Design and Calculation Agitation

Design and Calculation Agitation

Uploaded by

David LambertCopyright:

Available Formats

Design and Calculation Agitation

Design and Calculation Agitation

Uploaded by

David LambertOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Design and Calculation Agitation

Design and Calculation Agitation

Uploaded by

David LambertCopyright:

Available Formats

Problem Statement: Calculate the blend time for a mixer with one or two impellers

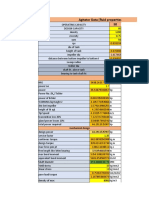

Inputs Fluid Mixing purpose Degree of agitation Fluid density Fluid viscosity

SI Units

US Units

ro mu

kg/m3 kg/m-s

1000 0.001

lb/ft3 lb/ft-s

62.43 0.000672

Tank Geometry T Diameter H Filled Height Impeller Lowest impeller Type Diameter Projected blade height Distance to mounting flange Distance to lower bearing Distance off bottom Second impeller Type Diameter Projected blade height Distance to mounting flange Speed

m m

3 3.5

ft ft

9.84252 11.48294

D1 W1 L1 L' C

m m m m m

ft ft ft ft ft

6.56168 0 0 0 0

D2 W2 L2 N Baffles B

m m m rps

ft ft ft rps

6.56168 0 0 1.42

1.42

Number of baffles Baffle width Space between baffle and wall

m m

4 0.25 0.041667

ft ft

4 0.82021 0.136702

Data Lookup and Calculations Nre Reynolds number gc Conversion factor NQ Pumping number Q Pumping capacity NP Power number - lower impeller

m3/s

12780000 1 0.8 9.088 1.3

ft3/s

12778151 32.17 0.8 320.9397 1.3

Power

119112.8

ft-lbf/s hp

87867.01 159.7582 1.3 87867.01 175734 319.5164

NP P P

Power number - upper impeller Power Total power (assume additive)

W W

1.3 119112.8 238225.6

ft-lbf/s ft-lbf/s hp

Mixing zone calculation, Np^(1/3) * Nre Mixing zone Theta95 Mixing time, 95% uniformity Desired mixing uniformity Adjusted mixing time Volume Turnovers, 95% uniformity s

13948001 Turbulent 9 99% 14.2 24.74004 3.40 ft3

13945983 Turbulent 9 99% 14.2 873.6863 3.40

s m3

Problem Statement: Calculate power and blend time for a helical ribbon impeller working in the laminar flow range

Inputs Fluid ro mu Mixing purpose Fluid density Fluid viscosity kg/m3 kg/m-s

SI Units Blend 1000 100

US Units

lb/ft3 lb/ft-s

62.43 67.20882

Tank Geometry T Diameter H Filled Height Helical Ribbon Geometry D Diameter h Overall height of impeller p Pitch (height of one turn) w Blade width nb Number of blades N gc Speed Conversion factor

m m

3 3.5

ft ft

9.84252 11.48294

m m m m

2.85 3.5 0.5 0.285 2 0.1 1

ft ft ft ft

9.350394 11.48294 1.64042 0.935039 2 0.1 32.17

rps

rps

Calculations c wall clearance clearance % of tank diameter Kp P Power factor for helical ribbon Power

0.075 2.5% 807.1066 18683.81

ft

0.246063

ft-lb/s hp

807.1066 13784.65 25.063 109.5456

Theta

Blend time

109.5456

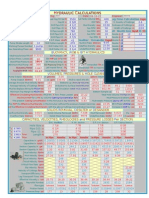

Problem Statement: Estimate the settling velocity of solids in liquid

Inputs Solids ps dn Liquid p u v Descriptive density nominal diameter solids concentration in slurry density dynamic viscosity kinematic viscosity kg/m3 mm wt % kg/m3 Pa-s cSt

SI Units Spheres 1,100 1.0 55% 1,000 0.0010 1.0

US Units Spheres 68.53 0.039 55% 62.30 1.0 1.0

lb/ft3 in wt % lb/ft3 cP cSt

Other g

gravitational acceleration

m/s2

9.80

ft/s2

32.17

Calculations and Results s specific gravity, solids A formula coefficient A B formula coefficient B S* dimensionless particle parameter W* dimensionless settling velocity terminal settling velocity correction factor ws settling velocity

cm/s

1.10 0.79 4.61 7.83 0.72 2.26 1.85 4.19

ft/min

1.10 0.79 4.61 7.83 0.72 4.46 1.85 8.25

Data Coefficients for Equation Crushed Natural Sediment Well-Rounded Spheres Correction for Solids Concentration

