Nike PDF

Nike PDF

Uploaded by

matloobilahiCopyright:

Available Formats

Nike PDF

Nike PDF

Uploaded by

matloobilahiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nike PDF

Nike PDF

Uploaded by

matloobilahiCopyright:

Available Formats

Sustainability Assessment of Nike Shoes

Andrew Derrig Jake Stocker Luke Warren Pearson King Ethan Tinson Ellen Winston

For Sustainability Science ENVS 195, Fall 2010, Dr. Saleem H. Ali

Introduction and Justification

In Greek, Nike means victory and since the beginning of the company in 1972, victory has been a term that has represented many things about the Nike brand. The Nike corporation produces athletic shoes, apparel, equipment and accessories that can be found in distributors in over 170 countries worldwide, it sponsors many professional and college level sports teams and has grown to be one of the largest athletic apparel corporations in the world. In the early 70s they started out manufacturing running shoes featuring innovative new technology that increased traction and made the shoe lighter as a whole. (Nike, 2010) Since then the Nike brand has taken off and become more than simply successful, it is infamous though for a few different reasons. The Nike name, generally linked to success and wealth, first got into trouble in the early 90s when footage of sweatshop and child labor in their factories was broadcast on international television, smearing their name across the globe. (Beder, 2002) In 1998 cofounder and CEO Phil Knight even recognized that the Nike name and product has become synonymous with slave wages, forced overtime, and arbitrary abuse.(Levenson, 2008) Since those dark days however, Nike has made a concerted effort to both improve their reputation as an internationally active corporation and improve their production and business practices. One of the ways in which these improvements were manifest was in a new focus on sustainability. Since the 90s Nike has been ranked 3rd in Corporate Responsibility Officers Best Corporate Citizens List as well as one of the Worlds Top Sustainable Stocks by Sustainable Business. (Epstein, 2010) Theyve implemented new design principles such as the 7 specific Designs for the Environment principles that represent another set of criteria their designers use while creating product ideas. There has also been increased communication between their materials sourcing department and their manufacturing department on ways in which products can be more sustainable, with waste reduction as a key issue. (Charter, 2001) Most importantly, for some authors, theyve changed the way they approach the idea of sustainability from a compliance-related or risk-oriented activity to an opportunity for innovation. (Epstein, 2010) Though Nike seems to have come a long way since a very low point, socially and environmentally speaking, a mere decade ago, there also appears to be fewer tangible results than plans made. One of their sustainability-based endeavors has been to attempt to eliminate polyvinyl chloride or PVC plastics in their footwear. This has been a fairly publicized goal and though it has been part of a plan for about 10 years now, it has not been fully implemented, though Nikes website says the plastics have been removed from almost all products. (Nike, 2010) Darcy Winslow, General Manager of Sustainable Strategies, was quoted in an interview

saying PVC alternatives can cost anywhere from twice to six times as much as PVC and this has been their primary deterrent. She was also quoted in that same interview in 2001 as saying that she sees every single product having sustainable attributes being build into it within 3 years. (Charter, 2001) We decided to look into the sustainability of Nike shoes because of a few simple reasons. Like innovative changes happening at corporations like Walmart, if Nike were to change its production standards for higher environmental quality it would force a change in much of the rest of the athletic apparel and sneaker industry. Besides the fact that it is a very wealthy company, Nike is a brand that almost all Americans can say theyve heard of and many Americans can say theyve bought from and in that way their shift as a corporation could have far-reaching effects. A few in our group had heard something about Nike working to move towards sustainable products and that helped spark our curiosity as well. We wanted to see whether a corporation of Nikes size and infamy could truly make the move towards a sustainable product or if what we heard were rumors or green-washing. We also found it interesting to look with more depth into a product that is used by all of us. Shoes are a basic necessity in our society and Nike shoes are very commonly found. By exploring the methods used by Nike in particular we were given an idea as to some of the basic methods of all shoe production and what it takes to make a sustainable, economically viable and stylish shoe product.

Materials Assessment

Considering that material supply chains account for 80% of the total energy required to make a shoe, the materials that comprise a tennis shoe are incredibly important when examining the sustainability of said shoe (Henderson et al, 2009). In an attempt to discover what materials go into the production of Nike tennis shoes, I utilized the online Customer Service chat option on Nikes website. The agent allotted to me was unable to answer any of my questions regarding materials. In fact, I was told that said information would need to be retrieved from the Nike USA Consumer Services. After connecting with an agent on the phone, I was informed that Nike will not release a comprehensive list regarding materials used in Nike products (Brian, personal interview). I was, however, directed to look into Nikes Considered Design program website which listed a few materials. From said website, I was able to find highly limited information regarding materials used in shoes. Moreover, the information gathered only covered shoes under the Considered Design label. Considered Design, Nike Inc.s attempt to assess and reduce environmental degradation coming from the production of their shoes, has allowed for Nike to set standards for sustainable manufacturing of products. These goals, listed on the Nike website, seek to shift towards environmentally friendly materials, eliminate the use of solvents, and reduce waste during production (Nike Inc., 2010). The website lists twelve of the Considered Design products, ten shoe designs and two jackets. Of the ten shoes, only six shoes have any mention of materials in their descriptions. The Grigoros kayak shoe, made with one single piece of rubber, was designed

