Wartsila O Pumps Hamworthy Pump Room

Wartsila O Pumps Hamworthy Pump Room

Uploaded by

liao_marcoCopyright:

Available Formats

Wartsila O Pumps Hamworthy Pump Room

Wartsila O Pumps Hamworthy Pump Room

Uploaded by

liao_marcoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Wartsila O Pumps Hamworthy Pump Room

Wartsila O Pumps Hamworthy Pump Room

Uploaded by

liao_marcoCopyright:

Available Formats

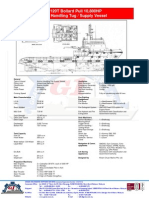

Pump Room Systems

Pump Systems

Our experience is advantageous to customers. Today we offer the

widest range of pumps and pumping systems for tankers based on

more than 100 years of successfull pump business. Thousands of

ships equipped with our pumps are in daily operation worldwide

benefting from of our high quality products and widespread

service network.

Our extensive experience, coupled with an ongoing research and

development programme, mean our products all latest improve-

ments in modern tanker design and operation. As a company we are

in a unique position to accomplish all expectations in the market.

For crude oil and product tankers with few cargo segregations, tradi-

tional pump room systems have unmatched performances.

Pump room systems

One supplier - one point of contact - one responsibility

System supplies typical scope:

The Cargo Handling System may come as an integrated package

consisting of:

Cargo pumps

Drivers steam, electric or diesel based

Steam condenser

Stripping system

Stripping pump

Tank cleaning pump

Ballast pumps

Bilge pump

Transmissions / deck seal units

Valves / actuators

Control and monitoring system

Important features of the system are compact and space-saving

confgurations for optimal pump room layouts combined with

high operational effciency.

Other potential Hamworthy deliveries:

Engine room pumps

Gas and inert gas systems

Sewage treatment plants

VOC recovery systems

The traditional Pump Room System (PRS) is characterized by a

separate room for pumping equipment located between the engine

room and the cargo hold an arrangement that provides easy ac-

cess to all key-components for regular inspection and maintenance.

To Control Cabinets /

Valves etc

Interface

Unit

Control

Panel

To discharge

Cross-over

Tank

Cleaning

Line

To

Ballast

Tanks

To

Ballast

Tanks

To

Sea

St. Pipe

Priming

Ballast

Pump

Ballast

Pump

Cow

Pump

Strip

Pump

Cargo

Pump

Cargo

Pump

Cargo

Pump

Cargo

Pump

From

Cargo Tanks

From

Ballast Tanks

A

i

r

/

G

a

s

S

e

p

a

r

a

t

o

r

A

i

r

/

G

a

s

S

e

p

a

r

a

t

o

r

El.

Motor

Steam

Turbine

Steam

Turbine

Non

Return

Valve

Capacity

Regulating

Valve

Closing

Valve

Deck

Seal

Unit

Control

Cabinet

Schematic diagram - typical

cargo / ballast pumping system

Vacuum

Pump Unit

Slop Tank

General system description

An automatic stripping system is normally supplied with the cargo

pumps and occasionally, also with the ballast pumps depending on

duty. When required cargo and ballast valves with matching actua-

tors can also be supplied.

The dry-installed pumps therein are driven by dedicated prime mov-

ers located in the engine room in a vertical or horizontal arrange-

ment. Gas-tight shaft seals prevent any hydrocarbon gasses from

entering the engine room.

The complete pumping process can be controlled and monitored

either automatically or manually remotely from the cargo control

room or bridge. The system is prepared for easy integration with

other systems onboard.

The pump room

The CB cargo and COW pumps are specially designed for pumping

crude oil and oil products at nominal heads and capacities from 400

to 6500 m/h in vertical or horizontal orientations. The pumps are

of exceptionally compact design and with various nozzle confgura-

tions. All components are sturdy and richly dimensioned to obtain

long-life trouble-free operation. All rotary elements are properly

balanced to ensure safe and reliable operation. The pumps are

equipped with double seals and barrier fuid and on request, also

leakage detection.

