General Catalogue

General Catalogue

Uploaded by

PhilipMDMCopyright:

Available Formats

General Catalogue

General Catalogue

Uploaded by

PhilipMDMCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

General Catalogue

General Catalogue

Uploaded by

PhilipMDMCopyright:

Available Formats

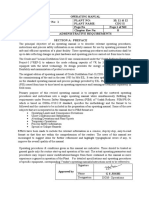

Groer Stein 72

Industriegebiet West

Postbox 6055

D-32646 Lemgo

Fon +49 (0) 52 61 6 80 04

Fax +49 (0) 52 61 6 80 06

www.bitherma.de

info@bitherma.de

PRODUCTS

Franz Wagner & Sohn GmbH

Bimetal thermometer

-Connectivities

-Standard, axial

-Standard, vertical

-Industrial version, axial, complete stainless steel

-Process industry series, axial

-Process industry series, vertical

-With alarm contact for signalling

-With flange for ventilation and air-conditioning

-With surface mounting flange for ventilation and air-conditioning, light-weight version

-With surface mounting flange for ventilation and air-conditioning, heavy-weight version

-For heating systems, standard version

-For heating systems

-For surface mounting

-For insertion, for underfloor heating, control fittings and valves

-With tip for insertion, for food

-With tip for insertion, for compost

-For exhaust gas measurements

-With bar magnets

-As surface thermometer for concrete and floors

-Process industry series, 90 adjustable every angle

Gas actuated thermometer, process industry series

Remote-reading thermometer, alcohol filled, standard version case diam. 60

Bimetal stack thermometer, for silos and clamps

Hygrometer for moisture measurements with stem

Hygrometer for dewpoint and indoor climate

Hygrometer for surface measurements Fig. 36

Hygrometer for surface measurements Fig. 37+38

Hygrometer with stem for pricking

V-shaped machine glass thermometer

-Casing 110 mm, straight

-Casing 150 mm, straight

-Casing 200 mm, straight

-Casing 110 mm, angle of 90

-Casing 150 mm, angle of 90

-Casing 200 mm, angle of 90

-Casing 110 mm, angle of 135

-Casing 150 mm, angle of 135

-Casing 200 mm, angle of 135

Industrial machine glass thermometer, DIN 16167, DIN 16168, short version

Industrial machine glass thermometer, DIN 16174, DIN 16175, long version

Heating glass thermometer

Glass thermometer for control measurements

Thermometer scoops in brass

Laboratory thermometer, DIN 12775 and similar DIN

Chemical glass thermometer for laboratory measurements

Thermowells screw-in type DIN 43772 form 5/6/8 and 9

Thermowells weld-in type DIN 43772 form 4

Special components, flange DIN 2527, clamp-flange, slotted ring nut

Resistance thermometer Pt 100

Conversion tables, tolerances

Electrical alarm contacts for temperature and pressure gauges

INDEX

THERMOMETERS and HYGROMETERS

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

030

031

032

033

034

040

041

042

043

044

045

046

047

048

050

051

052

060

060

061

061

070

072

073

075

089

090

Connection type: 0 1 2 3 4 5 6

Type: 0 1 2 3 4 5 6

Available stem 12/10 9/8 9/8 9/8 12/10 9/8 9/8

4 mm - x x x - x -

5 mm - x x x - x -

6 mm x x x x x x x

8 mm x x x x x x x

10 mm x x x x x x x

12 mm x x x x x x x

13 mm x x x x x x x

15 mm x x x x x x x

Material varieties: Brass 1.4305 1.4571

Available types of thread:

G 1/8 1/4 3/8 1/2 3/4 1

NPT 1/8 1/4 3/8 1/2 3/4 1

M 6 8 10 10x1 12x1 12x1,5 14x1

14x1,5 15x1 16x1 16x2 18x1,5 19x1 20x1

20x1,5 22x1 22x1,5 24x1 24x1,5 25x1 27x2

Further

connections: Hygienic coupling DN 25 / DN 50

Tapered thread and slotted ring nut DIN 11851 DN 25 / DN 50

Flange-thermowells for all requirements

e.g. DIN 2527 Form B / T / E

ND 6 / 10 / 16 / 25 / 40 / 64 / 100

NW 10 / 15 / 20 / 25 / 32

Other types on request!

Standard brass / Standard stainless steel

Separate pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

Union nut with

additional

thermowell acc. to

DIN 16179

form CD

oder DIN 43772

form 8

Turnable male

thread

Movable clamp

connection

001

Connectivities

for bimetal thermometer

Case: Steel zinced varnished

- Stainless steel 1.4301

- Bayonet-fitted stainless steel IP 54 (diam. 63-160)

Bezel: Steel nickel-plated

- Brass chromed (diam. 80-160)

- Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass (diam. 63-160)

- Max. drag pointer (diam. 63-160)

- Max./min. drag pointer (diam. 63-160)

- Red mark pointer (diam. 63-160)

Distance ring: Internal

up to 120C cellular rubber

from 160C on aluminium, diam. 160 ALU only

Stem: G 1/2 B brass detachable with fixing screw

L = 28 / 45 / 50 / 63 / 100 mm solid A/F 21

other lengths multi-part soldered A/F 21, tube 12

- Further connections see overleaf resp. 001

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.6

- Accuracy class 1.0

Then the article number changes

from 2XXX into 3XXX ! Meas. range Graduation

- Works test certificate -40+40C

-30+50C

- OPTIONS -20+60C

-20+40C

Article number: -15+45C

Diam. 34 50 63 80 100 160 -10+60C

Stem 28 mm 2030 2050 2060 2080 2100 2160 -10+50C

Stem 45 mm 2031 2051 2061 2081 2101 2161 0+40C

0+50C

Stem 50 mm 2032 2052 2062 2082 2102 2162 0+60C

Stem 63 mm 2033 2053 2063 2083 2103 2163 0+80C

0+100C

Stem 80 mm 2034 2054 2064 2084 2104 2164 0+120C

Stem 100 mm 2035 2055 2065 2085 2105 2165 0+160C

0+200C

Stem 120 mm 2036 2056 2066 2086 2106 2166 0+250C

Stem 160 mm 2037 2057 2067 2087 2107 2167 0+300C

0+400C

Stem 200 mm 2038 2058 2068 2088 2108 2168 0+500C *

Stem 250 mm 2039 2059 2069 2089 2109 2169 0+600C *

Other lengths Stem 28 mm only 0-120C available !

*Stem stainless steel needed !

are available ! Stem 45 mm shortest measuring span = 60C !

5.0

10.0

1.0

2.0

002

BIMETAL THERMOMETER

Standard version, axial

Accuracy class 1.6 and 1.0

2030 34 9 11 12 21 1/2 B 12

2050 50 12 11 12 21 1/2 B 12

2060 63 13 11 12 21 1/2 B 12

2080 80 13 11 12 21 1/2 B 12

2100 100 15 11 12 21 1/2 B 12

2160 160 19 11 12 21 1/2 B 12

Type a b c d SW G t

0

Sep. pocket

with fixing screw

1 2

Fixed connection

male thread

Union nut

female thread

Turnable

male thread

6

Movable clamp

connection

3 4 5

Union nut with

double nipple

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

002

BIMETAL THERMOMETER

Standard version, axial

Accuracy class 1.6 and 1.0

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

Case: Steel zinced varnished

- Bayonet-fitted stainless steel IP 54 (diam. 63-160)

Bezel: Steel chromed

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass (diam. 63-160)

- Max. drag pointer (diam. 63-160)

- Max./min. drag pointer (diam. 63-160)

- Red mark pointer (diam. 63-160)

Distance ring: Internal, Aluminium

Stem: G 1/2 B brass detachable with fixing screw

L = 28 / 45 / 50 / 63 / 100 mm solid A/F 21

other lengths multi-part soldered A/F 21, tube 12

- Further connections see overleaf resp. 001

Connection: Bottom entry

- sidewards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.6

- Accuracy class 1.0

Then the article number changes

from 2XXX into 3XXX !