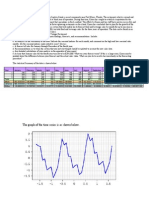

for the Beijing athletes and can be recycled without any separation (Nike Inc., 2010). This forethought in design harkens to Bill McDonoughs Cradle to Cradle thinking and allows for a drastic reduction in waste. This commitment to reduction of waste shows with the next Considered shoe. Released in 2008, the Trash Talk is made from scraps from the factory floor in both the upper and mid-sole of the shoe (Nike Inc., 2010). Following 2008, the information regarding how the shoes are deemed Considered Design becomes more and more vague. 2009s Dart VII is described in this way: recycled materials were used throughout (Nike Inc., 2010). This seems highly descriptive when compared to the Humara Cl and Tiempo Mystic II FG. These shoes each use recycled nylon and environmentally friendly materials whenever possible (Nike Inc., 2010). These vagaries, however, end with the Pegasus 25. This shoe uses Nike Grind, a rubber made from recycled shoes, an airbag made of 83% recycled polyurethane, and an upper mesh of 20-25% recycled PET (Nike Inc., 2010). In addition to the information garnered through the sales website, one can access a new tool used by Nike to rate the sustainability of materials used. In order to give public information, albeit limited information, regarding the Considered Design program, Nike has released a tool used in the examination of the life-cycle of materials needed during the production of shoes. This tool is called the Material Assessment Tool (MAT) and analyzes the life cycle of all raw materials used in production (Henderson et al, 2009). The MAT has allowed Nike to view the impacts from the materials used across four spectra: Chemistry, Energy/CO2-equivalence, Water/Land Use, and Waste (Nike Considered Design, 2010). In practice, the MAT allots a higher score for products deemed to be environmentally preferred materials (EPMs) while less sustainable products receive a lower score. The MAT Matrix itself shows the main materials used in the production of Nike shoes with scores associated within each stratum listed [Table 1]. This score is then calculated into Nikes own Considered Index by dividing the EPM points for each material by the total materials used. The examination of this average allows for a broader examination of the sustainability of each individual product (Henderson et al, 2009).While a product may have a higher score relating to each EPM, the use of a vast number of materials will pull the Considered Index down, accounting for all materials used in production. Table 1. Material Assessment Tool (MAT) Scores Matrix. Materials with the lowest and highest scores in each category are highlighted red and green, respectively. Material name Chemistry Total Energy/ CO2-eq Total 24 Water/Land Use Total Waste Total Total LCA score

Maximum possible points

40

16

20

100

Cotton Recycled Silk Polyester Recycled, Solution Dyed Polyester Recycled, Piece Dyed Down Polypropylene - Virgin Lyocell Polyester Virgin, Solution Dyed Rayon Beech Cellulose; Polynosic Polylactic Acid (PLA) Virgin Cotton Organic Polyester Virgin, Piece Dyed Cotton Conventional Hemp

28

15

16

13

72

34.5 16.1

13.2 17.5

9 12

7 12.3

63.6 57.9

20.1

17.3

11

57.4

21.1 18

20 20

9 12

4 4

54.1 54

18.2 12.6

14.7 18.8

11.5 12

4 5

48.4 48.4

15.2

16.3

11.5

47

12.1

17.5

13

46.6

21.8

16

45.8

9.4

16.3

39.7

13.8

16.3

39.1

18.2

10.3

6.3

38.8

Rayon Bamboo Synthetic Leather Ramie Rayon / Viscose Wood Cellulose Leather - Full Grain Acrylic Wool Nylon 6 Virgin Spandex (PU) Jute Nylon 6,6 Virgin

11.1

12.5

11

38.6

7.4

17.5

10.5

2.5

37.9

7.5 9.4

15 11.3

10 11.5

4 4

36.5 36.2

15

7.8

2.5

34.4

9.7 10.5 6.1

12.5 10.3 13.2

7.5 6.8 7.5

4 5 2.5

33.7 32.6 29.2

6.1 7.7 5.7

12.5 12.5 13.2

7.5 4 6

2.5 4 2.5

28.6 28.2 27.4

A close look at the MAT scores shows the comprehensiveness of the system. By breaking the assessment down into four separate categories, the score for each material is easily seen across many spectra. Additionally, the table allows for a close examination of each materials strengths and weaknesses in reference to sustainability. For example, while recycled cotton leads in Water/Land Use points, Waste Total points, and even Total Life Cycle-Assessment points, the necessity of solvents and refinement causes lower scores in the Chemistry and Energy strata. The chart also shows that, while prized for its sustainability in most industries, organic cotton scores lowest of all materials for Land/Water Use. After considering all of the materials and inputs used in the production of our Nike shoe sample, it is important to consider alternatives. Finding shoe alternatives pertaining to sustainability limits our selection, but one may hypothesize that a good factor for this would be

limiting the materials. Each material used in a product causes an environmental impact, whether it be through the methods of extraction, processing, transportation or disposal. For example, a shoe made of twenty different materials could mean environmental degradation, energy use, or waste production from each of these factors, for each of the twenty materials. If the shoe were made from only a few different materials, this would cut down on all of these factors significantly. This being said, certain materials have more of an impact than others. One material in particular may have more of a negative impact in the production process than, say, five other individual materials. Today most shoe materials can be processed synthetically, however the raw materials come from all around the world, depending on the shoe and what its inputs are. One alternative to our Nike shoe sample is Toms Shoes eco-friendly alpargata. Alpargatas are Argentinian, slipper-like shoes that are generally made from a few simple materials. (Irwin, 2007) The soles are made from a type of grass fiber called jute that is then spun into rope. This rope is then pressed into the shape of a shoe sole. The top of the shoe is made from cotton. The cotton is spun into fabric and sewed to the sole. The only other material is a wood insert in part of the sole, which sometimes is not used (Espadrilles, 2009). Toms Shoes has introduced a line of eco-friendly shoes that are made from organic cotton, a non leather interior, and recycled rubber soles. Some of the shoe models are also available with the traditional jute rope sole (Gordon, 2008). In the Nike Material Assessment Tool, organic cotton places towards the middle of the list of impacts of shoe material life cycles, jute places towards the bottom, and although they do not have recycled rubber, all of the recycled products placed at the top of the list (Henderson et al, 2009). Both companies are very vague when they are describing their production, which makes it very hard to compare the two products. However, only using three products in the Toms Shoe model compared to the long list of materials that go into the Nike shoe product does make a difference. Limiting materials will help Nike to reduce its footprint and in doing so become more sustainable. Another alternative is the Timberland Earthkeepers series of shoes. Timberland defines Earthkeeping as straightforward, practical, common sense. It means taking actions that enable us to be good stewards of the earth. Earthkeeping is the way we make our products (Timberland, 2010). Not only does Timberland use products such as Green Rubber (recycled rubber) to make their boot soles as well as use renewable energy in their facilities, and plant millions of trees to decrease their carbon emissions from manufacturing and energy use. Timberland also uses a Green Index to evaluate their production of footwear and clothing. This includes their climate impact, the chemicals used, and their resource consumption. The three equations below are used to generate this index. Climate Impact (kg CO2e for shoe)/10, score =10 =10 Chemicals ( 0 uses = 0, 1=2.5, 2=5, 3=7.5, 4=10) Resources (wt of non-recycled, organic or renewable material/weight of shoe) Climate impact measures the emissions of greenhouse gases from the production of each material to the manufacturing of the final product. Timberland is trying to eliminate chemicals used in production that have been linked to human or environmental harm so in measuring their

chemical output they can track their progress in this material sector. They are developing safer and more environmentally friendly substitutes to use instead of the conventional production chemicals. Lastly, the resources used are the measured land, water, and chemical use. The table below shows the Green Index as Timberland scored.

