GTP For Towers

GTP For Towers

Uploaded by

abhi_akCopyright:

Available Formats

GTP For Towers

GTP For Towers

Uploaded by

abhi_akOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

GTP For Towers

GTP For Towers

Uploaded by

abhi_akCopyright:

Available Formats

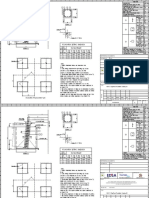

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

1.0 1.1 1.2

Tower Manufacturer/ Fabricator Name and address Name and address of supplier of materials i) Steel ii) Zinc iii) Bolts and nuts iv) Tower hardware v) Galvanized spring washers vi) Galvanizer

1.3

Governing Standards for materials at 1.2 above.

1.4 1.4.1

Design Parameters Gust speed (m/s) at 10m height i) At minimum temperature(10C) Zone A Zone B Zone C Zone D 55 YES

1.4.2

Temperature Every day temperature Minimum temperature Maximum temperature i) Conductor ii)Ground wire C C 75 53 C C 25 10 YES

1.4.3

Protection against lightning i) Angle of shield 330kV 132Kv Degree Degree 30 30 YES

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

ii)

Mid span clearance 330kV 132kV

m 6.5 max.(5m, 30degree shieldwire according to Clause 6.5.4) YES

1.4.3

Air clearance Suspension tower i) 330kV -Swing angle -Swing angle ii) 132kV -Swing angle -Swing angle Jumper (Tension tower) iii) 330kV -Swing angle -Swing angle iv) 132kV -Swing angle -Swing angle

mm

0-15 60 0-15 79

NA

1200 270 YES

0-15 45 0-15 71

NA

1200 270

1.4.4

Maximum ultimate stress Compression members Mild steel High tensile steel Tension members Mild steel High tensile steel N/mm2 N/mm2 450 510 N/mm2 N/mm2 450 510 YES

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

1.4.5

Shear on bolts Mild steel H,T.steel Bearing on bolts Mild steel H,T.steel N/mm2 N/mm2 N/mm2 N/mm2 As per ACSE 10-97 Clause 4.3 ( Contractor to indicate the values) YES

Slenderness ratio 1.4.6 Leg members, G.W.Peak and X-arm lower members Bracings Redundants / Nominal stress carrying members Tension members 120 200 250 400 YES

1.4.7

Minimum Flange Width Bolt dia. 12/ 16/ 20 mm 40/ 45/ 50 YES

1.4.8

Minimum thickness of members Leg/ Ground wire peak and external members of horn members/ lower cross arm Upper members of X-arm/ Bracing and inner members of horn peak/ Other members mm mm 5 YES 4

1.4.9

Chemical Composition (Mild) steel/ H.T. Steel Carbon Manganese Phosphorus Sulphur Silicon Mechanical Properties Tensile strength Yield Strength Elongation (minimum) Kg/mm2 Kg/mm2 % 45.89/52 28.04/36.2 23/22 % % % % % As per standards (IS 2062) YES

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

1.4.10

Nominal length, clamping length and weight of bolts of size( diameter) in mm and in kg 12mm 16mm 20mm mm, mm, Kg 50, 20, 0.08 105, 75,0.24 110, 80,0.39 YES

1.4.11

Spacing of bolts and Edge distances corresponding to bolt diameter 12mm 16mm 20mm mm mm mm 30 & 20 40 & 25 50 & 30 YES

1.4.12

Galvanized spring washers weight and thickness corresponding to both diameter 12mm 16mm 20mm Kg, mm 0.009 YES

2.0

Foundation

2.1

Name and address of supplier Cement Coarse aggregate Fine aggregate

2.2

Governing standards Cement Coarse aggregate Fine aggregate Water

2.3

Concrete mix Grade Composition by grade Cement

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

Coarse aggregate Fine aggregate Water 2.4 Bond stresses( Limit) Between concrete and reinforcement steel deformed bars in tension With M:15 With M:25 Between concrete and reinforcement steel deformed bars in tension With M:15 With M:25

