Draft of Boiler Efficiency Calculations

Draft of Boiler Efficiency Calculations

Uploaded by

Mohsin MajeedCopyright:

Available Formats

Draft of Boiler Efficiency Calculations

Draft of Boiler Efficiency Calculations

Uploaded by

Mohsin MajeedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Draft of Boiler Efficiency Calculations

Draft of Boiler Efficiency Calculations

Uploaded by

Mohsin MajeedCopyright:

Available Formats

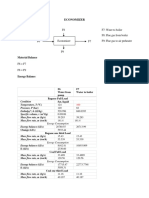

Boiler Efficiency

Indirect Method:

Boiler Heat Balance:

Input/Output Parameter

Heat Input in fuel

Various Heat losses in boiler

1. Dry flue gas loss

2. Loss due to hydrogen in fuel

3. Loss due to moisture in fuel

4. Loss due to moisture in air

5. Partial combustion of C to CO

6. Surface heat losses

7. Loss due to Unburnt in fly ash

8. Loss due to Unburnt in bottom ash

Total Losses

Boiler efficiency = 100 - (1+2+3+4+5+6+7+8)

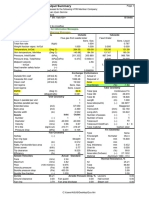

Heat Loss due to dry Fuel Gas:

m

Cp

Tf

Ta

GCV

L1 #DIV/0!

Heat Loss due to evaporation of water formed due to H2 in fuel:

H2

Cp

Tf

Ta

GCV of Fuel

L2 #DIV/0!

Heat Loss due to moisture present in fuel

M

Cp

Tf

Ta

GCV of fuel

L3 #DIV/0!

Heat Loss due to moisture present in air:

AAS

Humidity Factor

Cp

Tf

Ta

GCV of fuel

L4 #DIV/0!

Heat Loss due to incomplete combustion:

% CO

C

%CO2

GCV of Fuel

L5 #DIV/0!

Heat Loss due to the radiation and convection

Vm 77

Ts 46

Ta 45

L6 29.11406

Boiler Efficiency

kCal/Kg of Fuel %

100

Where,

L1 = % Heat loss due to dry flue gas

m = Mass of dry flue gas in kg/kg of fuel

= Combustion products from fuel: CO2 + SO2 + Nitrogen in fuel + Nitrogen in the actual mass of air supplied + O2 in flue gas.

(H2O/Water vapour in the flue gas should not be considered)

Where

H2 = kg of hydrogen present in fuel on 1 kg basis

Cp = Specific heat of superheated steam in kCal/kgC

Tf = Flue gas temperature in C

Ta = Ambient temperature in C

584 = Latent heat corresponding to partial pressure of water vapour

where

M = kg moisture in fuel on 1 kg basis

Cp = Specific heat of superheated steam in kCal/kgC

Tf = Flue gas temperature in C

Ta = Ambient temperature in C

584 = Latent heat corresponding to partial pressure of water vapour

where

AAS = Actual mass of air supplied per kg of fuel

Humidity factor = kg of water/kg of dry air

Cp = Specific heat of superheated steam in kCal/kgC

Tf = Flue gas temperature in C

Ta = Ambient temperature in C (dry bulb)

where

% Heat loss due to partial conversion of C to CO When CO is obtained in ppm during the flue gas analysis

CO = Volume of CO in flue gas leaving economizer (%) CO formation (Mco) = CO (in ppm) x 106 x Mf x 28

CO2 = Actual Volume of CO2 in flue gas (%) or Mf = Fuel consumption in kg/hr

C = Carbon content kg / kg of fuel L5 = Mco x 5744*

* Heat loss due to partial combustion of carbon.

L6= Radiation loss in W/m2

Vm = Wind velocity in m/s

Ts = Surface temperature (K)

Ta = Ambient temperature (K)

Nitrogen in the actual mass of air supplied + O2 in flue gas.

When CO is obtained in ppm during the flue gas analysis

CO formation (Mco) = CO (in ppm) x 106 x Mf x 28

* Heat loss due to partial combustion of carbon.

Test Conditions and Precautions for Indirect Method Testing

A) The efficiency test does not account for:

Standby losses. Efficiency test is to be carried out, when the boiler is operating under a

steady load. Therefore, the combustion efficiency test does not reveal standby losses,

which occur between firing intervals

Blow down loss. The amount of energy wasted by blow down varies over a wide range.

Soot blower steam. The amount of steam used by soot blowers is variable that depends on

the type of fuel.

