May May: E Lighting

Uploaded by

reacharunkCopyright:

Available Formats

May May: E Lighting

Uploaded by

reacharunkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

May May: E Lighting

Uploaded by

reacharunkCopyright:

Available Formats

6-42

I E S LIGHTING HANDBOOK

Operation of ordinary lamps at low ambient temperatures and in loca-

tions exposed to high winds results in below-optimum, bulb-wall tempera-

tures and low lumen output per watt. However, a special lamp, designed

and manufactured with a higher vapor pressure for operation at low tem-

perature, may have quite good lumen output per watt under similar con-

ditions. Starting difficulties encountered at low temperature with pre-

heat-type lamps may be minimized by the use of a thermal switch starter.

Hours in operation. Like that of other light sources, the lumen out-

put of fluorescent lamps decreases as the hours the lamps are operated

increase. Although the exact nature of the change of the phosphor

which causes the phenomenon is not understood, it is known that at least

during the first 4,000 hours of operation the reduction in lumen output

per watt is directly related to the arc-power: phosphor-area ratio.

32

This

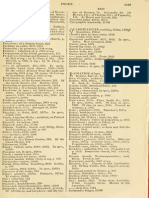

relationship in several typical lamps is shown in Fig. 6-39a. As would be

expected, lamps with different arc power-phosphor area ratios have differ-

ent lumen maintenance curves, as shown in Fig. 6-396.

Fluorescent lamp life and lamp starting.

Hours operation per start. The oxide cathode coating must be in good

condition to ensure proper starting at rated voltage of the preheat-starting

fluorescent lamp. However, each time a preheat-type lamp is started a

small amount of the oxide coating is consumed. A sufficient quantity of

the material may be removed in about one thousand starts to cause starting

failures. For this reason, the average life of these lamps is rated on the

basis of hours operation per start. See Tables 6-9 and 6-10.

Because the proper starting of cylindrical (cold) cathode lamps depends

primarily on a high voltage rather than on the oxide coating of the cathodes,

the life of this type of lamp is not appreciably affected by starting frequency.

Effect of

voltage and humidity on starting. To start a fluorescent lamp

requires a higher voltage than is necessary to keep the lamp in operation

once it has been started. Although all aspects of starting phenomena have

not been explained, it is believed, on the basis of one theory which fits the

available experimental data reasonably well, that capacitive current in the

lamp is a necessary prerequisite to starting of the lamps now available.

34

The two methods used are called preheat ("hot") starting and instant

("cold") starting. The usual sequences are:

Preheat starting: (a) A heating current is passed through the electrodes

and electrons are ejected from the electrodes by thermionic emission,

(b) Upon the application of a transient (600-1,200 volts) provided by the

ballast and timed by a manual or automatic starting switch, electrons will

flow through the tube, ionize the gases, and initiate a mercury vapor dis-

charge.

Instant starting: (a) By the application of a high open circuit voltage

(400-3,000 volts depending on the type of lamp and electrode) electrons

are ejected by field emission from the electrodes, (b) Electrons will flow

through the tube, ionize the gases, and initiate a mercury vapor discharge.

The high-voltage transient induced by rapid dissipation of the ballast

magnetic field upon separation of the contacts of the starter switches

You might also like

- 2003 Camry Diagnostic Trouble Code Chart DtcengNo ratings yet2003 Camry Diagnostic Trouble Code Chart Dtceng8 pages

- Osram HBO Guide For Design of Equipment Brochure 1975No ratings yetOsram HBO Guide For Design of Equipment Brochure 19756 pages

- Have You Ever Wondered How A Fluorescent Light Works? Even Though They're Nearly As100% (2)Have You Ever Wondered How A Fluorescent Light Works? Even Though They're Nearly As4 pages

- Gaseous Discharge Lamps:: UNIT-5 Various Illumination MethodsNo ratings yetGaseous Discharge Lamps:: UNIT-5 Various Illumination Methods17 pages

- 5.4.2 - Induction and Dielectric Heating 1No ratings yet5.4.2 - Induction and Dielectric Heating 127 pages

- Sylvania Engineering Bulletin - Mercury Lamps 1977100% (1)Sylvania Engineering Bulletin - Mercury Lamps 197720 pages

- Electronic Ballast Fundamentals: Dr. Bryan M.H. Pong Hong Kong UniversityNo ratings yetElectronic Ballast Fundamentals: Dr. Bryan M.H. Pong Hong Kong University23 pages

- Osram HBO Super Pressure Mercury Lamps Catalog 1977No ratings yetOsram HBO Super Pressure Mercury Lamps Catalog 19778 pages

- Arc Protection As Integrated Part of Line Protection RelaysNo ratings yetArc Protection As Integrated Part of Line Protection Relays7 pages

- Information Sheet 5.1 Fluorescent Lighting FixturesNo ratings yetInformation Sheet 5.1 Fluorescent Lighting Fixtures17 pages

- Osram Light For Cine Projection Technology & Science Catalog 1979100% (1)Osram Light For Cine Projection Technology & Science Catalog 197952 pages

- Sylvania Engineering Bulletin - Metalarc Lamps 1986No ratings yetSylvania Engineering Bulletin - Metalarc Lamps 198620 pages

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition Apparatus3/5 (1)

- LRL Accelerators, The 184-Inch SynchrocyclotronFrom EverandLRL Accelerators, The 184-Inch SynchrocyclotronNo ratings yet

- Young Uzbeks are finding new markets for traditional handicrafts online _ CNN BusinessNo ratings yetYoung Uzbeks are finding new markets for traditional handicrafts online _ CNN Business8 pages

- General Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja InsuranceNo ratings yetGeneral Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja Insurance19 pages

- And Rome.: in Front of The Prostyle Existed atNo ratings yetAnd Rome.: in Front of The Prostyle Existed at1 page

- The The Jamb The Name Much The: Tlio CL - AssesNo ratings yetThe The Jamb The Name Much The: Tlio CL - Asses1 page

- Chapter 2 Tensegrity 60 Years of Art, Science, and EngineeringNo ratings yetChapter 2 Tensegrity 60 Years of Art, Science, and Engineering77 pages

- Metal Detection and Classifi Cation Technologies: Carl V. NelsonNo ratings yetMetal Detection and Classifi Cation Technologies: Carl V. Nelson6 pages

- User's Manual: Oil Content Meter Model GQS-206No ratings yetUser's Manual: Oil Content Meter Model GQS-20619 pages

- Oracle Apps R12 - Backup Using Rapid Clone: Space) (Appldev@testerp (Root@testerp) # Du - CH - Grep TotalNo ratings yetOracle Apps R12 - Backup Using Rapid Clone: Space) (Appldev@testerp (Root@testerp) # Du - CH - Grep Total28 pages

- FP - B.1 - MSR - Neutral Earthing Resistors and Temperature Coefficient - 1 PDFNo ratings yetFP - B.1 - MSR - Neutral Earthing Resistors and Temperature Coefficient - 1 PDF16 pages

- Activity 02 Nyu - Physical - Computing - Activity1 - Act2makingledblinkas - v2 - TedlNo ratings yetActivity 02 Nyu - Physical - Computing - Activity1 - Act2makingledblinkas - v2 - Tedl4 pages