A 0.995 0.954 0.89 0.794 Solids% 0

B 5.211 5.121 4.974 4.606 Factor 0.75

2 5 10 15 20 25 30 35 40 45 50

0.8 0.84 0.91 1 1.1 1.2 1.3 1.42 1.55 1.7 1.85

Result

Problem Statement: Calculate the ungassed and gassed power required in an agitated vessel designed for gas dispersion

Inputs Geometry and Parameters T Tank diameter D Impeller diameter Impeller speed NP Power number Liquid H pL uL Gas Gas flow rate, actual Other g gc

SI Units m m rpm 1.30 0.52 42 5.0 ft ft rpm

US Units 4.27 1.71 42 5.0

Liquid height Density, liquid Viscosity, liquid

m kg/m3 Pa-s

3.77 1,000 0.0010

ft lb/ft3 lb/ft-s

12.37 62.3 0.00067

am3/h

14

acfm

Gravitational acceleration Conversion factor

m/s2 m/s2

9.81 1.00

ft/s2 ft/s2

32.17 32.17

Calculations A Tank cross-section V Volume v Superficial gas velocity QG N NFl NFr D/T Gas flow rate, actual Impeller speed Gas Flow Number Impeller Froude Number Impeller ratio

m2 m3 m/s m3/s rps

1.33 5.00 0.003 0.004 0.70 0.040 0.03 0.40

ft2 ft3 ft/s ft3/s rps

14.29 176.7 0.010 0.14 0.70 0.040 0.03 0.40

Gas Dispersion Regime

No discernable action Flooding

No discernable action Flooding

RPD Nre

Gas Flow number at transition RPD at transition Relative Power Demand Reynolds Number

0.04 0.86 0.85

0.04 0.86 0.85

P pG

Power, ungassed Power, gassed

W W

65 56

hp hp

0.09 0.07

Data

Results

N Regenerate Power 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460

Regime 49 No discernable actionFlooding 152 360 713 1,255 2,025 3,067 Recirculating 4,421 Recirculating 6,131 Recirculating 8,237 Recirculating 10,782 Recirculating 13,808 Recirculating 17,358 Recirculating 21,472 Recirculating 26,194 Recirculating 31,565 Recirculating 37,628 Recirculating 44,425 Recirculating 51,998 Recirculating 60,388 Recirculating 69,639 Recirculating 79,792 Recirculating

No discernable action

100,000

10,000 Ungassed Power, W

1,000

100

10 10 100 Impeller Speed, rpm

1000

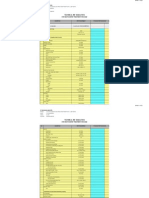

Problem Statement: Calculate shaft diameter, torque, and first critical speed, for up to 3 identical impellers on one shaft. Assume that power is equally distributed among the impellers.

Inputs Impellers D Diameter Number of impellers Np Power Number fH Hydraulic service factor Shaft Np Speed L Shaft length from bottom bearing Sb Bearing span, Sb Distance between impellers Modulus of elasticity Shaft density Allowable shear stress Allowable tensile stress Mixture ro Density of mixed liquid P Power, total Intermediate Calculations Geometry and Power - impeller-specific Shaft length, top impeller Shaft length, middle impeller Shaft length, bottom impeller Power per impeller Weight of blades, per impeller hydrofoil 4-blade PBT

SI Units m 0.660 2 5.0 1.0 2.08 4.22 0.30 2.01 1.97E+11 8,027 4.10E+07 6.90E+07 1,000 5,588 in

US Units

rps m m m N/m2 kg/m3 N/m2 N/m2 kg/m3 W

rpm in in in psi lb/in3 psi psi lb/in3 hp

m m m W kg kg

NA 2.21 4.22 2,794 7.35 5.70

in in in hp lb lb

Calculations Torque Bending moment (maximum) Shaft diameter Based on shear Based on tensile Selected shaft diameter Weight of hub

N-m N-m

434 626

in-lbf in-lbf

m mm m mm mm

0.05 45.57 0.05 46.79 50

in mm in mm in

Read from chart Total weight for each impeller with hub hydrofoil W 4-blade PBT Equivalent weight, not including shaft We hydrofoil 4-blade PBT Natural frequency - First Critical Speed hydrofoil 4-blade PBT

kg

9.0

lb

kg kg

16.35 14.70

lb lb

kg kg

18.71 16.81

lb lb

rps rps

1.24 1.27

rpm rpm

Data Conversion factors for blade weight formula hydrofoil 4-blade PBT

0.14 0.084

350

140

300

120

250

100

Mass of Hub, lbm

Mass of Hub, kg

200

80

Hydrofoil 150

4-Blade PBT

60

100

40

50

20

0 0 2 4 6 8

0 0

50

20

0 0 2 4 6 8

0 0

Shaft Diameter, in

Sh

llers on one

US Units 26.0 2 5.0 1.0 125.0 166.0 12.0 79.0 2.86E+07 0.29 6,000 10,000 0.036 7.50

