100%(1)100% found this document useful (1 vote)

629 viewsVaillant Commercial Range Brochure

Vaillant Commercial Range Brochure

Uploaded by

andreiasbdThis document discusses Vaillant's commercial heating systems. It describes Vaillant as a family owned global company that pioneers innovative heating products. It highlights Vaillant's ecoTEC line of wall hung condensing boilers for commercial use, including the ecoTEC 46 and 65 models. The ecoTEC boilers offer high efficiency, modulating burners, and easy installation features. The document also provides an example of Vaillant ecoTEC 65 boilers being installed at the Le Personne Trust to replace older, less efficient boilers and cut heating costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Vaillant Commercial Range Brochure

Vaillant Commercial Range Brochure

Uploaded by

andreiasbd100%(1)100% found this document useful (1 vote)

629 views45 pagesThis document discusses Vaillant's commercial heating systems. It describes Vaillant as a family owned global company that pioneers innovative heating products. It highlights Vaillant's ecoTEC line of wall hung condensing boilers for commercial use, including the ecoTEC 46 and 65 models. The ecoTEC boilers offer high efficiency, modulating burners, and easy installation features. The document also provides an example of Vaillant ecoTEC 65 boilers being installed at the Le Personne Trust to replace older, less efficient boilers and cut heating costs.

Original Description:

Vaillant brochure, domestic and commercial heating and hot water technology

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document discusses Vaillant's commercial heating systems. It describes Vaillant as a family owned global company that pioneers innovative heating products. It highlights Vaillant's ecoTEC line of wall hung condensing boilers for commercial use, including the ecoTEC 46 and 65 models. The ecoTEC boilers offer high efficiency, modulating burners, and easy installation features. The document also provides an example of Vaillant ecoTEC 65 boilers being installed at the Le Personne Trust to replace older, less efficient boilers and cut heating costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

629 views45 pagesVaillant Commercial Range Brochure

Vaillant Commercial Range Brochure

Uploaded by

andreiasbdThis document discusses Vaillant's commercial heating systems. It describes Vaillant as a family owned global company that pioneers innovative heating products. It highlights Vaillant's ecoTEC line of wall hung condensing boilers for commercial use, including the ecoTEC 46 and 65 models. The ecoTEC boilers offer high efficiency, modulating burners, and easy installation features. The document also provides an example of Vaillant ecoTEC 65 boilers being installed at the Le Personne Trust to replace older, less efficient boilers and cut heating costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 45

At a glance

Powered by AI

Vaillant is a global family owned company that has pioneered heating products and solutions. They offer a range of commercial boilers, renewables and controls.

Vaillant offers large output commercial condensing boilers, renewable solutions like solar thermal and heat pumps, and products that can be installed in a cascade formation.

Vaillant provides services like sales support, technical assistance, training courses and bespoke solutions for specifiers. They also aim to offer service excellence before, during and after installation.

Commercial Systems

Why Vaillant commercial? 04

'The Vaillant Experience' 06

Our systems 08

ecoTEC 10

Cascade rigs 43

ecoCRAFT 44

atmoCRAFT 58

Renewables 64

Controls 66

System accessories 74

Cylinders 80

Customer service support 82

3 2

Why Vaillant commercial?

A family owned global company

As a renowned global family owned company, we have

pioneered products that have revolutionised the

heating industry. Today, our innovative solutions are

still setting the standards in the heating market place.

Whether its our large output wall hung and oor

standing condensing commercial boilers - with the

ability to install into a cascade formation - or our

commercial renewable solutions including solar

thermal and heat pumps, capable of providing heating

and hot water to large scale commercial applications.

All are designed to push Vaillant to the forefront

of technology.

Pioneering commercial heating and

renewable products

Vaillant is not only looking forward in terms of its

products. For just about as long as weve been creating

appliances that transform the heating industry, weve

also been focusing on developing better and more

productive relationships with you - our customers.

Thats because we know that the partnerships we

establish with speciers, consultants, engineers and

installers are key to our continued future success -

and the success of our partners' businesses.

Unwavering service

The commercial industrys most advanced heating

solutions go hand in hand with the industrys most

developed and forward thinking service solutions.

At Vaillant theres an unwavering commitment to

providing service excellence before, during and after

the installation of the Vaillant appliance. In fact we

look after the project from conception to solution

and, through our service back up, afterwards as well.

Europes leading heating technology manufacturer

These combined objectives - to deliver the best

products and to provide the best service to you -

are the twin driving forces that keep Vaillant out in

front as Europes market leading heating technology

manufacturer.

For over 135 years Vaillant has been leading the way in the development of domestic and commercial

heating and hot water technology.

5 4

Our training courses are designed for Gas Safe

Registered Installers, low carbon and renewable

technology installers, local authorities, housing

associations, architects, speciers, merchants and

stockists. As the industrys leading training provider,

we offer an all-encompassing range of courses on

domestic boilers, cylinders, solar domestic hot water

systems, air to air heat pumps, commercial boilers,

certication in energy efciency, combustion analyser

assessment, ground source and air to water heat

pumps, domestic controls, mechanical ventilation

heat recovery and MCS Quality Management.

Training is provided in the main at six Vaillant

Centres of Excellence. These spacious state of the art

facilities offer a comfortable and superbly equipped

training environment, with plenty of opportunities

for hands-on experience and product familiarisation.

These centres are also conveniently located around

the country at Maidstone, Elland (near Leeds), Belper

(near Derby), Cambridge, Bristol and Central Scotland,

with a further centre opening soon in Ireland. So, rest

assured theres a centre within easy reach, wherever

you are.

As well as training, these centres offer our customers

a unique opportunity to nd out more about Vaillants

full range of services and any upcoming product

developments. Giving you the skills, knowledge and

understanding to help you take your business forward.

Its further testament to the fact that Vaillant isnt just

giving the end user the products they want were

also committed to providing our industry partners

with the tools to achieve future success.

For more information or to visit one of our Centres

of Excellence call 0845 601 8885 or

email training@vaillant.co.uk

The Vaillant Experience

Central Scotland

Elland(Leeds) Belper (Derby)

Cambridge

Bristol

Maidstone

7 6

The Vaillant Experience demonstrates that we strive to be the best in all we do and that Vaillant has

always stood for premium quality. So, when it comes to customer training, you know youre getting

the best the industry can offer.