Timberland also has a measure of their ecological footprint using the same three categories involving their eco-friendly practices.

These factors are based on all of Timberlands production, and is not specific to its eco-friendly line of Earthkeeper boots. These boots use a much higher percentage of recycled materials and safer chemicals, lowering their Green Index number and also lowering their footprint. The new Earthkeeper 2.0 Rugged is Timberlands most eco-friendly boot and boasts a plethora of sustainable amenities including: Designed for disassembly at least 50% of the materials on this shoe can be recycled or reused at the end of its first life.

"Premium full-grain leather from a Leather Working Group certified gold-rated tannery for comfort and durability. 100% recycled PET laces. 45% recycled PET linings. A detachable and recyclable Green Rubber outsole made from 42% recycled rubber can go back to a Green Rubber factory for recycling (Timberland, 2010). One of the most difficult elements of recycling is the issue of disassembly. Many products today are impossible to recycle because of the way they are put together, and cannot be taken apart for recycling of their individual parts. The Earthkeeper 2.0 Rugged is designed specifically to be easily disassembled for recycling purposes. Another innovative component to the boot is the use of recycled PET. Timberland mentions that Americans use 2,500,000 plastic bottles every hour (Timberland, 2010). They utilize the PET plastic in plastic bottles for components of their boots, helping to solve some of the waste issue developing from this problem (Timberland, 2010). Although Nike has dedicated an entire division to sustainability, and publishes a corporate responsibility report every year pertaining to environmental factors in their corporation and production, they are still very vague and have a far way to go in terms of becoming sustainable. Toms Shoes and Timberland both offer products that seem to be more sustainable than any of Nikes shoes in production. Nikes goal "To create innovative and sustainable products is progressing but seems to be doing so very slowly in their materials, and especially when compared to the alternatives (Nike Inc., 2004). As more companies like Timberland and Toms Shoes introduce eco-friendly and sustainable products, others like Nike will be pressured to improve their practices to more sustainable measures.

Social and Environmental Impacts and Potential For Recycling

As mentioned earlier in the report Nike refuses to share information about material use and processing, so the material assessment was very limited, which then limits the degree of impact evaluation. Nike only releases information about materials in their Considered design line, which is part of their sustainability initiative. And even then they use their own index to interpret information about the materials sustainability, so it is difficult to grasp or see the evidence to back up their claims. When companies control they evaluation of sustainability progress it looses legitimacy because the company can make things look any way they want. Also, not knowing where any of the materials came from makes it impossible to evaluate the social and environmental impacts related to the extractions, processing, and distribution of resources from that region. For instance where Nike gets their cotton from dramatically effect the degree of social and environmental impacts, in the sense that if cotton was produced on forced child labor practice in Uzbekistan and used intensive pesticides and other petroleum products the impacts would be much greater than if the cotton was produced organically in India or Turkey.

Due to the unavailability of information the evaluation focused more upon potentials for recycling. Reuse a Shoe Program/Nike Grind Nike has created a strategic alliance with an eco-non-profit organization National Recycling Coalition (NRC) in order to collect used tennis shoes, as part of Nikes Reuse a Shoe Program (Kumar, 2006). Founded in 1978, the National Recycling Coalition, Inc. is a non-profit organization representing all the diverse interests committed to the common goal of maximizing recycling to achieve the benefits of resource conservation, solid waste reduction, environmental protection, energy conservation, and social and economic development. Nike benefits in multiple ways from this partnership, firstly it is easier and less costly than collecting shoes themselves, also, having this partnership with an eco non-profity gives Nike that green image that they are clearly trying so hard to convey. From my research the legitamacy of this is questionable Worn out and defected shoes can be sent directly to processing plant, dropped off at all of the Nike location, or they can be given to an eco non-profit in collaboration with Nike. As of 2006 there was an average of only 3 drop-off locations for the 19 participating states in the US (Kumar, 2006). But since then the number has increased significantly. Reuse-A-Shoe program has gained a lot of popularity, having hundreds of organizations and groups have applied to be party of the Reuse-A-Shoe effort. Nike plans to the UK, Australia, and countries in Asia. Nike relies on its partner network to collect tennis shoes. Once a member of the NRC has collected 5000 pairs of shoes, Nike will arrange for the shoes to be sent to one of their two recycling centers, in Tennessee and Belgium (Nike, Inc.). Shoes are shipped free of charge. The process of collection depends on the geographic location and number of items. The NRC takes care of the logistics of collecting the shoes, leaving Nike to focus on the end uses for the resulting Nike Grind material (Kumar, 2006). Nearly two million shoes are collected annually. Once collected, shoes are sent to a Nike processing facility where they under go complex separation process (Nike, Inc.). Shoes are broken down into three parts, the rubber out sole, the upper fabric and the middle foam. Then each material gets ground up to what Nike refers to as Nike Grind (Nike, Inc.). Nearly every part of shoe is reused. Nike grind is a durable athletic surface material used in products such as fitness matting, running tracks, athletic fields, and playgrounds. the durability and usable life spanned is relevant to sustainability. Sports surfaces are the main way Nike recycles used shoes, and it extends use of shoes up to twenty years(Kumar, 2006). Through a chemical process at recycling center, Nike obtains three distinct types of Grind material (upper fabric, midsole foam and outsole rubber). Each are used in a different way to make new sports surfaces like soccer and football fields, basketball and tennis courts, tracks and playground surfacing. Nike licenses Field Turf uses Nike grind material from manufacturing byproducts exclusively (Nike, Inc.). There is a lack of information on the solvents used in such chemical processes because Nike doesnt release full and accurate information about materials, or chemical processes, which