NA 87.0 166.0 3.75 16.2 12.6

3,782 5,547

1.79 45.37 1.84 46.77 2.0

20.0

36.24 32.58

41.45 37.27

76.15 78.25

Results

0.5 0.3

140

120

100

Mass of Hub, kg

80

Hydrofoil 60

4-Blade PBT

40

20

0 0 50 100 150 200

20

0 0 50 100 150 200

Shaft Diameter, mm

You might also like

- Agitator CalculationDocument4 pagesAgitator CalculationAnkur Koul100% (6)

- Agitator Design: HP CalculationDocument20 pagesAgitator Design: HP Calculationravielb9873No ratings yet

- Agitator DesignDocument7 pagesAgitator DesignTint Tiger100% (4)

- Sizing DecantersDocument2 pagesSizing DecantersSoon Kenneth83% (6)

- Agitator Data (Fluid Properties, Client Data) 50Document23 pagesAgitator Data (Fluid Properties, Client Data) 50Mangesh Mandge100% (2)

- Calculation and Design of Critical Speed and Power AgitatorDocument2 pagesCalculation and Design of Critical Speed and Power AgitatorDavid Lambert75% (8)

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Filter Separator SizingDocument3 pagesFilter Separator SizingChem.Engg100% (2)

- Clarifier Torque CalculationDocument4 pagesClarifier Torque CalculationDavid Lambert100% (4)

- Agitator SelectionDocument20 pagesAgitator SelectionRamakrishna Koushik100% (2)

- Agitator Full Design PDFDocument8 pagesAgitator Full Design PDFRajesh KumarNo ratings yet

- Agitator Design CalcDocument5 pagesAgitator Design Calcranjit34380% (5)

- Design of AgitatorDocument3 pagesDesign of AgitatorDanEstradaNo ratings yet

- Rheology Mud CalculatorDocument9 pagesRheology Mud CalculatorShivaram SuppiahNo ratings yet

- Commissioning Procedure Air Pre HeaterDocument15 pagesCommissioning Procedure Air Pre HeaterDavid LambertNo ratings yet

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (4)

- 2 Nozzle Pressure DistributionDocument4 pages2 Nozzle Pressure DistributionKonul AlizadehNo ratings yet

- Design of AgitatorDocument23 pagesDesign of Agitatorkirandas_mullassery100% (3)

- Agitator Vessel (Design&Costing)Document34 pagesAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Agitator DesignDocument5 pagesAgitator DesignSaepul RochmanNo ratings yet

- Agitator DesignDocument6 pagesAgitator DesignrcchhajedNo ratings yet

- Agitator DatasheetDocument2 pagesAgitator Datasheetmshah222100% (1)

- Agitator Spreadsheet DetailsDocument7 pagesAgitator Spreadsheet DetailsAndrew0% (1)

- Agitator Design CalculationDocument21 pagesAgitator Design CalculationRupesh Ubale94% (36)

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- Existing:-Pitch Blade Turbine AgitatorDocument5 pagesExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- Design of AgitatorDocument12 pagesDesign of AgitatorPatil HemantNo ratings yet

- Agitator LATESTDocument17 pagesAgitator LATESTHARIPRASAD100% (1)

- Agitator DesignDocument9 pagesAgitator DesignDeepika100% (1)

- Sparger Design GuideDocument11 pagesSparger Design GuideHarshavardhan D. GorakhNo ratings yet

- Guid For The Selection of Agitator, Design Formula and Scale UpDocument60 pagesGuid For The Selection of Agitator, Design Formula and Scale Upscranderi100% (3)

- G-Value For Agitator DesignDocument5 pagesG-Value For Agitator DesignArunkumar100% (1)

- Design Calculations of Pitch Blade TurbineDocument6 pagesDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-Mageed100% (1)

- Agitator DesignDocument36 pagesAgitator DesignnileshNo ratings yet

- 16 - Blending and AgitationDocument20 pages16 - Blending and AgitationRafael ReyesNo ratings yet

- Design and Calculation AgitationDocument25 pagesDesign and Calculation Agitationibson045001256No ratings yet