Auxiliary equipment energy consumption. The combustion efficiency test does not

account for the energy usage by auxiliary equipments, such as burners, fans, and pumps.

B) Preparations and pre conditions for testing

Burn the specified fuel(s) at the required rate.

Do the tests while the boiler is under steady load. Avoid testing during warming up of boilers

from a cold condition

Obtain the charts /tables for the additional data.

Determination of general method of operation

Sampling and analysis of fuel and ash.

Ensure the accuracy of fuel and ash analysis in the laboratory.

Check the type of blow down and method of measurement

Ensure proper operation of all instruments.

Check for any air infiltration in the combustion zone.

C) Flue gas sampling location

It is suggested that the exit duct of the boiler be probed and traversed to find the location of the

zone of maximum temperature. This is likely to coincide with the zone of maximum gas flow

and is therefore a good sampling point for both temperature and gas analysis.

D) Options of flue gas analysis

Check the Oxygen Test with the Carbon Dioxide Test

If continuous-reading oxygen test equipment is installed in boiler plant, use oxygen reading.

Occasionally use portable test equipment that checks for both oxygen and carbon dioxide. If the carbon

dioxide test does not give the same results as the oxygen test, something is wrong. One (or both)

of the tests could be erroneous, perhaps because of stale chemicals or drifting instrument calibration.

Another possibility is that outside air is being picked up along with the flue gas. This occurs if the

combustion gas area operates under negative pressure and there are leaks in the boiler casing.

Carbon Monoxide Test

The carbon monoxide content of flue gas is a good indicator of incomplete combustion with all

types of fuels, as long as they contain carbon. Carbon monoxide in the flue gas is minimal with

ordinary amounts of excess air, but it rises abruptly as soon as fuel combustion starts to be incomplete.

E) Planning for the testing

The testing is to be conducted for a duration of 4 to 8 hours in a normal production day.

Advanced planning is essential for the resource arrangement of manpower, fuel, water and

instrument check etc and the same to be communicated to the boiler Supervisor and

Production Department.

Sufficient quantity of fuel stock and water storage required for the test duration should be

arranged so that a test is not disrupted due to non-availability of fuel and water.

Necessary sampling point and instruments are to be made available with working condition.

Lab Analysis should be carried out for fuel, flue gas and water in coordination with lab personnel.

The steam table, psychometric chart, calculator are to be arranged for computation of boiler

Occasionally use portable test equipment that checks for both oxygen and carbon dioxide. If the carbon

ordinary amounts of excess air, but it rises abruptly as soon as fuel combustion starts to be incomplete.

You might also like

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Efficiency of Waste Heat Boiler, HRSGDocument13 pagesEfficiency of Waste Heat Boiler, HRSGHasan Ahmed100% (2)

- Heat Rate Calc in ExcelDocument13 pagesHeat Rate Calc in ExcelMukesh VadaliaNo ratings yet

- Boiler Cost Per Hour CalculationDocument1 pageBoiler Cost Per Hour Calculationsreelu100% (3)

- ARK ETF Trust Annual ReportDocument62 pagesARK ETF Trust Annual ReportTam Jack100% (1)

- Boiler Efficiency-An AnalysisDocument18 pagesBoiler Efficiency-An AnalysisDebasish ChowdhuryNo ratings yet

- Power Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSDocument7 pagesPower Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSRajesh100% (1)

- Boiler Efficiency CalculationsDocument8 pagesBoiler Efficiency CalculationsmanishxlriNo ratings yet

- Heat BalanceDocument10 pagesHeat BalanceHoang VAN SI100% (2)

- Calculation of Boiler EfficiencyDocument14 pagesCalculation of Boiler EfficiencyBharat Choksi100% (1)

- Efficiency-Boiler & TGDocument21 pagesEfficiency-Boiler & TGAnand SwamiNo ratings yet

- BOILER Losses: Loss Due To Unburnt CarbonDocument5 pagesBOILER Losses: Loss Due To Unburnt CarbonVenkateswara Rao DoodalaNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Coal Consumption CalculationDocument1 pageCoal Consumption CalculationbrockNo ratings yet

- Boiler Efficiency CalculationsDocument65 pagesBoiler Efficiency Calculationssizmaru100% (1)

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerrareseNo ratings yet

- Steam TablesDocument16 pagesSteam TablesDanu MamlukatNo ratings yet

- Economize R 3 TrialDocument19 pagesEconomize R 3 TrialNitish AmnerkarNo ratings yet

- Boiler Efficiency CalculationDocument5 pagesBoiler Efficiency CalculationSuparna Bhose100% (3)