Standard materials:

Pump housing: Ni-Al-bronze / nodular cast iron / stainless steel

Impeller: Ni-Al-bronze / stainless steel

Shaft: Stainless steel (Duplex)

Engine room

Cardan Shaft

Deck Seal Unit

Cargo Pump

Driver

Main pump room system components

P

a

n

a

m

a

x

C

r

u

d

e

O

i

l

T

a

n

k

e

r

,

N

a

n

j

i

n

g

O

i

l

D

e

l

i

v

e

r

e

d

f

r

o

m

D

a

l

i

e

n

S

h

i

p

y

a

r

d

2

0

0

1

A

f

r

a

m

a

x

S

h

u

t

t

l

e

T

a

n

k

e

r

,

T

e

e

k

a

y

S

h

i

p

p

i

n

g

D

e

l

i

v

e

r

e

d

f

r

o

m

I

Z

A

R

G

r

o

u

p

1

9

9

9

H

e

a

d

(

m

)

200

180

160

140

120

100

80

60

40

20

Capacity (m

3

/ h)

2

0

0

3

0

0

4

0

0

5

0

0

6

0

0

7

0

0

8

0

0

9

0

0

1

0

0

0

3

0

0

0

4

0

0

0

5

0

0

0

7

0

0

0

6

0

0

0

2

0

0

0

Capacity Range

The CA ballast pumps are specially designed for pumping seawater

at capacities up to 6500 m/h in vertical or horizontal orientations.

The CS range benefts from the same design characteristics as the

CB range.

Standard materials:

Pump housing: Ni-Al-bronze / bronze

Impeller: Ni-Al-bronze

Shaft: Stainless steel (Duplex)

The stripping pump of electrically driven screw type is intended for

stripping pipelines, cargo pumps and separators only.

The TV and TH transmissions are designed for maximum safety and

reliability - with built-in fexibility to compensate for structural varia-

tions. The gas-tight sealing units prevent hazardous gasses from

expelling into the pump room.

The prime movers are placed in the safe-zone of the engine room

allowing free selection of alternative motors depending on power

sources available onboard:

Electrical motors - fange or foot mounted of marine

heavy-duty squirrel type of either single speed,

two-speed or variable speed.

Steam turbines of impulse single or multistage

type with step-less adjustable speed assembled

as one unit.

Diesel engines of 2 or 4 stroke marine

type with clutch.

Main pump room system components

A

f

r

a

m

a

x

S

h

u

t

t

l

e

T

a

n

k

e

r

,

K

n

u

t

s

e

n

O

A

S

D

e

l

i

v

e

r

e

d

f

r

o

m

I

Z

A

R

G

r

o

u

p

2

0

0

0

PA Priming and capacity regulating systems convert any centrifugal

pump into a self-primed unit. This ensures optimal discharge capac-

ity and stripping performances to reduce total discharge time to an

absolute minimum. As the system is capable of emptying the cargo

tanks entirely no separate stripping pump is needed. The complete

process is automatically or manually remotely controlled.

Closing

Valve

Non

Return

Valve

Capacity

Regulating

Valve

Pump

Room

Engine

Room

Control

Unit

Driver

To Discharge Cross-Over

Vacuum

Pump Units

Slop

Tank

Cargo

Tank

Closing

Valve

Closing

Valve

Stripping

Valve

Level

Indicator

Cargo

Pump

Deck

Seal

Unit

Float

Valve

Air / Gas

Separator

Main components:

Air/gas separator with built-in strainer

Vacuum pump units

Capacity regulating valve

Control unit

The stripping system

A

f

r

a

m

a

x

I

c

e

C

l

a

s

s

C

r

u

d

e

O

i

l

T

a

n

k

e

r

,

P

r

i

m

o

r

s

k

S

h

i

p

p

i

n

g

C

o

D

e

l

i

v

e

r

e

d

f

r

o

m

B

r

o

d

o

s

p

l

i

t

2

0

0

4

Type HCCS is a new generation of ship automation systems - with

modular design prepared for expansions. It controls and monitors

the complete cargo and ballast handling process as well as takes

care of all alarm and shutdown functions for maximum safety.

Control panels can be included for installation in the cargo control

room. The system is prepared for easy interconnection at various

levels with other control systems onboard. This forms an integrated

total system onboard.