- Plumbing Calculation - Rev 140113Document4 pagesPlumbing Calculation - Rev 140113Paijo TejoNo ratings yet

- Blending and AgitationDocument18 pagesBlending and AgitationSivanand SNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationCaptainTonies0% (1)

- Hydraulic CalculationsDocument20 pagesHydraulic CalculationsJayesh ChandranNo ratings yet

- 16 - Blending and AgitationDocument27 pages16 - Blending and AgitationSimon Tin Hann PyngNo ratings yet

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid Lambert100% (1)

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- CalculationDocument8 pagesCalculationmahaveenNo ratings yet

- Pressure Drop Within DuctsDocument2 pagesPressure Drop Within DuctsManoj Thakur67% (3)

- Unit ConversionsDocument2 pagesUnit Conversionsangry_granNo ratings yet

- Vertical Separator SizingDocument4 pagesVertical Separator SizingSyed Waqas HaiderNo ratings yet

- Name, Symbol, Dimensions Conversion Formula: Formulas For Unit ConversionsDocument3 pagesName, Symbol, Dimensions Conversion Formula: Formulas For Unit ConversionsQedew ErNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- 15 - Pneumatic ConveyingDocument1 page15 - Pneumatic ConveyingsbpathiNo ratings yet

- Conveyor 01Document2 pagesConveyor 01kmatsNo ratings yet

- Hydraulics CalculationDocument1 pageHydraulics CalculationSudish BhatNo ratings yet

- A - Conversion FactorsDocument14 pagesA - Conversion Factorssaeed65No ratings yet

- Drilling Formulas Calculation Sheet Verson 1.3Document186 pagesDrilling Formulas Calculation Sheet Verson 1.3Sarhad Ahmed100% (1)

- Hydraulic Calculations & MudpumpDocument1 pageHydraulic Calculations & MudpumpUok Ritchie100% (1)

- Venturi Scrubber Design CalculationDocument2 pagesVenturi Scrubber Design CalculationAnil DhamankarNo ratings yet

- Compressor InformationDocument5 pagesCompressor InformationwinarnobNo ratings yet

- Agitator - Anchor - Highly ViscousDocument2 pagesAgitator - Anchor - Highly ViscousWade ColemanNo ratings yet

- Separator DesignDocument3 pagesSeparator Designsondung4ver80% (5)

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- 16 - Blending and AgitationDocument27 pages16 - Blending and AgitationSarah DeanNo ratings yet

- Hydraulics, PsiDocument1 pageHydraulics, Psiscrbdgharavi100% (1)

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Cyclone DesignDocument1 pageCyclone DesignDavid LambertNo ratings yet

- Process Produksi WOOD PELLLETDocument3 pagesProcess Produksi WOOD PELLLETDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Venting DesignDocument1 pageVenting DesignDavid LambertNo ratings yet

- Pressure Drop CalculationDocument8 pagesPressure Drop CalculationDavid Lambert100% (1)

- Grease Trap SizingDocument9 pagesGrease Trap SizingEngFaisal Alrai67% (3)

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- Price List With Breakdown & Unit PriceDocument1 pagePrice List With Breakdown & Unit PriceDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- Gambar ProsesDocument1 pageGambar ProsesDavid LambertNo ratings yet

- Technical Form WWTPDocument35 pagesTechnical Form WWTPDavid LambertNo ratings yet

- Konversi Besi Tulangan Ke Wire MeshDocument1 pageKonversi Besi Tulangan Ke Wire MeshDavid LambertNo ratings yet

- Sizing ScrubberDocument62 pagesSizing Scrubberindahazhr100% (1)

- PFD WTP PDFDocument1 pagePFD WTP PDFDavid LambertNo ratings yet

- Besi Wide Flange (W.F) : Ukuran BeratDocument1 pageBesi Wide Flange (W.F) : Ukuran BeratDavid LambertNo ratings yet

- Ipal WikaDocument3 pagesIpal WikaDavid LambertNo ratings yet

- Bleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDocument1 pageBleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDavid LambertNo ratings yet

- Wiring Diagram DC IIDocument2 pagesWiring Diagram DC IIDavid LambertNo ratings yet

- Neraca PanasDocument3 pagesNeraca PanasDavid LambertNo ratings yet

- Pipa Baja Carbon For Pressure Schedule 40: Ukuran OD ID Tebal KG/M Kg/6MDocument1 pagePipa Baja Carbon For Pressure Schedule 40: Ukuran OD ID Tebal KG/M Kg/6MDavid LambertNo ratings yet

