Bending Radius

Bending Radius

Uploaded by

sexmanijakCopyright:

Available Formats

Bending Radius

Bending Radius

Uploaded by

sexmanijakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Bending Radius

Bending Radius

Uploaded by

sexmanijakCopyright:

Available Formats

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 271

H

orizontally and vertically curved members have seen

much use in construction for years. Starting with cast

iron bridges and bridge members as well as roof trusses for

various exhibit halls, curved elements have attracted the in-

terest of engineers and architects as expressions of structural

function and artistic endeavor. But the elegance of the arch

appears to be what always drew attention, covering large

spaces with few or no interior obstructions.

As a structure, the action of an arch makes it possible to

cover signicant spans, since the load is carried largely in

compression instead of through bending action. For certain

arch geometries, support conditions, and load distributions,

the effects of the imposed loads translate into uniform com-

pression within the entire arch.

The early arch structures were made from cast iron, for

which the compressive strength was paramount, since the

material had little, if any tensile strength. These elements

were cast at high temperatures, enabling the structure to be

shaped as needed by the architect. The development of struc-

tural steel as it is known today took place in the second half

of the 19th century, allowing for designs and structures that

were capable of carrying tension as well as compression.

The limitations imposed by the compression-only cast iron

were overcome, and structures evolved that carried compres-

sion and tension equally well. The oldest example is the Eads

Bridge of St. Louis, Missouri, generally regarded as the rst

structure to be built using what today is regarded as structur-

al steel. As shown in Figure 1, the arches of the Eads Bridge

(second bridge from the front of the picture) are excellent

examples of such structures. Also shown in Figure 1 is the

great Gateway Arch of St. Louis, a contemporary example of

a parabolic arch.

The arches that are used in bridges and buildings impose

relatively low deformation demands on the structure and its

materials. The radius of curvature is generally very large.

The shape is usually created by cutting the steel to form in

Cold Bending of Wide-Flange

Shapes for Construction

smaller elements, connecting the curved elements to develop

the arch, and then building the completed arch on the con-

struction site. Details of the procedure may vary signicant-

ly, but the point is that the shaping process for large-span

arches requires the steel only to undergo small plastic defor-

mations during the fabrication. In-service conditions entail

only elastic response demands for the arch, as is the case for

most structures.

In addition to complete structures such as arches, curved

structural members are also used extensively in construction,

and Figures 2 through 4 give some examples. Some of the

individual members are curved about the strong axis of the

shapes (Figures 2 and 4); others are curved about the weak

axis (Figure 3). Common to the examples shown in these

gures and to most building applications is the fact that the

curving of such members is mostly done at ambient tem-

perature. Such cold bending places greater demands on the

curving equipment that is used, to the effect that larger curv-

ing forces are needed. Higher temperature curving is certain-

ly feasible for many applications, and a number of bending

companies use it on a regular basis. It is almost always used

when straightening repair of bridge girders is needed (Struc-

tural Damage Control, 1998).

Reidar Bjorhovde is president, The Bjorhovde Group, Tucson,

AZ.

REIDAR BJORHOVDE

Fig. 1. The Eads Bridge and other bridges across the Mississippi

River at St. Louis, Missouri, along with the Gateway Arch (Princeton

University Art Museum, 1974).

272 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

For practical reasons the material that is presented focus-

es on applications of bent structural members for building-

type structures. Bridge structures rarely use members that

are curved as much as those described here, and fatigue and

similar considerations therefore need not be addressed.

STRAIGHTENING, CAMBERING, AND CURVING

Concepts and Applications

Straightening, cambering, and curving of structural shapes

are all representative of bending that involves local plasti-

cation of the steel to varying degrees. Although the principles

and basic mechanics of these processes are the same, they

are used for signicantly different purposes and with very

different magnitudes of bending deformations. The follow-

ing presents brief descriptions of these forming operations.

A detailed analysis of the large-deformation mechanics of

shape curving is given later in the paper, as well as practical

recommendations and limitations for cold curving of wide-

ange shapes.

While this work focuses on the curving of wide-ange

shapes, hollow structural sections (HSS) and other tubular

forms, as well as angles and channels, are also used for bent

construction. The bending mechanics theory applies equally

to these types of cross-sections, although certain specialized

conditions such as maintaining the geometry of a hollow sec-

tion during the curving operation also have to be addressed.

Changes in the depth through ovalization of a round tube,

for example, will inuence the stiffness of the element as a

structural component. This and other subjects have been ex-

amined in Dutch research work on the performance require-

ments for buried steel pipelines (Gresnigt, 1986).

Cold bending of plates exhibits some of the characteristics

of the processes that are addressed in this paper (Brocken-

brough, 2006). However, the degree of bending and the as-

sociated strain level is usually much higher, with bending

angles as large as 180. The geometric parameters are also

signicantly different.

Straightening

ASTM Specication A6/A6M gives detailed requirements

for bars, plates, shapes, and sheet piling used in construc-

tion (ASTM, 2006). Among these, the standard provides the

permitted variations for straightness for the various forms of

rolled shapes. For example, the maximum out-of-straight-

ness for wide-ange shapes with a ange width larger than

or equal to 6 in. is determined as

e = 8 [(number of feet of total length)/10]

which translates into approximately 1/1,000 of the length

of the shape. For the maximum out-of-straightness this cor-

responds to a radius of curvature of 12.5 times the actual

Fig. 2. Trolley terminal (photo courtesy of

Marks Metal Technology).

Fig. 3. Commercial structure (photo courtesy of

Max Weiss Company, Inc.).

Fig. 4. Commercial mall structure (photo courtesy

of Marks Metal Technology).

(1)

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 273

length of the member. As a purely theoretical example, if a

member is 1,000 in. (approximately 83 ft) long, the maxi-

mum allowable value of e is 1 in. The radius of curvature is

therefore approximately 1,042 ft. Such a large radius entails

levels of bending strain that are extremely small.

The out-of-straightness requirement is the same for cam-

ber and sweep, which are the terms used for the out-of-

straightness measured relative to the strong and weak axes,

respectively. Figure 5 illustrates these two measurements

(Geschwindner, Disque, and Bjorhovde, 1994). It is empha-

sized that the term camber as dened by ASTM A6/A6M is

not the same as the camber that is sometimes used for beams

and girders in buildings to arrive at near-level oors after the

placement of concrete slabs.

Out-of-straightness is measured by the steel mill during

the production of the shapes, and straightening is applied to

make any nonconforming element meet the ASTM straight-

ness requirements. Depending on the size of the shape, the

straightening is either done in continuous fashion, or if

the shape is heavy, it is done through point application of

loads. The former procedure is referred to as roller or rotary

straightening; the latter is known as gag straightening. Both

involve local plastication of certain regions of the cross

section.

In rotary straightening the yielding takes place continu-

ously along the length of the shape, effectively altering the

residual stress distribution in the shape in such a fashion

that the strength of a wide-ange shape as a column is usu-

ally increased (Galambos, 1998). This is a side benet of

the rotary straightening process, although it is emphasized

that strengthening does not apply to all types of shapes, us-

ages, and straightener settings. Gag straightening causes lo-

cal yielding in the shape only in short segments along the

length of the member, surrounding each of the load appli-

cation points. This procedure has no effect on the column

strength of the shape. But common to both of these methods

is the fact that the amount of curving and the accompanying

strain demands within the cross section are very small, and

the radius of curvature of the bent member is very large.

Straightening of shapes to meet delivery standards is used

by all of the worlds steel mills. The methods and results

are the same, and the equipment that is used operates on

the same principles and applications. Figure 6 shows rotary

straightening equipment; Figure 7 pictures a gag straighten-

ing press.

Fig. 5. Denitions of camber and sweep for wide-ange shapes.

Fig. 6. Rotary straightening equipment (photo courtesy

of Nucor-Yamato Steel Co.).

Fig. 7. Gag straightening equipment (photo courtesy

of Nucor-Yamato Steel Co.).

274 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

Because of the way the rotary straightening rolls are

applied to certain areas of a wide-ange shape, with the

edges of the rolls resting on or near the llet between the

ange and the web, the region near the llet that is known

as the k-area develops higher strength and hardness as well

as lower ductility and toughness than other regions of the

shape. This is prompted by high shear yield strains in the

through thickness direction at this location within the shape.

The higher material strength and lower toughness have no

effect for the overall strength of the member as a column or

a beam. However, it has to be borne in mind when detailing

certain types of welded connections, to the effect that welds

should not be terminated in or near the k-area (Iwankiw,

1997; Bjorhovde, Goland, and Benac, 2000; Kaufmann and

Fisher, 2001; Lee, Cotton, Dexter, Hajjar, Ye, and Ojard,

2002; Hajjar, Dexter, Ojard, Ye, and Cotton, 2003; Chi and

Uang, 2004).

Cambering

For a structural engineer, cambering a beam means to pre-

bend the member in the direction opposite to the deec-

tion that will be developed by the anticipated gravity loads

(Ricker, 1989; Larson and Huzzard, 1990). In this context

the gravity loads usually mean the dead load. The aim is to

have a structural component that is horizontal or nearly so

following the application of the most closely known load

component. Since the dead load generally is known more ac-

curately than the live load, for example, cambering is almost

always done to an extent that equals a fraction or even all of

the dead load deection.

The loads being considered are all at service levels, mean-

ing that the deections are expected to occur during the op-

eration of the building. The most commonly used live load

deection limit equals the span divided by 360; dead load

deections may be on the same order of magnitude or some-

what larger. For a 30-ft-long simply supported beam, these

values come out as deections of approximately 1 in. It is

therefore understood that the amount of curving that has to

be done to counteract a dead load deection of 1 in. for a 30

ft span is very small, and the corresponding radius of curva-

ture is very large.

Structural cambering can be accomplished through selec-

tive heating of areas of the shape, or, as is most common,

through gag pressing the member at ambient temperature

while it is installed in a cambering frame (Ricker, 1989).

Cold cambering does involve plastication of small areas of

the cross section, similar to gag straightening, as discussed

previously. But the accompanying deformation demands for

the steel in the shape are very small, and the force(s) neces-

sary to develop the camber curve tends to be fairly small.

Studies by Gergess and Sen (2005a, 2005b) have dealt

with cold bending of symmetric and unsymmetric cross-section

plate girders. Because of the depth of the girders, the lack of

symmetry of some of the cross sections as well as the bend-

ing about the weak axis for some of the girders, the correla-

tion to what is presented here for hot-rolled W-shapes is lim-

ited. The Gergess and Sen studies also made use of a single

load application point. The associated radius of curvature is

therefore much larger than what is applied to the W-shapes

of the study presented here.

On the other hand, while the deformation and force de-

mands associated with cambering are small, it is important

to bear in mind the modications of the cross-sectional area

that will occur as a result of punching or drilling of holes

and similar fabrication operations. Some fabricating shops

are set up such that hole punching occurs at the beginning

of the various operations, with the cambering done at a later

stage. The cross-sectional area changes associated with hole

punching or drilling can create a preferred plane for yield-

ing, with the potential for localized failure (excessive defor-

mations or even fracture in the net section) during the cold

cambering process. This issue is further addressed later in

this paper.

Curving

Curving or bending of steel members for structures such as

those shown in Figures 2 through 4 involve substantial de-

formations and local plastication demands for the steel. It

can be applied about the strong or weak axes of the shapes,

depending on the structural requirements, to satisfy the ar-

chitectural or engineering designs. The curving is typically

performed to meet specic radii or other geometric congu-

rations.

The strong axis stiffness of shapes is the largest, and the

corresponding bending requirements are therefore the most

demanding. The bending commonly entails large axial strains

in the extreme bers of the cross section. The procedure also

involves local (point) application of forces from the bending

equipment, with subsequent potential for local web or ange

buckling of the shape or even overall lateral-torsional buck-

ling of the member during the curving operation. In extreme

cases, parts of the cross section may even undergo fracture.

This has been observed in a number of actual curving cases,

including one where the beams had been subjected to axial

strains more than 19 times the yield strain of the steel. It has

also occurred in members where local ange bending led to

web buckling, which in turn caused a crack to develop in the

ange close to the web-ange intersection. Similar failure

scenarios have been observed in several cases.

The most common equipment that is used by bending

companies focuses on passing the member through a set of

rolls that gradually deform the shape into a circle (most com-

monly) with the required radius. The basic principle is illus-

trated in Figure 8, whereby forces are applied via the rolls on

either side of the member. The shape is fed through the ma-

chine on repeated passes, with each one bending the member

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 275

into successively smaller radii of curvature. Some machines

also utilize rolls on the tension ange of the W-shape, to

provide additional restraint against local ange bending as

the curvature gets smaller. This is especially important for

shapes with small web thicknesses (Steel Construction Insti-

tute, 2002). In Figure 8 the large rolls are the usual elements

in the bending machine; the small (dashed outline) roll is

actually a pair that is applied to the tension ange on both

sides of the web.

The bending process indicated by the rolls in Figure 8 is

the most common, but there are machines and bending com-

panies that do not rely on such rolls. Certain patented pro-

cesses utilize an articulated mechanism that distributes the

load over a larger region than what is possible with the rolls.

This is particularly the case for the smaller (tension ange)

roll, which these processes do not use. A key feature of other

curving operations is the use of restraining elements that pre-

vent ange bending and web buckling, thereby allowing for

smaller curving radii than what would otherwise be required.

Some of the bending problems that are described here are

therefore much less prevalent for the no-rolls and the re-

straint equipment operations, and the radius data that are

described below can be expanded to include smaller radii.

Bending companies also provide curved elements with

noncircular geometries. These may include elliptical forms,

combinations of circles and ellipses, and members that are

eventually made into S-type curves. However, such is usually

achieved by joining elements that have been curved in oppo-

site directions. An example of the latter is shown in Figure 9.

BENDING EQUIPMENT AND APPLICATIONS

There are a number of manufacturers of bending equipment,

but the Swedish company Roundo is possibly the best-known

supplier. Several bending companies use machinery of their

own design, and certain rms have patented equipment and

processes.

Figures 10 and 11 show two of the Roundo models and

Figures 12 through 15 give additional examples of bending

applications.

Fig. 8. Principle of bending process for shapes.

Fig. 9. Structure with members curved in opposite directions

(photo courtesy of Marks Metal Technology).

Fig. 10. Bending machine, Roundo model R3

(photo courtesy of Comeq, Inc.).

Fig. 11. Bending machine, Roundo model R-15-S

(photo courtesy of Comeq, Inc.).

276 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

CURVING MECHANICS AND ANALYSIS

Basic Concepts

As has been indicated for several applications of bending

shapes into permanent curves, a certain amount of plastic

deformation must take place in the cross section during the

process in order for the curving operation to work. Elastic

stress analysis and bending will not sufce, since any de-

formations taking place under such conditions will revert to

zero once the applied force or moment is removed. Further,

it has already been emphasized that bending about the strong

axis of the member, also referred to as bending the hard way,

is more demanding, because of the larger shape depth and

distance to the extreme bers in the cross section, as well as

the larger bending stiffness. Finally, curving may be done

to have a nal product in the form of a circle or part of one;

this can be arranged in many ways to arrive at combined

geometric forms. However, the bending machinery is most

commonly used to develop the circular form, for any number

of reasons.

Using the principles of mechanics of materials, classical

bending theory implies that to arrive at a circular form, a

constant moment is developed along the full length of the

member. Since the rst derivative of the moment is the shear

force and the moment is a constant, shear force, stresses, and

strains will be zero. Only exural stresses and strains will

develop in the cross section under these conditions.

However, it is important to recall that transverse forces

are developed by the rollers used in the bending machine

(see Figure 8). These produce local compressive stresses in

the web of the shape. Further, and especially with small ra-

dii, the curving operation has a tendency to promote local

bending of the tension ange of the shape, which in turn

may promote the possibility of local web buckling. Both of

these phenomena can be somewhat controlled by careful

alignment of the shape in the curving machine, but if the

web of the shape is very thin, local buckling can be avoided

by limiting the magnitude of the radius of curvature. The

use of restraints, as mentioned previously, to prevent or at

least delay the onset of ange bending and/or web buckling

can also enhance the bending capacity signicantly. The re-

straints facilitate the use of smaller bending radii.

Fig. 12. Curved W1253 shapes

(photo courtesy of Max Weiss Company).

Fig. 13. Curved W2144 shapes (photo courtesy

of Max Weiss Company).

Fig. 14. Wedding chapel (photo courtesy

of Marks Metal Technology).

Fig. 15. Industrial installation (photo courtesy

of Max Weiss Company).

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 277

Finally, if local web buckling occurs and it is not promptly

discovered, chances are very good that the web or even the

ange may fracture as a result of the combination of com-

pressive stress in the web and the ange bending that accom-

panies the buckling action. Figures 16 and 17 demonstrate

web buckling and ange bending of a W1226 shape that

had been curved to a tight radius. Figure 17 shows the ange

actually broken away from the web. This occurred as a result

of the web buckling and the subsequent ange bending.

Material Properties of Curved Members

The mechanical properties of steel are based on the common

uniaxial tension test. This reects a consensus approach to

the properties of a wide range of materials and is very useful

when it comes to correlation and comparison between steels

from various producers. Of course, the tension test does not

represent the response characteristics of the steel in actual

structures, and was never intended to do so, but it is still a

practical tool for designers, fabricators, and other users of

the material.

As the beam is curved to the extent that plastic deforma-

tions occur in smaller or larger areas of the cross-section,

the yielded regions may undergo material property changes

as a result of the strains. As an example, Figure 18 shows

the stress-strain curve for the proverbial mild steel (ASTM

A36 in this case).

When the steel has been deformed plastically, it has un-

dergone permanent deformations that are not removed upon

unloading of the material (Bjorhovde, Engestrom, Grifs,

Kloiber, and Malley, 2001). This is indicated by the dashed

lines in Figure 18, to the right of the solid line initial stress-

strain curves in the diagram.

Upon reloading, the steel responds in accordance with the

dashed lines in the gures, seeming to indicate a material

with a yield stress and elongation properties as dened by

the new stress-strain curve. If there is only a small or even

no yield plateau, which is typical of higher strength materi-

als, the reloading response appears to be that of a steel ma-

terial with a yield stress that is larger and an elongation at

rupture that is smaller than the corresponding properties of

the original material. If the steel has been strained into the

strain hardening range, the change in the apparent mechani-

cal properties can be substantial (Brockenbrough, 1992).

This elastic-inelastic behavior of the steel must be con-

sidered when planning the curving operations for structural

shapes. It is taken into account in the curving criteria pre-

sented in the section entitled, Practical Criteria for Structur-

al Shape Curving. But specically, since a smaller or larger

part of the cross-section of the member must be deformed

Fig. 16. Wide-ange shape with buckled web and ange bending

(right side) (photo courtesy of Nucor-Yamato Steel Company).

Fig. 17. Wide-ange shape with buckled web and one-half of

ange broken off (photo courtesy of

Nucor-Yamato Steel Company).

Fig. 18. Stress-strain curve for typical mild structural steel.

278 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

plastically in order for the curving to work, the extreme -

bers in the cross section will be deformed well beyond the

level of the initial yield strain,

y

, of the steel. Depending on

the curving radius, the maximum strain is likely to exceed

the yield strain by a signicant amount. If the curving ra-

dius is too small, or if there are stress concentrations such as

holes in the ange(s) or coped areas of the beam, the mag-

nitude of the strain that is imposed by the curving operation

may reach the fracture level. This has been observed in a

number of actual curving cases at bending facilities, but it

has never been seen in the eld. In brief, therefore, once the

curving has been completed successfully, a failure due to the

bending operation will not occur after the member has been

placed into service. The exural strains the member will ex-

perience during service are within the elastic range of behav-

ior, and at least one order of magnitude smaller than those

associated with the curving. In terms of service load stress

levels, it is important to bear in mind that these stresses are

well below the yield stress, typically no more than half of

the yield level.

A study by Schlim (Schlim, 1987) used a range of curving

radii for shapes in 36 ksi steel that were 220 mm (8.8 in.)

deep. For a curving radius of 12.7 m (44 ft), which correlates

very well with the curving criterion developed here, it was

found that the yield and tensile strengths increased by about

10%; the elongation at rupture decreased by a small amount.

There was no measurable change in the fracture toughness,

as based on Charpy V-Notch tests. However, Schlim also

noted that curving to much smaller radii would result in sig-

nicant changes in the material properties.

Curving Mechanics

Curving Geometry

The curving is usually performed to meet a certain radius

required for the member. Sometimes only the length of

the span that is to be covered is given, and the offset of the

curved member is specied. Figure 19 illustrates this for an

element with a radius R, a span (in other words, circle chord

length) of c, and an offset of b.

The mathematics of the circle gives the following rela-

tionships:

The curving radius is the most important factor, since it de-

termines the moment, curvature and levels of strain that will

develop when the shape is bent to the specied congura-

tion.

Moments and Strains Developed by Curving Operation

Given the radius of the member to be curved, R, the curva-

ture, , is given by Equation 3.

For a constant radius for the full length of the member, the

moment-curvature relationship is dened by the expression

which gives the value of the constant moment along the

length of the member as

where

M

ce

= constant moment of the circular member when

the material and the shape behave elastically

E = modulus of elasticity

I = moment of inertia for the axis of bending

about which the shape is being curved

It is emphasized that the moment of Equation 5 reects

the elastic moment-curvature relationship. Since the curv-

ing operation necessitates a certain amount of plastication

of the shape, Equation 5 does not apply. For example, the

effective modulus of elasticity is zero for yielded material,

and the moment of inertia of the shape is reduced by the

loss of the stiffness contribution of the yielded areas of the

cross section. Equation 5 can be replaced by an inelastic

version, thus

Fig. 19. Circle with radius, chord length, and offset.

Offset: b R R c =

( )

2 4

2 2

(2a)

Radius: R

b c

b

=

4

8

2 2

(2b)

(3) =

1

R

(4)

= =

1

R

M

EI

(5)

M M

EI

R

ce

= =

(5a) M M

EI

R

ie

eff

= =

( )

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 279

where

M

ie

= inelastic moment

(EI)

eff

= effective bending stiffness of the partially

yielded cross section

However, this is a cumbersome and less than practical ap-

proach, especially since the effective stiffness changes as the

radius changes.

For inelastic behavior, the moment-curvature expressions

of Equations 4 and 5 do not apply. In this case it is neces-

sary to go to the fundamental strain-curvature relationship,

which dictates that plane sections remain plane. Although it

is satised only approximately for curved members, it is suf-

ciently accurate for the applications addressed here.

For this case the following applies, as illustrated by the

strain distribution of Figure 20, using a doubly symmetric

cross section for the example (the linear strain distribution

applies for all types of shapes):

or

where

= strain at a distance y from the neutral axis

The linear strain distribution in Figure 20 applies for any

level of applied moment.*

The traditional linear stress distribution applies only when

all areas of the cross section are elastic, for which stress and

strain are related by Hookes Law, that is, = E .

For a doubly symmetric cross section, the maximum

bending strains occur at the top and bottom extreme bers,

thus

where

= rotation of the cross section, equal to the cur-

vature, = 1/R

At the point when yielding rst takes place,

max

=

y

=

F

y

/E, which reects the limit of elastic behavior. The yield

strain,

y

, and the corresponding yield rotation,

y

, are:

which occur for a moment equal to the yield moment, M

y

.

The yield and fully plastic moment capacities of the cross

section are:

M

y

= F

y

S

x

M

p

= F

y

Z

x

where

S

x

= elastic section moduli

Z

x

= plastic section moduli

For a given radius, R, the maximum strain in the cross

section is given by Equation 7, and the corresponding cross-

sectional rotation is

and

max

is reformulated as

*The principle of plane sections remain plane applies for all practical structural engineering issues. If very large bending or

shear deections occur, it does not. However, such considerations need not be made here.

Fig. 20. Linear strain distribution

over the depth of the cross section.

(6a)

= =

1

R y

(6b)

=

y

R

(7)

max

=

\

)

l

l

l

l

l

l

=

(

\

)

d

R

d

2

2

(8a)

y

y

F

E

=

(8b)

y

y

d

=

\

)

2

(9a)

(9b)

(10)

max

max

=

(

\

)

=

y

y

y

(11)

max

=

\

)

=

d

R

y

2

280 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

where

= the maximum strain factor

Equation 11 indicates that the maximum strain in the cross

section is a multiple, , of the yield strain,

y

. The maximum

strain value can now be compared to the stress-strain curve

for the material of the shape in question.

The strain and stress distributions in the cross section for

the required amount of curving can now be determined. The

stress distribution may then be used to calculate the magni-

tude of the curving moment, M

c

, taking into account the fact

that portions of the cross section have yielded.

Together with the yield and fully plastic moments and the

corresponding yield and fully plastic rotations, the moment-

rotation curve for the shape is then determined. The magni-

tudes of the curving moment and the corresponding rotation

serve as an illustration of the degree to which the shape has

been plastied.

Figure 21 shows a hypothetical strain and corresponding

stress distribution for a doubly symmetric cross section, not-

ing that the strain is larger than the yield strain

y

over the

two symmetrical portions of the depth, d

y

. The remaining

elastic portion of the cross section is the central area of depth

equal to 2(d/2 d

y

).

Figure 22 shows the resulting moment-rotation diagram

for the shape in question, including the data for the maxi-

mum rotation,

max

, that is being imposed by the curving

moment.

The size of the yielded portion of the cross section is de-

termined from the relationship (see Figure 21)

which gives

The actual magnitude of the curving moment, M

c

, can now

be found from the stress distribution shown in Figure 21b,

along with the respective areas of the cross section and their

moment arms.

Development of Curving Requirements

Based on the magnitudes of the maximum strains and rota-

tions, an assessment can now be made as to whether it is

feasible to curve the given shape and steel material to the

specied radius. As will be seen in the following, the smaller

the value of the maximum strain factor, the larger will be

the portion of the shape that remains elastic when the maxi-

mum curving moment (in other words, the target radius) is

applied. The value of dictates the reserve moment capacity

and hence the available ductility of the shape for the required

radius of curvature.

Obviously, there are pros and cons in choosing small or

large values, but the key considerations are as follows:

1. A small value of provides for larger reserve moment

capacity and therefore a larger margin of safety against

potential overstraining of the steel.

2. The smaller the value, the larger the radius that should

be used for a given shape.

3. A large value of leaves a smaller portion of the cross

section elastic by the time the target radius has been

reached. This may be acceptable to the engineer and the

curving company, but it is important to understand the

Fig. 21. Strain and stress distributions for

the specied radius of curving.

Fig. 22. Moment-rotation relationship for curved shape.

d

d

y

y

max max

( )

=

\

)

2

(12) d

d

y

y

=

( )

l

l

l

l

l

\

)

max

max

2

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 281

implications of the small reserve moment capacity. Ac-

cidental overloads or curving to a smaller radius than the

required value in particular may result in steel fracture,

local buckling, or other failure while the member is being

curved at the bending facility.

4. Shapes with thin webs are particularly vulnerable to

web buckling for small reserve moment capacities and,

therefore, also to overstraining and fracture of the steel in

the web-to-ange region.

5. Flange and/or web restraint elements are effective in

preventing ange bending and web buckling. Such equip-

ment will allow for the use of a larger value, in other

words, a smaller radius of curvature. The restraints allow

the shape to be able to accommodate the kind of larger

maximum strains that are associated with smaller radii.

6. Overstraining and consequent overloading of a shape

through improper curving is more likely to occur for

lower strength steels. This is because the yield strain is

lower for such steels.

7. Pre-curving fabrication operations such as punching or

drilling of holes in the anges, coping of the anges,

and similar may provide areas of stress and consequently

strain concentrations, with the possibility of fracture of

the material at these locations. Such fractures have been

observed in several cases.

For structural steels with yield stresses of 36 and 50 ksi

and a modulus of elasticity of 29,000 ksi, maximum strain

factor limitations of 4, 6, 8, 10, 16, 24, and 36 correspond to

yield and maximum strain levels as illustrated below.

Yield Stress: F

y

= 36 ksi

y

= 0.00124 = 0.124%

= 4

max

= 0.00496 = 0.496%

= 6

max

= 0.00744 = 0.744%

= 8

max

= 0.00992 = 0.992%

= 10

max

= 0.0124 = 1.24%

= 16

max

= 0.01984 = 1.98%

= 24

max

= 0.02976 = 2.98%

= 36

max

= 0.04464 = 4.46%

Yield Stress: F

y

= 50 ksi

y

= 0.00172 = 0.172%

= 4

max

= 0.00688 = 0.688%

= 6

max

= 0.01032 = 1.03%

= 8

max

= 0.01376 = 1.38%

= 10

max

= 0.0172 = 1.72%

= 16

max

= 0.02752 = 2.75%

= 24

max

= 0.04128 = 4.13%

= 36

max

= 0.06192 = 6.19%

Expressing the equations in terms of the maximum level of

strain,

max

=

y

, the yielded portions of the cross section

become (see Figure 21),

and the central fraction of the web that remains elastic is

Checking for Web Buckling and Similar Limit States

The installation and alignment of the shape in the curving

machine are important considerations. These are very dif-

cult to have done exactly, since the actual support condi-

tions, the placement of the equipment rolls, etc., are rarely

known. However, the following checks should be made for

the shape by the structural engineer, as broad assessments of

the potential for local failures:

1. Web compression buckling (AISC Equation J10-8)

2. Web sidesway buckling (AISC Equations J10-6 and

J10-7)

3. Web crippling (AISC Equations J10-4 and J10-5a,b)

4. Web local yielding (AISC Equations J10-2 and J10-3)

The references to AISC give the equation numbers for the

respective limit states, as addressed in the AISC Specica-

tion for Structural Steel Buildings, hereafter referred to as

the AISC Specication (AISC, 2005).

Of the preceding four checks, the web compression buck-

ling (No. 1) and web sidesway buckling (No. 2) are the ones

most likely to indicate a potential local buckling problem

associated with the curving of the shape. It is also noted that

the application of No. 1 to the curving of a beam is conser-

vative.

In some actual cases, during curving at a bending facility,

web buckling has been found along with ange local bend-

ing. The ange bending was a result of the too-small radius

and the phenomenon described earlier. However, the large

axial strain demands imposed by the curving operation and

the web buckling were the driving forces, eventually hav-

ing caused the fracture of the web or the ange by through-

thickness bending. Flange and web restraints might have

eliminated these problems.

It has been noted that shapes with a larger web thickness

tend to perform better during the bending operation. The

increased web thickness provides a higher buckling strength

and hence less opportunity for transverse ange bending to

d

d

y

y y y

y

=

( )

l

l

l

l

l

\

)

=

( )

( )

max

max

2

ll

l

l

l

\

)

=

( )

l

l

l

l

\

)

d

d

2

1

2

(13)

Elastic portion = =

( )

l

l

l

l

EP 1

1

(14)

282 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

take place. As of 2005, there are no actual data or operational

suggestions that can be used to arrive at enhanced radii when

curving such shapes. An experienced bending company

should be approached for advice in these cases.

A nal comment is needed regarding gradually increasing

the plastication of the shape during the curving operation.

Most companies send a shape through the machine in sev-

eral passes, each of which imposes additional yielding of the

steel. This provides for curving cycles that demand smaller

roller forces for each pass. However, the process does not

limit the eventual maximum strains. In addition, since there

is only a small time lag between the individual bending

passes, issues such as strain aging most likely will not play a

role. However, this is very difcult to conrm or reject with-

out actual tests for material properties.

Some Other Considerations

The text has focused on the technical issues and potential

difculties associated with curving wide-ange shapes about

the strong axis at ambient temperature. These are the most

demanding conditions insofar as the material and the shapes

are concerned. Some other considerations are outlined in the

following.

Curving by Concentrated Load Application (Gag Pressing)

Depending on the available equipment in the bending shop,

curving by concentrated load application is sometimes per-

formed. The operation is similar to what is done for normal

cambering of beams as described previously, except that the

level of force and the amount of bending are signicantly

larger than the magnitudes associated with structural camber.

Using the model of a concentrated load applied centrally

to a simply supported beam, the moment distribution varies

linearly from zero at the supports to the maximum at the load

application point. The shear force is constant for each half of

the beam and equal to half of the applied load. The deection

is a maximum at mid-span.

The location of the maximum moment is also the location

of the maximum strain demand within the length of the beam.

Further, the deformation capacity of the steel is the smallest

when the member is subjected to a uniform moment along

the full length, or, in other words, when all cross-sections are

subjected to the same maximum strain demand. The latter

occurs for a beam that is bent to a constant curvature, when

the moment is a constant for the full length of the member.

It is clear that bending by cambering is at most as severe as

curving by constant radius bending. The strain demand at

the location of the maximum moment is always the critical

consideration. The performance requirements as dened by

the constant radius and the corresponding maximum strain

factor therefore apply equally to gag pressing.

Curving about the Weak Axis of W-Shapes

The bending mechanics approach and the equations that

have been developed here are equally applicable to the case

of weak axis bending of W-shapes. However, the strain

demands will be signicantly different, due to the smaller

dimension across the ange (as compared to the depth of

the shape) and the smaller moment of inertia. In theory,

a shape being bent about its weak axis will be able to ac-

commodate smaller curving radii. However, it is important

to bear in mind that the maximum strain will occur at the

ange tips, and that the ange tips are laterally unsupported.

That is, the anges are unstiffened and will be subjected

to exural strains and stresses whose values are zero at the

level of the web. For smaller ange thicknesses and/or larger

ange widths the potential problem of ange buckling (in a

direction transverse to the centroidal axis of the shape) must

be addressed. This is a situation similar to having the web

(stem) of a tee shape subjected to compression.

Section B4 (Table B4.1) of the AISC Specication for

Structural Steel Buildings (AISC, 2005) details the criteria

for compactness of shapes. A compact shape by denition is

capable of reaching the fully plastic moment and to sustain

signicant plastic rotation before local buckling or strain

hardening occur. However, compactness does not guarantee

that the shape can be curved to any radius. The compactness

concept and criteria were not developed with shape curv-

ing in mind. Further stability considerations are presented

in the Guide of the Structural Stability Research Council

(Galambos, 1998).

Curving Other Types of Shapes

Channels, tees, angles, and various hollow structural sec-

tions (HSS) are sometimes used in curved applications. The

basic mechanics criteria also apply to these types of shapes,

although some special considerations need to be made for

local buckling of outstanding legs and anges, unstiffened

anges, stems and angle legs, and the shape of circular and

square/rectangular HSS. The AISC Specication provides

width-to-thickness criteria for the plate elements of these

shapes (AISC, 2005); however, other local buckling and

stability assessments can be made for the individual types

of shapes.

Considerations for Pre- and Post-Curving Operations

The curving model determines the requirements to deform a

shape to the desired curvature. The forming operations can

create areas of higher strain in the shape than predicted by

the model. Local areas of higher plastic strains (for example,

when small amounts of web or ange buckling occur) can

inuence the ability to perform post-curving operations such

as coping or galvanizing. Any post-curving operations need

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 283

to be considered when selecting a value for the maximum

strain factor and may necessitate the use of a more conserva-

tive (in other words, smaller) value of .

Bracing members or purlins are sometimes attached to the

outside ange of a curved member, most commonly by bolts.

It is recommended that bolt holes in the ange of a curved

shape be made after the curving has been completed, even

if this may be somewhat inconvenient. The stress concentra-

tions associated with the holes may create additional strain

limitations for the material in the anges, and fractures have

been known to occur at the exact locations of the bolt holes.

However, if the curving is completed rst, no difculties are

anticipated. It is known that this approach has been used suc-

cessfully.

Galvanizing is sometimes used to provide corrosion pro-

tection for curved members that will be exposed to the envi-

ronment during regular service. This is effectively a form of

heat treatment, and although difculties have been reported

in some cases, there are no hard data that can be used to

analyze the inuence of the galvanization. Most applications

have been successful, as reported by the industry, but careful

inspection of post-galvanizing is very important.

PRACTICAL CRITERIA FOR

STRUCTURAL SHAPE CURVING

Development of Criteria

The following parameters are paramount in the initial as-

sessment of the curving needs for wide-ange structural

members:

1. Radius of curvature, R

2. Depth of shape, d

3. Yield stress of steel, F

y

In addition, to prevent excessive straining of the steel and

to ensure a minimum of reserve bending capacity of the

shape:

4. Maximum strain factor,

5. Maximum bending strain,

max

=

y

With the maximum strain factor of , this gives:

which means that the minimum curving radius must satisfy

the following criterion:

and substituting for

y

= F

y

/E, this gives

With the value of E as 29,000 ksi, this gives the basic

curving criterion, thus

with R and d expressed in inches and F

y

in ksi. The maximum

strain factor is dimensionless.

The limiting radius is used here for the curving criterion,

not the least because of the physical illustration that is pro-

vided by the radius. It is possible to express the curving cri-

terion in terms of the maximum longitudinal strain, which is

given directly by the magnitude of maximum strain factor.

An value of 8, for example, implies a maximum total strain

of 8

y

. Another denition might be to use the total plastic

strain that is developed during curving, especially when it

is done to repair damaged girders (Brockenbrough and Bar-

som, 1992). However, it is felt that the radius approach is

preferable.

Sample Limits of Curving Using

the Basic Curving Criterion

The following data are given only as examples of the radii

that are implied for two grades of steel and two values of the

maximum strain factor. Again, it is noted that the radii that

are used for the higher strength steel are smaller than those

that can be used with the lower strength material (in other

words, higher strength implies higher curving capacity for

otherwise identical shapes).

1. 50 ksi yield stress steel and = 8:

R > 36.25d

d = 12 in. R > 435 in. = 36 ft

d = 18 in. R > 653 in. = 54 ft

d = 24 in. R > 870 in. = 73 ft

d = 30 in. R > 1,088 in. = 91 ft

d = 40 in. R > 1,450 in. = 121 ft

2. 36 ksi yield stress steel and = 8:

R > 50.35d

d = 12 in. R > 604 in. = 50 ft

d = 18 in. R > 906 in. = 76 ft

d = 24 in. R > 1,208 in. = 101 ft

d = 30 in. R > 1,511 in. = 126 ft

d = 40 in. R > 2,014 in. = 168 ft

max

= =

\

)

y

d

R

2

R

d

d

y y

\

)

=

( )

2

2

R

d

F

E

dE

F

y y

\

)

l

l

l

l

=

( )

( )

2

2

(15)

R

d

F

y

( )

l

l

l

l

l

14 500 ,

(16)

284 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

3. 50 ksi yield stress steel and = 12:

R > 24.2d

d = 12 in. R > 290 in. = 24 ft

d = 18 in. R > 426 in. = 36 ft

d = 24 in. R > 581 in. = 48 ft

d = 30 in. R > 726 in. = 61 ft

d = 40 in. R > 968 in. = 81 ft

4. 36 ksi yield stress steel and = 12:

R > 33.6d

d = 12 in. R > 403 in. = 34 ft

d = 18 in. R > 605 in. = 50 ft

d = 24 in. R > 806 in. = 67 ft

d = 30 in. R > 1,008 in. = 84 ft

d = 40 in. R > 1,344 in. = 112 ft

These data reect the rst and most important check for curv-

ing capacity, taking into account the properties of the steel as

well as the key dimension of the shape. It is emphasized that

these data are based on unrestrained steel shapes, without the

use of restraint equipment or tensile force application, as is

done in some processes.

It is recommended that if an value larger than 12 is be-

ing considered, advice should be sought from an experienced

bending company.

The basic curving citerion demonstrates that the larger

the depth of the shape, the larger the curving radius must

be in order to avoid overstrain. Similarly, for two otherwise

identical shapes, the one with the lower yield stress steel

requires a larger curving radius to avoid overstrain, simply

because yielding will occur at a smaller moment than it will

for the higher strength material. In other words, overstrain-

ing is more likely to occur in lower strength steel, as would

be expected.

The second stage of checking by the structural engineer

requires an evaluation of the potential for web compression

buckling and web sidesway buckling, as outlined earlier.

SUMMARY

These guidelines present a discussion of current cold bend-

ing practices for hot-rolled steel wide-ange shapes for ap-

plication to building-type structures, with illustrations using

a number of current projects. The criteria do not apply to

stainless steel.

A theoretical formulation has been developed to empha-

size that the key consideration for shape bending is the strain

demand that will be imposed on the material. Following fun-

damental moment-curvature relationships and aiming for a

certain maximum strain in the extreme bers of the cross

section, the basic curving criterion has been developed. The

expression is a simple relationship between the radius of

curvature, the depth of the shape, the yield stress of the steel

and the maximum strain factor. It is also noted that other

limit states need to be evaluated. Practical applications of

the basic curving criterion may focus on a range of suitable

curving radii. The radius depends on the preferences and ex-

perience of the bending contractor, as well as the equipment

that is used.

When a shape has been curved successfully, with no buck-

ling or localized cracking in the steel, the strains the member

will experience under actual service conditions will be much

smaller than those associated with the curving operation.

Once the curving is done, the member can be expected to

perform as intended.

Although the focus of the guidelines has been on the use

of wide-ange shapes bent about their strong axis at room

temperature, the basic curving criterion applies equally to

other cross-sections. However, for such other shapes addi-

tional attention must be given to the potential limit states

that may inuence the response of the cross-section during

bending.

Developments in bending equipment and techniques con-

tinue to improve and expand the capacities of companies to

curve shapes to increasingly tighter radii. Maintaining sec-

tional integrity with minimal distortion and avoidance of lo-

calized material failures will aid in providing bent members

that will perform effectively in service. Additional research

studies may be warranted to continue to expand the offerings

of bending companies.

The analyses and the criteria that have been developed are

not intended for application with structures that are subjected

to high-cycle loads, such as bridges.

ACKNOWLEDGMENTS

Sincere appreciation for detailed and very useful comments

on the study presented in this paper are extended to the

members of the AISC Rollers and Benders Committee, in

particular George Wendt, committee chair, Allan Flamholz,

David Marks, Joe Rogers, and Ray Weiss. Additional thanks

are due the Technical Committee on Structural Shapes, in

particular Mike Engestrom, and to numerous Nucor-Yamato

Steel Company staff members.

NOMENCLATURE

E = modulus of elasticity

(EI)

eff

= effective bending stiffness of a partially yielded

cross section

EP = remaining elastic portion of cross section

F

y

= yield stress of steel

I = moment of inertia

M = bending moment (general)

ENGINEERING JOURNAL / FOURTH QUARTER / 2006 / 285

M

c

= curving moment

M

ce

= elastic constant moment of a circular beam seg-

ment

M

ie

= inelastic moment

M

p

= fully plastic moment of a cross section

M

y

= yield moment

R = radius

S

x

= elastic section modulus of cross section about the

x-axis

Z

x

= plastic section modulus of cross section about the

x-axis

b = offset of a circle segment

c = chord length of a circle segment

d = depth (height) of beam

d

y

= yielded portion of cross section

e = initial out-of-straightness

t

w

= web thickness

y = coordinate within beam cross section

= maximum strain factor

= strain

max

= maximum strain within cross section

y

= yield strain

= rotation of cross section

max

= maximum rotation of cross section

p

= rotation of cross section upon reaching fully plas-

tic moment

y

= rotation of cross section upon reaching yield mo-

ment

= curvature

= stress

REFERENCES

AISC (2005), Specication for Structural Steel Buildings,

ANSI/AISC 360-05, March 9, American Institute of Steel

Construction, Inc., Chicago, IL.

ASTM (2006), Standard Specication for General Require-

ments for Rolled Structural Steel Bars, Plates, Shapes,

and Sheet Piling, ASTM A6/A6M, American Society for

Testing and Materials, West Conshohocken, PA.

Bjorhovde, R., Goland, L.J., and Benac, D.J. (2000), Per-

formance of Steel in High-Demand Full-Scale Connec-

tion Tests, Proceedings, 2000 North American Steel Con-

struction Conference, Las Vegas, NV, February 2326, pp.

3-13-22.

Bjorhovde, R., Engestrom, M.F., Grifs, L.G., Kloiber, L.A.,

and Malley, J.O. (2001), Structural Steel Selection Con-

siderationsA Guide for Students, Educators, Design-

ers and Builders, American Society of Civil Engineers,

Reston, VA, and American Institute of Steel Construction,

Chicago, IL.

Brockenbrough, R.L. and Barsom, J.M. (1992), Metal-

lurgy, Chapter 1.1, Constructional Steel DesignAn

International Guide, P.J. Dowling, J.E. Harding, and

R. Bjorhovde, Eds., Elsevier Applied Science, London,

England, pp. 116.

Brockenbrough, R.L. (1992), Material Properties, Chapter

1.2, Constructional Steel DesignAn International Guide,

P.J. Dowling, J.E. Harding, and R. Bjorhovde, Eds., Else-

vier Applied Science, London, England, pp. 1732.

Brockenbrough, R.L. (2006), Development of Fabrica-

tion Guidelines for Cold Bending of Plates, Engineering

Journal, Vol. 43, No. 1, pp. 4956.

Chi, B. and Uang, Chia-Ming (2004), Effect of Straight-

ening Method on the Cyclic Behavior of k-Area in Steel

Rolled Shapes, Engineering Journal, Vol. 41, No. 1, pp.

1522.

Galambos, T.V., Ed. (1998), Guide to Stability Design Crite-

ria for Metal Structures, 5th ed., Wiley-Interscience, New

York, NY.

Gergess, A.N. and Sen, R. (2005a), Fabrication of Unsym-

metrical Curved Plate Girders by Cold Bending, Jour-

nal of Constructional Steel Research, Vol. 61, No. 10, pp.

13531372.

Gergess, A.N. and Sen, R. (2005b), Cold Curving Sym-

metric Unstiffened I-Girders, Journal of Constructional

Steel Research, Vol. 61, No. 4, pp. 473492.

Geschwindner, L.F., Disque, R.O., and Bjorhovde, R. (1994),

Load and Resistance Factor Design of Steel Structures,

Prentice-Hall, Englewood Cliffs, NJ.

Gresnigt, A.M. (1986), Plastic Design of Buried Steel Pipe-

lines in Settlement Areas, Heron, Delft University of

Technology, Delft, the Netherlands, Vol. 31, No. 4.

Hajjar, J.F., Dexter, R.J., Ojard, S.D., Ye, Y., and Cotton, S.C.

(2003), Continuity Plate Detailing for Steel Moment-

Resisting Connections, Engineering Journal, AISC, Vol.

40, No. 4, pp. 8197.

Iwankiw, N.R. (1997), AISC Advisory Statement on Me-

chanical Properties Near the Fillet of Wide-Flange Shapes

and Interim Recommendations, Modern Steel Construc-

tion, Vol. 37, No. 2.

286 / ENGINEERING JOURNAL / FOURTH QUARTER / 2006

Kaufmann, E.J. and Fisher, J.W. (2001), The Effect of

Straightening Method on the k-Area Loading Behavior

of Rolled Column Sections, ATLSS Report No. 01-16,

ATLSS Research Center, Lehigh University, Bethlehem,

PA.

Larson, J.W. and Huzzard, R.K. (1990), Economical Use

of Cambered Steel Beams, Proceedings, 1990 National

Steel Construction Conference, Kansas City, MO, March

1417, pp. 13-113-21.

Lee, D., Cotton, S.C., Dexter, R.J., Hajjar, J.F., Ye, Y., and

Ojard, S.D. (2002), Column Stiffener Detailing and Panel

Zone Behavior of Steel Moment Frame Connections,

Report No. ST-01-3.2, Department of Civil Engineering,

University of Minnesota, Minneapolis, MN.

Princeton University Art Museum (1974), The Eads

Bridge, Princeton University, Princeton, NJ.

Ricker, D.T. (1989), Cambering Steel Beams, Engineering

Journal, AISC, Vol. 26, No. 4, pp. 136142.

Schlim, R. (1987), Effect of Bending on Mechanical Prop-

erties of Sections, Technical Report, Arbed, Centre de

Recherches, Esch-sur-Alzette, Luxembourg.

SCI (2002), Design of Curved Steel, Specialist Design Guide,

The Steel Construction Institute, Ascot, England.

Structural Damage Control, Inc. (1998), Heat-Straighten-

ing Repairs of Damaged Steel Bridges, A Technical Guide

and Manual of Practice, Federal Highway Administra-

tion, Washington, DC.

You might also like

- Psoriasis Excerpts From The Edgar Cayce ReadingsDocument26 pagesPsoriasis Excerpts From The Edgar Cayce ReadingsjunghiuNo ratings yet

- Manual de Servicio Desfibrilador Zoll M Series (Inglés)Document138 pagesManual de Servicio Desfibrilador Zoll M Series (Inglés)Jorge Anaya100% (1)

- The New Guide To Stability Design Criteria For Metal StructuresDocument3 pagesThe New Guide To Stability Design Criteria For Metal StructuresBilly BobNo ratings yet

- Wire Welded Fabric Mesh PDFDocument2 pagesWire Welded Fabric Mesh PDFHarish RajaramNo ratings yet

- Strengh Training DemonoidDocument5 pagesStrengh Training DemonoidGastón FalconiNo ratings yet

- Chien1993 PDFDocument33 pagesChien1993 PDFRicardo MoraisNo ratings yet

- Priciples of Below Ground Waterproofing BS 8102 PDFDocument28 pagesPriciples of Below Ground Waterproofing BS 8102 PDFTaiCheong LeeNo ratings yet

- Development of AS1170.4 2007 PDFDocument12 pagesDevelopment of AS1170.4 2007 PDFfatherofgeorgeNo ratings yet

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsDocument10 pagesSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinNo ratings yet

- Analysis Anda Design Pre Stressd SleepersDocument25 pagesAnalysis Anda Design Pre Stressd SleeperspoezpietaNo ratings yet

- (Std-003) Grating Layout ClearancesDocument1 page(Std-003) Grating Layout ClearancesConifer YuNo ratings yet

- 2007 - Manual For The Assessment of Load Bearing URM Structures - Ok Ok OkDocument101 pages2007 - Manual For The Assessment of Load Bearing URM Structures - Ok Ok OkJuan Carlos Jiménez PachecoNo ratings yet

- A Study of R.C.C. Beam-Column Connection Subjected To PDFDocument7 pagesA Study of R.C.C. Beam-Column Connection Subjected To PDFInternational Journal of Research in Engineering and TechnologyNo ratings yet

- There's Always A Solution in SteelDocument12 pagesThere's Always A Solution in Steeldarienko100% (1)

- Fatigue Design of BridgesDocument12 pagesFatigue Design of BridgesEvelin StefanovNo ratings yet

- 2 Piles Pilecap DesignDocument4 pages2 Piles Pilecap Designwun chwenNo ratings yet

- Bond Under Cyclic LoadDocument5 pagesBond Under Cyclic Loadjeff100% (1)

- Behaviour of Beam-Column Joint Under Cyclic LoadingDocument3 pagesBehaviour of Beam-Column Joint Under Cyclic LoadingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rebar - Sizes PDFDocument8 pagesRebar - Sizes PDFharold_bhieNo ratings yet

- Steel Vs Concrete StructureDocument2 pagesSteel Vs Concrete StructureDedy KristiantoNo ratings yet

- General Notes Standard Precast Concrete Box Culvert: SheetDocument30 pagesGeneral Notes Standard Precast Concrete Box Culvert: SheetRamiro JiménezNo ratings yet

- Slim Concrete Columns EC Vs BS - NHBCDocument25 pagesSlim Concrete Columns EC Vs BS - NHBCalberto5791No ratings yet

- Moment Connections Bolted WeltedDocument6 pagesMoment Connections Bolted WeltedRavirajsinh JadejaNo ratings yet

- Boral Book of Concrete PDFDocument52 pagesBoral Book of Concrete PDFjohan.hafiz6926No ratings yet

- Bridge Expansion Joints - Design For Movements, Performance and DurabilityDocument7 pagesBridge Expansion Joints - Design For Movements, Performance and DurabilitykhudubaNo ratings yet

- Rigid Pavement: Joints & ReinforcementDocument7 pagesRigid Pavement: Joints & ReinforcementTeCkMunNo ratings yet

- Construction Techniques of Steel and Concrete Composite StructuresDocument8 pagesConstruction Techniques of Steel and Concrete Composite StructuresAvinash KommireddiNo ratings yet

- Half Joint Assessment Management Plan Report - Issue 2 June 2017Document30 pagesHalf Joint Assessment Management Plan Report - Issue 2 June 2017Beacher QNo ratings yet

- Seminar Deep Foundation Unpar PDFDocument2 pagesSeminar Deep Foundation Unpar PDFryan rakhmat setiadi0% (1)

- RCC 1 PDFDocument8 pagesRCC 1 PDFNgọc TuyênNo ratings yet

- Smi Flat SlabDocument6 pagesSmi Flat SlabimadNo ratings yet

- Con 1302Document12 pagesCon 1302Sanket Arun More100% (1)

- Cable Suspended Roof Structureppt CompressDocument12 pagesCable Suspended Roof Structureppt CompressYousif MustafaNo ratings yet

- Effect of Temperature Variation and Shrinkage On Circular TanksDocument12 pagesEffect of Temperature Variation and Shrinkage On Circular TanksGelbert SilotNo ratings yet

- Evaluating Old SystemsDocument18 pagesEvaluating Old SystemsimadNo ratings yet

- Structure Damage Robustness Stability PDFDocument20 pagesStructure Damage Robustness Stability PDFDodi CastelloNo ratings yet

- Tips 2001 03 PopovTakhirovDocument49 pagesTips 2001 03 PopovTakhirovRigobertoGuerraNo ratings yet

- Traffic Rail T80HT (00000002)Document3 pagesTraffic Rail T80HT (00000002)BobNobbitsNo ratings yet

- Design of Simply-Supported Composite Beams For StrengthDocument54 pagesDesign of Simply-Supported Composite Beams For StrengthBarrasons Engineers TeamNo ratings yet

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDocument6 pages1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosNo ratings yet

- Composite StructuresDocument25 pagesComposite StructuresVivek Premji100% (1)