Between concrete and stubs in tension With M:15 With M:25 Between Rock and Concrete Fissured rock Hard rock Between Hard Rock and grout 2.5 Assumed density of earth pile foundations 2.6 Assumed angle to the vertical of sides of frustum of earth resisting uplift degree I Ii 2.7 Light concrete foundation. Heavy concrete foundation

Maximum angle between base and side of concrete foundation for uplift conditions Assumed density of foundation concrete ... Density of earth for foundation. Ultimate earth pressure . Ultimate Lateral earth pressure for foundation Shear forces ,per meter of depth

TECHNICAL DATA SCHEDULE

330 KV and 132kV TRANSMISSION LINE for Towers and Foundations

CODE NO:3100

ITEM DESCRIPTION UNITS REQUIRED GUARANTEED

2.8

Assumed depth of application of resultant lateral Earth pressure below ground line to top of foundation block.. Maximum ultimate allowable stresses in concrete for foundation design : Tensile stress due to blending. Bond stress, galvanized steel/concrete................... Bearing stress.. Punching shear stress..

2.9

2.10

28-day cube strength (1:2:4) (after allowing for deviations)

N/mm2

33

2.11

Minimum portion of stub loads to be allowed for in the design of stub cleat

You might also like

- Technical Specification FOR: (PART-II)Document12 pagesTechnical Specification FOR: (PART-II)binodeNo ratings yet

- 33 KV Tower Line On PantherDocument4 pages33 KV Tower Line On PantherKc NarulaNo ratings yet

- 132kv-internal-5BAYS-DESIGN REPORTDocument102 pages132kv-internal-5BAYS-DESIGN REPORTNewton AdhikariNo ratings yet

- Revised Bom - Basic Tower - TB - 18.11.23Document11 pagesRevised Bom - Basic Tower - TB - 18.11.23Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Cable Tray Catalogue.Document18 pagesCable Tray Catalogue.stuart3962No ratings yet

- Sag (Hot) ACSR 150 KV 250-50 SQMM - 400 - ReportDocument4 pagesSag (Hot) ACSR 150 KV 250-50 SQMM - 400 - ReportYoga PratamaNo ratings yet

- 2022-03-08 GIS Report RangpurDocument28 pages2022-03-08 GIS Report RangpurChandan ChakmaNo ratings yet

- Development of 765 KV AC Transmission KEPCODocument4 pagesDevelopment of 765 KV AC Transmission KEPCOGuru MishraNo ratings yet

- 66kV SS TypeTower Foundation DrawingDocument2 pages66kV SS TypeTower Foundation DrawingBAWA ALEXNo ratings yet

- Is 802 1977 PDFDocument21 pagesIs 802 1977 PDFBhavin Shah0% (1)

- Optimum Body and Leg Extension Selection in PLS CADDDocument5 pagesOptimum Body and Leg Extension Selection in PLS CADDGiancarlos Fenco BravoNo ratings yet

- Design Basis Report For Lattice & Monopole TowerDocument5 pagesDesign Basis Report For Lattice & Monopole TowerMd MohsinNo ratings yet

- Technical Specification: Haryana Vidyut Prasaran Nigam LimitedDocument9 pagesTechnical Specification: Haryana Vidyut Prasaran Nigam LimitedAdmin 3DimeNo ratings yet

- 33K Single Stand VT SupportDocument6 pages33K Single Stand VT SupportNNANYELU CHINWUBANo ratings yet

- KSH International Enamelled Copper Conductors/Strips BrochureDocument2 pagesKSH International Enamelled Copper Conductors/Strips Brochurekshintl100% (1)

- PGCIL Dreams 2.0Document6 pagesPGCIL Dreams 2.0Nitish Singh0% (1)

- MPPTCL TR-25 String Chart (Opgw)Document25 pagesMPPTCL TR-25 String Chart (Opgw)Rakshit KumarNo ratings yet

- Technical SpecificationDocument14 pagesTechnical SpecificationbinodeNo ratings yet

- Wind On Tower NS Actual As Per en 50341 - R0 - 1 To CheckDocument3 pagesWind On Tower NS Actual As Per en 50341 - R0 - 1 To ChecksujalkalpataruNo ratings yet

- Cables & Power Network CalculationsDocument65 pagesCables & Power Network Calculationssalemg82No ratings yet