leads me to think they have a lot to hide about the truth of Nikes sustainability. Although this program does reduce a significant amount of municipal solid waste, and reuses material rather than putting them into a landfill or an incinerator, which is a positive aspect. The closed loop supply chain is definitely a more sustainable model than the previously used conventional supply chain, yet without concrete information it is difficult to confidently say just how sustainable the closed loop is, or weather it is actually a closed loop at all. It is unclear what emissions are produce, or how much energy is consumed, or if the chemicals used are toxic, bur regardless of that, transforming waste into secondary material reduces waste. That in its-self reduces social and environmental impacts by decreasing the amount of unfair waste dumped in peoples back yards, which pollutes the soil and water through chemical leaching and run off. Using waste as a secondary product also decreases environmental impacts related to the primary resources that would have been used otherwise. It also reuses dependence of resources such as petroleum. yet It is difficult to evaluate the level of environmental and social impacts related to Nikes footwear industry because there is a huge gap in the information and research. But at a more universal level it is unjust and unsustainable to pollute the soil and water upon which all life is dependent. There is great potential for reducing impacts related to waste and shoe production, Nikes Reuse-A-Shoe is a good example of this. with millions of shoes being made and throw away every day even changing the design of the shoe so it can be more easily taken apart goes a long way in making the product more sustainable, on a count that it makes it easier to reprocess the materials. when its easier, its cheaper, when its cheaper more businesses with be attracted and adopt the method. Even if the company didnt reprocess the shoes, it creates an opportunity for a business to be created for that purpose. This would create jobs, reduce waste, and give the company a greener image which i becoming increasingly valued by companies around the world.

Corporate Practices

Nike as a company has made significant efforts to improve its own corporate practices with regard to sustainability, as well as influencing legislation internationally to improve global corporate practices. Nike CEO Mark Parker has been instrumental in changing the companys vision regarding responsible, environmentally sound practices. Nikes history of sustainability efforts begins in the late 1995 when the company attempted to lower greenhouse gas emissions by replacing sulfur hexafluoride (SF6) in its shoes. Sulfur hexafluoride is a greenhouse gas used in air cushioned shoes. By 2003, Nike completely replaced SF6, which represents 80% of the companys total greenhouse gas emissions since 1997. A second GHG previously found in Nike shoes, perfluoropropane (PFP), was removed by 2006 when a large research and development project called Considered Design found all nitrogen alternatives for PFP. (Ceres, 2008) The company also has a history of offsetting emissions. In 2000, Nike purchased its first offsets for business travel emissions. Since 2000, the company has purchased 111,000 tons of CO2 offsets. (Ceres, 2008) The next year Nike joined the World Wildlife Fund Climate Savers

Program and set CO2 emission reduction targets. Part of this program requires Nike to submit inventory data for third party review, as well as biannual progress reports. Nike exceeded its carbon reduction goals in 2005 and has since expanded these goals.(Ceres, 2008) Joining the WWF Climate Savers Program shows Nikes commitment to accountability and responsibility. Another example of this commitment is the Corporate Responsibility Committee. Established in 2001, this committee meets three times per year to review policies and make recommendations. All Corporate Responsibility meetings are attended either by CEO Mark Parker or chairman Philip Knight. (Ceres, 2008) In 2006, the company improved its framework for ensuring executive accountability and responsibility. Nike has organized corporate responsibility teams that are managed by the Vice President of Corporate Responsibility, who in turn answers directly to CEO Mark Parker. Since 2007 the Nike Board of Directors approved new global corporate responsibility targets, GHG reduction goals, and climate neutrality goals. (Ceres, 2008) Nike is also very politically active and has facilitated meaningful change in legislation. In November, 2007 Nike joined other corporations such as Sun Microsystems and Coca Cola as signatories of the Bali Communiqu. (Ceres, 2008) The Bali Communiqu calls for a legally binding United Nations framework to solve climate change issues. At the signing of this communiqu, CEO Mark Parker said, Tackling climate change is a catalyst for growth and innovation. These are complex issues, which is why international agreement and action is imperative to creating positive change. (Ceres, 2008) Parker has also personally written letters to congressional leaders in 2007 and 2008 urging meaningful legislative changes with regard to climate change. Nike has attempted to further the discussion of climate change by sponsoring the Focus the Nation initiative, which is designed to open dialogue between civic organizations, faith organizations and students. Also, in 2008, Nike joined the Climate group, which aims to accelerate climate action internationally. Another huge step Nike took in promoting sustainability was BICEP, the Business for Innovative Climate and Energy Policy. (Ceres, 2008) This business coalition was founded in November 2008 by Nike, Sun Microsystems, and Starbucks in partnership with Ceres, a coalition of environmental and special interest groups working with companies to address global sustainability challenges. The goal of BICEP is to promote strong climate and energy legislation in the United States. BICEP promotes policy changes based on 8 guiding principles: 1.) Set short- and long-term greenhouse gas reduction targets 2.) Stimulate green job growth 3.) adopt a national renewable portfolio standard 4.) Capture vast energy efficiency opportunities 5.) Boost investment in renewable energy, energy efficiency and carbon capture and storage technologies 6.) Establish cap-and-trade system with 100% auction of carbon allowances 7.) Encourage transportation for clean energy economy 8.) Limit construction of new coal plants to those that capture and store CO2. (Ceres, 2008)