S

e

r

v

i

c

e

Our systems

9 8

The world is changing and, just as we recognise the

importance of developing ever more sustainable

heating solutions for the home, Vaillant is also

harnessing its unrivalled expertise to deliver these

same technological advances to the commercial

heating environment.

For instance, we have developed a range of large

output boilers that has the ability to cascade and has

been designed specically to meet the requirements

of the commercial installation.

Furthermore, Vaillant is leading the way in commercial

systems that utilise renewable energy sources.

Alongside sustainability, Vaillant places a major

emphasis on integration. So, not only are we

developing class leading boilers, cylinders, controls,

solar systems and other renewable products were

also making sure that they all blend seamlessly

together. A total system solution that is ideal for a

whole host of commercial specications, whether the

businesses are large or small.

The Vaillant name has long been associated with technological advances in the heating and hot water

industry. Today, as well as focusing our energies on taking home heating comfort to a new level, we are

applying this passion for innovation to the commercial arena.

11 10

ecoTEC

Wall hung condensing boiler range

ecoTEC 46 & 65

Two models

ecoTEC 46

heat output range (heating 50/30C) 12.9 - 46.4kW

heat output range (heating 80/60C) 12.3 - 44.1kW

ecoTEC 65

heat output range (heating 50/30C) 14.6 - 67.6kW

heat output range (heating 80/60C) 13.7 - 63.7kW

High performance

High efciency SEDBUK 2005 band A rating

Fully modulating low NOx burner and fan (Class 5)

Heating output up to 65kW

Stainless steel heat exchanger

Easy installation

Case dimensions:

ecoTEC 46 H800mm x W480mm x D450mm

ecoTEC 65 H800mm x W480mm x D472mm

Connections:

1

1

/4 female BSP ow and return service valves

1 female BSP gas service valve

Gas - 20mm with adapter for 1 (ecoTEC 46)

25mm with adapter for 1 (ecoTEC 65)

Pressure safety valve outlet -

3

/4 female BSP

(ecoTEC 46) 1 female BSP (ecoTEC 65)

Condensate 19mm

Combined lling/emptying valve on return pipe

All major components built-in:

Siphonic condensate discharge (ecoTEC 65 only)

Condensate trap (ecoTEC 46)

Energy saving 2-stage frost protection

0 10v compatible for BEMS applications

(via VR34 accessory)

8m head shunt pump

Pressure sensor to monitor system pressure

via diagnostics

Flow sensor to monitor water ow through boiler

Air separator with auto air vent and lter for

bleeding system and ltering of ne particles

Push-t ue system

LPG conversion kit available (ecoTEC 46 only)

Full range of intelligent eBUS controls including

weather compensators and multiple boiler

management controls available

Flexible siting

Flue lengths up to 18m horizontal or 21m vertical

with 125mm ue

Optional 125mm stainless faade kit available

3 bar PRV

IP X 4D electrical safety rating

No compartment ventilation needed*

Easy service and repair

Built-in comprehensive boiler status/diagnostic

display system

Blue backlit display for easy reading

Easy access to all components from the front

Single electronic circuit board

Flue gas analysis point

Quality and reliability

Stainless steel heat exchanger

Production to ISO 9001

2-year guarantee on boiler

Commissioning service available

High efciency condensing gas system boilers

With a whole host of built-in features, installation and servicing of ecoTEC commercial boilers could not be

more straightforward. Lightweight for its class, compact design, and a comprehensive range of ues, ttings

and accessories means that ecoTEC boilers can be sited almost anywhere. For larger buildings, or buildings

with more complex layouts, multiple boilers can be installed in cascade to provide a highly effective and

extremely efcient heating system. They are congured to automatically optimise heat and hot water supply

according to the demands on the system at any particular time.

* See BS6644 for more specic advice if appliance installed in boiler room/enclosure

13 12

15 14

Client:

Le Personne Trust

Contractor:

S&S Engineering Ltd

Project:

Commercial heating solution

When the Le Personne Trust in Caterham, Surrey,

needed a highly efcient and economical heating

solution to help cut heating bills, only one

manufacturer truly tted the bill Vaillant.

Meeting the challenge

Le Personne Trust was established in 1941 from a

legacy from Mr Louis Le Personne in memory of his

wife, Henrietta Frances, who was the rst lady County

Councillor in Surrey. The Trust has been providing

affordable housing for the elderly ladies of Caterham

for 58 years. The original buildings, constructed in

1952, have since been extended in order to increase

the accommodation available from 23 ats to 44.

Providing the solution

During the recent modernisation phase, outside

consultants were employed to advise the Trust on

how to make the buildings more energy efcient.

One of the recommendations made to the Trust was

to upgrade the existing heating and hot water system

for something more energy efcient. Vaillant products

were recommended for this project because of their

reliability and Vaillants excellent technical support

services. Following this recommendation, six Vaillant

ecoTEC 65 commercial boilers were installed by S&S

Engineering Ltd to replace three inefcient boilers.

Enjoying the benet

The six ecoTECs now successfully meet the hot water

and heating requirements of all 44 ats and communal

areas, which continue to provide affordable housing

for elderly ladies.

Dave Yarwood, Maintenance Manager, Le Personne

Trust, commented:

Our residents feel the cold. Boilers here run 24 hours

a day, 365 days a year, so its vital they are as efcient

as possible. Were really pleased with ecoTEC; our gas

bills have noticeably reduced since installation.

ecoTEC 46 & 65

Case study - Le Personne Trust

ecoTEC 46 & 65

System design

1 2

3

14

7

8

9

8

10

12 13

Variable temperature

mixing circuit HK2

Variable temperature

direct circuit HK1

Hot water circuit

VRC 470

VRC 693

outdoor sensor

15

VR 61/2 wiring

centre

VR 81/2

19

18

17

16

11 11

H

K

2

c

irc

u

it

m

ix

in

g

v

a

lv

e

BUS 230 volt

E N L E N L E N L E N L E N

LP / ZP HK2-P

m

a

in

s

in

p

u

t

c

o

n

n

e

c

tio

n

e

B

U

S

Lowvoltage terminals 230 mains voltage terminals

Vaillant VR 61/2 Extension Module

VF2

2 1

HK2

o

p

e

n

clo

se HK1-P

H

K

1 c

irc

u

it

p

u

m

p

H

K

2

c

irc

u

it

P

u

m

p

H

K

2

c

irc

u

it

s

e

n

s

o

r

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F0 1 2 7 8 9 - + L N E 3 4 5