- Works test certificate

Meas. range Graduation

- OPTIONS -40+40C

-30+50C

-20+60C

Article number: -20+40C

Diam. 50 63 80 100 160 -15+45C

Stem 28 mm 2250 2260 2280 2300 2360 -10+60C

Stem 45 mm 2251 2261 2281 2301 2361 -10+50C

0+50C

Stem 50 mm 2252 2262 2282 2302 2362 0+60C

Stem 63 mm 2253 2263 2283 2303 2363 0+80C

0+100C

Stem 80 mm 2254 2264 2284 2304 2364 0+120C

Stem 100 mm 2255 2265 2285 2305 2365 0+160C

0+200C

Stem 120 mm 2256 2266 2286 2306 2366 0+250C

Stem 160 mm 2257 2267 2287 2307 2367 0+300C

0+400C

Stem 200 mm 2258 2268 2288 2308 2368 0+500C *

Stem 250 mm 2259 2269 2289 2309 2369 0+600C *

Other lengths Stem 28 mm only 0-120C available !

*Stem stainless steel needed !

are available ! Measuring span 50 and 60C shortest stem = 100 mm !

10.0

1.0

2.0

5.0

003

BIMETAL THERMOMETER

Standard version, vertical

Accuracy class 1.6 und 1.0

003

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

BIMETAL THERMOMETER

Standard version, vertical

Accuracy class 1.6 und 1.0

2250 50 35 11 12 21 1/2 B 12

2260 63 36 11 12 21 1/2 B 12

2280 80 36 11 12 21 1/2 B 12

2300 100 38 11 12 21 1/2 B 12

2360 160 38 11 12 21 1/2 B 12

5

t

0

SW b c d

Sep. pocket

with fixing screw

1 2

Fixed connection

male thread

Union nut

female thread

4

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Union nut with

double nipple

G

Movable clamp

connection

6 3

Type a

004

Case: Stainless steel, 1.4301

Bezel: Stainless steel, 1.4301

-Diam. 80 and diam. 100 with crimped ring IP 44

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass (diam. 63-160)

- Max. drag pointer (diam. 63-160)

- Max./min. drag pointer (diam. 63-160)

- Red mark pointer (diam. 63-160)

Distance ring: Internal

diam. 34-63 mm up to 120C cellular rubber

from 160C on Aluminium

diam. 80-160 Aluminium

Stem: G 1/2 A stainless steel V2a, A/F 27, with fixing screw

multi-part welded - tube 10 x 0.9 mm 1.4571

- Further connections see overleaf resp. 001

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.0

- Works test certificate

Meas. range Graduation

- OPTIONS -40+40C

-30+50C

-20+60C

-20+40C

Article number: -15+45C

Diam. 34 50 63 80 100 160 -10+60C

Stem 28 mm 2930 2950 2960 2980 3000 3040 -10+50C

Stem 45 mm 2931 2951 2961 2981 3001 3041 0+40C

0+50C

Stem 50 mm 2932 2952 2962 2982 3002 3042 0+60C

Stem 63 mm 2933 2953 2963 2983 3003 3043 0+80C

0+100C

Stem 80 mm 2934 2954 2964 2984 3004 3044 0+120C

Stem 100 mm 2935 2955 2965 2985 3005 3045 0+160C

0+200C

Stem 120 mm 2936 2956 2966 2986 3006 3046 0+250C

Stem 160 mm 2937 2957 2967 2987 3007 3047 0+300C

0+400C

Stem 200 mm 2938 2958 2968 2988 3008 3048 0+500C

Stem 250 mm 2939 2959 2969 2989 3009 3049 0+600C

Other lengths Stem 28 mm only 0-120C available !

are available ! Stem 45 mm shortest measuring span = 60C !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

Industrial version, axial

Complete stainless steel, accuracy class 1.0

004

2930 34 9 14 14 27 1/2 A 10

2950 50 12 14 14 27 1/2 A 10

2960 63 13 14 14 27 1/2 A 10

2980 80 13 14 14 27 1/2 A 10

3000 100 15 14 14 27 1/2 A 10

3040 160 19 14 14 27 1/2 A 10

0 3

G t d SW Type

4 5 1 2

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Sep. pocket

with fixing screw

Movable clamp

connection

a b c

6

BIMETAL THERMOMETER

Industrial version, axial

Compl. stainless steel, accuracy class 1.0

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

005

Case: Bayonet-fitted stainless steel, 1.4301

- Liquid filling

Bezel: Bayonet-fitted stainless steel, 1.4301

- With front flange for panel mounting

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Stem end welded

- Silicone damped

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Seal washer: Rubber, black

Stem: G 1/2 A stainless steel V2a, A/F 27, with fixing screw

multi-part welded - tube 10 x 0.9 mm 1.4571

- Thread 1.4571

- Further connections see overleaf resp. 001

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.0

- Works test certificate Meas. range Graduation

-40+40C

- OPTIONS -30+50C

-20+60C

-20+40C

Article number: -15+45C

Diam. 63 80 100 160 -10+60C

Stem 28 mm 2460 2480 2500 2560 -10+50C

Stem 45 mm 2461 2481 2501 2561 0+40C

0+50C

Stem 50 mm 2462 2482 2502 2562 0+60C

Stem 63 mm 2463 2483 2503 2563 0+80C

0+100C

Stem 80 mm 2464 2484 2504 2564 0+120C

Stem 100 mm 2465 2485 2505 2565 0+160C

0+200C

Stem 120 mm 2466 2486 2506 2566 0+250C

Stem 160 mm 2467 2487 2507 2567 0+300C

0+400C

Stem 200 mm 2468 2488 2508 2568 0+500C

Stem 250 mm 2469 2489 2509 2569 0+600C

Other lengths Stem 28 mm only 0-120C available !

are available ! Stem 45 mm shortest measuring span = 60C !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

Process industry series, axial

IP 65, accuracy class 1.0

005

2460 63 32 14 14 27 1/2 A 10

2480 80 33 14 14 27 1/2 A 10

2500 100 27 14 14 27 1/2 A 10

2560 160 33 14 14 27 1/2 A 10

4 5 6

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Movable clamp

connection

0 1 2 3

Type SW G t d a b c

BIMETAL THERMOMETER

Process industry series, axial

IP 65, accuracy class 1.0

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

006

Case: Bayonet-fitted stainless steel, 1.4301

- Liquid filling

Bezel: Bayonet-fitted stainless steel, 1.4301

Zifferblatt: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

- Silicone damped

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Seal washer: Rubber, black

Stem: G 1/2 A stainless steel V2a, A/F 27, with fixing screw

multi-part welded - tube 10 x 0.9 mm 1.4571

- Further connections see overleaf resp. 001

Connection: Bottom entry

- sidewards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.0

- Works test certificate

- OPTIONS

Meas. range Graduation

-40+40C

-30+50C

-20+60C

Article number: -20+40C

Diam. 63 80 100 160 -15+45C

Stem 28 mm 2660 2680 2700 2760 -10+60C

Stem 45 mm 2661 2681 2701 2761 -10+50C

0+40C

Stem 50 mm 2662 2682 2702 2762 0+50C

Stem 63 mm 2663 2683 2703 2763 0+60C

0+80C

Stem 80 mm 2664 2684 2704 2764 0+100C

Stem 100 mm 2665 2685 2705 2765 0+120C

0+160C

Stem 120 mm 2666 2686 2706 2766 0+200C

Stem 160 mm 2667 2687 2707 2767 0+250C

0+300C

Stem 200 mm 2668 2688 2708 2768 0+400C

Stem 250 mm 2669 2689 2709 2769 0+500C

0+600C

Other lengths Stem 28 mm only 0-120C available !

are available ! Measuring span 50 and 60C shortest stem = 100 mm !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