- Transmission Tower Presentation PDFDocument27 pagesTransmission Tower Presentation PDFIlham HusseinNo ratings yet

- Is 802 Part - 6Document24 pagesIs 802 Part - 6mano chandranNo ratings yet

- Spec BPI KaraikudiDocument39 pagesSpec BPI Karaikudishuruaat2003No ratings yet

- 132kv - PI Design ReportDocument18 pages132kv - PI Design ReportNewton AdhikariNo ratings yet

- 795mcm Acsr CondorDocument1 page795mcm Acsr Condorgari_monsanto100% (1)

- Optimization of Transmission TowerDocument7 pagesOptimization of Transmission TowerVenkataLakshmiKorrapatiNo ratings yet

- Tower Spotting Data of 220 KV M/C Transmission Line: Nepal Electricity AuthorityDocument7 pagesTower Spotting Data of 220 KV M/C Transmission Line: Nepal Electricity AuthorityHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Steel Structure SheduleDocument22 pagesSteel Structure SheduleisanNo ratings yet

- PSCC Poles DrawingsDocument5 pagesPSCC Poles DrawingsNagabhushanamNo ratings yet

- Vol. 5.1 400 KV GIS SUBSTATION. Technical SpecificationDocument533 pagesVol. 5.1 400 KV GIS SUBSTATION. Technical SpecificationbrahimialiNo ratings yet

- KEC International Limited: Power T & D Cables Railways Civil SolarDocument42 pagesKEC International Limited: Power T & D Cables Railways Civil SolarPlanning Engineering100% (1)

- La 33KVDocument6 pagesLa 33KVPritam SinghNo ratings yet

- Conductor Parameters-SI UnitsDocument15 pagesConductor Parameters-SI UnitsMunesu Innocent DizamuhupeNo ratings yet

- HPSC Panchayati Raj Conventional Paper 2023Document11 pagesHPSC Panchayati Raj Conventional Paper 2023vikram SinghNo ratings yet

- Modeling Mid-Span Taps, Mid-Span Phase Transpositions and Phase SpacersDocument14 pagesModeling Mid-Span Taps, Mid-Span Phase Transpositions and Phase SpacersDejanNo ratings yet

- Is 802Document16 pagesIs 802Sourav DeyNo ratings yet

- BOQ UttungaDocument3 pagesBOQ UttungaSmart ShivaNo ratings yet

- Is 802 (Part 1/sec 2) : 1992Document14 pagesIs 802 (Part 1/sec 2) : 1992ced32820% (1)

- Earthing RodDocument5 pagesEarthing Rodfake fNo ratings yet

- 6m Mono Pole DRWDocument1 page6m Mono Pole DRWmanohargudNo ratings yet

- OPGW Drum ScheduleDocument5 pagesOPGW Drum SchedulePrabhakar Sv100% (1)

- T-230-0240 - Design Criteria, Sag Tension & Tower Spotting DataDocument19 pagesT-230-0240 - Design Criteria, Sag Tension & Tower Spotting DataSajan PrajapatiNo ratings yet

- Cox - 1975 - Overhead-Line PracticeDocument9 pagesCox - 1975 - Overhead-Line PracticePoleomanNo ratings yet

- Analysis and Design of Four Legged Transmission Tower: Archana R, Aswathy S KumarDocument5 pagesAnalysis and Design of Four Legged Transmission Tower: Archana R, Aswathy S Kumaranon_108261563No ratings yet

- اوزان البرج PDFDocument55 pagesاوزان البرج PDFAkram ElhadiNo ratings yet

- Transmission and Distribution DesignDocument31 pagesTransmission and Distribution DesignER.Master Ajay RimalNo ratings yet

- 17052016PL67CN14miningplan PDFDocument91 pages17052016PL67CN14miningplan PDFRyadNo ratings yet

- Pit Marking Details Package - I Line-4: Tower Type Classification J G OA OABDocument2 pagesPit Marking Details Package - I Line-4: Tower Type Classification J G OA OABanon_637123560100% (1)

- Vol2 TL-S1-6 3626 PGCBDocument124 pagesVol2 TL-S1-6 3626 PGCBabhi120783No ratings yet