L N E L N E

X6 X13

BUS 24 volt 230 volt

ecoTEC 466 & 656 / ecoCRAFT boiler terminals

safety

circuit

boiler

enable

230 mains voltage terminals Lowvoltage terminals

VRC 693

outdoor

sensor

V

R

10

lo

w

lo

s

s

h

e

a

d

e

r s

e

n

s

o

r

Hot water secondary

circulation pump

(set ecoTEC parameter

d.26 to No 1)

Vaillant VR81

For use on HK2 set address to A2

C

y

lin

d

e

r

p

rim

a

ry

p

u

m

p

L

P

o

r s

e

c

p

u

m

p

Z

P

Please note:

The default setting in the VRC 470 program

for the LP/ZP output is ZP which will switch

on the cylinder secondary pump. If this

connection is to be used for the cylinder

primary pump (as shown), then the LP/ZP

relay connection setting in the installer level

systemconfiguration screen for hot water will

need to be set to LP

Cylinder Pump

Cylinder

sensor

Cylinder sensor

connector inside

boiler plug must be

cut off and joined

using connector block

2 & C

Cylinder high limit thermostat

(uniSTOR cylinders only remove wire link)

Pump 1 Pump 2

Vaillant VRC 470 controller

If used with VR61 and two heating zones this must

be wall mounted to control the temperature of the

heating circuit.

Strap sensor

to flowpipe

after pump for

this circuit

Note:

1. All electrical connections to the equipment must be in accordance

with current IEE Wiring Regulations.

2. For drawing clarity, some earth wires have been omitted;

these must be included on the installation.

VR 10 sensor

V

R

10

s

e

n

s

o

r

Vail Vail ail Vail Vailllant ant lant lant VVRC 470 controller

If used with VR61 and two heating zones this must

be wall mounted to control the temperature of the

heating circuit.

Unvented

hot water

cylinder

motorised valve

Vaillant VR81

For use on HK2 set address to A2

Key

1. Boiler flow isolation valve (supplied only with ecoTEC)

2. Boiler return isolation valve (supplied only with ecoTEC)

3. Boiler safety valve (supplied only with ecoTEC)

4. Boiler shunt pump (supplied internally with ecoTEC 46 & 65,

available as an accessory with ecoTEC 80, 100 & 120 and

ecoCRAFT 80 - 280 ranges)

5. Single check valve required (supplied only with cascade rigs)

6. Primary pressurisation unit (available as an accessory)

7. Primary expansion vessel (available as an accessory)

8. Heating pumps

9. System check valve

10. Heating circuit mixing valve

11. Service valves (not supplied by Vaillant)

12. Cylinder primary pump

13. Cylinder motorised valve (supplied only with uniSTOR cylinder)

14. Dirt separator or strainer (available as an accessory)

15. Low loss header (available as an accessory)

16. Low loss header VR 10 sensor (supplied with VRC 630 controller)

17. Heating circuit VR 10 sensor (supplied with VRC 630 controller)

or VR 692 clip on pipe sensor (available as an accessory)

18. Cylinder VR 10 sensor (supplied with VRC 630 controller)

19. Cylinder high limit thermostat

(supplied only with uniSTOR cylinder)

Wiring Colours

purple eBUS

green sensors

blue 230 volt

Note items are not supplied by Vaillant unless stated

17 16

A typical single boiler installation

Note:

1. Vaillant strongly recommends the installation of a suitably

sized dirt separator in the return pipe work to the header

or system separation plate heat exchanger, particularly in

the case of old systems.

2. The schematic drawings depicted in this brochure are a

suggested layout of a typical system and should not be

solely relied upon as a definitive design.

1 1 2 2

3 3

5 5

14

7

8

6

9

3

1 2

5

15

Variable temperature

mixing circuit HK3

8 8

10 10

11 11

12

13

Variable temperature

mixing circuit HK2

Variable temperature

direct circuit HK1

Hot water circuit - SP

VR 90 zone

controller

VR 90 zone

controller

VRC 630 boiler

management system

VRC 693

outdoor sensor

16

17 17

18

19

VR 90 zone

controller

VRC 630 boiler

zone

oller oller

System design

A typical cascade boiler installation

19 18

ecoTEC 46 & 65

VR 10 sensor

VR 10 sensor

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

1 b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

1.

VR 10 sensor

U

n

v

e

n

te

d

h

o

t

w

a

te

r

c

y

lin

d

e

r

m

o

to

r

is

e

d

v

a

lv

e

2

&

C

C

y

lin

d

e

r

h

ig

h

lim

it

th

e

r

m

o

s

ta

t (u

n

iS

T

O

R

c

y

lin

d

e

r

o

n

ly

r

e

m

o

v

e

w

ir

e

lin

k

)

B

U

S

+_

B

U

S

+_

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

2

b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

2

.

C

y

lin

d

e

r

p

r

im

a

r

y

p

u

m

p

2

3

0

v

o

lt

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

2

3

0

v

o

lt

L

P

/

U

V

1

Z

P

H

K

1-P

H

K

2

H

K

2

-P

H

K

3

-P

K

P

/

A

V

E

N

O

n

O

ff

S

tu

fe

1

2

1

S

tu

fe

2

2

1

mains output

to external

VR 60

mains input

connection

6 amps

HK3 circuit

pump

not used

not used

not used

1 2

V

F

1

1 2

V

F

2

1 2

V

F

3

1 2

K

F

1 2

S

P

1 2

1x

Z

P

1 2

T

e

l

-+B

U

S

D

C

F

/0

/A

F

C

2

C

1

9

8

7

I

9

8

7

II

lowloss

header

HK 2 sensor

HK3 sensor

not used

not used

telephone activation

switch not used

eBUS

outside

temperature

sensor

L

o

w

v

o

lta

g

e

te

r

m

in

a

ls

2

3

0

m

a

in

s

v

o

lta

g

e

te

r

m

in

a

ls

V

a

illa

n

t V

R

C

6

3

0

C

o

n

tr

o

lle

r

not used

not used

not used

o p e n

c l o s e

E

N

H

K

3

o p e n

c l o s e

HK1 circuit

pump

HK2 circuit

pump

Cylinder

sensor

Cylinder

motorised

valve

Hot water

secondary

pump

HK3 circuit

mixing valve

HK2 circuit

mixing valve

B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

1

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

1.