Load

Calculator

Cargo

Control Valve interface

Level

Gauging

Emergency

Stop

Driver

Control

Unit

Instrument

Interface

Solenoid

Rack

Starters

Driver

Turbine

Driver

El. Motors

Control system diagram

Cargo

Pump

Ballast

Pump

Crude Oil

Washing

Stripping

System

Tank

Pressure

Sensor

Valves

The control system

The Hamworthy valve control system ensures reliable operation of

valves by controlling the volumetric fow. Automatic calibrations

during operation ensure correct valve positioning without any

costly wiring.

Complete through-life support

With a worldwide support and service network Hamworthy is able

to respond to breakdowns within a matter of hours.

From installation to in-service operation, Hamworthy is supported

by dedicated and highly mobile engineers to ensure through-life

operational security and support.

4

2

k

D

W

T

P

r

o

d

u

c

t

T

a

n

k

e

r

,

C

h

i

n

a

S

h

i

p

p

i

n

g

D

e

l

i

v

e

r

e

d

f

r

o

m

G

u

a

n

g

z

h

o

u

S

h

i

p

y

a

r

d

2

0

0

5

A

f

r

a

m

a

x

S

h

u

t

t

l

e

T

a

n

k

e

r

,

K

n

u

t

s

e

n

O

A

S

D

e

l

i

v

e

r

e

d

f

r

o

m

S

a

m

s

u

n

g

2

0

0

4

The manufacturers reserve the right to alter the

specifcation and data to incorporate improvements

in design. Certifed drawings will be issued on request.

All details copyright Hamworthy plc.

Hamworthy Pte Limited

15 Benoi Crescent

Singapore 629978

tel:+65 6261 6066

fax: +65 6261 6011

e-mail: prs@hamworthy.com

web: www.hamworthy.com

r

e

f

:

H

S

I

0

0

0

2

0

4

0

5

/

1

w

w

w

.

i

n

d

o

k

.

n

o

8

7

9

3

You might also like

- Hydrant DrillDocument9 pagesHydrant Drillliao_marco100% (3)

- M Patricia - Pdi0423Document32 pagesM Patricia - Pdi0423Fauzan AriqNo ratings yet

- IAMI Revision QuestionsDocument7 pagesIAMI Revision QuestionsStewart Long100% (1)

- CARTEX Operating Manual Incl - Sctional DRWG Rev 4Document11 pagesCARTEX Operating Manual Incl - Sctional DRWG Rev 4keyur1109No ratings yet

- TP0003 BM Series BulkmeterDocument0 pagesTP0003 BM Series Bulkmeterwferry27No ratings yet

- Nautical Science SyllabusDocument77 pagesNautical Science Syllabusliao_marco100% (1)

- Container Stowage PlanningDocument5 pagesContainer Stowage Planningliao_marcoNo ratings yet

- RT FlexDocument15 pagesRT FlexprasadcshettyNo ratings yet

- Eexi MEPC76-15-Add2 Annex9Document10 pagesEexi MEPC76-15-Add2 Annex9SYAMiLLiONNo ratings yet

- Types and Causes of Engine Room AccidentsDocument3 pagesTypes and Causes of Engine Room AccidentsАлександр КармалитаNo ratings yet

- Kuliah Turbine Gas STT 1Document123 pagesKuliah Turbine Gas STT 1Kristian d hNo ratings yet

- A2 Fore Peak Ballast System On Oil Tankers F44Document1 pageA2 Fore Peak Ballast System On Oil Tankers F44Seong Ju KangNo ratings yet

- 2007 Kobelco Stern Tube Seal Installation ManualDocument18 pages2007 Kobelco Stern Tube Seal Installation Manualvjmariner100% (2)

- Bourbon Front: DP2 Diesel Electric Platform Support Vessel 4,250 T DeadweightDocument2 pagesBourbon Front: DP2 Diesel Electric Platform Support Vessel 4,250 T DeadweightЕгор Лядов100% (1)

- MARINE NOTICE 2-2015 (2) Final Edited VersionDocument8 pagesMARINE NOTICE 2-2015 (2) Final Edited VersionTagel wondimuNo ratings yet

- 7.3NYK Engine Cadet Course Handouts (Air Comp) .Document15 pages7.3NYK Engine Cadet Course Handouts (Air Comp) .rahhul100% (1)