Process industry series, vertical

IP 65, accuracy class 1.0

006

2660 63 45 14 14 27 1/2 A 10

2680 80 46 14 14 27 1/2 A 10

2700 100 49 14 14 27 1/2 A 10

2760 160 49 14 14 27 1/2 A 10

SW G t

Union nut with

double nipple

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Movable clamp

connection

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

0 1 2 4 5 6 3

Type a b c d

BIMETAL THERMOMETER

Process industry series, vertical

IP 65, accuracy class 1.0

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

007

Case: Bayonet-fitted stainless steel, 1.4301

- Diam. 160 Bayonet-fitted steel, black varnished

Bezel: Diam. 100 Bayonet-fitted stainless steel, 1.4301

- Diam. 160 Bayonet-fitted steel, black varnished

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Aluminium, black

adjustable at end of stem

Window: Polycarbonate, with adjust lock, oil-tight

with seperate contact adjust key

Seal washer: Rubber, black

Stem: G 1/2 A brass detachable with fixing screw

multi-part soldered - tube 12 x 1

- Further connections see overleaf resp. 001

Connection: Backwards

- If vertical connection then gas-filled thermometers

page 021 or induktive contacts should be used

Measuring range: 0-120C

- Resp. opposite

Special model: - Cable junction box

- Contact relais

Alarm contacts: Sliding, single or double

adjustable over the whole range

- Contacts as changer

- Magnetic contacts depending on range on request

- Induktive contacts

Wiring: 1 mtr. cable with PG gland

Accuracy class: 2

- OPTIONS

Diam. 100 Article-number: Meas. range Graduation

Contact type: S 1 S 2 S 11 S 12 S 21 S 22 -30+50C

Stem 63 mm 10400 10406 10412 10418 10424 10430 -20+60C

Stem 100 mm 10401 10407 10413 10419 10425 10431 0+80C

0+100C

Stem 120 mm 10402 10408 10414 10420 10426 10432 0+120C

Stem 160 mm 10403 10409 10415 10421 10427 10433 0+160C

0+200C

Stem 200 mm 10404 10410 10416 10422 10428 10434 0+250C

Stem 250 mm 10405 10411 10417 10423 10429 10435 0+300C

Function: 1 = contact makes when pointer reaches set point

2 = contact breakes when pointer reaches the set point

S = sliding contact

Further contact prescriptions on page 090

1.0

2.0

5.0

BIMETAL THERMOMETER

with electrical alarm contact

007

100 58 30 14 27 1/2 A 12

160 68 30 14 27 1/2 A 12

6

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Movable clamp

connection

4 5

10400

10436

0 1 2 3

a b c Type SW G t f

BIMETAL THERMOMETER

with electrical alarm contact

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

008

Case: Steel zinced

- Varnished

- Stainless steel 1.4301

Bezel: Steel zinced

- Brass chromed (diam. 80-160)

- Stainless steel 1.4301

Dial: Aluminium, white varnished

Lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Distance ring: Internal

Up to 120C cellular rubber

From 160C on aluminium, diam. 160 ALU only

Stem: Brass, 9 mm

- Stainless steel 1.4571

Mounting method: Flange steel zinced 40 mm with fixing screw

Movable on stem

Diam. 160 flange 80 steel zinced

- Thread G 1/2 B brass with fixing screw, movable on stem

- Flange 80 mm steel zinced

- Flange 80 mm stainless steel

- Angular shaped flange steel zinced, 50 x 28 mm

Connection: Backwards

Measuring range: 0-120C Meas. Range Graduation

- Resp. opposite -40+40C

-30+50C

Accuracy class: 2 -20+60C

- Accuracy class 1.0 -20+40C

-15+45C

- Works test certificate -10+60C

-10+50C

- OPTIONS 0+40C

0+50C

Article number: 0+60C

Diam. 63 80 100 160 0+80C

Stem 50 mm 1261 1281 1301 1361 0+100C

0+120C

Stem 100 mm 1262 1282 1302 1362 0+160C

0+200C

Stem 150 mm 1263 1283 1303 1363 0+250C

0+300C

Stem 200 mm 1264 1284 1304 1364 0+400C

0+500C *

Stem 250 mm 1265 1285 1305 1365 0+600C *

Other lengths

*Stem stainless steel needed !

are available !

5.0

10.0

1.0

2.0

BIMETAL THERMOMETER

for air ducts, with flange, accuracy class 2

008

63 13 9 14 14 10 28 40 1,5 9

80 13 9 14 14 10 28 40 1,5 9

100 15 9 14 14 10 28 40 1,5 9

160 19 9 14 14 10 54 80 2,0 9

c

1280

1300

1360

1260

Type a b i t h e d f LK

BIMETAL THERMOMETER

for air ducts, with flange, accuracy class 2

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

009

Case: Steel zinced

- Varnished

Bezel: Steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Distance ring: without

Stem: Brass, 9 mm

- Stainless steel 1.4571

Mounting method: With back flange

lightweight version, round

for surface mounting on air duct

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 2

- Accuracy class 1.0

Meas. range Graduation

- Works test certificate -40+40C

-30+50C

- OPTIONS -20+60C

-20+40C

-15+45C

-10+60C

-10+50C

0+40C

0+50C

Article number: 0+60C

Diam. 63 80 100 0+80C

Stem 50 mm 1661 1681 1701 0+100C

0+120C

Stem 100 mm 1662 1682 1702 0+160C

0+200C

Stem 150 mm 1663 1683 1703 0+250C

0+300C

Stem 200 mm 1664 1684 1704 0+400C

0+500C *

Stem 250 mm 1665 1685 1705 0+600C *

Other lengths

*Stem stainless steel needed !

are available !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

with back flange, light version

for air ducts, accuracy class 2

009

63 14 9 14 82 74 9

80 14 9 14 102 91 9

100 14 9 14 118 110 9

1680

1700

Type f a b c d

1660

LK t

BIMETAL THERMOMETER

with back flange, light version

for air ducts, accuracy class 2

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

010

Case: Steel zinced, black varnished

- Diam. 100 stainless steel 1.4301

Bezel: Steel nickel-plated

- Brass chromed (diam. 80-160)

- Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Distance ring: Internal

up to 120C cellular rubber

from 160C on aluminium, diam. 160 ALU only

Stem: Brass, 9 mm

- Stainless steel 1.4571

Mounting method: With back flange

heavy version, flattened

for surface mounting on air duct

- Diam. 100 stainless steel round

- With front flange brass chromed, for panel mounting

Connection: Backwards

Measuring range: 0-120C Meas. range Graduation

- Resp. opposite -40+40C

-30+50C

Accuracy class: 2 -20+60C

- Accuracy class 1.0 -20+40C

-15+45C

- Works test certificate -10+60C

-10+50C

- OPTIONS 0+40C

0+50C

Article number: 0+60C

Diam. 63 80 100 160 0+80C

Stem 50 mm 1461 1481 1501 1561 0+100C

0+120C

Stem 100 mm 1462 1482 1502 1562 0+160C

0+200C

Stem 150 mm 1463 1483 1503 1563 0+250C

0+300C

Stem 200 mm 1464 1484 1504 1564 0+400C

0+500C *

Stem 250 mm 1465 1485 1505 1565 0+600C *

Other lengths

*Stem stainless steel needed !

are available !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

with back flange, heavy version

for air ducts, accuracy class 2

010

63 17 7 14 85 76 9

80 21 7 14 110 95 9

100 22 7 14 132 116 9

160 23 7 14 190 182 9 1560

a b c Type

1460

1480

1500

f LK t d

BIMETAL THERMOMETER

with back flange, heavy version

for air ducts, accuracy class 2

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

011

Case: Steel zinced

Bezel: Steel nickel-plated

Dial: Plastic, white

with raised edge

lettering and graduation black

- Imprint

- Double scale C/F

Pointer: Plastic, black

adjustable at end of stem

Window: Plastic

Stem: G 1/2 B brass, detachable, with fixing screw

L = 40 / 60 / 100 mm solid A/F 21

L = 150 mm multi-part, soft soldered

- Plug-in version

Connection: Backwards

Accuracy class: 2.5

- OPTIONS

Measuring range:

Article number:

Diam. 63 80 100 160 63 80 100

Stem 40 mm 903 906 909 912 923 926 929

Stem 60 mm 904 907 910 913 924 927 930

Stem 100 mm 905 908 911 914 925 928 931

Stem 150 mm 915 916 917 918 935 936 937

0-120C -20+60 / -10+50 / 0+60C

Please quote the measuring range!