- Flue Gas 360 PDFDocument2 pagesFlue Gas 360 PDFwatson123No ratings yet

- Stoichiometric Calc VisaDocument4 pagesStoichiometric Calc Visamkchy12No ratings yet

- Instructions Natural Gas Boiler Calculations: AcknowledgementsDocument17 pagesInstructions Natural Gas Boiler Calculations: AcknowledgementsDavid Muñoz CastroNo ratings yet

- 4.10.4 Performance Evaluation of BoilersDocument7 pages4.10.4 Performance Evaluation of BoilersGanti AsegarNo ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Turbine Efficiency - Ch-8.1 PDFDocument8 pagesTurbine Efficiency - Ch-8.1 PDFGopal Chandra SahuNo ratings yet

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- Calculation of Heat Rate and Efficiency 04 Desember 2017 CFK #2Document1 pageCalculation of Heat Rate and Efficiency 04 Desember 2017 CFK #2Nur Ali SaidNo ratings yet

- Steam Turbine EfficiencyDocument71 pagesSteam Turbine EfficiencyAnonymous LjE1R12CasNo ratings yet

- Chimney Design CalcDocument5 pagesChimney Design CalcDenny ThomasNo ratings yet

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNo ratings yet

- Boiler Perform CalculateDocument29 pagesBoiler Perform CalculateAnsarNo ratings yet

- Steam Cost Calculations 2020Document3 pagesSteam Cost Calculations 2020Malwadkar P.B.0% (1)

- CalculationsDocument14 pagesCalculationsPratyush BadrinarayanNo ratings yet

- Boiler Efficiency Improvement Through Analysis of Losses PDFDocument5 pagesBoiler Efficiency Improvement Through Analysis of Losses PDFTambun BerdikariNo ratings yet

- Combustion Table Industrial Energy ProcessDocument4 pagesCombustion Table Industrial Energy Processsara_ghaemNo ratings yet

- Boiler CalculationDocument2 pagesBoiler CalculationShamsur Rahman RussellNo ratings yet

- Procedure For Calculation of Efficiency-1Document7 pagesProcedure For Calculation of Efficiency-1JAY PARIKHNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Boiler System EfficiencyDocument7 pagesBoiler System EfficiencyDhirendra Singh RathoreNo ratings yet

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDocument87 pagesAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalNo ratings yet

- Fan Flow Calculation For FBC BoilerDocument3 pagesFan Flow Calculation For FBC BoilerOmprakaash MokideNo ratings yet

- Design of Air Pre Heater and EconomizerDocument4 pagesDesign of Air Pre Heater and EconomizerRyan PerezNo ratings yet

- Sample Computation For Boiler EfficiencyDocument6 pagesSample Computation For Boiler Efficiencyra_tagolimotNo ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Waste Heat BoilerDocument2 pagesWaste Heat BoilerSharon LambertNo ratings yet

- Boiler Performance Test CalcDocument53 pagesBoiler Performance Test CalcdgmprabhakarNo ratings yet

- Fuel and CombustionDocument79 pagesFuel and CombustionRahul Reddy100% (1)

- Distillation PDFDocument20 pagesDistillation PDFKiril AckovskiNo ratings yet

- Pump Formula SheetDocument2 pagesPump Formula SheetVíctor RojasNo ratings yet

- Standard Technical Features OF BTG System For Supercritical 660/ 800 MW Thermal UnitsDocument10 pagesStandard Technical Features OF BTG System For Supercritical 660/ 800 MW Thermal UnitsnareshvkkdNo ratings yet

- Boiler CalculatorDocument4 pagesBoiler CalculatorMarc EdwardsNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Boiler Pressure PartDocument19 pagesBoiler Pressure PartTahir SaeedNo ratings yet

- Chemical Reactor Design, Optimization, and ScaleupFrom EverandChemical Reactor Design, Optimization, and ScaleupRating: 5 out of 5 stars5/5 (1)

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Boiler PerformanceDocument53 pagesBoiler PerformanceHariri Dwi KusumaNo ratings yet

- Module 8 - Energy Performance Assessment of BoilersDocument24 pagesModule 8 - Energy Performance Assessment of BoilersAnonymous a19X9GHZNo ratings yet

- Energyauditofboiler 161207011009Document38 pagesEnergyauditofboiler 161207011009Randy PrandykaNo ratings yet

- Boiler DesignDocument10 pagesBoiler DesignbobNo ratings yet

- Boiler EfficiencyDocument32 pagesBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Raw MaterialsDocument8 pagesRaw Materialsmahmuda chowdhury100% (1)