Nike is also a signatory to the World Wildlife Fund Tokyo declaration in 2008, which claims that greenhouse gas emissions must be reduced by 50% by 2050, and that total emissions must decline within 10 to 15 years to avoid serious consequences. (Sony Corp., 2008) Other notable signatories of this declaration include Sony and Nokia. Nike has also stepped up its sustainability efforts in the United States: the company is now a member of the Oregon Governors Climate Change Integration Group as their headquarters is located in Beaverton, Oregon. In addition to this, Nike has testified on two occasions at field hearings of the US House of Representatives Select Committee on Global Warming and Energy Independence. (Ceres, 2008) While Nike has testified in favor of stricter legislation in the US, their motives must be considered as over 97% of Nike shoe production occurs outside the US. (Nike, Inc. 10k Form, 2010) Hence, Nike would not feel the economic burden of cap-and-tax legislation, giving them an advantage over domestic US shoe companies. In addition to Nikes many efforts to effect change through legislation and international agreements, the company has made significant internal improvements as well. Nike publishes an annual Corporate Responsibility Strategy report detailing the companys sustainability efforts, goals and results. (Nike, Inc., 2010) In addition to the CRS reports, Nike introduced the Considered Index in 2007. (Henderson et al, 2009) This index is a tool for measuring material usage across the diverse line of shoes Nike produces. The Considered Index evaluates and scores Nike shoes based on metrics like amount of waste and solvent usage. (Henderson, 2009) The index also incorporates awards for innovation and gives production teams incentives to improve the production process of their shoe. (Henderson, 2009) Nike has also attempted to reduce its employee carbon emissions through various workshops, including one called Climate Caf located at their headquarters. In 2008, the company introduced an internet forum for employees to share and discuss ideas related to lowering emissions. (Ceres, 2008) Nike also promotes alternative transportation options for employees such as electric vehicle charging stations, as well as promoting virtual meetings to lower travel emissions. Nike also offsets 100% of its business air travel emissions. (Ceres, 2008) Efforts to improve the companys manufacturing practices include audits of factories with the goal of increasing efficiency. The Nike Energy Challenge is another program that creates a competition between company facilities to spur innovation and efficiency. Not only is Nike looking to lower its energy demands through increased efficiency, but the company is looking to clean up the supply of energy used in its factories. For example, in the Nike European Distribution Center, located in Laakdal, Belgium, there are 6 wind turbines producing electricity. This facility is the largest of its kind in Belgium to run solely on clean energy produced on-site. (Ceres, 2008) Nike has proved without a doubt in the last decade that the company is dedicated to a more sustainable future. While improvement is still needed in some areas, the company has made significant efforts to open dialogue about and reduce greenhouse gas emissions over the last ten years. Through political and social means Nike has led by example and looks to keep improving in the future. New goals for the company include achieving climate neutrality in Nike brand facilities and business travel by FY11, to achieve climate neutrality among all Nike facilities by

FY15, to achieve a 30% reduction in their inbound logistics footprint (Using 2003 as a baseline) by FY20. (Ceres, 2008) Nikes dedication to carbon neutrality, accountability, responsibility, and sustainable corporate practices sets a fine example for other corporations to emulate. While the companys image has had its ups and downs over the years, Nikes dedication to sustainability seems genuine and their progress is encouraging.

Recommendations for Consumers and Policy-Makers

As the largest producer of athletic footwear in the world, Nike has a huge impact on people and resources around the globe. The company has recognized their dependence on fossil fuel energy and oil for materials, exposing them to high oil prices or carbon restrictions in the future. Meanwhile, waste production and use of toxic materials and water also pose major risks. They also face public criticism from the conditions of the factories making their products. Nike, Inc. has claimed sustainability is a core value of their company, recognizing the opportunities for innovation, corporate responsibility and increased profitability. The company still has many improvements to make, but could use new government regulation and transparency requirements that would level the playing field with other footwear companies, encourage innovation and inform consumers. The company was one of the first in the footwear industry to embrace globalization, contracting manufacturing to other companies located in countries with cheap labor at a time when most shoes were still produced in the United States (Locke, 2002). Factories that Nike contracted with employed 823,026 people in FY09, about half of which worked in footwear (Nike, Inc. CRR, 2009). Shoe factories are located almost exclusively in China, Thailand, Indonesia and Vietnam. With an outsourced manufacturing network widely distributed across the world, its difficult for U.S. policy makers to have a major impact on the sustainability of Nikes footwear. Regardless of this hurdle, policy makers can require transparency about corporate impacts on sustainability, as well as the potential impacts of a changing climate on their business. This is especially true for publicly traded companies (like Nike, Inc.), because the Securities and Exchange Commission (SEC) can require them to release information to benefit shareholders. The SEC recently issued an interpretive guidance that clarifies what companies need to disclose to investors in terms of climate-related material effects on business operations, whether from new emissions management policies, the physical impacts of changing weather or business opportunities associated with the growing clean energy economy (Securities and Exchange Comission, 2010). Policies from the SEC should also require the release of data on the embedded energy and emissions from the materials purchased by companies for the production of their products, and the risks they pose. Such information will make it easier for companies to see their impact and find areas of improvement. Government regulation (no necessarily from the SEC) could also require companies to release the materials and chemicals used in their products, which would disallow them from claiming that its proprietary information.

With a lack of data, a company like Nike that outsources most of its products might think that the majority of energy use comes from transportation from factory to store. When they looked at the whole picture, they found that 59 percent of the embedded energy in a typical running shoe was in the materials, 22 percent in manufacturing and 10 percent in shipping (Nike, Inc. CRR, 2009). When calculating GHG emissions, Nike still does not include the emissions from materials. Without new regulations, the publicly available information released from companies will be inconsistent. Programs like Nike Reuse-A-Shoe should be encouraged by the government through tax breaks and investment into research of closed loop systems. Nike is currently struggling with a lack of locations for drop offs and high shipping costs (Nike Inc. CRR, 2009). Considering the U.S. doesnt have a federal recycling program, a national recycling system for apparel is unlikely. But research in this area could be especially useful for footwear, which has a short useful life. Nike has been very active in the U.S. policy arena, particularly around sustainability issues. As previously mentioned, they have been active in the WWF Climate Savers Program, Corporate Responsibility Committee and signed the Bali Communiqu. It was a founding member of BICEP, an organization advocating for a strong national U.S. climate and energy policy. This should indicate policy makers that major U.S. based global corporations are ready to innovate, and a level playing field would be very beneficial. Consumers have a plethora of choices to make when buying a pair of shoes, and sustainability is usually not their primary concern. In focus groups, Nike found that consumers were skeptical about the performance of shoes made from Environmentally Preferred Materials (Henderson, 2009). If a consumer is a big fan of Nike shoes and sustainability minded, we encourage them to buy a shoe with a Considered Design rating of gold. Despite criticism of the scoring system (which could result in a silver rated shoe with heavy solvent usage), the MAT is a through assessment of all the materials used to make a shoe. Nike should make these ratings (and the reasoning behind them) publicly available and more easily accessible to their customers. Due to differing measurements of sustainability used by shoe manufactures, and the material requirements of different footwear styles (sandals versus boots for example), its difficult to make a recommendation about which shoes are the most sustainable. The alpargatas and boots we examined earlier are certainly more sustainable than your average shoe. Toms shoes are more socially sustainable, since they give away a pair for every pair thats bought. The Timberland Earthkeeprs and Nikes Considered Design shoes are certainly more sustainable than the other shoes their companies make, but more data needs to be made public in order to make a strong recommendation.