BIMETAL THERMOMETER

for heatings, standard version

011

63 12 7 12 12 21 1/2 B

80 14 7 12 12 21 1/2 B

100 15 7 12 12 21 1/2 B

160 17 7 12 12 21 1/2 B

906

909

912

Type

903

a b c d t SW G

BIMETAL THERMOMETER

for heatings, standard version

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

012

Case: Steel zinced

- Varnished

Bezel: Steel zinced

- Brass chromed (diam. 80-160)

- Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

Stem: G 1/2 B brass detachable with fixing screw

L = 28 / 45 / 50 / 63 / 100 mm solid A/F 21

other lengths multi-part soldered A/F 21, tube 12

- Stainless steel welded

Connection: Backwards

Accuracy class: 2

- OPTIONS

Measuring range:

Article number:

Daim. 63 80 100 160 63 80 100 160

Stem 28 mm 1061 1081 1101 1161 - - - -

Stem 45 mm 1062 1082 1102 1162 11062 11082 11102 11162

Stem 50 mm 1063 1083 1103 1163 11063 11083 11103 11163

Stem 63 mm 1064 1084 1104 1164 11064 11084 11104 11164

Stem 80 mm 1065 1085 1105 1165 11065 11085 11105 11165

Stem 100 mm 1066 1086 1106 1166 11066 11086 11106 11166

Stem 120 mm 1067 1087 1107 1167 11067 11087 11107 11167

Stem 160 mm 1068 1088 1108 1168 11068 11088 11108 11168

Stem 200 mm 1069 1089 1109 1169 11069 11089 11109 11169

Other lengths Stem 28 mm only 0-120C available !

are available !

-30+50 / -20+60 / -20+40C

-10+50 / 0+60 / 0+80 / 0+100C

0-120C

BIMETAL THERMOMETER

for heatings, quality version

012

63 13 11 12 21 1/2 B 12

80 13 11 12 21 1/2 B 12

100 15 11 12 21 1/2 B 12

160 19 11 12 21 1/2 B 12

1060

1080

1100

t d SW G

1160

a b c Type

BIMETAL THERMOMETER

for heatings, quality version

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

013

HEATING VERSION

Case: Steel zinced

Bezel: Steel nickel-plated

Dial: Plastic, white

with raised edge

lettering and graduation black

- Imprint

- Double scale C/F

Pointer: Plastic, black

adjustable at end of stem

Window: Plastic

Stem: 15 x 10 mm high at case back in brass

Connection: Backwards

Mounting method: Spiral spring for pipes 1"-2"

- additional spiral springs for larger pipe

Accuracy class: 2.5

Measuring range:

Diam. 63 80 63 80

Article number: 960 A 980 A 960 B 980 B

INDUSTRIAL VERSION

Case: Stainless steel 1.4301

Bezel: Stainless steel 1.4301 - diam. 50 steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

960 63 26

980 80 26

Window: Instrument glass

- Safety glass

- Max. drag pointer

Connection: Backwards

Mounting method: by use of a spring for pipes 1-2"

- Additional springs for larger pipe diameters

- Double spring at case, for better stability

Accuracy class: 2

Diam. 50 63 78 100

Article number: 400 A 420 A 440 A 460 A

Measuring range:

-50+200C -20+40C 0-60C 0-200C

-40+40C -20+60C 0-80C 0-250C

-40+120C -20+100C 0-100C 0-300C

-30+70C -10+60C 0-120C 0-400C

-30+50C -10+50C 0-160C

- OPTIONS

For diam. 50 up to 100 mm to be quoted

0-120C -20+60 / 0+60C / 0+200C

Type a b

BIMETAL THERMOMETER

for surface mounting

014

Case: Steel, nickel-plated, diam. 34 mm

Bezel: Steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

- Imprint

Pointer: Aluminium, black

Window: Plastic

Stem: At the back of the case

Mounting method: Plug-in version diam. 15 mm, brass nickel-plated

Connection: Backwards

34 8 9 15

Accuracy class: 2

-OPTIONS

Measuring range: 0+50C 0+80C

Article number: 700 701

Accessories: Holder made of brass

with spiral spring

for pipes with 22 mm outer

-without thermometer-

Article number: 730

Accessories: Screw connection made of brass

G 3/4 union nut and G 3/4 male thread

with socket for the thermometer

Article number: 731

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

a b c d

BIMETAL THERMOMETER

for insertion, for control fittings and valves

015

Case: Stainless steel 1.4301

- Steel zinced

- Steel zinced and varnished

- Bayonet-fitted SS 1.4301 (diam. 63 und 80)

Bezel: Stainless steel 1.4301

- Diam. 80 with rim ring IP 44

- Steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

- Silicone damped

Window: Instrument glass

- Safety glass (diam. 63 and 80)

- Max. drag pointer (diam. 63 and 80)

- Max./min. drag pointer (diam. 63 and 80)

- Red mark pointer (diam. 63 and 80)

Distance ring: Internal

Diam. 34-63 mm up to 120C cellular rubber

from 160C on aluminium, diam. 80 ALU only

Stem: With tip for insertion

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 2

- Accuracy class 1

- Works test certificate

- OPTIONS

Article number:

Version: Stem 4 made of 1.4571 with tip

Diam. 34 50 63 80 Meas. range Graduation

Stem 100 mm 1732 1752 1762 1782 -40+40C

-30+50C

Stem 200 mm 1734 1754 1764 1784 -20+60C

-20+40C

Stem 300 mm 1736 1756 1766 1786 -15+45C

-10+50C

Accessories: - PVC stem protection with Clip 0+40C

0+60C

Version: Stem 4 made of 1.4571 with tip 0+80C

and foldable handle 0+100C

Diam. 34 50 63 80 0+120C

Stem 100 mm 1732-1 1752-1 1762-1 1782-1 0+160C

0+200C

Stem 200 mm 1734-1 1754-1 1764-1 1784-1 0+250C

0+300C

Stem 300 mm 1736-1 1756-1 1766-1 1786-1 0+400C 10.0

Other lengths Stem 5, 6, 8 and 9 mm are available on request !

are available !

1.0

2.0

5.0

BIMETAL THERMOMETER

with tip for insertion

for food

015

34 9 12,5 7 4 34 9 10 13 4 110

50 12 12,5 7 4 50 12 10 13 4 110

63 13 12,5 7 4 63 13 10 13 4 110

80 13 12,5 7 4 80 13 10 13 4 110

Type

1730

b c d e

1760

1780-1

1730-1

1750-1

1760-1

1780

d e

1750

a b c SS Type a

BIMETAL THERMOMETER

with tip for insertion

for food

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

016

Case: Stainless steel, 1.4301

- Steel zinced

- Steel zinced and varnished

- Bayonet-fitted SS 1.4301 (without diam. 50)

Bezel: Stainless steel 1.4301

- Diam. 80 and 100 with rim ring IP 44

- Steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

- Silicone damped

Window: Instrument glass

- Safety glass (without diam. 50)

- Max. drag pointer (without diam. 50)

- Max./min. drag pointer (without diam. 50)

- Red mark pointer (without diam. 50)

Distance ring: Internal

up to 120C cellular rubber

from 160C on aluminium, diam. 80 ALU only

Stem: With tip for insertion

Connection: Backwards

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 2

- Accuracy class 1

- Works test certificate

- OPTIONS Meas. range Graduation

-40+40C

Version: Stem 9 made of brass with tip -30+50C

Article number: -20+60C

Diam. 50 63 80 100 -20+40C

Stem 100 mm 1751-2 1761-2 1781-2 1801-2 -15+45C

-10+60C

Stem 200 mm 1752-2 1762-2 1782-2 1802-2 -10+50C

0+40C

Stem 300 mm 1753-2 1763-2 1783-2 1803-2 0+50C

0+60C

Accessories: - Handle made of stainless steel movable on stem 0+80C

0+100C

Version: Stem 12 made of brass with tip 0+120C

Article number: 0+160C

Diam. 63 80 100 0+200C

Stem 800 mm 1760-3 1780-3 1800-3 0+250C

0+300C

Stem 1.000 mm 1761-3 1781-3 1801-3 0+400C

0+500C *

Stem 1.200 mm 1762-3 1782-3 1802-3 0+600C *

Accessories: - Handle made of stainless steel movable on stem *Stem stainless steel needed !

Important advice:

Other lengths The gauges are NOT watertight and thus they are NOT suitable for

are available ! permanent outdoor use. Guarantee voids whenever water to be found in case.

