Design Data - Bucket Elevators

Uploaded by

Mohammed Shafi AhmedDesign Data - Bucket Elevators

Uploaded by

Mohammed Shafi Ahmed9.

22

DESIGN DATA-PSGT

DENSITY & ANGLE OF REPOSE OF COMMONLY CONVEYED MATER1AI5

Recommended

max. angle of belt Density

Material

to horiz, deg. tonne/m'

6

anthracite, fine, dry

0.8 - 0.95 45

gypsum, small lump

1.2- 1.4 40

Clay, dry , lump

1.0 - 1.5 SO

gravel

12 1.5 - 1.9 45

earth, dry

1.2

45

foundrysand (shake out)

24-26 1.25 - 1.3 45

ash, dry

23 0.4 - 0.6 SO

lime stone, lump

20 1.2- 1.5 45

Coke 17 0.36 - 0.53 SO

Wheat flour 23 0.45 - 0.66 55

Oat 18 0.4 - 0.5 35

saw dust 27 0.16 - 0.32 39

dry sand

18 1.4- 1.65 4\

Wheat 18 0.65 - 0.83 3\

iron ore 18-25 2.1 - 2.5 SO

peat, dry lump

18 0.33 - 0.41 45

Coal (from mine)

18 0.65 - 0.78 SO

dry cement

20 1.0 - 1.3 SO

slag, anthracite

22 0.6 - 0.9 4S

DESIGN OF BUCKET ELEVATORS

./

Equation

Nomenclature

i. Q

a = -3.6 vp~-

A""a",.." m

Sm.." = 1.15 H (q+K1q.)

Q

q = 3.6 v

Power on the drive shaft:

QH

N = 367 (l.lS+K.Kav)

DESIGN DATA-PSG TECH

io Capacity of each bucket, litre

a, pitch of bucket, m

==(2.5 to 3) h

h, height of bucket at the belt or chain end, m

v, belt or chain velocity, m/s

p, bulk density of conveyed material, tonne/cll.rn

..y, bucket loading efficiency, table. I, p. 9.24

0, capacity of elevator, tonne/hr

i

; , values from table 2. p. 9.24

A, projection of bucket from belt face, mm

a",,,,, dimension of the largest lump of material conveyed, mm

m, = 2 to 2.5 if 20% of material is of size ilm""

=4.25 to 4.75 if 50 to 100% of the material is of size am""

SIIIU, max. static tension in the belt, kgf.

H, ht to which the load is elevated, m

q, wI. of load/ metre of elevator, kgf/m

Klo factor of resistance, see table 3, p. 9.25

qQ' wI. per meter of belt or chain with buckets, kgf/m

== K2 Q (For K2 see table 3)

N, power, kw

Ka,

factor, see table 3, p. 9.2)

9.23

PARAMETERS OF BUCKET ELEVATORS

v

Table I.

Range of Speed, v, mls

belt chain

D, d'C'ep; V, Vec; Sh, Sh:lIlow.

~.24

DESIGN DATA-PSG TECH

Typical loads Type of

Type of Loading

elevator

bucket

efficiency,

'

Coal dust

slow speed gravity

D 0.85

d is.:harge

Cement, chalk, high speed centrifugal

D 0.75

fert ilizer

dis.:harge

Saw dust, dry clay

D 0.7-0.8

in lumps, coal

Gravel, ore, slag. .Iow speed directed gr." ity

V 0.7-0.85

discharge

Sand, ash, earth, high speed centrifugal

D 0.7-0.8

rock discharge

Moist chemicals, high speed centrifugal

Sh 0.4-0.6

wet sand &c., dis.:harge

-

..

'-

slow speed gravity discharge

Sh

-..-

0.6-0.8

I}5-1.8

-

1.25-2 1.25-1.6

0.8-1 0.8-1

1.6-1.8

-

1.25-1.8 1.25-1.6

0.6-0.8

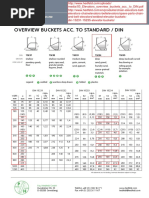

SELECTlO OF BUCKETS: based on io

a

Table 2.

Deep buckets

Shallow buckets

V buckets

bucket

.

io

io 10 .1

io

width,

B

a

a

.. mm

I/m

litre

-

2.5 0.75

- - - -

135

3.67 J.I 2.17 0.65 9.4 1.5 160

6.67 2.0

3.67 1 1

- -

200

8 3.2 6.5

2.6 18.0 3.6 250

15.6 7.8

14.0 7.0 31.2 7.8 350

24.2 R5

25.0 15.0 50.0 16.0 450

85.0 34 600

134 67 750

206 130 900

j

D,sh

v

T~bJi':3;

FACTORS

...