B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

2

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

2

.

B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

3

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

3

.

VR 10 sensor

B

U

S

+_

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

3

b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

3

.

N

o

t

e

:

1. A

ll e

le

c

tr

ic

a

l c

o

n

n

e

c

tio

n

s

to

th

e

e

q

u

ip

m

e

n

t m

u

s

t b

e

in

a

c

c

o

r

d

a

n

c

e

w

ith

c

u

r

r

e

n

t IE

E

W

ir

in

g

R

e

g

u

la

tio

n

s

.

2

. F

o

r

d

r

a

w

in

g

c

la

r

ity

, s

o

m

e

e

a

r

th

w

ir

e

s

h

a

v

e

b

e

e

n

o

m

itte

d

; th

e

s

e

m

u

s

t b

e

in

c

lu

d

e

d

o

n

th

e

in

s

ta

lla

tio

n

.

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 7 8 9 - + L N E 3 4 5

L N E L N E

X6 X13

BUS 24 volt 230 volt

ecoTEC 466 & 656 / ecoCRAFT boiler terminals

safety

circuit

boiler

enable

230 mains voltage terminals Lowvoltage terminals

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 7 8 9 - + L N E 3 4 5

L N E L N E

X6 X13

BUS 24 volt 230 volt

ecoTEC 466 & 656 / ecoCRAFT boiler terminals

safety

circuit

boiler

enable

230 mains voltage terminals Lowvoltage terminals

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 7 8 9 - + L N E 3 4 5

L N E L N E

X6 X13

BUS 24 volt 230 volt

ecoTEC 466 & 656 / ecoCRAFT boiler terminals

safety

circuit

boiler

enable

230 mains voltage terminals Lowvoltage terminals

V

R

C

6

9

3

Key

1. Boiler flow isolation valve (supplied only with ecoTEC)

2. Boiler return isolation valve (supplied only with ecoTEC)

3. Boiler safety valve (supplied only with ecoTEC)

4. Boiler shunt pump (supplied internally with ecoTEC 46 & 65,

available as an accessory with ecoTEC 80, 100 & 120 and

ecoCRAFT 80 - 280 ranges)

5. Single check valve required (supplied only with cascade rigs)

6. Primary pressurisation unit (available as an accessory)

7. Primary expansion vessel (available as an accessory)

8. Heating pumps

9. System check valve

10. Heating circuit mixing valve

11. Service valves (not supplied by Vaillant)

12. Cylinder primary pump

13. Cylinder motorised valve (supplied only with uniSTOR cylinder)

14. Dirt separator or strainer (available as an accessory)

15. Low loss header (available as an accessory)

16. Low loss header VR 10 sensor (supplied with VRC 630 controller)

17. Heating circuit VR 10 sensor (supplied with VRC 630 controller)

or VR 692 clip on pipe sensor (available as an accessory)

18. Cylinder VR 10 sensor (supplied with VRC 630 controller)

19. Cylinder high limit thermostat

(supplied only with uniSTOR cylinder)

Wiring Colours

purple eBUS

green sensors

blue 230 volt

Note items are not supplied by Vaillant unless stated

Note:

1. Vaillant strongly recommends the installation of a suitably

sized dirt separator in the return pipe work to the header

or system separation plate heat exchanger, particularly in

the case of old systems.

2. The schematic drawings depicted in this brochure are a

suggested layout of a typical system and should not be

solely relied upon as a definitive design.

21 20

ecoTEC 46

A

B

C

D

E

F

G

H

I

J

K

L

Key

A Air intake

B Heat exchanger

C Burner

D Silencer

E Flow switch

F Gas valve

G Pressure switch

H Fan

I Automatic air vent

J Pump

K Air separator

L Electronics/PCB

Service valves

Flow and return isolation valve

Gas isolation valve

All ecoTEC boilers are supplied with the above

ecoTEC 65

A

B

C

D

E

F

G

H

I

J

K

L

M

Key

A Pressure differential switch

B Heat exchanger

C Air intake

D Auto air vent

E Burner

F Air separator

G Mixing arm

H Pressure switch

I Flow switch

J Fan

K Gas valve

L Pump

M Electronic/PCB board

Key components

ecoTEC 46 & 65

Connection dimensions in mm

Key

1. Flue gas connection, 80/125mm diameter, dimension A (hanging

bracket centre of air/ue gas pipe) with 87 elbow: 297mm

2. Hanging bracket

3. Gas pipe, 25mm diameter, gas connection R1

4. Connection provision - expansion vessel

5. Connection for heating return

6. Connection for heating ow

7. Connection provision - expansion relief valve

8. Connection for condensate drain pipework

9. Flow line drainage opening

10. Connection provision - lling (combined lling and emptying valve)

11. Siphon cartridge

A

80/125

R 1

100 100

152 152

100

48

190

8

0

0

3

0

4

9

20, R1

G 11/2

1 p R 1 p R

G 11/2

R 1/2

480 450

7

8

6

5

4

3

9

5, 8

1

2

Connection dimensions in mm

Key

1. Flue gas connection, 80/125 mm

diameter, dimension A (hanging bracket centre of air/flue gas

pipe) with 87 elbow: 253 mm

2. Hanging bracket

3. gas pipe, 20 mm diameter, gas connection R1

4. Connection for condensate drain pipework

5. Connection for expansion vessel

6. Connection for heating return

7. Connection for heating flow

8. Connection for expansion relief valve

9. Filling device (combined filling and emptying valve)

Required minimumgaps/assembly clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and assembly clearances given below:

250

350

5 5

A

80/125

R 1 172 172

3

2

224 224

121

1

4

0

75

211

8

0

0

6

1

9

4

1

1

9

25, R1

G 1 1/2

1 p R 1 p R

G 1 1/2

R 3/4

480 472

6

7

5

4

3

9

11

10

8

1

2

Connection dimensions in mm

Key

1 Flue gas connection, 80/125 mm

diameter, dimension A (hanging bracket centre of air/flue gas

pipe) with 87 elbow: 297 mm

2 Hanging bracket

3 Gas pipe, 25 mm diameter, gas connection R1

4 Connection provision - expansion vessel

5 Connection for heating return

6 Connection for heating flow

7 Connection provision - expansion relief valve

8 Connection for condensate drain pipework

9 Flow line drainage opening

10 Connection provision - filling (combined filling

and emptying valve)

11 Siphon cartridge

Required minimumgaps/assembly clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and assembly clearances given below:

400

500

5 5

Required minimum gaps/assembly clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and assembly clearances given above.