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

with tip for insertion

for compost - soil - grain

016

50 9 20 14 4 14 9 63 13 28 14 4 14 12

63 13 20 14 4 14 9 80 13 28 14 4 14 12

80 13 20 14 4 14 9 100 15 28 14 4 14 12

100 15 20 14 4 14 9

c d g

1760-3

1780-3

e Type f g a b

1800-3

1750-2

1760-2

1780-2

1800-2

d e f Type a b c

BIMETAL THERMOMETER

with tip for insertion

for compost - soil - grain

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

017

Case: Steel zinced

- Varnished

- Stainless steel 1.4301

Bezel: Steel nickel-plated

- Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

from 500C blank aluminium

- With colour field

- Red mark

- Imprint

- Double scale C/F

Pointer: Aluminium, black

adjustable at end of stem

- Silicone damped

Window: Instrument glass

- Safety glass (without diam. 50)

- Max. drag pointer (without diam. 50)

- Max./min. drag pointer (without diam. 50)

- Red mark pointer (without diam. 50)

Distance ring: Internal made of aluminium

Stem: L = 200 x 8 mm made of stainless steel 1.4571

- 6 mm

Mounting method: conical thread A/F 13 made of brass

with fixing screw

- anular magnet below case

incl. colour fields and max. drag pointer

Connection: Backwards

Accuracy class: 2

- Accuracy class 1

- Works test certificate

- OPTIONS

Measuring range: Article number:

Diam. 50 63 80 100

0-250C 1851 1861 1881 1901

0-300C 1852 1862 1882 1902

0-400C 1853 1863 1883 1903

0-500C 1854 1864 1884 1904

BIMETAL THERMOMETER

for exhaust gas measurements

017

50 12 14 8

63 13 14 8

80 13 14 8

100 15 14 8

t

1860

1880

1900

a b e Type

1850

BIMETAL THERMOMETER

for exhaust gas measurements

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

018

Case: Diam. 50 steel nickel-plated

Diam. 63 and 80 stainless steel 1.4301

Diam. 100 steel zinced

Bezel: Diam. 50 steel nickel-plated

Diam. 63 and 80 stainless steel 1.4301

Diam. 100 brass chromed

Dial: Aluminium, white varnished

Diam. 80 at 0-500C and 0-600C steel enamels

Lettering and graduation black

Pointer: Aluminium, black

Adjustable

Window: Instrument glass

- Safety glass (without diam. 50)

- Max./min. drag pointer (without diam. 50)

Distance ring: Internal made of aluminium

Meas. element: Bimetal sprial spring

Measuring range: See opposite

Mounting method: Bar magnets

Connection: Backwards

Accuracy class: 2.5

Features: - Single or double alarm contacts

- Flexible measuring pot

- Flexible magnets

- As humidity gauge 0-100%

- Works test certificate

- OPTIONS

Article number:

Magnets Diam. 50 63 80 100

2 simple 1951 1961 1981 -

3 simple - 1962 1982 -

4 simple - 1963 1983 -

2 strong - - 1984 -

3 strong - - 1985 -

4 strong - - 1986 2006

* Dial in steel enamels necessary !

Annular magnets affect the measuring result because of the

heat emission on the bimetal spiral spring.

That's the reason why our gauges are fitted with bar magnets

mounted as far as possible from the measuring element.

-20+80C

0-350C

0-500C *

0-600C *

0-300C

Measuring ranges

for diam. 80 mm

-50+50C

-30+70C

-30+50C

-20+40C

-20+60C

0-100C

-20+100C

-10+60C

0-400C

for diam. 50 - 100 mm

0-120C

0-160C

0-200C

0-250C

-10+50C

0-60C

0-80C

BIMETAL THERMOMETER

with bar magnets

018

50 30

63 31

80 31

100 33 2000

b

Number of

magnets

Measuring

range

Type

1950

1960

1980

a

Layout of magnets

4 pieces

Layout of magnets

2 pieces

Layout of magnets

3 pieces

BIMETAL THERMOMETER

with bar magnets

Masses and dimensions are conform to current company standard. Changes to improve ou

gauges will be made without preannouncement.

019

Case: Diam. 63 (68) plastic-grey

Bezel: Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Air: Aluminium blue

Ground: Aluminium red

Window: Instruments glass

- 2-fold drag pointer for max. und min. temperature

- Single drag pointer for max. temperature Fig. 25

Handling: To seat with total surface contact on concrete or the like

Measuring

system: Double chamber with bimetal spiral spring

Measuring range: -20+80C

Accuracy class: Ground: 2.5C

Air: 1.0C

Features: Fig. 25

With single chamber system for ground measurements

- OPTIONS

Diam. Article number:

63 Fig. 25 1290001

63 Fig. 26 1290002

BIMETAL SURFACE THERMOMETER

for concrete and floors, Fig. 25+26

019

depends on the setting temperature resp. the setting speed.

When both measuring systems have reached again the original position after finished

measurement, the drag pointers can be readjusted to the actual value pointer by turning

the buttons. Thenafter a new measurement can be made.

lowest temperature value according to temperature changes.

Another system is placed in a separate upper measuring chamber (fitted with venting bore holes)

and indicates the surrounding air temperature by a blue instrument pointer.

To find out the highest ground and the lowest air temperature time-independend

Even in the floor laying technic this gauge has been efficient.

the thermometer additionally can be fitted with a minimum and

maximum drag pointer.

drag pointer mounted in the glass window pulled to the highest resp.

temperature and the air temperature can be measured separately.

The temperature-sensitive base transfers the temperature to the measuring spiral spring

and can be read off by a red instrument pointer.

Fig. 25 Fig. 26

The actual value pointer is fitted with a flag equally coloured as the

As the gauge is produced with a plastic case, the surrounding temperature doesn't influence the

ground measuring system.

The case contains a measuring system with two chambers. That's the reasion why the ground

This gauge is used as a thermometer to be seated with total surface contact for ground and air

measurements. It is mainly used in the concrete processing because the quality of concrete

BIMETAL SURFACE THERMOMETER

for concrete and floors, Fig. 25+26

Masses and dimensions are conform to current company standard. Changes to improve ou

gauges will be made without preannouncement.

020

Case: Stainless steel, 1.4301

- filled with glycerine (up to +200C)

- filled with silicone oil (from +250C on)

Bezel: Stainless steel, 1.4301

Diam. 80, 100, 125 mm crimped

Diam. 160 mm bayonet-fitted

- Bayonet-fitted diam. 80 and 100 mm

Dial: Aluminium, white varnished

lettering and graduation black

- Double scale C/F

Pointer: Aluminium, black

Window: Instrument glass

- Safety glass

- Max. drag pointer

available to bayonet-fitted diam. 80 to 160 mm

Stem: Plain without thread

6 or 8 mm made of st.st. 1.4571

- connectivities see overleaf

Connection: Backwards, 90 adjustable every angle

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1.0

- Works test certificate

- OPTIONS

Meas. range Graduation

-40+40C

-40+60C

-30+50C

Article number: -20+40C

Diam. 80 100 125 160 -20+60C

Stem 100 mm 31490 31500 31530 31510 0+60C

Stem 120 mm 31491 31501 31531 31511 0+80C

0+100C

Stem 160 mm 31492 31502 31532 31512 0+120C

Stem 200 mm 31493 31503 31533 31513 0+160C

0+200C

Stem 250 mm 31494 31504 31534 31514 0+250C

Stem 300 mm 31495 31505 31535 31515 0+300C

0+350C

Stem 400 mm 31496 31506 31536 31516 0+400C

Stem 500 mm 31497 31507 31537 31517 0+500C

Other measuring ranges are available on request !

Max. stem length L = 1.000 mm !

10.0

1.0

2.0

5.0

BIMETAL THERMOMETER

Process industry series, 90 adjustable every angle

Compl. stainless steel, class 1

020

Union nut with

additional

thermowell acc.

to DIN 16179

form CD or DIN

43772 form 8

Turnable

male thread

Movable clamp

connection

0 1

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

6 2 3 4 5

BIMETAL THERMOMETER

Process industry series, 90 adjustable every angle

Compl. stainless steel, class 1

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

021

Case: Bayonet-fitted stainless steel 1.4301

- liquid-filled

Bezel: Bayonet-fitted stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

- Red mark

- Double scale C/F

Pointer: Aluminium, black

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

- Red mark pointer

Gasket: Rubber

Stem: Made of stainless steel 1.4571

Standard up to 200 mm long x 6-8 mm

- other lengths are available

Connectivities: See overleaf

Features: - Pointer adjustment

- With contact for signalling page 090

Measuring range: 0-120C

- Resp. opposite

Accuracy class: 1

- Works test certificate

-OPTIONS

Version: Back centric connection Meas. range Graduation

Diam. 63 80 100 160 -60+40C

Article number: 3364 3384 3404 3464 -60+60C

-40+40C 1.0

Version: Bottom connection -40+60C

Diam. 63 80 100 160 -40+120C

Article number: 3364-1 3384-1 3404-1 3464-1 -30+30C

-30+50C

Version: Stem angular 90 / 135 bottom/back entry -30+70C

Diam. 63 80 100 160 -30+170C

Article number: 3364-2 3384-2 3404-2 3464-2 -20+40C

-20+60C

Version: Stem back entry with hinge 90 adjustable -20+80C

Diam. 63 80 100 160 -20+100C

Article number: 3364-3 3384-3 3404-3 3464-3 -20+180C

-10+50C 1.0

Gauges with capillary - length please quote ! -10+150C 2.0

0+60C

Version: With wall bracket made of aluminium 0+80C

Diam. 63 80 100 160 0+100C

Article number: 3664 3684 3704 3764 0+120C

0+160C

Version: With 3 hole front flange for panel mounting 0+200C

Diam. 63 80 100 160 0+250C

Article number: 3664-1 3684-1 3704-1 3764-1 0+300C

0+400C

Version: With back flange for surface mounting 0+500C

Diam. 63 80 100 160 0+600C

Article number: 3664-2 3684-2 3704-2 3764-2 0+700C

Other measuring ranges available on request !