Conveying

capacity

Q

tonne/hr

~

Belt Do"bl" .cb;\iQ

D,sh

~

DESIGN DATA-PSG TECH

9.25

Kit Kit

Ka

-

Elevator type

Single Chain

Type of buckets.

D,sh

.y

-

K.

upto 10

0.6

-

1.1

10to 25 '0.5

-

0.8 1.1 1.2

.'

l5 to 50 0.45 ' 0.6 0.6 0.85 .1

50to 100 0.4 0.55 . 0.5 0.7 (). 1.1

Over100 0.35 0.5

- -

0.6 1),9

KI

2.5 2 1.5 1.25 1.5 I.2S

Ka

1.6 1.1 1.3 0.8 1.3 O.X

f

i DIMENSIONS & CAPACITY OF BUCKETS

Tolble 4.

.f

j

BUCKET

Type

width

height capacity

Slandard pih:h. a. 111111

-

of B h

io

bucItct

,

mtn mm litre

bucket o:hain

I

,

deep

135-400 100-240 0.75-14.5

300, 400. l

100, 115,

shaDow 160-450 100-285 (1.65-15

500, 600 J 160, 100.

Vee 160-%0 155-620 1.5-130

160, 200, 250. 250, .\1S.

.,

315, 400, 500, 400, 500,

630:

630

You might also like

- Bucket Elevator Excel Calculations Bucket Elevator Applications100% (3)Bucket Elevator Excel Calculations Bucket Elevator Applications22 pages

- Bucket Elevator Calculation: Yellow Cell To Be Filled100% (2)Bucket Elevator Calculation: Yellow Cell To Be Filled2 pages

- Feeder Breaker Chain (Renold Chain) Double Pitch Sprocket Design0% (1)Feeder Breaker Chain (Renold Chain) Double Pitch Sprocket Design1 page

- Designcalculation 19260009 Cal Me CNV 00No ratings yetDesigncalculation 19260009 Cal Me CNV 0071 pages

- Mechanical Conveyors: 29 Materials HandlingNo ratings yetMechanical Conveyors: 29 Materials Handling2 pages

- "Design and Model of Bucket Elevator": Under The Guidance ofNo ratings yet"Design and Model of Bucket Elevator": Under The Guidance of92 pages

- Calculation of The Torque Required To OperateNo ratings yetCalculation of The Torque Required To Operate3 pages

- Calculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMANo ratings yetCalculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMA9 pages

- Cross Travel Motor Power Calculation:: For Steelage IndustriesNo ratings yetCross Travel Motor Power Calculation:: For Steelage Industries22 pages

- Problem Example of Pneumatic Conveying System100% (2)Problem Example of Pneumatic Conveying System9 pages

- Conveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee MemberNo ratings yetConveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee Member7 pages

- Particle Size Distribution: 1. Calculating The Diameter of The CycloneNo ratings yetParticle Size Distribution: 1. Calculating The Diameter of The Cyclone6 pages

- CIVL 392 - Chapter 3 - Excavating MachinesNo ratings yetCIVL 392 - Chapter 3 - Excavating Machines50 pages

- Bearing Capacity Determination Using Plate Load Test - A Case StudyNo ratings yetBearing Capacity Determination Using Plate Load Test - A Case Study7 pages

- A) Brief History On Roller Coaster: Russian Ice SlidesNo ratings yetA) Brief History On Roller Coaster: Russian Ice Slides6 pages

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.From EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.No ratings yet

- Time Value of Money: Dr. M. SubramanianNo ratings yetTime Value of Money: Dr. M. Subramanian49 pages

- Refractories For The Cement Industry KILNNo ratings yetRefractories For The Cement Industry KILN16 pages

- Review of Anti-Corruption Strategies: Rob Mccusker100% (2)Review of Anti-Corruption Strategies: Rob Mccusker82 pages

- C. Polymer and Chemical Based Industries PCBINo ratings yetC. Polymer and Chemical Based Industries PCBI2 pages

- 4.7 Velocity Triangles at The Eye Hub and TipNo ratings yet4.7 Velocity Triangles at The Eye Hub and Tip22 pages