Required minimum gaps/assembly clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and assembly clearances given above.

23 22

ecoTEC 46

Connections and dimensions

ecoTEC 65

Connections and dimensions

Connection dimensions in mm

Key

1. Flue gas connection, 80/125mm diameter, dimension A

(hanging bracket centre of air/ue gas pipe) with

87 elbow: 253mm

2. Hanging bracket

3. Gas pipe, 20mm diameter, gas connection R1

4. Connection for condensate drain pipework

5. Connection for expansion vessel

6. Connection for heating return

7. Connection for heating ow

8. Connection for expansion relief valve

9. Filling device (combined lling and emptying valve)

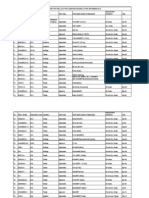

ecoTEC 46 65

Article number 0010004139 0010001440

Heat output range (heating 50/30C) kW 12.9 - 46.4 14.6 - 67.6

Heat output range (heating 80/60C) kW 12.3 - 44.1 13.7 - 63.7

Maximum heat input (net) kW 45 65

SEDBUK 2005 rating A A

SEDBUK 2009 annual efficiency % 89.1 88.7

Part L2 seasonal efficiency (natural gas) % 95.8 95.2

Part L2 seasonal efficiency (LPG) % 98.0 N/A

Net efficiency @ 100% load % 98.4 97.4

Net efficiency @ 30% load % 108.3 107.6

Inlet gas working pressure required (natural gas) mbar 20 20

Inlet gas working pressure required (LPG) mbar 37 N/A

NOx class 5 5

NOx levels mg/kWh 36 36

CO2 percentage (after 5 minutes full load +/- 1) % 8.8 8.8

Maximum CO level ppm 150 150

Gas rate (natural gas) m

3

/h 4.8 6.9

Gas rate (LPG) kg/h 3.5 N/A

Water flow rate (when T = 20K) l/h 1935 2750

Available pump head (without check valve) mbar 280 280

Available pump head (with check valve) mbar 190 190

Pressure drop across the heat exchanger

(at full load and 20K temperature difference)

mbar 350 375

Maximum flow temperature C 85 85

Maximum operating primary pressure bar 3 3

Minimum operating primary pressure bar 0.8 0.8

Condensate volume (pH value: 3.0-4.0) l/h 4.5 6.5

Electrical connection V / Hz 230 / 50 230 / 50

Electrical power consumption min./max. (with integrated pump) W 138 / 180 170 / 260

Electrical protection rating - IP X 4 D IP X 4 D

Dimensions

Height mm 800 800

Width mm 480 480

Depth mm 450 472

Lift weight kg 46 75

Water content l 4.5 6.5

Flue

Flue gas mass flow min./max g/s 5.7 / 20.5 6.5 / 30.3

Flue gas temperature min./max. C 40 / 70 40 / 70

Maximum length of concentric flue horizontal m 18 15

Maximum length of concentric flue vertical m 21 18

Connections

Heating flow/return (isolation valve size) 1

1

4 female BSP 1

1

4 female BSP

Gas isolation valve size 1 female BSP 1 female BSP

Pressure safety valve outlet

3

4 female BSP 1 female BSP

Condensate drain mm 19 19

Flue connection mm 80/125 80/125

ecoTEC 46 & 65

Technical specications

25 24

27 26

Flue accessories

ecoTEC 46 & 65

ecoTEC

46 65

Max.

permissible

length of

concentric flue

21.0m

without elbow

18.0m

without elbow

Maximum length of flue is reduced by

2.5m for each additional 87

0

elbow

Maximum length of flue is reduced by

1.0m for each additional 45

0

elbow

ecoTEC

46 65

Max.

permissible

length of

concentric flue

18.0m plus

1 elbow, 87

0

15.0m plus

1 elbow, 87

0

Maximum length of flue is reduced by

2.5m for each additional 87

0

elbow

Maximum length of flue is reduced by

1.0m for each additional 45

0

elbow

Key

A Adjustable roof tile for

pitched roofs (009076)

B 87 elbow (303210)

C Flue extension pieces:

470mm extension (303202)

970mm extension (303203)

1970mm extension (303205)

D 45 elbow (2 of) (303211)

E Flue support clips -

pack of 5 (303616)

F Sliding sleeve (303215)

G Flat roof penetration

collar (009056)

H Vertical flue duct &

terminal (303200)

I Lead slate penetration seal

for pitched roofs (303980)

Key

A - D Horizontal flue terminal (303209)

A

A

B

C

D

B

C

D

E

F

G

I

H

80/125mm concentric horizontal flue 80/125mm concentric vertical flue

I

ecoTEC commercial boilers can be used in cascade

conguration similar to that shown above. Each

boiler must be tted with the ue gas non-return

valve accessory (303960). Please refer to the ue

installation manual (0020046373) for further help.

The non-return valve is not necessary if the chimney

is designed to EN 13384-2 and the natural draught is

greater than the pressure losses.