Conclusion

With the scope of a corporation like Nike, it is important to consider the legitimacy of its production, materials and practices, especially when much of it is private, classified, and unavailable to the public. When dealing with materials, Nike was uncooperative with divulging

any information, besides a few inputs to production in their MAT. It is important to consider alternative shoes or footwear companies that may have a more sustainable approach, not only for consumers, but also to help compare production procedures and encourage companies like Nike to improve their practices to be more environmentally friendly and more sustainable. Companies such as Timberland with their Earthkeeper series is a good example and a step in the right direction to using recycled materials in their shoes, less hazardous materials, and crediting some of their emissions by planting millions of trees or using renewable energy.

Works Cited

Beder, S. (2002). Nike's Greenwashing Sweatship Labor Retrieved December 6, 2010, from http://www.organicconsumers.org/clothes/nikesweatshop.cfm Ceres. (2008). Corporate governance and climate change: consumer and technology companies. Retrieved from: http://www.ceres.org/Document.Doc?id=398 Charter, M. "Darcy Winslow, General Manager, Sustainable Business Strategies, Nike Inc. US." The Journal of Sustainable Product Design 1.1 (2001): 53-56. SpringerLink. Springer Netherlands, 9 May 2002. Web. 27 Oct. 2010. http://www.springerlink.com/content/e2qgxud1l8fyyter/fulltext.pdf DeTienne, K. B., & Lewis, L. W. (2005). The pragmatic and ethical barriers to corporate social responsibility disclosure: the Nike case. Journal of Business Ethics, 60(4), 359-376. "Espadrilles." Alpargata, the Spanish and French Espadrilles Website. Espadrilles, 2009. Web. 06 Dec. 2010. http://www.alpargata.ca/. Epstein, M. J., Buhovac, A. R., & Yuthas, K. (2010). Why Nike kicks butt in sustainability. Organizational Dynamics, 39(4), 352-356. http://www.linkinghub.elsevier.com/retrieve/pii/S0090261610000616 Gordon, Jacob. "The TH Interview: TOMS Shoes (Part Two)." TreeHugger. Discovery Communications, LLC, 18 Sept. 2008. Web. 06 Dec. 2010. http://www.treehugger.com/files/2008/09/the-th-interview-toms-2.php Henderson, R., Locke, R. M., Lyddy, C., & Reavis, C. (2009). Nike considered: Getting traction on sustainability: MIT Sloan Management. Irwin, J. (2007). The lowly alpargata steps forward, The New York Times.

Kumar, S., Malegeant, P. (2006). Strategic alliance in a closed-loop supply chain, a case of manufacturer and eco-non-profit organization. Technovation, 26, 1127-1135. Retrieved December 23, 2010 from Http://www.sciencedirect.com/science Locke, R., & Romis, M. (2007). Improving Work Conditions in a Global Supply Chain (Vol. 48): MIT Sloan Management Review. http://www.wcfia.harvard.edu/sites/default/files/privategovernance_ws_lockeromis.pdf Locke, R., M. (2002). The Promise and Perils of Globalization: The Case of Nike. Industrial Performance Center MIT. Cambridge, MA: MIT IPC-02-007.

Nike Considered Design. (2010). Material assessment tool (mat) scores matrix. Retrieved from http://www.nikebiz.com/Pages/ScoresDetail.aspx http://media.corporate-ir.net/media_files/IROL/10/100529/nike-ar20100804/docs/NIKE_2010_10-K.pdf Nike Inc., FY04 Corporate Responsibility Report, 2004, http://www.nikebiz.com/responsibility/documents/Nike_FY04_CR_report.pdf Nike Inc. FY07-09 Corporate Resonsibility Report, 2007-2009, http://www.nikebiz.com/crreport/pdf/ Nike. Nike: History and Heritage Retrieved December 6, 2010, from http://www.nikebiz.com/company_overview/history/1970s.html Nike Reuse-A-Shoe (2008). Drop-off locations: where to recycle shoes. Retrieved from http://www.nikereuseashoe.com/get-involved/drop-off-locations "Timberland Community | Product Philosophy." Timberland Community. The Timberland Company, 2010. Web. 06 Dec. 2010. <http://community.timberland.com/ProductPhilosophy>. Securities and Exchange Commission. (2010, January 27). SEC Issues Interpretive Guidance on Disclosure Related to Business or Legal Developments Regarding Climate Change. Retrieved from: http://www.sec.gov/news/press/2010/2010-15.htm Sony Corp., (2008). Business leaders sign Tokyo Declaration to tackle global warming and enact industry-wide change Retrieved 05 Dec. 2010. From http://www.sony.net/SonyInfo/News/Press/200802/08-0215E/index.html

University of Cambrige. (2007). Bali Communique & Signatories. Retrieved 05 Dec. 2010 From http://www.cpsl.cam.ac.uk/pdf/Bali%20Communique%20&%20Signatories%201.pdf Nike, Inc. (2010). "Annual Report on Form 10-K" Retrieved 01 Dec. 2010 From http://media.corporate-ir.net/media_files/IROL/10/100529/nike-ar20100804/docs/NIKE_2010_10-K.pdf

You might also like

- Assessment of RTE Television's Operational EnvironmentDocument11 pagesAssessment of RTE Television's Operational EnvironmentJakeNo ratings yet

- Collier and Evans Operations Management Chapter 7Document37 pagesCollier and Evans Operations Management Chapter 7Omar100% (1)

- ERP Assignment QBDocument3 pagesERP Assignment QBAbhishek Karekar50% (6)

- HP Case StudyDocument9 pagesHP Case Studyspbhuvan0% (1)

- Productivity Improvement Through The Application of Cleaner Production in The Environmental Management System of Msmes in The Furniture IndustryDocument36 pagesProductivity Improvement Through The Application of Cleaner Production in The Environmental Management System of Msmes in The Furniture IndustryYork John LopezNo ratings yet

- Reflection Papers (Prelims To Finals)Document7 pagesReflection Papers (Prelims To Finals)Kristine Jhoy Nolasco SecopitoNo ratings yet

- Ch04 Production SCMDocument28 pagesCh04 Production SCMSha Eem100% (1)

- Section 11 Arbitration ActDocument41 pagesSection 11 Arbitration ActShivansh AryaNo ratings yet

- Handbook MogliceDocument63 pagesHandbook MoglicesolidsverigeNo ratings yet

- Automated School Form 2 DepEdDocument4 pagesAutomated School Form 2 DepEdChris Vincent Claro Damayo100% (9)