1.0

2.0

1.0

2.0

2.0

2.0

10.0

5.0

2.0

1.0

GAS ACTUATED THERMOMETER

Process industry series, compl. stainless steel

021

63 38 60 80 14 20 8

80 37 60 80 14 20 8

100 45 60 80 14 20 8

160 45 60 80 14 20 8

Type

3364

3384

9 5 6 7 8 4

3404

3464

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

0 1 2 3

With

helical air bulb

With

helical air bulb

with adjustable

connection

Union nut with

additional

thermowell

acc. to DIN 16179

form CD or

DIN 43772

form 8

Turnable

male thread

Movable

clamp connection

With flange 40

for air ducts

f g t a b d e

GAS ACTUATED THERMOMETER

Process industry series, compl. stainless steel

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

021

63 38 86 75 14 8

80 37 110 95 14 8

100 45 132 116 14 8

160 45 196 178 14 8

f t c

With

helical air bulb

with adjustable

connection

With

helical air bulb

Union nut with

additional

thermowell

acc. to DIN 16179

form CD or

DIN 43772

form 8

Turnable

male thread

Movable

clamp connection

With flange 40

for air ducts

3684

3704

3764

Sep. pocket

with fixing screw

Fixed connection

male thread

Union nut

female thread

Union nut with

double nipple

0 1 2

Type a b

3664

3 9 5 6 7 8

LK

4

GAS ACTUATED THERMOMETER

Process industry series, compl. stainless steel

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

022

Case: Diam. 60 steel zinced

- Diam. 50 / 80 / 100 mm

Bezel: Triangular bezel brass chromed

for panel mounting

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Aluminium, black

Window: Instrument glass

Gasket: Plastic

Capillary: PVC-coated, black

Mounting method: With u-clamp for panel mounting

Connection: Backwards, off-centre

Stem: Cu-alloy, L = 36 x 8,5 mm

With compression spring and round nut M 10 x 1

Measuring range: 0-120C

- Others on request

Accuracy class: 2.0

- OPTIONS

Article number:

Capillary: mtr. 1 2 3 5

Diam. 60 3901 3902 3903 3905

Other lengths resp. versions on request !

Accessories: Thermowells made of brass G 1/2 B soft soldered

L = 45 63 80 100 160 200 mm

REMOTE-READING THERMOMETER

Alcohol filled

Diam. 60, for panel mounting

022

60 33 64 4 45

e f c Type a

3900

b

REMOTE-READING THERMOMETER

Alcohol filled

Diam. 60, for panel mounting

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

023

Case: Diam. 80 stainless steel 1.4301

- Steel zinced

Bezel: Stainless steel 1.4301

- Steel nickel-plated

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Aluminium, black

Window: Instrument glass

- Safety glass

Distance ring: Internal made of aluminium

Insertion stem: L = 1.000 x 13 up to L = 4.000 x 20 tapered to 16 mm

Handling: 2 solid handles made of brass

Measuring

system: Bimetal measuring element

Measuring range: 0-120C

- Others on request

Accuracy class: 1.0

- OPTIONS

Fig. 3

Diam. 80 L= 1.000 1.500 2.000 2.500 3.000 3.500 4.000 mm

Article number: 1110053 1110054 1110055 1110056 1110057 1110058 1110059

Fig. 3-Std. contains a case steel zinced and a

nickel-plated bezel. Stem only available in 13 mm.

Fig. 3-Std.

Diam. 80 L= 500 750 1.000 1.250 1.500 1.750 2.000 mm

Article number: 1110081 1110082 1110083 1110084 1110085 1110086 1110087

BIMETAL STACK THERMOMETER, Fig. 3

for silos and clamps

023

BIMETAL STACK THERMOMETER, Fig. 3

for silos and clamps

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

030

Case: Steel zinced / varnished

- Diam. 160

Bezel: Brass chromed

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Aluminium, black

adjustable at end of stem

Window: Instrument glass

- Safety glass

- Max. drag pointer

- Max./min. drag pointer

Distance ring: Internal made of aluminium

Stem: L = 100 x 28 mm Cu-varnished

- Other lengths are available

Measuring

system: Tripple fold for rel. humidity

Measuring range: 0-100% rel. humidity

Operating range: -30+80C

Connection: Backwards

- Bottom (not available with double stem)

Features: - With sliding contact for signalling

- With double scale for humidity and temperature -10+50C

( 2 stems backwards - 160 only with surface mounting flange)

Mounting method: With back flange, steel varnished, surface mount

- With back flange made of stainless steel 1.4301 (diam.100 only)

or with fixed connection thread G 1 B made of brass

- Stem with movable flange steel zinced 80 mm, surface mount

Accuracy class: 2.5

- OPTIONS

Article number:

Mounting method: Back flange G 1 B brass

Diam. 100 894 890

HYGROMETER for moisture measurements

with stem for air ducts

030

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

100 132 116 18 28 100 15 28 1 B 41

vertical or in oblique position.

The measuring element is suitable for a permanent temperature up to plus 80C.

A temporary max. load up to 120C is acceptable and causes no damage.

(approx. 60 minutes). The gauge should then indicate approx. 96% rel. humidity.

Perhaps the instrument can be recalibrated by using a screwdriver.

The activation takes place by bandaging the perforation of the stem with a wet cloth

If the gauge works at steady low humidity, an annual activation and a recalibration of the

measuring element should be made.

t

894

a G

890

b Type a

As such gauges are insensitive to their orientation, the instrument can be mounted axial,

These gauges are produced for air duct and climatic chamber installations.

For good ventilation of the humidity measuring element the stem is fitted with air vents.

The air vents are sealed with a stainless steel gauze inside the stem, in order to prevent

the infiltration of dust and therefore the damage of the measuring element.

t c b LK SW Type

HYGROMETER for moisture measurements

with stem for air ducts

031

Case: Diam. 130 stainless steel 1.4301

Bezel: Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

with dewpoint scale

Pointer: Aluminium, black

adjustable

Window: Plastic, raised

Measuring

systems: 1 x bimetal for temperature

1 x rel. humidity

Measuring range: Air: -10+40C

Rel. humidity: 20100%

Saturation moisture: 450 gr./m

Dewpoint temperature: -8+26C

Accuracy class: Temperature 1C

Humidity 2.5%

Mounting method: With lifting lug

Miscellanea: Fig. 35-K

With scale for indoor climate

Diam. Article number:

130 Fig. 35-Ta 1530001

130 Fig. 35-K 1530002

THERMO-HYGROMETER-COMBINATION

for dewpoint and indoor climate measurements Fig. 35-Ta

031

Hereafter we give an explanation of the mentioned moisture values:

Saturation moisture = maximum absorbable humidity at the responsible temperature in gr./m

Absolute humidity = substantial humidity in gr./m

Relative humidity = absolute humidity

saturation moisture

Dewpoint = temperature, at which the water vapour included in the air just would

condensate in C

Saturation deficit: = saturation moisture minus absolute humidity

The dewpoint temperature can be read off directly in C by following the curves from the point of

intersection of the pointers. Now you are able to calculate the saturation moisture deficit.

E.G. air temperature 20.5C, saturation moisture = 18 gr./m, rel. humidity 70% = 14C dewpoint

can be read off at the intersection of the pointers.