Note

For non-standard ueing systems (e.g. chimneys with exible liners and cascade ue system) advice from specialist ue companies

must be sought. All ue installations must comply with the current Gas Safety (Installation and Use) regulations as well as current

editions of BS5440-1, BS6644 and where necessary for installations over 150kW The Clean Air Act. Additionally any ue material

must be suitable for the use and CE marked or comply with the current edition of BS715, also the ue system must be sized in

accordance with EN13384-2 (chimneys - thermal and uid dynamics calculation methods - Part 2: Chimneys serving more than

one heating appliance).

ecoTEC 46 & 65

Cascade ueing

ecoTEC

VU GB 466/4-5 VU GB 656/4-5

Max.

permissible

length of

concentric

flue gas pipe

22.0m plus

3 elbows 87

0

and

support elbow

22.0m plus

3 elbows 87

0

and

support elbow

Air intake piece positioned no further than

4m from the connection with the boiler

A

E

F

G

1 2

3 4 6

5

H

B

C

D

Key

A 45 elbow (pair of) (0020042757)

B 87 elbow (0020042756)

C Fixing bracket extension (0020042752)

D Rain collar for vertical roof penetrations

(0020042760)

E Flue extension pieces available in:

500mm extension (0020042753)

1m extension (0020042754)

500mm cutable extension (0020042755)

F Fixing bracket (0020042751)

G Fixing bracket (0020042751)

H Adjustable wall support for heights

in excess of 4m (0020042749)

Faade basic connection set (0020042748)

contains items:

1 - T-piece elbow

2 - Transition piece

3 - Inner wall rosette

4 - Outer wall rosette

5 - Wall penetration elbow

6 - Air intake piece

7 - Bird cage terminal

7

29 28

80/125mm concentric stainless steel faade flue

80mm flue non-return valve

ecoTEC 80, 100 & 120

Three models

ecoTEC 80

heat output range (heating 50/30C) 16.5 - 82.3kW

heat output range (heating 80/60C) 14.9 - 74.7kW

ecoTEC 100

heat output range (heating 50/30C) 20.7 - 102.8kW

heat output range (heating 80/60C) 18.8 93.3kW

ecoTEC 120

heat output range (heating 50/30C) 24.7 - 123.4kW

heat output range (heating 80/60C) 22.4 - 112kW

High performance

Exceeds Part L2 seasonal efciency

Fully modulating low NOx burner and fan (class 5)

<40mg/kWh

Single boiler heating output up to 120kW

Stainless steel heat exchanger

Modulation range of 1:5

Intelligent fault system

Easy installation

Case dimensions H960mm x W480mm x D602mm

Connections:

1

1

4 female BSP ow and return service valves

1 female BSP gas service valve

Pressure safety valve outlet - 1 female BSP

Condensate 19mm

Combined lling/emptying valve on return pipe

All major components built-in:

Siphonic condensate discharge

Energy saving 2-stage frost protection

0 10v compatible for BEMS applications

(via VR 34 accessory)

8m head shunt pump (available as an accessory)

Pressure sensor to monitor system pressure

via diagnostics

Flow sensor to monitor water ow through boiler

Auto air vent

Push-t ue system

Full range of intelligent eBUS controls including

weather compensators and multiple boiler

management controls available.

Flexible siting

Flue lengths up to 22m concentric horizontal or

24m concentric vertical with 110/160mm ue - for

further information, see ues and accessories

Optional 160mm stainless faade kit available

6 bar PRV

IP X 4D electrical safety rating

No compartment ventilation needed*

Easy service and repair

Built-in plain text comprehensive boiler status/

diagnostic display system

Blue backlit display for easy reading

Easy access to all components from the front

Removable side panels for easy installation

and servicing

Single electronic circuit board

Flue gas analysis point

Intelligent fault system

Quality and reliability

Stainless steel heat exchanger

Production to ISO 9001

5-year guarantee on boiler (subject to conditions)

Commissioning service available

* See BS6644 for more specic advice if appliance installed in boiler room/enclosure

31

* See BS6644 for more specic advice if appliance installed in boiler room/enclosure

Higher output

Vaillant is pushing back the technological boundaries to provide commercial wall hung boiler solutions that

are bigger and better than ever before. Incorporating all the same high performance and efciency features

as its smaller domestic counterparts, the ecoTEC offers a superb output of 80kW, 100kW and 120kW with the

ability to cascade up to 960kW. A wall-to-wall solution for every commercial specication.

30

1 2

3

14

7

8

9

8

10

12 13

Variable temperature

mixing circuit HK2

Variable temperature

direct circuit HK1

Hot water circuit

VRC 470

VRC 693

outdoor sensor

1 2

333

7

15

VR 61/2 wiring

centre

VR 81/2

19

18

17

16

11 11

33 32

ecoTEC 80, 100 & 120

System design

A typical single boiler installation

VRC 693

outdoor

sensor

Hot water secondary

circulation pump

(set ecoTEC parameter

d.26 to No 1)

Please note:

The default setting in the VRC 470 program

for the LP/ZP output is ZP which will switch

on the cylinder secondary pump. If this

connection is to be used for the cylinder

primary pump (as shown), then the LP/ZP

relay connection setting in the installer level

systemconfiguration screen for hot water will

need to be set to LP

Cylinder Pump

Cylinder

sensor

Cylinder sensor

connector inside

boiler plug must be

cut off and joined

using connector block

Unvented

hot water

cylinder

motorised valve

Pump 1 Pump 2

Strap sensor to flowpipe

after pump for this circuit

230 volt mains input

connection fused at 3 amps

factory

link

must be

fitted

factory

link

must be

fitted

1 2 - + L N E L N E L N E

X13 X16 BUS 230 volt

ecoTEC 80-120 boiler terminals

Burner

off

230 mains voltage terminals Lowvoltage terminals

1 2

24VRT

L N E

X11

L N E

X18

H

K

2

c

irc

u

it

m

ix

in

g

v

a

lv

e

BUS 230 volt

E N L E N L E N L E N L E N

LP / ZP HK2-P

m

a

in

s

in

p

u

t

c

o

n

n

e

c

tio

n

e

B

U

S

Lowvoltage terminals 230 mains voltage terminals

Vaillant VR 61/2 Extension Module

VF2

2 1

HK2

o

p

e

n

clo

se HK1-P

H

K

1 c

irc

u

it

p

u

m

p

H

K

2

c

irc

u

it

P

u

m

p

H

K

2

c

irc

u

it

s

e

n

s

o

r

C

y

lin

d

e

r

p

rim

a

ry

p

u

m

p

L

P

o

r s

e

c

p

u

m

p

Z

P

Vaillant VR 81

For use on HK2 set address to A2

Vaillant VR 81

For use on HK2 set address to A2

Vaillant VRC 470 controller

If used with VR61 and two heating zones this must

be wall mounted to control the temperature of the

heating circuit.