- Suspension Cable Tension Vs Tower Height SpreadsheetDocument10 pagesSuspension Cable Tension Vs Tower Height Spreadsheettanujaayer100% (1)

- Power Transmisison Towers Loading TreeDocument30 pagesPower Transmisison Towers Loading TreeAnonymous ep7LE5ZdP5No ratings yet

- Sag-Tension ReportDocument4 pagesSag-Tension ReportHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006No ratings yet

- Bangladesh National Building Code 2012 Part6 Chapter 6Document111 pagesBangladesh National Building Code 2012 Part6 Chapter 6morphie_blackNo ratings yet

- Sag Tension Report - 4pm 15th MayDocument12 pagesSag Tension Report - 4pm 15th MayRakshit KumarNo ratings yet

- Technical Specification of 132KV TLDocument10 pagesTechnical Specification of 132KV TLShree Krishna GoraNo ratings yet

- TCC33 Flat Slabs (A&D)Document47 pagesTCC33 Flat Slabs (A&D)Nazar Shafiq100% (1)

- 01A Design Criteria For TowersDocument3 pages01A Design Criteria For TowersNisarg TrivediNo ratings yet

- EC4 Composite DesignDocument51 pagesEC4 Composite DesignbsitlerNo ratings yet

- Flat SlabDocument14 pagesFlat Slabbasanth_712982100% (1)

- Greek Orthodox School-SolarDocument24 pagesGreek Orthodox School-Solarabhi_akNo ratings yet

- Survey Design of Overhead Electrical Transmission LinesDocument12 pagesSurvey Design of Overhead Electrical Transmission Linesabhi_akNo ratings yet

- SBI PO Memory Based Preliminary Exam Paper 2015Document11 pagesSBI PO Memory Based Preliminary Exam Paper 2015abhi_ak100% (1)

- A Review of Dissolved Gas Analysis in Power Transformers: Energy ProcediaDocument6 pagesA Review of Dissolved Gas Analysis in Power Transformers: Energy Procediaabhi_akNo ratings yet

- SBI PO Mains 2016 Reasoning Question PaperDocument10 pagesSBI PO Mains 2016 Reasoning Question Paperabhi_akNo ratings yet

- Difference Between Alternating CurrentDocument23 pagesDifference Between Alternating Currentabhi_akNo ratings yet

- Nsitf ActDocument55 pagesNsitf Actabhi_akNo ratings yet

- Your Shipment 9683882305 Final Status Details On 22 December 2018 at 16.47Document1 pageYour Shipment 9683882305 Final Status Details On 22 December 2018 at 16.47abhi_akNo ratings yet

- Basic Requirements For Fresh StudentsDocument17 pagesBasic Requirements For Fresh Studentsabhi_akNo ratings yet

- Ch4E03 Advanced Physical ChemistryDocument3 pagesCh4E03 Advanced Physical Chemistryabhi_akNo ratings yet

- Syllabus 2Document7 pagesSyllabus 2abhi_akNo ratings yet

- (MM/DD/YYYY) (MM/DD/YYYY) : (40 Days Left)Document2 pages(MM/DD/YYYY) (MM/DD/YYYY) : (40 Days Left)abhi_akNo ratings yet

- Example 3: SolutionDocument1 pageExample 3: Solutionabhi_akNo ratings yet

- Rehabilitation, Reinforcement of 330/132Kv and 132/133Kv Transmission SubstationDocument3 pagesRehabilitation, Reinforcement of 330/132Kv and 132/133Kv Transmission Substationabhi_akNo ratings yet

- CDC UP Kick-Off Meeting Agenda Checklist PDFDocument1 pageCDC UP Kick-Off Meeting Agenda Checklist PDFabhi_akNo ratings yet

- IEEMA CircularDocument2 pagesIEEMA Circularabhi_ak0% (1)

- MOM - With - Travel Date: - DateDocument2 pagesMOM - With - Travel Date: - Dateabhi_akNo ratings yet

- 2015 House of Reps Candidates (Federal)Document160 pages2015 House of Reps Candidates (Federal)abhi_akNo ratings yet

- 2015 Senatorial CandidatesDocument62 pages2015 Senatorial Candidatesabhi_akNo ratings yet