At an air temperature of 14C the saturation moisture is = 12 gr./m. Deficit = 18 - 12 = 6 gr./m.

So in this case the air is able to absorb further 6 gr. water / m.

The thermo-hygrometer contains a precision humidity meter and a bimetal measuring system.

x 100 = % rel. humidity

Here the temperature, the relative humidity, the saturation moisture and the dewpoint can be

read off directly following the curves from the point of intersection of the surface temperature pointer

and the relative surface humidity pointer.

Its field contains a series of possibilities as controlling the temperature, the rel. humidity and the

dewpoint temperature in climatic chambers, storage rooms, living rooms, sheds, barns, in all industrial

factories like the textile and clothing sector, in paper, powder and canning-factories, in the wood

working industry and tobacco processing.

For the quality of such products it is very important to comply to special grades of humidity and

temperature during production, storage and drying. Corrosive materials have to be protected against

rust and oxidation. By all means it must be avoided that the temperature cools down to the dewpoint.

THERMO-HYGROMETER-COMBINATION

for dewpoint and indoor climate measurements Fig. 35-Ta

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

032

Case: Diam. 130 stainless steel 1.4301

Bezel: Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

with dewpoint scale

Pointer: Aluminium, black

adjustable

Window: Plastic, raised

Measuring

systems: 2 x bimetal for temperature

1 x rel. humidity

Measuring range: Air: -10+40C

Rel. humidity: 20100%

Saturation moisture: 450 gr./m

Dewpoint temperature: -8+26C

Surface temperature: -10+40C

Features: Flexible measuring pot

for surface temperature

Accuracy class: Temperature 1C

Humidity 2.5%

Mounting method: With 3 bar magnets and a lifting lug

Diam. Article number:

130 Fig. 36 1530011

THERMO-HYGROMETER-COMBINATION

for surface measurements Fig. 36

032

commands, that rust removing and painting works only can be done, if the temperature of the

After fixing the combination to the surface of the material to be worked on, the measuring elements

The air temperature shows 9.5C. This indicates that the surface temperature sinks slowly and a

dewpoint precipitation is possible.

For that reason the testing should be repeated in certain intervals.

The thermo-hygrometer contains a precision humidity meter and two bimetal measuring systems.

The difference between surface temperature and dewpoint temperature is 6C, so that the conserving

mounting method.

works can begin, because it is higher than 3C.

surface that shall be given a finish is min. 3C higher than the dewpoint of the surrounding air.

Here the temperature, the relative humidity, the saturation moisture and the dewpoint can be

read off directly following the curves from the point of intersection of the surface temperature pointer

and the relative surface humidity pointer. The back of the case is fitted with 3 strong bar magnets for

steel part usage. The additional lifting lug at the top of the case gives the instrument an additional

In the coating technic difficulties often arise because the paint doesn't stay on a wet base coat.

In order to make paintings fast, there is a decision of the German "Bundesministerium fr Verkehr" that

absorb the temperature and the relative humidity. This can take about half an hour depending on

The instrument was developed for the requirements of the metallization and is normally used in the field of

ship conservation, docks, bridges, steel constructions, mining and pipeline engineering.

At work in such fields of application it is possible to define directly the dewpoint temperature on the surface

of the steel girder. This measurement has to convey certainty, that there will be no dewpoint precipitation.

conditions. Thenafter the dewpoint can be read off in C at the intersection of both pointers.

E.G. air temperature 9.5C, rel. humidity 80% = 6C dewpoint at 12C surface temperature.

THERMO-HYGROMETER-COMBINATION

for surface measurements Fig. 36

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

033

Case: Diam. 130 stainless steel 1.4301

Bezel: Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

with dewpoint scale

Pointer: Aluminium, black

adjustable

Window: Plastic, raised

Measuring

systems: 2 x bimetal for temperature

1 x rel. humidity

Measuring range: Surface temperature: -10+40C

Rel. surface humidity: 20100%

Saturation moisture: 450 gr./m

Dewpoint temperature: -8+26C

Air temperature: -10+40C

Features: Fig. 38 with flexible measuring pots

for surface temperature and surface humidity.

With these instruments you can reach highest precision.

Accuracy class: Temperature 1C

Humidity 2.5%

Mounting method: With 3 bar magnets and a lifting lug

Daim. Article number:

130 Fig. 37 1530021

130 Fig. 38 1530023

THERMO-HYGROMETER-COMBINATION

for surface measurements Fig. 37+38

033

E.G.

works can begin, because it is higher than 3C.

The air temperature shows 12C. This indicates that the surface temperature sinks slowly and a

dewpoint precipitation is possible.

absorb the temperature and the relative humidity. This can take about half an hour depending on

conditions. Thenafter the dewpoint can be read off in C at the intersection of both pointers.

The difference between surface temperature and dewpoint temperature is 3.5C, so that the conserving

air temperature 9.5C, rel. humidity 80% = 6C dewpoint at 12C surface temperature.

In order to make paintings fast, there is a decision of the German "Bundesministerium fr Verkehr" that

commands, that rust removing and painting works only can be done, if the temperature of the

surface that shall be given a finish is min. 3C higher than the dewpoint of the surrounding air.

After fixing the combination to the surface of the material to be worked on, the measuring elements

At work in such fields of application it is possible to define directly the dewpoint temperature on the surface

of the steel girder. This measurement has to convey certainty, that there will be no dewpoint precipitation.

In the coating technic difficulties often arise because the paint doesn't stay on a wet base coat.

The thermo-hygrometer contains a precision humidity meter and two bimetal measuring systems.

Here the temperature, the relative humidity, the saturation moisture and the dewpoint can be

read off directly following the curves from the point of intersection of the surface temperature pointer

and the relative surface humidity pointer. The back of the case is fitted with 3 strong bar magnets for

steel part usage. The additional lifting lug at the top of the case gives the instrument an additional

mounting method.

The instrument was developed for the requirements of the metallization and is normally used in the field of

ship conservation, docks, bridges, steel constructions, mining and pipeline engineering.

THERMO-HYGROMETER-COMBINATION

for surface measurements Fig. 37+38

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

034

Case: Diam. 80 st. steel 1.4301

Bezel: Stainless steel 1.4301

Dial: Aluminium, white varnished

lettering and graduation black

Pointer: Aluminium, black

Window: Instrument glass

- Safety glass

Insertion stem: L = 500 x 23 mm in brass chromed with tip

- L = 1.000 mm

Features: Measuring systems proteced by st. steel gauze

and by turnable double stem

Handling: 2 solid handles made of brass for pricking

Measuring

system: Tripple fold for humidity

Measuring range: 0-100% rel. humidity

Accuracy class: 2.5%

- OPTIONS

Diam. Article number:

80 1440001

HYGROMETER Fig. 68

034

The hygrometer for pricking is mainly used in agriculture to define the moisture content of corn.

The hygrometer is insensible to its position and can be used axial, vertical or in oblique position.

The measuring element qualifies to a permanent temperature of 80C.

A short time load up to 120C is justifiable and causes no damage.

There are two screwable handles installed beneath the case for inserting the stem into the

goods stored.

Before insertion into the goods stored the outer stem has to be turned to close the perforation

at the stem end. After reaching the measuring depth the perforation has to be opened by

turning to the other direction. Now the measurement can begin.

The stem should stay in the goods stored for approx. 30 to 60 minutes, at least until the pointer

doesn't move anymore.

Thenafter the reached value can be read off and the water content of the goods stored can be

read off by the scales or by defining it according to the also delivered curve sheets.

After finishing the measurement the perforation has to be closed again before the stem is pulled

out again. IMPORTANT!

By this measure it is avoided that corn dust or corn dirt comes inside the perforation during

insertion or pulling out. Disregarding this can cause damage to the measuring element.

The ascertaining of the relative humidity follows by a scale 0100%.

The instrument is produced for the following goods stored:

field beans, cotton, cottonseed, peas, peanut kernels, barley, grass seed, oats, hay, millet,

wood, industrial silk, leather, linseed, corn, milo, rapeseed, rice, rye, real silk, sunflower seed,

wheat and wool.