- Behind The Curtain of ConsultingDocument31 pagesBehind The Curtain of Consultingpfc webNo ratings yet

- La Excellence: General ScienceDocument45 pagesLa Excellence: General SciencelakshNo ratings yet

- Part 5 Matching Information TransferDocument6 pagesPart 5 Matching Information TransferStayMarcusNo ratings yet

- Law and Poverty - The Legal System and Poverty PDFDocument316 pagesLaw and Poverty - The Legal System and Poverty PDFRahul GuptaNo ratings yet

- Entrepreneurship Report: Topic: Idea For Starting New BusinessDocument5 pagesEntrepreneurship Report: Topic: Idea For Starting New BusinessshafiqNo ratings yet

- MDT Regimens PDFDocument1 pageMDT Regimens PDFAnnisa KartikasariNo ratings yet

- Ayurveda Food Combining - Banyan BotanicalsDocument6 pagesAyurveda Food Combining - Banyan BotanicalsRajVeerNo ratings yet

- Datasheet: OLC-D1, OLC-K1Document2 pagesDatasheet: OLC-D1, OLC-K1Behnam AshouriNo ratings yet

- TTA Sublimation InkDocument4 pagesTTA Sublimation Inkde_kurNo ratings yet

- Hostel Affidavit Mens Hostel 2020 2021Document4 pagesHostel Affidavit Mens Hostel 2020 2021HarshNo ratings yet

- JFR FMCW Radar Level Transmitter - B0 - 65774187Document10 pagesJFR FMCW Radar Level Transmitter - B0 - 65774187ciocioi iancuNo ratings yet

- 11th Basic Electrical EngineeringDocument256 pages11th Basic Electrical EngineeringARPIT ANIL PANWAR ME118No ratings yet

- Unit 7 Activity 2Document2 pagesUnit 7 Activity 2Jeremiah Paul UretaNo ratings yet

- Sportsfest Plan Sy 2023Document8 pagesSportsfest Plan Sy 2023Melody Anne Dinoso EvangelistaNo ratings yet

- High-Performance Blending For Demanding Applications.: Kenics™ KMX-V Static MixerDocument1 pageHigh-Performance Blending For Demanding Applications.: Kenics™ KMX-V Static Mixermember1000No ratings yet

- Pupillary Light Reflex - Wikipedia - Https - en - Wikipedia.org - Wiki - Pupillary - Light - ReflexDocument6 pagesPupillary Light Reflex - Wikipedia - Https - en - Wikipedia.org - Wiki - Pupillary - Light - ReflexMatthew PrestonNo ratings yet

- Patar Elementary School Fourth Periodic Test in Mapeh 6Document8 pagesPatar Elementary School Fourth Periodic Test in Mapeh 6Mark Angel MorenoNo ratings yet

- Ealn-7g7k3r R3 enDocument1 pageEaln-7g7k3r R3 enFloyd PinkNo ratings yet

- MGT 420 Management Case Study - Motivation: Present To: Roseamilda BT MansorDocument4 pagesMGT 420 Management Case Study - Motivation: Present To: Roseamilda BT MansorkimimuraNo ratings yet

- Technical Elective ReportDocument43 pagesTechnical Elective ReportSaajan SharmaNo ratings yet

- Chem 314 Lab 1Document9 pagesChem 314 Lab 1Tshephang Karabo ThuthukaNo ratings yet

- AhpDocument9 pagesAhpDSIT MECHANICALNo ratings yet

- Cellular Microbiology - 2016 - Pereira Silva - Genome Wide Transcriptome Analysis of Aspergillus Fumigatus Exposed ToDocument21 pagesCellular Microbiology - 2016 - Pereira Silva - Genome Wide Transcriptome Analysis of Aspergillus Fumigatus Exposed ToEllie SmithNo ratings yet

- Selected Works in Contemporary TimesDocument46 pagesSelected Works in Contemporary TimesAcey Acey AceyNo ratings yet

- Ineco Hse Manual-SignedDocument27 pagesIneco Hse Manual-SignedTantely RazafimahatratraNo ratings yet

- Elapsed Time, Daylight Saving TimeDocument31 pagesElapsed Time, Daylight Saving TimesareetadevirayNo ratings yet

- Joncryl 668 TDSDocument3 pagesJoncryl 668 TDSBryanNo ratings yet

- Research Proposal PresentationDocument17 pagesResearch Proposal PresentationFathima Nuzha67% (3)