- Me Running HourDocument2 pagesMe Running HourPranay SomaniNo ratings yet

- On Board Diagnostic Linafi Marine Engineering DepartmentDocument34 pagesOn Board Diagnostic Linafi Marine Engineering DepartmentAtem JuniorNo ratings yet

- Ur-Z7-Rev26-Jan-2018-Cln (1) Hull Classification SuveysDocument51 pagesUr-Z7-Rev26-Jan-2018-Cln (1) Hull Classification SuveysJohnNo ratings yet

- M2 Pipe Identification Tape To ISO14726 Technical MaritimeprogresDocument1 pageM2 Pipe Identification Tape To ISO14726 Technical Maritimeprogresxfile34No ratings yet

- Man-Es l3 Man L48-60cr-Propulsion PreviewDocument2 pagesMan-Es l3 Man L48-60cr-Propulsion PreviewPiotrNo ratings yet

- Ajit Vadakayil - Deepwell Pumps On Chemical Tankers - Capt Ajit VadakayilDocument24 pagesAjit Vadakayil - Deepwell Pumps On Chemical Tankers - Capt Ajit VadakayilMannMannNo ratings yet

- What Are Ship Bottom Plugs or Dock PlugsDocument11 pagesWhat Are Ship Bottom Plugs or Dock PlugsstamatisNo ratings yet

- (Vol VII), 2021 Rules For Small Vessels Up To 24 M, 2021Document261 pages(Vol VII), 2021 Rules For Small Vessels Up To 24 M, 2021Rahmat IbrahimNo ratings yet

- Dimensi MesinDocument28 pagesDimensi MesinSyahrir QoimNo ratings yet

- Cy - Head 2strokeDocument33 pagesCy - Head 2strokeغازي عليNo ratings yet

- Primavac System - 2Document36 pagesPrimavac System - 2UmairNo ratings yet

- Bunkering FormulasDocument6 pagesBunkering FormulasΜπαμπης Παναγιωτιδης100% (1)

- DEF STAN 02-848 Part 1 Iss.4Document20 pagesDEF STAN 02-848 Part 1 Iss.4liammusson56No ratings yet

- Alfa Laval Fuel Conditioning Module For Methanol (Meoh) : Low-Flashpoint Fuel Supply System For Me-Lgi EnginesDocument2 pagesAlfa Laval Fuel Conditioning Module For Methanol (Meoh) : Low-Flashpoint Fuel Supply System For Me-Lgi EnginesSamo SpontanostNo ratings yet

- Wartsila 20121 PDFDocument53 pagesWartsila 20121 PDFDan Alin Mircea100% (1)

- ABS Regulatory News - MARPOL Sampling PointsDocument2 pagesABS Regulatory News - MARPOL Sampling Pointssjsship100% (1)

- Man v51 E2f3Document2 pagesMan v51 E2f3Fandy Ahmad HasanuddinNo ratings yet

- 909 - Fuel Oil System: Documents in This ChapterDocument46 pages909 - Fuel Oil System: Documents in This ChapterAkhil Mathew100% (1)

- LR - Class - News - 02.2022 MARPOL Ann VI Fuel Oil Sampling PointDocument3 pagesLR - Class - News - 02.2022 MARPOL Ann VI Fuel Oil Sampling PointTomas CasisNo ratings yet

- (Vol B), 2018 Guidance For Class Notations, 2018Document93 pages(Vol B), 2018 Guidance For Class Notations, 2018imam alfariziNo ratings yet

- BWM Electrolysis TypeDocument4 pagesBWM Electrolysis TypeAldo Sitorus100% (1)

- TIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas EconomizerDocument6 pagesTIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas Economizerajshsu5682No ratings yet

- MT Adara Routine Inspection and Audit Report PDFDocument28 pagesMT Adara Routine Inspection and Audit Report PDFelisalde fantilloNo ratings yet

- Vaf Lorcon ManilaDocument61 pagesVaf Lorcon ManilaJamie Coleman100% (1)

- 70m 120T Bollard Pull 10,800HPDocument1 page70m 120T Bollard Pull 10,800HPMohd ZaidNo ratings yet

- Khaleda Shipping SDN BHD: Sea Service TestimonialDocument1 pageKhaleda Shipping SDN BHD: Sea Service TestimonialArafatul AlamNo ratings yet