- Closed Conduit Hydraulics: CE154 - Hydraulic DesignDocument44 pagesClosed Conduit Hydraulics: CE154 - Hydraulic Designger80No ratings yet

- Fluid Mechanics Lab Report Name Muhammad Fawad Naeem Roll NO. 2021-ME-527 Submit To Sir Shahid Department MechanicalDocument15 pagesFluid Mechanics Lab Report Name Muhammad Fawad Naeem Roll NO. 2021-ME-527 Submit To Sir Shahid Department Mechanicalfawad naeemNo ratings yet

- 44CDocument9 pages44Cjhacademyhyd100% (3)

- Computation of Incompressible Flow Around The DARPA SUBOFF BodiesDocument88 pagesComputation of Incompressible Flow Around The DARPA SUBOFF BodiesEternity ImmortalityNo ratings yet

- Fluid StaticDocument24 pagesFluid StaticNurhidayah AzmiNo ratings yet

- 流體力學Document30 pages流體力學sonkuas100% (1)

- 2130 Turbidity (2011)Document4 pages2130 Turbidity (2011)AndreaCarolinaMoraNo ratings yet

- (Scientific Proceedings Faculty of Mechanical Engineering) Preliminary Computational Fluid Dynamics (CFD) Simulation of EIIB Push Barge in Shallow WaterDocument7 pages(Scientific Proceedings Faculty of Mechanical Engineering) Preliminary Computational Fluid Dynamics (CFD) Simulation of EIIB Push Barge in Shallow WaterMohammed AttiaNo ratings yet

- Un Balance Liquid Level of Central Separator Ulubelu Geothermal PowerDocument6 pagesUn Balance Liquid Level of Central Separator Ulubelu Geothermal PowertiantaufikNo ratings yet

- Assignment 2Document1 pageAssignment 2Krishna JaiswalNo ratings yet

- Construction Engineering 2104ENGDocument4 pagesConstruction Engineering 2104ENGSneha StephenNo ratings yet

- Buckley-Leverett Theory For Immiscible Displacement - Fundamentals of Fluid Flow in Porous MediaDocument12 pagesBuckley-Leverett Theory For Immiscible Displacement - Fundamentals of Fluid Flow in Porous Mediaarjun2014No ratings yet

- Influence of Substrate Elasticity On Droplet Impact DynamicsDocument5 pagesInfluence of Substrate Elasticity On Droplet Impact DynamicsAdvaitNo ratings yet

- Effect of Spoilers On Aerodynamic ProperDocument10 pagesEffect of Spoilers On Aerodynamic ProperNguyễn Đình ĐứcNo ratings yet

- Question Bank Unit 1 Fluid Properties and Fluid Statics Part ADocument3 pagesQuestion Bank Unit 1 Fluid Properties and Fluid Statics Part AHekoNo ratings yet

- Fan TestDocument10 pagesFan Testwhoelse_iNo ratings yet

- Flender Gearbox Lubricant 7300 (En)Document28 pagesFlender Gearbox Lubricant 7300 (En)samer salameh100% (1)

- ColloidDocument4 pagesColloidSUNSHINE A. ACUESTANo ratings yet

- Heat Exchanger OverviewDocument5 pagesHeat Exchanger OverviewrahulNo ratings yet

- TIY383 - Milwaukee Grease ManualDocument7 pagesTIY383 - Milwaukee Grease ManualCarlos SalcedoNo ratings yet

- 6.hydraulic Structure Lab ManualDocument57 pages6.hydraulic Structure Lab ManualAmmar Ahmad EED100% (2)

- Design of PumpsDocument29 pagesDesign of PumpsRenz Alfred Adremesin100% (1)

- ME 320 Lab 4Document17 pagesME 320 Lab 4Ajay KrishNo ratings yet

- Turbine Blade Profile - Bezier CurvesDocument10 pagesTurbine Blade Profile - Bezier Curvesvarun gopiNo ratings yet

- Chapter 7 - PERMEABILITY PDFDocument39 pagesChapter 7 - PERMEABILITY PDFVivekka Olivia JohnNo ratings yet

- Erosion Evaluation On Offshore Production Facility By@omc-2017-676Document14 pagesErosion Evaluation On Offshore Production Facility By@omc-2017-676Mahfoud AMMOURNo ratings yet

- Single Particle MotionDocument12 pagesSingle Particle MotionMD IMRAN HOSSENNo ratings yet

- Evaluation of Oral LiquidsDocument9 pagesEvaluation of Oral LiquidsAln Albin71% (7)

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet