0 ratings0% found this document useful (0 votes)

735 viewsArzel Zoning Bypass Calculator

Arzel Zoning Bypass Calculator

Uploaded by

Víctor RojasThis document provides guidance on sizing bypass ducts for zoned HVAC systems. It includes charts listing recommended bypass duct sizes for different range of cooling capacities and airflow requirements. The key factors that influence bypass duct sizing are the total system airflow, airflow of the smallest zone, and whether branch or trunk dampers are used. The document also notes that bypass air is only used to eliminate noise from high static pressure and does not provide cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Arzel Zoning Bypass Calculator

Arzel Zoning Bypass Calculator

Uploaded by

Víctor Rojas0 ratings0% found this document useful (0 votes)

735 views6 pagesThis document provides guidance on sizing bypass ducts for zoned HVAC systems. It includes charts listing recommended bypass duct sizes for different range of cooling capacities and airflow requirements. The key factors that influence bypass duct sizing are the total system airflow, airflow of the smallest zone, and whether branch or trunk dampers are used. The document also notes that bypass air is only used to eliminate noise from high static pressure and does not provide cooling.

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides guidance on sizing bypass ducts for zoned HVAC systems. It includes charts listing recommended bypass duct sizes for different range of cooling capacities and airflow requirements. The key factors that influence bypass duct sizing are the total system airflow, airflow of the smallest zone, and whether branch or trunk dampers are used. The document also notes that bypass air is only used to eliminate noise from high static pressure and does not provide cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

735 views6 pagesArzel Zoning Bypass Calculator

Arzel Zoning Bypass Calculator

Uploaded by

Víctor RojasThis document provides guidance on sizing bypass ducts for zoned HVAC systems. It includes charts listing recommended bypass duct sizes for different range of cooling capacities and airflow requirements. The key factors that influence bypass duct sizing are the total system airflow, airflow of the smallest zone, and whether branch or trunk dampers are used. The document also notes that bypass air is only used to eliminate noise from high static pressure and does not provide cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 6

At a glance

Powered by AI

The key takeaways are that bypass duct sizing is influenced by factors like duct style, equipment location, diffuser style, and size of the smallest zone. Maintaining a minimum of 3 outlets per ton of AC in each zone is also important. The bypass duct aims to eliminate air noise caused by high static pressure and velocity.

Factors that influence bypass sizing include duct style, equipment location, diffuser style, size of the smallest zone, location of the smallest zone, size of the smallest zone compared to its CFM output, blower performance, and flex duct applications. Variables like equipment size and number of outlets also affect sizing.

Branch dampering refers to dampers placed on individual branch runs, while trunk dampering refers to a damper placed on the main trunk or supply duct. Trunk dampering causes static pressures in open supply ducts to increase at a higher rate.

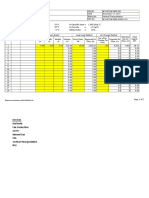

Leave blank if NO

Enter a "Y" if YES

Min-cfm Max-cfm Required

Duct Size Amount Total cfm Total Small zone Bypass cfm Round Duct Rectangular Duct

R-6 0 0 0 0 bypass not needed bypass not needed

R-7 0

R-8 0

R-10 0 CFM ROUND

R-12 0 Minimum Maximum

R-14 0 200 300 6"

R-16 0 300 500 7"

8" x 10" 0 400 700 8"

8" x 12" 0 550 1100 10"

8" x 16" 0 800 1600 12"

8" x 20" 0 1100 2100 14"

8" x 30" 0 1600 3000 16"

Total 0 Copyright Arzel Zoning Technology, Inc. 2002 Rev- 2/25/03 jcr

8" X 20" or 10" X 16"

3.25" x 10"

3.25" x 12"

6" x 10"

Arzel Zoning Technology Inc.

Bypass Sizing calculator

A/C Tons

Trunk Dampering?

capacity required See README File.

This sizing calculation is only an estimate of bypass capacity needed, consideration of duct style, equipment location, diffuser style, etc, influences actual bypass

Bypass Duct Size

* If branch ducts are FlexDuct drop to next size smaller bypass

8" X 30", 10" X 20", 12" X 18"

8" X 10" or 6"x 14"

8" X 16" or 10" X 12"

RECTANGLE

Bypass Duct CFM Capacity

Enter Capacity of Cooling Unit in Ton's (over 5 ton multiply by 1.2)

Enter Number of and size of Branch runs in smallest zone

Bypass Calculator will determine size of Bypass Duct needed

Smallest Zone Size

A/C Tonnage Adjusted CFM 5" Round 140 CFM

2 600 6" Round 200 CFM

2.5 750 7" Round 280 CFM

3 900 8" Round 340 CFM

3.5 1050 10" Round or 8" X 10" 550 CFM

4 1200 8" X 12" 600 CFM

5 1500 8" X 14" or 10" X 12" 700 CFM

5 ton w/ branch dampers 300 cfm / ton 12" Round or 8" X 16" 800 CFM

Over 5 Ton 400 cfm / Ton 8" X 20" 1000 CFM

Trunk Dampering 400 cfm / Ton 10" X 20" 1260 CFM

(3) CFM @ Round

1500 to 2000 fpm Metal pipe

300 - 400 6"

400 - 550 7"

550 - 750 8"

750 - 1150 10"

1150 - 1600 12"

1600 - 2100 14"

Dynamics of Air Flow and Zoning

To maintain maximum heat transfer and peak effectivness with the smallest zone calling, we attempt to deliver 200% of design cfm.

To deliver 200% of design cfm, we must increase static pressure by approximatley 400 to 500% .

In most applications the smallest zone can deliver twice the design cfm without air noise issues.

Arzel Zoning Technology, Inc.

Bypass Sizing Chart

What determines bypass need and size ?

If the smallest zone moves less than 40% of the total cfm at design static, you might need a bypass duct

If Equipment Size is larger than 5 tons , the blower has the capacity to deliver higher static pressure. (use 400 cfm/ton in step #1)

If Location of smallest zone is very close to equipment and has minimal friction, next size larger bypass might be appropriate

If the smallest zone is far from equipment and has significant friction, you might need to decrease bypass size

If the Size of the smallest zone(sg ft) compared to cfm output at 200% increase is out of balance, it may require larger bypass

Blower performance (cfm output) decreases up to 25% as the static pressure increases.

Bypass air does not provide BTU exchange at equipment and is used soley to eliminate air noise caused by elevated static and velocity.

Velocity incresaes at the open branch runs and decreases at the main trunk and equipment.

Variables that influence Bypass Sizing

When in doubt, call for application assistance

1-800-611-8312 / 216-831-6068

(1) Determine Total CFM @ max static pressure

(2) Subtract CFM of smallest zone @ max static pressure

Excessive cfm into a small area might cause overshooting of thermostat set-point

When Trunk Dampering static pressures in open supply duct will increase at a higher rate ( use 400 cfm/ton for total in step #1)

In Flex Duct Applications, it might require higher static to deliver max cfm to the small zone.

(downsizing bypass might be appropriate)

(3) Size Bypass per chart below

Rectangle

Metal duct

3.25" X 10"

(3) Size bypass for remaining cfm per chart

(1) Approx CFM @ max static pressure (2) Max CFM of smallest zone

Subtract (2) from (1) to find required bypass CFM (3)

8" X 20" or 10" X 16"

When bypassing over 2100 cfm, use two bypass ducts

Copyright 2002 by Arzel Zoning Technology, Inc.

3.25" X 12"

8" X 6"

8" X 10"

8" X 16" or 10" X 12"

Min-cfm Max-cfm

Outlet Amount Total cfm

Total

Small zone

Stnd- 5" OD 0 0 0

Slotted .5x8 0

Total 0

CFM

Minimum Maximum

400 600

500 800

700 1000

Copyright Arzel Zoning Technology, Inc. 2002

Smallest Zone Size

This sizing calculation is an estimate of required bypass, consideration of duct style, equipment location, diffuser style, etc, influences actual bypass required

Unico's recommendation when zoning their system is to maintain a minimum of 3 outlets per ton of A/C in each zone

Bypass Calculator will determine size of Bypass Duct needed

Bypass Duct CFM Capacity

Arzel Zoning Technology Inc.

"High Velocity" Bypass Sizing calculator

Enter Capacity of Cooling Unit in Ton's

A/C Tons Enter Number of Outlets in smallest zone

Required

Bypass cfm

0

ROUND

6"

7"

8"

Rev- 3/04/04 jcr

Bypass Duct Size

This sizing calculation is an estimate of required bypass, consideration of duct style, equipment location, diffuser style, etc, influences actual bypass required

Round Duct

bypass not needed

Unico's recommendation when zoning their system is to maintain a minimum of 3 outlets per ton of A/C in each zone

Bypass Calculator will determine size of Bypass Duct needed

Bypass Duct CFM Capacity

Arzel Zoning Technology Inc.

"High Velocity" Bypass Sizing calculator

Enter Capacity of Cooling Unit in Ton's

Enter Number of Outlets in smallest zone

A/C tonnage CFM DUCT SIZE CFM @ 1000fpm

5" Round 140 CFM

2

800 x.75 = 600

6" ROUND 200 CFM

2.5

1000 x.75 = 750

7" ROUND 280 CFM

3

1200 x.75 = 900

8" ROUND 340 CFM

3.5

1400 x.75 = 1050

10" ROUND & 8"X 10" 550 CFM

4

1600 x.75 = 1200

8" X 12" 600 CFM

4.5

1800 x.75 = 1350

8" X 14" - 10"x 12" 700 CFM

5

2000 x.75 = 1500

12" Round & 8" X 16" 800 CFM

8" X 20" 1000 CFM

10" X 20" 1260 CFM

(3) CFM

ROUND

1000-1500fpm Barometric

300 to 600 8"

500 to 800 10"

800 to 1200 12"

1100 to 1600 14"

Arzel Zoning Technology

Bypass (Barometric) Sizing Chart

Subtract (CFM capacity of smallest zone(2)) from (total cfm x.75(1))

Size bypass for remaining cfm according to chart below (3)

RECTANGLE

Barometric

8" X 12"

(1) Minimum CFM of System (2) CFM Capacity of smallest zone

Subtract (2) from (1) for BYPASS SIZING (3)

Over 5 Ton- Use 400 cfm/ton

400 cfm x .75 = 300 cfm/ton

8" X 12" to 10" x 12"

10" X 12" to 12" x 12"

8" X 20" to 12" X 20"

1054

Bypass sizing factors

Branch dampering vs Trunk dampering

Tonnage divided by total runs damperd

Protect/Unprotect Password

You might also like

- Calculating Cooling LoadsDocument2 pagesCalculating Cooling LoadsPrakash ChandraNo ratings yet

- Sound Attenuation in Lined Rectangular Ducts With Flow and Its Application To The Reduction of Aircraft Engine NoiseDocument16 pagesSound Attenuation in Lined Rectangular Ducts With Flow and Its Application To The Reduction of Aircraft Engine Noisecarbon89No ratings yet

- UPSDocument63 pagesUPSgavinilaa100% (1)

- Btu CalculationsDocument1 pageBtu CalculationsVíctor RojasNo ratings yet

- MCCB & Cable Size CalculationsDocument6 pagesMCCB & Cable Size Calculationsnicrajesh90% (10)

- 2011wksht Heating Curve - CalcsDocument3 pages2011wksht Heating Curve - Calcsapi-2982478730% (2)

- HVAC Eng - Mohamed MobarkDocument152 pagesHVAC Eng - Mohamed MobarkMUBASHIRNo ratings yet

- Mockup T510Document5 pagesMockup T510ardiansyah marwanNo ratings yet

- Ah HVAC System 04Document41 pagesAh HVAC System 04A OmairaNo ratings yet

- Sound AbsorptionDocument2 pagesSound AbsorptionautomotNo ratings yet

- 1.0) Design Flow: Rectangle R.C.Open DrainDocument1 page1.0) Design Flow: Rectangle R.C.Open DrainjjdavidNo ratings yet

- Minutes of Meeting - TCS Interface Coordination 001Document6 pagesMinutes of Meeting - TCS Interface Coordination 001Zulkarnain Dahalan0% (1)

- Sweety Home T&C Form PDFDocument4 pagesSweety Home T&C Form PDFHtin Aung KyawNo ratings yet

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- Micro Schedule of Installation and T/C Status of Overall Zones Zone A Ground Floor Appendix 4Document9 pagesMicro Schedule of Installation and T/C Status of Overall Zones Zone A Ground Floor Appendix 4MohamedSulthanNo ratings yet

- Ash Rae Clean Room Design Guide Content DraftDocument6 pagesAsh Rae Clean Room Design Guide Content DraftQuan TranNo ratings yet

- Meeting Agenda: Tower Proposals (PCD)Document9 pagesMeeting Agenda: Tower Proposals (PCD)Rizki SuryoNo ratings yet

- CRONOLOGYDocument75 pagesCRONOLOGYHemantSharmaNo ratings yet

- Sierra02-0716y3 Data SheetDocument6 pagesSierra02-0716y3 Data SheetjonathanNo ratings yet

- 2011 06 13-DI-PER8-Acoustic Insulation Catalogue-Rev 01Document12 pages2011 06 13-DI-PER8-Acoustic Insulation Catalogue-Rev 01Tien PhamNo ratings yet

- ScheduleDocument1 pageScheduleMOHAMMADNo ratings yet

- Cooling Load Estimation TableDocument2 pagesCooling Load Estimation TableeimanNo ratings yet

- Guide Spec Summary: Option ListDocument20 pagesGuide Spec Summary: Option ListRamachandra Reddy ChinthamreddyNo ratings yet

- GE2152 Basic Civil and Mechanical Engineering Question BankDocument9 pagesGE2152 Basic Civil and Mechanical Engineering Question BankJOHN PAUL V100% (1)

- KINGSUN CTI Certified (HKD) Cross-Flow Cooling Tower CatalogueDocument9 pagesKINGSUN CTI Certified (HKD) Cross-Flow Cooling Tower CataloguehyperchandikaNo ratings yet

- XSteam Excel v2.6Document11 pagesXSteam Excel v2.6Karen Piñeros GonzalezNo ratings yet

- HVAC Rule of Thumb Electrical LoadDocument1 pageHVAC Rule of Thumb Electrical LoadsauroNo ratings yet

- Single-Screw Chiller-Rating Output: Daikin Industries, LTDDocument1 pageSingle-Screw Chiller-Rating Output: Daikin Industries, LTDNguyễn Hồng TháiNo ratings yet

- P StationDocument3 pagesP StationNghiaNo ratings yet

- Air Leakage Measurement and Analysis in Duct SystemsDocument7 pagesAir Leakage Measurement and Analysis in Duct SystemsUmeshKsNo ratings yet

- Balancing ValveDocument7 pagesBalancing Valvea_salehiNo ratings yet

- Design Calculation Sheet: Fuel PumpsDocument1 pageDesign Calculation Sheet: Fuel PumpsfebousNo ratings yet

- Date: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionDocument3 pagesDate: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionMohsin ShaikhNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- Plantroom ExhaustDocument2 pagesPlantroom ExhaustDota NgNo ratings yet

- Chiller Giai Nhiet Nuoc PDFDocument8 pagesChiller Giai Nhiet Nuoc PDFHa CongNo ratings yet

- Spec For Ecological UnitDocument4 pagesSpec For Ecological UnitPradeep SukumaranNo ratings yet

- Summery of Thermal Load Calculation: Hide Empty RowsDocument1 pageSummery of Thermal Load Calculation: Hide Empty RowsMuhammad KaleelNo ratings yet

- Calc-Plum Fire IrtankDocument6 pagesCalc-Plum Fire IrtankAmro Metwally El HendawyNo ratings yet

- Design Calculation Sheet: GymnasiumDocument2 pagesDesign Calculation Sheet: GymnasiumfebousNo ratings yet

- Load Calculation Sheet - 071 Dve - Cw3 - 001Document16 pagesLoad Calculation Sheet - 071 Dve - Cw3 - 001jeerashetNo ratings yet

- Fan Sizing VENTILATIONDocument1 pageFan Sizing VENTILATIONArun KumarNo ratings yet

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationLuis Alfonso González VergaraNo ratings yet

- E Ductulator09Document9 pagesE Ductulator09Carlos SamaniegoNo ratings yet

- UGA Tunnel-Ventilated Poultry House Heat Gain Analysis 2014Document1 pageUGA Tunnel-Ventilated Poultry House Heat Gain Analysis 2014Vũ Hằng PhươngNo ratings yet

- Sound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power LevelDocument1 pageSound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power Levelmefaisal75No ratings yet

- Wave GuidesDocument6 pagesWave GuidesEric John Dela Cruz0% (1)

- DataSheetSpec YVFA0259Document2 pagesDataSheetSpec YVFA0259Jorge Antonio Díaz NambrardNo ratings yet

- HTTP WWW - Bryair.com Manuals Man07Document17 pagesHTTP WWW - Bryair.com Manuals Man07rama deviNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- Air Condition Size Calculator - UNLOCK (1.1.15)Document8 pagesAir Condition Size Calculator - UNLOCK (1.1.15)Rodel D DosanoNo ratings yet

- Installation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitDocument10 pagesInstallation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitMidha NeerNo ratings yet

- Aero Ducts IDocument31 pagesAero Ducts ImanhngoducNo ratings yet

- Esp Calculation Exhaust Air-TaDocument4 pagesEsp Calculation Exhaust Air-TaAshiq NishmaNo ratings yet

- Wsfu Storey BuildingDocument2 pagesWsfu Storey BuildingfebousNo ratings yet

- Cold Stor CalculationDocument3 pagesCold Stor CalculationEngFaisal AlraiNo ratings yet

- Final Design Values of PHE C-510 CoolersDocument4 pagesFinal Design Values of PHE C-510 CoolersRamji MishraNo ratings yet

- Genetics Pharma Dehumidifying Load Input Sheet: 1 BlisteringDocument1 pageGenetics Pharma Dehumidifying Load Input Sheet: 1 Blisteringirfanbaig36No ratings yet

- Power Capacity HVAC CalculationDocument12 pagesPower Capacity HVAC CalculationEdNo ratings yet

- Hotel Motel Dorm DBDocument1 pageHotel Motel Dorm DBsajuhereNo ratings yet

- Unit ConversionDocument1 pageUnit ConversionJitheesh Sahadevan100% (1)

- Filcar Fan Calculation 2007Document11 pagesFilcar Fan Calculation 2007NikosNo ratings yet

- Static Pressure Calculation Sheet: Disclaimer!! Use This at Your Own Risk! Hire A Professional EngineerDocument4 pagesStatic Pressure Calculation Sheet: Disclaimer!! Use This at Your Own Risk! Hire A Professional EngineerMohammed RayanNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Bussman - How To Size A FuseDocument15 pagesBussman - How To Size A FuseSJS68No ratings yet

- Ibm Exp810Document17 pagesIbm Exp810Víctor RojasNo ratings yet

- Electrical Standard Products: Switchgear Training Centre, CoonoorDocument20 pagesElectrical Standard Products: Switchgear Training Centre, CoonoorVíctor RojasNo ratings yet

- Fault Level Calculation - MethodsDocument46 pagesFault Level Calculation - MethodsPichumani100% (5)

- Wiring Diagram-Split System Air ConditionerDocument1 pageWiring Diagram-Split System Air ConditionerSohail Ejaz Mirza85% (13)

- IBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECDocument10 pagesIBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECVíctor RojasNo ratings yet

- Case Studies On Paralleling of TransformersDocument7 pagesCase Studies On Paralleling of Transformersmuaz_aminu1422100% (1)

- 4 4Document34 pages4 4Samir Ranjan ParidaNo ratings yet

- Setting Calulation For Gen Tms TRF and BusbarDocument10 pagesSetting Calulation For Gen Tms TRF and BusbarVíctor Rojas100% (1)

- AP01200003E - Fault Current - Coordination CalculatorDocument13 pagesAP01200003E - Fault Current - Coordination CalculatorVíctor RojasNo ratings yet

- Assignment SUBJECT: Industrial Power System Analysis and DesignDocument1 pageAssignment SUBJECT: Industrial Power System Analysis and DesignthavaselvanNo ratings yet

- Temp CalculationDocument1 pageTemp CalculationVíctor RojasNo ratings yet

- Short Circuit inDocument1 pageShort Circuit inVíctor RojasNo ratings yet

- 49cd247039c68100 600v Wiring Voltage Drop Spreadsheet 1Document3 pages49cd247039c68100 600v Wiring Voltage Drop Spreadsheet 1Víctor Rojas0% (1)

- Relay Setting CoordinationDocument8 pagesRelay Setting Coordinationsmepp100% (2)

- Ac Sizing Battery Charging EvaluationDocument2 pagesAc Sizing Battery Charging EvaluationVíctor RojasNo ratings yet

- Air Conditioning Carbon Footprint Calculator: Using TheDocument2 pagesAir Conditioning Carbon Footprint Calculator: Using TheVíctor RojasNo ratings yet

- ASHRAE 90-1 New Centrifugal Chiller Equation For 2010Document2 pagesASHRAE 90-1 New Centrifugal Chiller Equation For 2010Víctor RojasNo ratings yet

- Load CalculationDocument14 pagesLoad CalculationVíctor RojasNo ratings yet

- Math 8 - Q3 M1Document12 pagesMath 8 - Q3 M1Soysoy AtilloNo ratings yet

- Coursework Implementing A 7-Band Equaliser: 1. TaskDocument3 pagesCoursework Implementing A 7-Band Equaliser: 1. TaskAya MohamedNo ratings yet

- Ijert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyDocument5 pagesIjert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyburhanNo ratings yet

- XF105 System and Component Information Disc Brake and Drum Brake ConstructionsDocument26 pagesXF105 System and Component Information Disc Brake and Drum Brake ConstructionsAnd DronNo ratings yet

- TP Ref Book SathyabamaDocument249 pagesTP Ref Book SathyabamaPadmavathy RNo ratings yet

- Regulating Pulse Width Modulators: Features DescriptionDocument7 pagesRegulating Pulse Width Modulators: Features DescriptionkkaytugNo ratings yet

- Quantech Network ModelsDocument32 pagesQuantech Network ModelsCha chaNo ratings yet

- ETEK Technology (Promotional Catalog)Document67 pagesETEK Technology (Promotional Catalog)Aidi FinawanNo ratings yet

- Open Channel Notes - AnswersDocument39 pagesOpen Channel Notes - AnswersGertjan Duniceri100% (4)

- (A) Business Statistics - Regression AnalysisDocument2 pages(A) Business Statistics - Regression Analysisbcomh2103012No ratings yet

- Kono2019ikigaiJOHS PDFDocument30 pagesKono2019ikigaiJOHS PDFnashib sainNo ratings yet

- LogDocument31 pagesLogFrankNo ratings yet

- Lecture21 Canonical TransformationDocument25 pagesLecture21 Canonical TransformationKelvin LNo ratings yet

- Bitsat DPP-3 DT 08-04-2015Document8 pagesBitsat DPP-3 DT 08-04-2015Phani KumarNo ratings yet

- Estimate and MeasureDocument53 pagesEstimate and MeasureChynaZSosaNo ratings yet

- MicroBit CULMINATING Project Rubric - ROBOTICS Space ExplorationDocument3 pagesMicroBit CULMINATING Project Rubric - ROBOTICS Space Explorationjaspal.ughraNo ratings yet

- Software Requirements EngineeringDocument45 pagesSoftware Requirements Engineeringwikiy72731No ratings yet

- Maths Assessment Year 8 QuestionsDocument8 pagesMaths Assessment Year 8 QuestionsAngeline NgouNo ratings yet

- Validation and Quality Control of an ICP‐MS Method for the Quantification and Discrimination of Trace Metals and Application in Paper Analysis-An OverviewDocument18 pagesValidation and Quality Control of an ICP‐MS Method for the Quantification and Discrimination of Trace Metals and Application in Paper Analysis-An Overviewdariasne1No ratings yet

- OracleDocument67 pagesOraclepattabhikvNo ratings yet

- MT 96 RM Operating ManualDocument12 pagesMT 96 RM Operating Manualwahyu dwi prastyoNo ratings yet

- IT Quiz Questions PrelimsDocument21 pagesIT Quiz Questions PrelimsSubhojit PaulNo ratings yet

- Simulation of Conjugate Heat Transfer in Thermal Processes With Open Source CFDDocument17 pagesSimulation of Conjugate Heat Transfer in Thermal Processes With Open Source CFDkkkkNo ratings yet

- How To Build Your Own PC by Andrew SmithDocument27 pagesHow To Build Your Own PC by Andrew SmithgreatgeniusNo ratings yet

- The Real "Total Cost of Ownership" of Your Test Equipment: Keysight TechnologiesDocument8 pagesThe Real "Total Cost of Ownership" of Your Test Equipment: Keysight TechnologiesAshwin BhatNo ratings yet

- 6-大规模电力系统仿真用新能源... 法研究 (二) 机电暂态模型 孙华东Document13 pages6-大规模电力系统仿真用新能源... 法研究 (二) 机电暂态模型 孙华东Qin yuwenNo ratings yet

- BPS-Solar Power System 300W To 20KW - BESTSUN - ABT2017Document8 pagesBPS-Solar Power System 300W To 20KW - BESTSUN - ABT2017s_aguilNo ratings yet

- PROSOLV-tech Info Prosolv Func Inv GB 1809Document12 pagesPROSOLV-tech Info Prosolv Func Inv GB 1809raju1559405No ratings yet