V

R

10

s

e

n

s

o

r

2 & C

Cylinder high limit thermostat

(uniSTOR cylinders only remove wire link)

Note:

1. All electrical connections to the equipment must be in accordance

with current IEE Wiring Regulations.

2. For drawing clarity, some earth wires have been omitted;

these must be included on the installation.

VR10 sensor VRC edge

connector X41

0 F

B

D

C

F A

F

R

F0

V

R

10

lo

w

lo

s

s

h

e

a

d

e

r s

e

n

s

o

r

Hot water secondary

i l ti

Vail Vail Vail Vailll t lant lant ant lan ant VR VRC VRC VRC VRC 444470 controller

If If u If used with VR61 and two heating zones this must

be wall mounted to control the temperature of the

heating circuit.

Note items are not supplied by Vaillant unless stated

Key

1. Boiler flow isolation valve (supplied only with ecoTEC)

2. Boiler return isolation valve (supplied only with ecoTEC)

3. Boiler safety valve (supplied only with ecoTEC)

4. Boiler shunt pump (supplied internally with ecoTEC 46 & 65,

available as an accessory with ecoTEC 80,100 & 120 and

ecoCRAFT 80 - 280 ranges)

5. Single check valve required (supplied only with cascade rigs)

6. Primary pressurisation unit (available as an accessory)

7. Primary expansion vessel (available as an accessory)

8. Heating pumps

9. System check valve

10. Heating circuit mixing valve

11. Service valves (not supplied by Vaillant)

12. Cylinder primary pump

13. Cylinder motorised valve (supplied only with uniSTOR cylinder)

14. Dirt separator or strainer (available as an accessory)

15. Low loss header (available as an accessory)

16. Low loss header VR 10 sensor (supplied with VRC 630 controller)

17. Heating circuit VR 10 sensor (supplied with VRC 630 controller)

or VR 692 clip on pipe sensor (available as an accessory)

18. Cylinder VR 10 sensor (supplied with VRC 630 controller)

19. Cylinder high limit thermostat

(supplied only with uniSTOR cylinder)

Wiring Colours

purple eBUS

green sensors

blue 230 volt

Note:

1. Vaillant strongly recommends the installation of a suitably

sized dirt separator in the return pipe work to the header

or system separation plate heat exchanger, particularly in

the case of old systems.

2. The schematic drawings depicted in this brochure are a

suggested layout of a typical system and should not be

solely relied upon as a definitive design.

1 1 2 2

3 3

5 5

14

7

8

6

9

3

1 2

5

15

Variable temperature

mixing circuit HK3

8 8

10 10

11 11

12

13

Variable temperature

mixing circuit HK2

Variable temperature

direct circuit HK1

Hot water circuit - SP

VR 90 zone

controller

VR 90 zone

controller

VRC 630 boiler

management system

VRC 693

outdoor sensor

16

17 17

18

19

VR 90 zone

controller

VRC 630 boiler

zone

oller oller

1

3

1 2

3

1 2 2

3

System design

A typical cascade boiler installation

35 34

ecoTEC 80, 100 & 120

B

U

S

+_

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

3

b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

2

.

B

U

S

+_

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

3

b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

1.

V

R

C

6

9

3

2

&

C

C

y

lin

d

e

r

h

ig

h

lim

it

th

e

r

m

o

s

ta

t (u

n

iS

T

O

R

c

y

lin

d

e

r

o

n

ly

r

e

m

o

v

e

w

ir

e

lin

k

)

C

y

lin

d

e

r

p

r

im

a

r

y

p

u

m

p

2

3

0

v

o

lt

2

3

0

v

o

lt

L

P

/

U

V

1

Z

P

H

K

1-P

H

K

2

-P

H

K

3

-P

K

P

/

A

V

S

tu

fe

1

S

tu

fe

2

2

1

mains output

to external

VR 60

mains input

connection

6 amps

HK3 circuit

pump

not used

not used

not used

1 2

V

F

1

1 2

V

F

2

1 2

V

F

3

1 2

K

F

1 2

S

P

1 2

1x

Z

P

1 2

T

e

l

- +

B

U

S

C

2

C

1

9

8

7

9

8

7

I

II

lowloss

header

HK 2 sensor

HK3 sensor

not used

not used

telephone activation

switch not used

eBUS

outside

temperature

sensor

L

o

w

v

o

lta

g

e

te

r

m

in

a

ls

2

3

0

m

a

in

s

v

o

lta

g

e

te

r

m

in

a

ls

V

a

illa

n

t V

R

C

6

3

0

C

o

n

tr

o

lle

r

not used

not used

not used

HK1 circuit

pump

HK2 circuit

pump

Cylinder

sensor

Cylinder

motorised

valve

Hot water

secondary

pump

HK3 circuit

mixing valve

HK2 circuit

mixing valve

B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

1

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

1.

B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

2

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

2

.B

U

S

+_

V

R

9

0

H

e

a

tin

g

Z

o

n

e

3

c

o

n

tr

o

lle

r

s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

3

.

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 - + L N E L N E L N E

X13 X16 BUS 230 volt

ecoTEC 80-120 boiler terminals

Burner

off

230 mains voltage terminals Lowvoltage terminals

1 2

24V RT

L N E

X11

L N E

X18

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 - + L N E L N E L N E

X13 X16 BUS 230 volt

ecoTEC 80-120 boiler terminals

Burner

off

230 mains voltage terminals Lowvoltage terminals

1 2

24V RT

L N E

X11

L N E

X18

230 volt

mains input

connection

fuse at 3

amps

factory links

must be fitted

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F

0 1 2 - + L N E L N E L N E

X13 X16 BUS 230 volt

ecoTEC 80-120 boiler terminals

Burner

off

230 mains voltage terminals Lowvoltage terminals

1 2

24V RT

L N E

X11

L N E

X18

VR 10 sensor

VR 10 sensor

VR 10 sensor

VR 10 sensor

D

C

F

/0

/A

F

E

N

O

n

O

ff

2

1

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

H

K

3

o p e n

c l o s e

E

N

H

K

2

o p e n

c l o s e

B

U

S

+_

V

R

3

2

B

U

S

c

o

u

p

le

r

fo

r

N

o

3

b

o

ile

r

-s

e

t th

e

B

U

S

a

d

d

r

e

s

s

to

3

.