- Licenced Tax Practioners of NigeriaDocument1 pageLicenced Tax Practioners of Nigeriaabhi_akNo ratings yet

- Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 7Document7 pagesSri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 7Sanaka LogesNo ratings yet

- Layers of Flexible PavementDocument52 pagesLayers of Flexible Pavementsavan chavanNo ratings yet

- Monocoque & Semio-MonocoqueDocument2 pagesMonocoque & Semio-MonocoquePRIYA mohadNo ratings yet

- Bơm EurofloDocument8 pagesBơm EuroflokimcucspktNo ratings yet

- Nu Way NOLDocument32 pagesNu Way NOLmohd sakirin roslanNo ratings yet

- BFC34803 - Test 1 - S2 20202021 - QuestionDocument4 pagesBFC34803 - Test 1 - S2 20202021 - Questionznyaphotmail.com0% (1)

- MFL37562519 English PDFDocument21 pagesMFL37562519 English PDFCărunta-Crista CristinaNo ratings yet

- Laminate CompositeDocument9 pagesLaminate CompositeDhias VidathyaNo ratings yet

- Trade BriefsDocument924 pagesTrade BriefsNathan PalNo ratings yet

- Air Compressor Overall - Component DiagramDocument18 pagesAir Compressor Overall - Component DiagramHafizuddin RazakNo ratings yet

- Stainless Steel Bolts ManufacturerDocument3 pagesStainless Steel Bolts ManufacturerRajtilak MetalNo ratings yet

- Architecture Portfolio: Wadiyar Centre For Architecture, MysuruDocument42 pagesArchitecture Portfolio: Wadiyar Centre For Architecture, MysuruAnna JoseNo ratings yet

- Grade 9Document2 pagesGrade 9Ernesto LalicNo ratings yet

- Welded Deformed Steel Bar Mats For Concrete ReinforcementDocument3 pagesWelded Deformed Steel Bar Mats For Concrete Reinforcementnorerny shuhadaNo ratings yet

- Roller Cone BitsDocument29 pagesRoller Cone BitsMahmoud NassarNo ratings yet

- Product Catalogue (KIPL)Document9 pagesProduct Catalogue (KIPL)ramgopal_danduNo ratings yet

- Modernity Modernism ModerizationDocument35 pagesModernity Modernism ModerizationAayushi SNo ratings yet

- k11 2Document6 pagesk11 2jeshupunkNo ratings yet

- Osha 1910.24 and 1910.27 PDFDocument20 pagesOsha 1910.24 and 1910.27 PDFDuy HaNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFGustavoNo ratings yet

- HAMPIDocument16 pagesHAMPIChanchal Soni100% (1)

- Natural Aggregate Consists of Manufactured Crushed Stone and Sand Created by CrushingDocument2 pagesNatural Aggregate Consists of Manufactured Crushed Stone and Sand Created by CrushingTheJohnnyBravoooNo ratings yet

- Xtralift NBS Specification MAY21Document4 pagesXtralift NBS Specification MAY21Ahmed AbdelftahNo ratings yet

- Ammonia: Product Performance For Insulation of Ammonia PipingDocument12 pagesAmmonia: Product Performance For Insulation of Ammonia Pipingashraf haniaNo ratings yet

- EPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Document10 pagesEPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Structures ProductionNo ratings yet

- Hostel Building With Daycare CenterDocument65 pagesHostel Building With Daycare Centervignesh kumar100% (1)

- 4D8 Prestressed Concrete Examination 2016 Solutions: Section A Long QuestionsDocument10 pages4D8 Prestressed Concrete Examination 2016 Solutions: Section A Long QuestionsshafiullahNo ratings yet

- ROMANDocument25 pagesROMANShantanu ParolkarNo ratings yet

- CDB Registration No .: Initial Registration Date.:: Up-Gr/Revalidation Date.: Registration Expiry Date.Document2 pagesCDB Registration No .: Initial Registration Date.:: Up-Gr/Revalidation Date.: Registration Expiry Date.Ojhal RaiNo ratings yet

- 2134 RlhaDocument2 pages2134 RlhajoravicaNo ratings yet