- Shell Argina S2 40 TDSDocument2 pagesShell Argina S2 40 TDSDonny HendrawanNo ratings yet

- Bunker SampleDocument4 pagesBunker Sampledassi99No ratings yet

- V 10 WCMBR Sewage Treatment Unit CatalougeSILI PUMPDocument4 pagesV 10 WCMBR Sewage Treatment Unit CatalougeSILI PUMPRokhmatuSivaNo ratings yet

- YSZ Series 15 PPM Bilge Water SeparatorDocument3 pagesYSZ Series 15 PPM Bilge Water Separatorthu aungNo ratings yet

- Chemical Tanker Made Simple v5Document204 pagesChemical Tanker Made Simple v5onur2613No ratings yet

- CLC and Fund Convention: ObjectivesDocument2 pagesCLC and Fund Convention: ObjectivesRiteshNo ratings yet

- Different Bulk Carriers ActivitiesDocument2 pagesDifferent Bulk Carriers ActivitiesKarina EcayNo ratings yet

- 08.KS, KF E992-1103-02Document37 pages08.KS, KF E992-1103-02juho5305No ratings yet

- Container Vessel: Reefers/ContainersDocument5 pagesContainer Vessel: Reefers/ContainersErmanda Mesquita SoaresNo ratings yet

- Brake Test KitDocument2 pagesBrake Test KitBadea IonelNo ratings yet

- Pa ManuelDocument82 pagesPa ManuelThanh Nghị BùiNo ratings yet

- Fuel Oil PurifierDocument7 pagesFuel Oil PurifiermagicalseasNo ratings yet

- Ship Survey Status: Tirumala GasDocument27 pagesShip Survey Status: Tirumala GasHoa LuuNo ratings yet

- Desain Bilga KapalDocument1 pageDesain Bilga Kapalhimmawan aan listyantoNo ratings yet

- 0404 - A - Complete The Annual Servicing On Both Gyro Compass UnitsDocument3 pages0404 - A - Complete The Annual Servicing On Both Gyro Compass UnitsYaw AndersonNo ratings yet

- Crosshead LubricationDocument4 pagesCrosshead Lubricationrajishrrr100% (1)

- Pump Room SystemsDocument8 pagesPump Room SystemsArdyas Wisnu Baskoro100% (1)

- Hamworthy Pump Room SystemsDocument45 pagesHamworthy Pump Room SystemspetertaboadaNo ratings yet

- Electric Submersible Sewage PumpsDocument8 pagesElectric Submersible Sewage PumpsMiroslavCrnogoracNo ratings yet

- Eureka FW LeafletDocument12 pagesEureka FW LeafletJay JayNo ratings yet

- Marine Pumps and EquipmentDocument34 pagesMarine Pumps and EquipmentmavericksailorNo ratings yet

- JASON Felles Brosjyre LavoppDocument11 pagesJASON Felles Brosjyre Lavoppliao_marcoNo ratings yet

- JASON Felles Brosjyre LavoppDocument11 pagesJASON Felles Brosjyre Lavoppliao_marcoNo ratings yet

- Honbun-5518 00Document22 pagesHonbun-5518 00liao_marcoNo ratings yet

- Approach Channels DesignDocument22 pagesApproach Channels DesignjetsonpNo ratings yet

- Heavy Containers Over Light ContainersDocument4 pagesHeavy Containers Over Light Containersliao_marcoNo ratings yet

- Guidance For Naval ArchitectsDocument44 pagesGuidance For Naval Architectsliao_marco100% (1)

- Container Shipping Course ModuleDocument49 pagesContainer Shipping Course Moduleliao_marcoNo ratings yet

- CS MD08 Oct 2011Document18 pagesCS MD08 Oct 2011liao_marcoNo ratings yet

- CantoneseDocument43 pagesCantoneseliao_marcoNo ratings yet

- GSKDocument6 pagesGSKliao_marco100% (1)

- A Model For The Stowage Planning of 40 Feet Containers at Container TerminalsDocument9 pagesA Model For The Stowage Planning of 40 Feet Containers at Container Terminalsliao_marcoNo ratings yet