- 15mm Strand Properties - VSLDocument1 page15mm Strand Properties - VSLenggmohanNo ratings yet

- Understanding The Cost of Structural Steelwork Part 2 Design Development and DetailingDocument4 pagesUnderstanding The Cost of Structural Steelwork Part 2 Design Development and Detailingkhoohuikiang100% (1)

- Composite StructuresDocument12 pagesComposite StructuresArpit GuptaNo ratings yet

- Plastic Hinge Length of Reinforced Concrete Columns.Document8 pagesPlastic Hinge Length of Reinforced Concrete Columns.nvnrevNo ratings yet

- Properties of A Semi-Discrete Approximation To The Beam EquationDocument11 pagesProperties of A Semi-Discrete Approximation To The Beam EquationjtorerocNo ratings yet

- Behavior and Design of Single Plate Shear ConnectionsDocument21 pagesBehavior and Design of Single Plate Shear ConnectionsMilmxmenNo ratings yet

- Composite Masonry1Document17 pagesComposite Masonry1Bibek Basnet0% (1)

- Structural Engineering VUDocument6 pagesStructural Engineering VUshan kumarNo ratings yet

- Strengthening of Concrete Beams Using Fiber-Reinforced PlasticsDocument7 pagesStrengthening of Concrete Beams Using Fiber-Reinforced PlasticsOttawa CanadaNo ratings yet

- IEI Rules of Thumb Line Card 03012016Document2 pagesIEI Rules of Thumb Line Card 03012016Anonymous 4ItkiwINo ratings yet

- Beam DesignDocument33 pagesBeam DesignstructuresNo ratings yet

- Waffle DesignDocument8 pagesWaffle Designmy09No ratings yet

- Seismic Design of Foundations: The 2015 Canadian Building CodeDocument11 pagesSeismic Design of Foundations: The 2015 Canadian Building CodeRay GongNo ratings yet

- Prec 38Document6 pagesPrec 38منصوري شيوخيNo ratings yet

- A Catalogue of Details on Pre-Contract Schedules: Surgical Eye Centre of Excellence - KathFrom EverandA Catalogue of Details on Pre-Contract Schedules: Surgical Eye Centre of Excellence - KathNo ratings yet

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingFrom EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingNo ratings yet

- Reidars Paper PDFDocument16 pagesReidars Paper PDFvivi100% (1)

- Composite Slabs DLam 1Document11 pagesComposite Slabs DLam 1Massimo LatourNo ratings yet

- IX H 727 10 Photo Atlas of Weld Appearance FiguresDocument21 pagesIX H 727 10 Photo Atlas of Weld Appearance FiguressexmanijakNo ratings yet

- Teguflex®: Expansion JointsDocument8 pagesTeguflex®: Expansion JointssexmanijakNo ratings yet

- 6series F12-F13Document16 pages6series F12-F13sexmanijakNo ratings yet

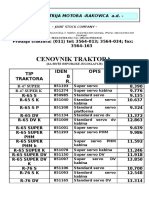

- Cenovnik Traktora: TIP Traktora Iden B R. Opis Cena/Eu RDocument2 pagesCenovnik Traktora: TIP Traktora Iden B R. Opis Cena/Eu RsexmanijakNo ratings yet

- BP Jastrebac ClanakDocument6 pagesBP Jastrebac ClanaksexmanijakNo ratings yet

- AVK Dam Reservoir Applications Glenfield PDFDocument16 pagesAVK Dam Reservoir Applications Glenfield PDFsexmanijakNo ratings yet

- Solenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65Document2 pagesSolenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65sexmanijakNo ratings yet

- Portable Boring MachineDocument2 pagesPortable Boring Machinesexmanijak100% (1)

- Tax II Outline 2012 MonteroDocument11 pagesTax II Outline 2012 MonteroTerence GuzmanNo ratings yet

- Equipment Maintenance Step 1 2 3 - ACT - TRG - 053Document74 pagesEquipment Maintenance Step 1 2 3 - ACT - TRG - 053occhityaNo ratings yet

- Risk Analysis in Capital BudgetingDocument21 pagesRisk Analysis in Capital BudgetingRajyaLakshmiNo ratings yet

- Digestive System of A FrogDocument14 pagesDigestive System of A FrogLoida Gigi AbanadorNo ratings yet

- Virtual Gym Management System: Manjiri R. Girnale Komal D. UntwalDocument6 pagesVirtual Gym Management System: Manjiri R. Girnale Komal D. UntwalRHEALYN JOY BALDERAMANo ratings yet

- Business Environment - MergedDocument142 pagesBusiness Environment - MergedAkhilesh JadhavNo ratings yet

- UAWP BrochureDocument17 pagesUAWP BrochureHakimuddin GheewalaNo ratings yet

- ArchiTalk Series 1 Attendees BreakdownDocument6 pagesArchiTalk Series 1 Attendees Breakdownfachrin anugrahNo ratings yet

- Man Basket Use 1926.1431Document10 pagesMan Basket Use 1926.1431gunnery02No ratings yet

- ADB - Deepak TanejaDocument40 pagesADB - Deepak TanejaAsian Development BankNo ratings yet

- Enko Education Culture Book - EN-2Document18 pagesEnko Education Culture Book - EN-2Kelly. cutyNo ratings yet

- ProstaglandinsDocument33 pagesProstaglandinsAshwanth M.SNo ratings yet

- Proses Berpikir Dalam Mengkomunikasikan Perencanaan Dan Pemrograman ArsitekturDocument11 pagesProses Berpikir Dalam Mengkomunikasikan Perencanaan Dan Pemrograman ArsitekturAris AgustinusNo ratings yet

- BIG 5 Uniform Acceleration EquationsDocument2 pagesBIG 5 Uniform Acceleration EquationsJeevikaGoyalNo ratings yet

- To Study The Customer Satisfaction in AirtelDocument77 pagesTo Study The Customer Satisfaction in AirtelSami Zama0% (1)

- GPrinter ISH58 Spread-OfficialDocument4 pagesGPrinter ISH58 Spread-Officialhandsome125No ratings yet

- 7 Common Mistakes in Technical AnalysisDocument2 pages7 Common Mistakes in Technical AnalysisEdgar MuyiaNo ratings yet

- Module 5 - Chapter 2Document11 pagesModule 5 - Chapter 2Bnks SdfdsfsNo ratings yet

- Laird Barron - Hour of The CyclopsDocument9 pagesLaird Barron - Hour of The CyclopsJuvanji JuvanjiNo ratings yet

- Marginal Standing Facility - ArthapediaDocument3 pagesMarginal Standing Facility - ArthapediasoumyajitroyNo ratings yet

- Emerging Technologies in Computing: Industries Influenced by TechnologiesDocument7 pagesEmerging Technologies in Computing: Industries Influenced by TechnologiesYan YanNo ratings yet

- Osteosarcoma and OsteoarthritisDocument17 pagesOsteosarcoma and OsteoarthritisCricelle Rose CobreNo ratings yet

- Spek Teknispengadaan Mesin Pompa PortableDocument1 pageSpek Teknispengadaan Mesin Pompa PortabletamitaNo ratings yet

- 2014-15 HANDBOOK FOR First and Second Level Modules in The School of Physics and Astronomy, University of ST AndrewsDocument58 pages2014-15 HANDBOOK FOR First and Second Level Modules in The School of Physics and Astronomy, University of ST AndrewsLimYCNo ratings yet

- Classification of Rotary PumpsDocument3 pagesClassification of Rotary Pumpsapi-26349602100% (2)

- Sueduresearchjournal, Journal Manager, 01Document7 pagesSueduresearchjournal, Journal Manager, 01Fabio Andrés Bernal rincónNo ratings yet

- Time: 3.00 Hours) : This Question Paper Contains 8 Printed PagesDocument8 pagesTime: 3.00 Hours) : This Question Paper Contains 8 Printed PagesrafikdmeNo ratings yet