HYGROMETER Fig. 68

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

040

Upper section: Aluminium, brass anodised, 30 mm wide

- 36 mm wide

- Anodised aluminium

- Made of shining stainless steel

Figures: Beneath an anodic coating

Joint to

measuring stem: Thread M 18 x 1,5 with locknut

Measuring stem: G 1/2 A brass - from 300C on steel

- Further threads on request

- Special brass SoMs76 (resistant to seawater)

- Steel

- Stainless steel 1.4571

Connection: Form B - immersion tube with threaded socket

- Form C union nut

Glass tube: Elastic mounted, graduation acid-proof

Accuracy class: 1

Filling: Up to 200C alcohol blue

From 250C on mercury cap. yellow backed

- Alcohol red

- Mercury cap. yellow backed or blue shining

Capillary form: Prismatic or round

Version: S T R A I G H T

Stem 10 mm L= 40 63 75 100 120 160 200

Measuring range: Article number

-30+50C 4001 4002 4003 4004 4005 4006 4007

-10+50C 4011 4012 4013 4014 4015 4016 4017

0-50C 4021 4022 4023 4024 4025 4026 4027

0-60C 4031 4032 4033 4034 4035 4036 4037

0-100C 4041 4042 4043 4044 4045 4046 4047

0-120C 4051 4052 4053 4054 4055 4056 4057

0-160C 4061 4062 4063 4064 4065 4066 4067

0-200C 4071 4072 4073 4074 4075 4076 4077

0-250C 4071-2 4072-2 4073-2 4074-2 4075-2 4076-2 4077-2

0-300C 4081 4082 4083 4084 4085 4086 4087

0-500C 4091 4092 4093 4094 4095 4096 4097

+100+600C 4091-6 4092-6 4093-6 4094-6 4095-6 4096-6 4097-6

Double scale: -C/F

- OPTIONS

Spare parts: Glass tubes

Immersion tubes

Further measuring ranges and stem lengths on request !

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 181, staight version

Nominal size 110

040

110 27 1/2A 10

150 27 1/2A 10

200 27 1/2A 10

t Type a SW G

4000

4300

4600

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 181, straight Form

Nominal size 110

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

041

Upper section: Aluminium, brass anodised, 30 mm wide

- 36 mm wide

- Anodised aluminium

- Made of shining stainless steel

Figures: Beneath an anodic coating

Joint to

measuring stem: Thread M 18 x 1,5 with locknut

Measuring stem: G 1/2 A brass - from 300C on steel

- Further threads on request

- Special brass SoMs76 (resistant to seawater)

- Steel

- Stainless steel 1.4571

Connection: Form B - immersion tube with threaded socket

- Form C union nut

Glass tube: Elastic mounted, graduation acid-proof

Accuracy class: 1

Filling: Up to 200C alcohol blue

From 250C on mercury cap. yellow backed

- Alcohol red

- Mercury cap. yellow backed or blue shining

Capillary form: Prismatic or round

Version: S T R A I G H T

Stem 10 mm L= 40 63 75 100 120 160 200

Measuring range: Article number

-30+50C 4301 4302 4303 4304 4305 4306 4307

-10+50C 4311 4312 4313 4314 4315 4316 4317

0-50C 4321 4322 4323 4324 4325 4326 4327

0-60C 4331 4332 4333 4334 4335 4336 4337

0-100C 4341 4342 4343 4344 4345 4346 4347

0-120C 4351 4352 4353 4354 4355 4356 4357

0-160C 4361 4362 4363 4364 4365 4366 4367

0-200C 4371 4372 4373 4374 4375 4376 4377

0-300C 4381 4382 4383 4384 4385 4386 4387

0-400C 4381-4 4382-4 4383-4 4384-4 4385-4 4386-4 4387-4

0-500C 4391 4392 4393 4394 4395 4396 4397

0-600C 4391-6 4392-6 4393-6 4394-6 4395-6 4396-6 4397-6

Double scale: -C/F

- OPTIONS

Spare parts: Glass tubes

Immersion tubes

Further measuring ranges and stem lengths on request !

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 185, straight version

Nominal size 150

041

110 27 1/2A 10

150 27 1/2A 10

200 27 1/2A 10

4000

4300

4600

t Type a SW G

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 185, straight version

Nominal size 150

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

042

Upper section: Aluminium, brass anodised, 30 mm wide

- 36 mm wide

- Anodised aluminium

- Made of shining stainless steel

Figures: Beneath an anodic coating

Joint to

measuring stem: Thread M 18 x 1,5 with locknut

Measuring stem: G 1/2 A brass - from 300C on steel

- Further threads on request

- Special brass SoMs76 (resistant to seawater)

- Steel

- Stainless steel 1.4571

Connection: Form B - immersion tube with threaded socket

- Form C union nut

Glass tube: Elastic mounted, graduation acid-proof

Accuracy class: 1

Filling: Up to 200C alcohol blue

From 250C on mercury cap. yellow backed

- Alcohol red

- Mercury cap. yellow backed or blue shining

Capillary form: Prismatic or round

Version: S T R A I G H T

Stem 10 mm L= 40 63 75 100 120 160 200

Measuring range: Article number

-30+50C 4601 4602 4603 4604 4605 4606 4607

-10+50C 4611 4612 4613 4614 4615 4616 4617

0-50C 4621 4622 4623 4624 4625 4626 4627

0-60C 4631 4632 4633 4634 4635 4636 4637

0-100C 4641 4642 4643 4644 4645 4646 4647

0-120C 4651 4652 4653 4654 4655 4656 4657

0-160C 4661 4662 4663 4664 4665 4666 4667

0-200C 4671 4672 4673 4674 4675 4676 4677

0-300C 4681 4682 4683 4684 4685 4686 4687

0-400C 4681-4 4682-4 4683-4 4684-4 4685-4 4686-4 4687-4

0-500C 4691 4692 4693 4694 4695 4696 4697

0-600C 4691-6 4692-6 4693-6 4694-6 4695-6 4696-6 4697-6

Double scale: -C/F

- OPTIONS

Spare parts: Glass tubes

Immersion tubes

Further measuring ranges and stem lengths on request !

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 189, straight version

Nominal size 200

042

110 27 1/2A 10

150 27 1/2A 10

200 27 1/2A 10

t

4000

4300

4600

Type a SW G

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 189, straight version

Nominal size 200

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

043

Upper section: Aluminium, brass anodised, 30 mm wide

- 36 mm wide

- Anodised aluminium

- Made of shining stainless steel

- 360 turnable

Figures: Beneath an anodic coating

Joint to

measuring stem: Plug-in type - with locking screw

Measuring stem: G 1/2 A brass - from 300C on steel

- Further threads on request

- Special brass SoMs76 (resistant to seawater)

- Steel

- Stainless steel 1.4571

Connection: Form B - immersion tube with threaded socket

- Form C union nut

Glass tube: Elastic mounted, graduation acid-proof

Accuracy class: 1

Filling: Up to 200C alcohol blue

From 250C on mercury cap. yellow backed

- Alcohol red

- Mercury cap. yellow backed or blue shining

Capillary form: Prismatic or round

Version: A N G L E 9 0 back entry

Stem 10 mm L= 40 63 75 100 120 160 200

Measuring range: Article number

-30+50C 4101 4102 4103 4104 4105 4106 4107

-10+50C 4111 4112 4113 4114 4115 4116 4117

0-50C 4121 4122 4123 4124 4125 4126 4127

0-60C 4131 4132 4133 4134 4135 4136 4137

0-100C 4141 4142 4143 4144 4145 4146 4147

0-120C 4151 4152 4153 4154 4155 4156 4157

0-160C 4161 4162 4163 4164 4165 4166 4167

0-200C 4171 4172 4173 4174 4175 4176 4177

0-250C 4171-2 4172-2 4173-2 4174-2 4175-2 4176-2 4177-2

0-300C 4181 4182 4183 4184 4185 4186 4187

0-500C 4191 4192 4193 4194 4195 4196 4197

+100+600C 4191-6 4192-6 4193-6 4194-6 4195-6 4196-6 4197-6

Double scale: -C/F

- OPTIONS

Spare parts: Glass tubes

Immersion tubes

Further measuring ranges and stem lengths on request !

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 182, angle 90

Nominal size 110

043

110 27 1/2A 10

150 27 1/2A 10

200 27 1/2A 10

t

4100

4400

4700

Type a SW G

V-SHAPED MACHINE GLASS THERMOMETER

DIN 16 182, angle 90

Nominal size 110

Masses and dimensions are conform to current company standard. Changes to improve our

gauges will be made without preannouncement.

044

Upper section: Aluminium, brass anodised, 30 mm wide