- Operation and Performance Test On A Steam Engine: de La Salle UniversityDocument7 pagesOperation and Performance Test On A Steam Engine: de La Salle UniversityNazario Emil LintagNo ratings yet

- Atlas Copco Construction Tools - Facts BookDocument144 pagesAtlas Copco Construction Tools - Facts Bookmnowaq100% (1)

- Three Phase LocomotiveDocument138 pagesThree Phase LocomotiveManas Moharana67% (3)

- Specs x35 TM T - Jy-SignedDocument2 pagesSpecs x35 TM T - Jy-SignedAndrés IzaNo ratings yet

- O300DDocument1 pageO300DAndreyNo ratings yet

- Synerject Asdi Sepi PDFDocument22 pagesSynerject Asdi Sepi PDFModesto Olmedo RamirezNo ratings yet

- Mechanical Technician: Babu.M Tamil Nadu, IndiaDocument4 pagesMechanical Technician: Babu.M Tamil Nadu, Indiajohn MNo ratings yet

- D10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesD10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsEdison PondaNo ratings yet

- Quote Summary: Nandini BisoyDocument25 pagesQuote Summary: Nandini BisoyBhushanNo ratings yet

- General Electric: Lessons in Strategic Management: P.R. BhattDocument8 pagesGeneral Electric: Lessons in Strategic Management: P.R. BhattLM_SNo ratings yet

- CH 19Document28 pagesCH 19lule latifiNo ratings yet

- POLAR Rotary Screw Manual - EM-RTS - 5-13Document22 pagesPOLAR Rotary Screw Manual - EM-RTS - 5-13Aaron ArceNo ratings yet

- Lister Type Slow Speed Diesel Engine Custom Builts Engine Order FormDocument1 pageLister Type Slow Speed Diesel Engine Custom Builts Engine Order FormhamadaeidNo ratings yet

- Chapter 8 - Transport, Energy and Environment: Paradoxical Environmental SystemsDocument24 pagesChapter 8 - Transport, Energy and Environment: Paradoxical Environmental SystemsRomani Noel S. Chavez Jr.No ratings yet

- Lista Comandos WindowsDocument6 pagesLista Comandos Windowsdiogenes torresNo ratings yet

- Operator S Manual: Model Series 760-770 Lawn TractorDocument108 pagesOperator S Manual: Model Series 760-770 Lawn Tractorb2gk99hmxzNo ratings yet

- Unit 3 - Steam and Gas TurbinesDocument94 pagesUnit 3 - Steam and Gas TurbinesDHANASEKAR K IV A 9023No ratings yet

- 2276 Design Manufacturing and Operation of A Small Turbojet Engine For Research Purposes807fDocument15 pages2276 Design Manufacturing and Operation of A Small Turbojet Engine For Research Purposes807fÃn ÍsNo ratings yet

- Diesel Engine Starting SystemDocument25 pagesDiesel Engine Starting SystemAbrar Hussain100% (1)

- 13 Chapter Energy AuditDocument24 pages13 Chapter Energy AuditShir Ahmad LaiwalNo ratings yet

- Gujarat Technological University: Bachelor of EngineeringDocument3 pagesGujarat Technological University: Bachelor of EngineeringJigneshkumar PatelNo ratings yet

- Pre-Delivery Information Form: SP1850 SP2254Document1 pagePre-Delivery Information Form: SP1850 SP2254Esteban MunaresNo ratings yet

- Ukuran ForkliftDocument15 pagesUkuran ForkliftJefa DanarNo ratings yet

- Florabest FBS 43b2 ManualDocument15 pagesFlorabest FBS 43b2 ManualJohn Estick100% (1)

- Wo 2013104040 A 1Document5 pagesWo 2013104040 A 1Mladen MuskinjaNo ratings yet

- Technical Writing Seminar PDFDocument82 pagesTechnical Writing Seminar PDFallen.20.79308No ratings yet

- Suspension Active TPDocument210 pagesSuspension Active TPmajdoubNo ratings yet

- Adzer CZDeutz F2 L912Document82 pagesAdzer CZDeutz F2 L912Alex Robledo OlarteNo ratings yet

- Design of IC EngineDocument30 pagesDesign of IC EngineAshitosh SinghNo ratings yet