- Tamara L. Roleff-Satanism-Greenhaven Press (2002)Document112 pagesTamara L. Roleff-Satanism-Greenhaven Press (2002)lucaslmoraesNo ratings yet

- The Social Media Hack Guide Updated Feb 19Document19 pagesThe Social Media Hack Guide Updated Feb 19Neev100% (1)

- SOR (Stimulus-Organism-Response) Model Application in Observing The Influence of Impulsive Buying On Consumer S Post-Purchase RegretDocument13 pagesSOR (Stimulus-Organism-Response) Model Application in Observing The Influence of Impulsive Buying On Consumer S Post-Purchase RegretPUTU MEIDITA LARASTRININo ratings yet

- Inventory Management System ProjectDocument27 pagesInventory Management System Projectaayanshaikh775No ratings yet

- Jesika - Kumbhar - CV - SDA Bocconi Asia CenterDocument1 pageJesika - Kumbhar - CV - SDA Bocconi Asia CenterJesika KumbharNo ratings yet

- Impact of Internet On BusinessDocument11 pagesImpact of Internet On Businessusman5555380100% (1)

- Ikea Strategy in Covid19Document2 pagesIkea Strategy in Covid19Wiwi BuiNo ratings yet

- Operations & Productivity-Practice ProblemsDocument3 pagesOperations & Productivity-Practice ProblemsRezaul Karim Tutul50% (2)

- Case Study Challenges Faced by Cognizant TechDocument6 pagesCase Study Challenges Faced by Cognizant TechAkshay GuptaNo ratings yet

- Lesson 2 - Module 002 Demand ForecastingDocument16 pagesLesson 2 - Module 002 Demand ForecastingNoe AgubangNo ratings yet

- IS110 Case FacilitationDocument37 pagesIS110 Case FacilitationSean WoonNo ratings yet

- Ethical Dilemmas Faced by Multinational CompaniesDocument3 pagesEthical Dilemmas Faced by Multinational CompaniessupriyaNo ratings yet

- How To Write A Comprehensive Business PlanDocument2 pagesHow To Write A Comprehensive Business PlanODUNBAKU SAHEEDNo ratings yet

- Drivers of Supply Chain Performance in Tri-Star Tooth Brush CompanyDocument15 pagesDrivers of Supply Chain Performance in Tri-Star Tooth Brush Companyzarin rahmanNo ratings yet

- Executive SummaryDocument18 pagesExecutive SummaryDeepak RawatNo ratings yet

- Design and Implementation Performance Based Payroll Management System Case Study: Healing Stream LaboratoryDocument70 pagesDesign and Implementation Performance Based Payroll Management System Case Study: Healing Stream LaboratoryNwachinaere NnamdiNo ratings yet

- QTDocument5 pagesQTRohit Sharma100% (1)

- COst Accounting SystamDocument4 pagesCOst Accounting SystamAishwary SakalleNo ratings yet

- CPROBS2 Case StudyDocument10 pagesCPROBS2 Case StudyPancho Tinsay100% (1)

- OB 33 BS 16 Employee Stakeholders and Workplace IssuesDocument25 pagesOB 33 BS 16 Employee Stakeholders and Workplace IssuesberitahrNo ratings yet

- IkeaDocument26 pagesIkeaBilal ShamimNo ratings yet

- Activity Based Costing ExampleDocument7 pagesActivity Based Costing ExampleMohsin BashirNo ratings yet

- Cases 3 - Berlin Novanolo G (29123112)Document4 pagesCases 3 - Berlin Novanolo G (29123112)catatankotakkuningNo ratings yet

- CBP Case Study of D&C CarwashDocument3 pagesCBP Case Study of D&C CarwashMuhammad Shakir Bin ZulkafliNo ratings yet

- Sample AssignmentDocument11 pagesSample AssignmentKemas Ridho Aditya100% (1)

- Week 10&11 Assignment-HernandezDocument3 pagesWeek 10&11 Assignment-HernandezDigna HernandezNo ratings yet

- Quiz 2Document6 pagesQuiz 2Mukund AgarwalNo ratings yet

- FinalpayrollsmsdocuDocument127 pagesFinalpayrollsmsdocuapi-271517277No ratings yet

- Process and Product DesignDocument12 pagesProcess and Product DesignShivam KumarNo ratings yet

- Updated Case Westover ElectricalDocument8 pagesUpdated Case Westover ElectricalRalph Adrian MielNo ratings yet

- Chapter 1Document7 pagesChapter 1Micah Shaine ValdezNo ratings yet

- Course: Applied Statistics Projects: Bui Anh Tuan March 1, 2022Document9 pagesCourse: Applied Statistics Projects: Bui Anh Tuan March 1, 2022Dien Duong LeNo ratings yet

- Guide For ThesisDocument148 pagesGuide For ThesisRocky MontañerNo ratings yet

- Multahadi Qisman 2119492 - AssignmentDocument11 pagesMultahadi Qisman 2119492 - AssignmentMultahadi QismanNo ratings yet

- 10 Buying, Using, DisposingDocument14 pages10 Buying, Using, Disposingsofia fiersNo ratings yet

- 01.C Lidu LiquorDocument6 pages01.C Lidu LiquorCahyo Ady NugrahaNo ratings yet

- Learning Objectives: c04.qxd 6/2/06 2:53 PM Page 124Document54 pagesLearning Objectives: c04.qxd 6/2/06 2:53 PM Page 124Eric M. KathenduNo ratings yet

- Case Analysis 1:: Members: de Guzman, Jerone T. Abante, Efril Sheine Abu, Patricia Ann D. Vivo, Lea Queen LDocument8 pagesCase Analysis 1:: Members: de Guzman, Jerone T. Abante, Efril Sheine Abu, Patricia Ann D. Vivo, Lea Queen LLeyya VivoNo ratings yet

- Absorption and Marginal Costing BasicDocument2 pagesAbsorption and Marginal Costing BasicDavilla CuptaNo ratings yet

- PEST AnalysisDocument10 pagesPEST Analysisamit.dasNo ratings yet

- CSR Case StudyDocument14 pagesCSR Case StudyBushra ChowdhuryNo ratings yet

- Business ResearchDocument2 pagesBusiness ResearchGeleen CantosNo ratings yet

- Goal ProgrammingDocument52 pagesGoal Programmingvineeth kumarNo ratings yet

- Sixteenth Edition: Foundations of Business Intelligence: Databases and Information ManagementDocument43 pagesSixteenth Edition: Foundations of Business Intelligence: Databases and Information ManagementQuỳnh NguyễnNo ratings yet

