 API 5,000 API

A 8.00 11.38 11.38 11.75 11.50 11.75 11.38

B 6.87 8.88 8.88 10.38 9.94 10.38 9.88

D 13.25 18.50 18.50 18.75 18.69 19.00 18.75

14

SRI ENERGY VALVES

Choke, Model S-H2, Adjustable & Positive

TRIM CHART HYDRAULIC VALVES - MATERIAL

MATERIAL TRIM BODY BONNET STEM SEAT or BEAN

AA BB CC DD

Carbon Alloy Steel Carbon Alloy Steel Stainless Steel Carbon Alloy Steel 22 RC MAX Carbon Alloy Steel 22 RC MAX Stainless Steel 22 RC MAX

Carbon Alloy Steel Carbon Alloy Steel Stainless Steel Carbon Alloy Steel 22 RC MAX Carbon Alloy Steel 22 RC MAX Stainless Steel 22 RC MAX

Carbon Alloy Steel Stainless Steel Stainless Steel Stainless Steel

Carbon Alloy Steel Stainless Steel Stainless Steel Stainless Steel

EE

Stainless Steel

Stainless Steel

FF

Stainless Steel

Stainless Steel

AVAILABLE IN ABOVE MENTIONED TRIMS WITH 1", 1 3/4" & 2" ORIFICE.

15

SRI ENERGY VALVES

Check Valve, Model LAC (CIW Type S-R)

These check valves are predominantly used for drilling and production services. Pressure Rating: 5,000 psi to 15,000 psi Construction: Forged body and bonnet. Design Features: Poppet seat and other internals are interchangeable with OEM model known as type R Available in any specified trim

SEVPL

L

FACE TO FACE LENGTH (L)

MATERIAL SIZE 5K 10K 15K 20K

1 13/16 2 1/16 2 9/16 3 1/8 3 1/16

14.62 16.62 18.62 -

18.25 20.5 22.5 24.38

18 19 21 23.56

21 23 26.5 30.5

A field proven familiar to the user type S-R type Check Valve provides interchangeability and reliability. For operating conditions, trim chart is provided to select a suitable one. It will be suitable for drilling & production services. It meets or exceeds API standard and related quality requirements. TRIM CHART CHECK VALVES - MATERIAL

TRIM AA DD EE FF BODY Carbon Alloy Steel Carbon Alloy Steel Carbon Alloy Steel Stainless Steel BONNET Carbon Alloy Steel Carbon Alloy Steel Carbon Alloy Steel Stainless Steel POPPET Carbon Alloy Steel Stainless Steel Stainless Steel Stainless Steel SEAT Carbon Alloy Steel Stainless Steel Stainless Steel Stainless Steel SCREW, SEAT Carbon Alloy Steel Carbon Alloy Steel Stainless Steel Stainless Steel GASKET Carbon Alloy Steel Stainless Steel Stainless Steel Stainless Steel

16

SRI ENERGY VALVES

Check Valve, Model LAC (CIW Type S-R)

1. Body 2. Bonnet 3. Poppet 4. Seat 5. Screw seat 6. Sprint 7. Gasket 8. Stud, Bonnet 9. Nut, Bonnet 10. Stud, Retainer 11. Nut, Retainer 12. Packing 13. Seal, Seat

Warranty 1. The company warrants that all products manufactured by it shall be free from defects in workmanship, provided that these products are used within the service, pressure and temperature range for which they were manufactured. Such warranty shall be binding upon the company in respect to products for a period of one year, from shipment of such products and in respect to repair work for a period of 60 days from completion of such repairs and applies only to materials furnished and work performed in the repair operations. 2. If, at any time within such periods, it is established to the satisfaction of the Company, that any product manufactured by the Company was defective, the Company , at its option, shall repair or exchange such an item, F.O.B. Place of manufacture or repair or other, the Company designated shipping point, or refund the price paid. 3. It is understood that the liability of the Company shall be limited to such repair or replacement and THE COMPANY SHALL NOT BE LIABLE FOR ANY DIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGE ARISING OUT OF ANY DEFECTS OR FROM ANY CAUSE WHATSOEVER. 4. This warranty does not cover deterioration by corrosion or aging of non-metallic parts, including stress corrosion or any other cause of failure and misuse other than defects in workmanship and material. 5. Unless repairs to, alterations of, or work done on said products by the buyer shall be specifically authorized in writing by the Company, any warranty applicable thereto shall become null and void.

Pressures upto 20,000 PSI Meets or exceeds the API Standards Fully assembled FAT Tested Skid mounted manifold systems Premium SEV Valves for high and low temps and high pressures CRA-applied for harsh environments OEM Interchangeables

SRI ENERGY VALVES PVT. LTD.

SF.No. 115/4A Vadugapatti village, Illupur Taluk, Viralimalai 621 316, Pudukottai District, Tamilnadu, INDIA. Ph: 91 4339 221358

Email: sales@srienergy.com Web: www.srienergy.com

You might also like

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20From EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20No ratings yet

- List of Equipment Available For Disposal 1 / Factory Available For DismantlingNo ratings yetList of Equipment Available For Disposal 1 / Factory Available For Dismantling58 pages

- Appendix Information: SF-515/XAA SF-515/XETNo ratings yetAppendix Information: SF-515/XAA SF-515/XET19 pages

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BA0% (1)Condensadora Westinghouse 5TR Mod DS3BA - DS5BA4 pages

- Chapter 1-8: Industrial Gas Generator Illustrated Parts CatalogueNo ratings yetChapter 1-8: Industrial Gas Generator Illustrated Parts Catalogue18 pages

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1No ratings yetISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.142 pages

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackNo ratings yet

- Stress Analysis of Gate Valve by Ansys - Sumit DharmaraoNo ratings yetStress Analysis of Gate Valve by Ansys - Sumit Dharmarao10 pages

- Appurtenances Commonly Used in A Distribution System - Water EngineeringNo ratings yetAppurtenances Commonly Used in A Distribution System - Water Engineering12 pages

- API Standard 600: Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted BonnetsNo ratings yetAPI Standard 600: Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted Bonnets3 pages

- Avk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved RubberNo ratings yetAvk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved Rubber2 pages

- KREBS Technequip Knife Gate Valves BrochureNo ratings yetKREBS Technequip Knife Gate Valves Brochure9 pages

- Design and Analysis of A Gate Valve Fluid Flow Using SolidworksNo ratings yetDesign and Analysis of A Gate Valve Fluid Flow Using Solidworks6 pages

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20From EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20

- List of Equipment Available For Disposal 1 / Factory Available For DismantlingList of Equipment Available For Disposal 1 / Factory Available For Dismantling

- Chapter 1-8: Industrial Gas Generator Illustrated Parts CatalogueChapter 1-8: Industrial Gas Generator Illustrated Parts Catalogue

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head Guide

- Uses of ASME Boiler & Pressure Vessels CodesFrom EverandUses of ASME Boiler & Pressure Vessels Codes

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and Track

- Stress Analysis of Gate Valve by Ansys - Sumit DharmaraoStress Analysis of Gate Valve by Ansys - Sumit Dharmarao

- Appurtenances Commonly Used in A Distribution System - Water EngineeringAppurtenances Commonly Used in A Distribution System - Water Engineering

- API Standard 600: Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted BonnetsAPI Standard 600: Steel Gate Valves-Flanged and Butt-Welding Ends, Bolted Bonnets

- Avk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved RubberAvk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved Rubber

- Design and Analysis of A Gate Valve Fluid Flow Using SolidworksDesign and Analysis of A Gate Valve Fluid Flow Using Solidworks