- Chemicals Zetag DATA Inverse Emulsions Zetag 8814 - 0410No ratings yetChemicals Zetag DATA Inverse Emulsions Zetag 8814 - 04102 pages

- Schematic EMC WIRING 2020-05-23 22-49-18No ratings yetSchematic EMC WIRING 2020-05-23 22-49-181 page

- FMDS 03 10 - Installation & Maintenance of Fire Service Mains100% (1)FMDS 03 10 - Installation & Maintenance of Fire Service Mains59 pages

- Column Plan 3: Tarlac State University Bungalow Residential Arquero, Jennel ANo ratings yetColumn Plan 3: Tarlac State University Bungalow Residential Arquero, Jennel A1 page

- 31504569-TP48300-A Power System Quick Installation Guide (V100R001 - 05)75% (4)31504569-TP48300-A Power System Quick Installation Guide (V100R001 - 05)25 pages

- Readings - Q0212679 - 01-May-2020 03-41-35-000 PM PDFNo ratings yetReadings - Q0212679 - 01-May-2020 03-41-35-000 PM PDF3 pages

- Handbook FOR Protection Engineers: Mohammed Fasil T 9746988538 0483 2854487100% (2)Handbook FOR Protection Engineers: Mohammed Fasil T 9746988538 0483 2854487127 pages

- Technician Jailed Over Accident That Saw Trapped Worker Bleed To Death in Lift ShaftNo ratings yetTechnician Jailed Over Accident That Saw Trapped Worker Bleed To Death in Lift Shaft4 pages

- Ca781, Pre Assembled Shorting Link, Jumper, Cross Connection, Cross Connection BridgeNo ratings yetCa781, Pre Assembled Shorting Link, Jumper, Cross Connection, Cross Connection Bridge1 page

- Bucket Elevator Excel Calculations Bucket Elevator ApplicationsBucket Elevator Excel Calculations Bucket Elevator Applications

- Bucket Elevator Calculation: Yellow Cell To Be FilledBucket Elevator Calculation: Yellow Cell To Be Filled

- Feeder Breaker Chain (Renold Chain) Double Pitch Sprocket DesignFeeder Breaker Chain (Renold Chain) Double Pitch Sprocket Design

- "Design and Model of Bucket Elevator": Under The Guidance of"Design and Model of Bucket Elevator": Under The Guidance of

- Calculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMACalculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMA

- Cross Travel Motor Power Calculation:: For Steelage IndustriesCross Travel Motor Power Calculation:: For Steelage Industries

- Conveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee MemberConveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee Member

- Particle Size Distribution: 1. Calculating The Diameter of The CycloneParticle Size Distribution: 1. Calculating The Diameter of The Cyclone

- Bearing Capacity Determination Using Plate Load Test - A Case StudyBearing Capacity Determination Using Plate Load Test - A Case Study

- A) Brief History On Roller Coaster: Russian Ice SlidesA) Brief History On Roller Coaster: Russian Ice Slides

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.From EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.

- Review of Anti-Corruption Strategies: Rob MccuskerReview of Anti-Corruption Strategies: Rob Mccusker

- Chemicals Zetag DATA Inverse Emulsions Zetag 8814 - 0410Chemicals Zetag DATA Inverse Emulsions Zetag 8814 - 0410

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsFMDS 03 10 - Installation & Maintenance of Fire Service Mains

- Column Plan 3: Tarlac State University Bungalow Residential Arquero, Jennel AColumn Plan 3: Tarlac State University Bungalow Residential Arquero, Jennel A

- 31504569-TP48300-A Power System Quick Installation Guide (V100R001 - 05)31504569-TP48300-A Power System Quick Installation Guide (V100R001 - 05)

- Readings - Q0212679 - 01-May-2020 03-41-35-000 PM PDFReadings - Q0212679 - 01-May-2020 03-41-35-000 PM PDF

- Handbook FOR Protection Engineers: Mohammed Fasil T 9746988538 0483 2854487Handbook FOR Protection Engineers: Mohammed Fasil T 9746988538 0483 2854487

- Technician Jailed Over Accident That Saw Trapped Worker Bleed To Death in Lift ShaftTechnician Jailed Over Accident That Saw Trapped Worker Bleed To Death in Lift Shaft

- Ca781, Pre Assembled Shorting Link, Jumper, Cross Connection, Cross Connection BridgeCa781, Pre Assembled Shorting Link, Jumper, Cross Connection, Cross Connection Bridge