- Ikea C3Document5 pagesIkea C3Nicole Cliano100% (1)

- Week 2 Practice Questions - ProductivityDocument6 pagesWeek 2 Practice Questions - ProductivityHeah Wan Yee100% (1)

- Commitment From The Industry of NikeDocument14 pagesCommitment From The Industry of NikeUmme Rukaiya MituNo ratings yet

- Nike Case Study FritzDocument11 pagesNike Case Study Fritzridhi0412No ratings yet

- Sustainability and Innovation - NIKEDocument3 pagesSustainability and Innovation - NIKESangkarii MahadevanNo ratings yet

- Nike SustainabilityDocument2 pagesNike Sustainabilityjalena.holmesNo ratings yet

- Nike Sustainability HolmesDocument2 pagesNike Sustainability Holmesjalena.holmesNo ratings yet

- Written Assignment #1Document3 pagesWritten Assignment #1weirdforeheadguyNo ratings yet

- Nike Case StudyDocument6 pagesNike Case Studyapi-361156846100% (1)

- TMA02 Nike and Its EnvironmentDocument14 pagesTMA02 Nike and Its EnvironmentkwokchiuNo ratings yet

- Tarfah Al Sheikh Asia Yasin Deeqa Ali Mercy Etuk TSZ Ue SzetoDocument14 pagesTarfah Al Sheikh Asia Yasin Deeqa Ali Mercy Etuk TSZ Ue SzetoMercia Nattyl EtukNo ratings yet

- Best Coputer ShortcutsDocument20 pagesBest Coputer Shortcutsmatloobilahi100% (1)

- ACCA CAT Paper T5 Managing People and Systems Solved Past PapersDocument139 pagesACCA CAT Paper T5 Managing People and Systems Solved Past Papersdastgeer007100% (1)

- The Concise Guide To EconomicsDocument137 pagesThe Concise Guide To EconomicsLudwig von Mises Institute100% (58)

- East Asia Economic Update Appendix TablesDocument10 pagesEast Asia Economic Update Appendix TablesmatloobilahiNo ratings yet

- What Is Organizational CultureDocument4 pagesWhat Is Organizational Culturematloobilahi100% (2)

- CFA Institute Integrity List:: 50 Ways To Restore Trust in The Investment IndustryDocument1 pageCFA Institute Integrity List:: 50 Ways To Restore Trust in The Investment IndustrymatloobilahiNo ratings yet

- Sa Apr12 p3 ValuesDocument10 pagesSa Apr12 p3 ValuesSyed Umair Ahmed RizviNo ratings yet

- 10 Reasons Strategic Plans FailDocument3 pages10 Reasons Strategic Plans FailmatloobilahiNo ratings yet

- 15 SN BusinessstrategyJulyAugust08Document2 pages15 SN BusinessstrategyJulyAugust08mondy81No ratings yet

- Tome1 1bacsef Math HiyabDocument63 pagesTome1 1bacsef Math HiyabHayat SawatNo ratings yet

- Esdc Ins5217Document2 pagesEsdc Ins5217M CraftNo ratings yet

- S.3 Eot Assessment 2023 Mathematics TIME: 2 Hours InstructionsDocument4 pagesS.3 Eot Assessment 2023 Mathematics TIME: 2 Hours InstructionsOwani Jimmy100% (4)

- Fibre To Fabric - MFDocument5 pagesFibre To Fabric - MFMehak FatimaNo ratings yet

- Full Stack Interview QuestionsDocument22 pagesFull Stack Interview Questionsdorian451No ratings yet

- Nexon Facelift Price List 01 Feb 2024Document2 pagesNexon Facelift Price List 01 Feb 2024yashs12238No ratings yet

- LESSON 4philosophy of Man 1Document17 pagesLESSON 4philosophy of Man 1ernieNo ratings yet

- Group12 - Falcon Industries LTD - 1Document14 pagesGroup12 - Falcon Industries LTD - 1guygarrettNo ratings yet

- Business Intelligence in Banking IndustryDocument11 pagesBusiness Intelligence in Banking IndustryKrishna Bhaskar100% (1)

- Marine Boilers 25Document99 pagesMarine Boilers 25Anjaana PrashantNo ratings yet

- Low-Fat Vs Low-CarbDocument8 pagesLow-Fat Vs Low-CarbTrismegisteNo ratings yet

- Sehra e SeenaDocument26 pagesSehra e Seenarida84377No ratings yet

- Strategic Global Sourcing: Supplier DiversityDocument10 pagesStrategic Global Sourcing: Supplier DiversityYeasir HasanNo ratings yet

- MF ISIN CodeDocument49 pagesMF ISIN CodeshriramNo ratings yet

- David Alanis ResumeDocument1 pageDavid Alanis Resumeapi-340744993No ratings yet

- Grade 9 (Edexcel) Biology IDocument16 pagesGrade 9 (Edexcel) Biology INithika De SilvaNo ratings yet

- User Manual: Etronic RA640Document9 pagesUser Manual: Etronic RA640Vincent StanleyNo ratings yet

- Elizabeth Crowley's Letter Regarding Maspeth Homeless ShelterDocument2 pagesElizabeth Crowley's Letter Regarding Maspeth Homeless SheltercrainsnewyorkNo ratings yet

- 01 - Full Score - ChatGPTDocument2 pages01 - Full Score - ChatGPTramsnakeNo ratings yet

- African Economic Zones Outlook 1Document24 pagesAfrican Economic Zones Outlook 1Hagos GebreamlakNo ratings yet

- Mahindra Report: Analysis of Mahindra & Mahindra ScorpioDocument58 pagesMahindra Report: Analysis of Mahindra & Mahindra ScorpioAnand Singh TomarNo ratings yet

- Jump To Navigation Jump To Search: This Article Is About The Actor. For Other Uses, SeeDocument11 pagesJump To Navigation Jump To Search: This Article Is About The Actor. For Other Uses, Seeanon_539130656100% (1)

- Carpet Languages PeoplesDocument1,557 pagesCarpet Languages PeoplespronaturaalNo ratings yet

- English All For CssDocument25 pagesEnglish All For CssŠąłm ĄńNo ratings yet