N

o

t

e

:

1. A

ll e

le

c

tr

ic

a

l c

o

n

n

e

c

tio

n

s

to

th

e

e

q

u

ip

m

e

n

t m

u

s

t b

e

in

a

c

c

o

r

d

a

n

c

e

w

ith

c

u

r

r

e

n

t IE

E

W

ir

in

g

R

e

g

u

la

tio

n

s

.

2

. F

o

r

d

r

a

w

in

g

c

la

r

ity

, s

o

m

e

e

a

r

th

w

ir

e

s

h

a

v

e

b

e

e

n

o

m

itte

d

; th

e

s

e

m

u

s

t b

e

in

c

lu

d

e

d

o

n

th

e

in

s

ta

lla

tio

n

.

U

n

v

e

n

te

d

h

o

t w

a

te

r

c

y

lin

d

e

r

m

o

to

r

is

e

d

v

a

lv

e

Note items are not supplied by Vaillant unless stated

Key

1. Boiler flow isolation valve (supplied only with ecoTEC)

2. Boiler return isolation valve (supplied only with ecoTEC)

3. Boiler safety valve (supplied only with ecoTEC)

4. Boiler shunt pump (supplied internally with ecoTEC 46 & 65,

available as an accessory with ecoTEC 80, 100 & 120 and

ecoCRAFT 80 - 280 ranges)

5. Single check valve required (supplied only with cascade rigs)

6. Primary pressurisation unit (available as an accessory)

7. Primary expansion vessel (available as an accessory)

8. Heating pumps

9. System check valve

10. Heating circuit mixing valve

11. Service valves (not supplied by Vaillant)

12. Cylinder primary pump

13. Cylinder motorised valve (supplied only with uniSTOR cylinder)

14. Dirt separator or strainer (available as an accessory)

15. Low loss header (available as an accessory)

16. Low loss header VR 10 sensor (supplied with VRC 630 controller)

17. Heating circuit VR 10 sensor (supplied with VRC 630 controller)

or VR 692 clip on pipe sensor (available as an accessory)

18. Cylinder VR 10 sensor (supplied with VRC 630 controller)

19. Cylinder high limit thermostat

(supplied only with uniSTOR cylinder)

Wiring Colours

purple eBUS

green sensors

blue 230 volt

Note:

1. Vaillant strongly recommends the installation of a suitably

sized dirt separator in the return pipe work to the header

or system separation plate heat exchanger, particularly in

the case of old systems.

2. The schematic drawings depicted in this brochure are a

suggested layout of a typical system and should not be

solely relied upon as a definitive design.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

A

B

C

D

E

F

G

H

I

J

K

L

M

N

Key

A Ignition transformer

B Automatic air vent

C Gas valve

D Fan

E Flow STL

F Flow NTC

G Silencer

H Flue gas pressure switch

I Heat exchanger

J Burner (inside heat exchanger)

K Air intake

L Pressure gauge

M Water pressure sensor

N Return NTC

O Electronics/PCB

Key

A Air intake

B Fan

C Gas valve

D Ignition transformer

E Automatic air vent

F Flow STL

G Flow NTC

H Burner (inside heat exchanger)

I Flue gas pressure switch

J Heat exchanger

K Pressure gauge

L Return NTC

M Pressure sensor

N Electronics/PCB

Service valves and pump group

Pump group

(includes pump and insulation)

Available as an accessory

37 36

ecoTEC 100 & 120

Key components

ecoTEC 80, 100 & 120

ecoTEC 80

Flow and return isolation valve

Gas isolation

valve

All ecoTEC 80, 100 & 120 boilers

are supplied with the above

Pressure

release valve

ecoTEC 80 100 120

Article Number 0010010767 0010010780 0010010791

Heat output range (heating 50/30C) kW 20 - 80 25 - 100 30 - 120

Heat output range (heating 80/60C) kW 18.5 - 73.9 23.1 - 92.4 27.7 - 110.9

Maximum heat input (net) kW 76.2 95.2 114.3

Net efficiency @ 100% load % 98 98 98

Net efficiency @ 30% load % 109 109 109

Inlet gas working pressure required (natural gas) mbar 20 20 20

Inlet gas working pressure required (LPG) mbar 37 37 37

NOx class 5 5 5

NOx levels mg/kWh 39 36 38

CO

2

percentage (after 5 minutes full load +/- 1) % 8.8 9 9

Maximum CO level ppm <30 <30 <30

Gas rate (natural gas) m

3

/h 8 10.1 12.1

Water flow rate (when T = 23K) l/h 2990 3740 4485

Available pump head (without check valve) mbar 240 380 360

Available pump head (with check valve) mbar 150 100 90

Residual fan duty Pa 220 300 300

Maximum flow temperature C 85 85 85

Maximum operating primary pressure bar 6 6 6

Minimum operating primary pressure bar 0.8 0.8 0.8

Condensate volume @ 40/30C (pH value: 3.0 - 4.0) l/h 12.16 15.2 18.24

Electrical connection V/Hz 230 / 50 230 / 50 230 / 50

Electrical power consumption min./max. (with integrated pump) W 165 181 181

Electrical protection rating IP X 4D IP X 4D IP X 4D

Dimensions

Height mm 960 960 960

Width mm 480 480 480

Depth mm 610 610 610

Lift weight kg 68 86 90

Water content l 17 23.7 22.5

Flue

Flue gas mass flow min./max. g/s 6.9 / 34.4 8.9 / 43.6 10.6 / 52.5

Flue gas temperature max. C 85 85 85

Maximum length of concentric flue horizontal m 22 22 22

Maximum length of concentric flue vertical m 24 24 24

Connections

Heating flow/return (isolation valve size) 1

1

4" 1

1

4" 1

1

4"

Gas isolation valve size 1" 1" 1"

Pressure safety valve outlet 1" 1" 1"

Condensate drain mm 19 19 19

Flue connection mm 110 / 160 110 / 160 110 / 160

39

Connections and dimensions

ecoTEC 80, 100 & 120

Technical specications

ecoTEC 80, 100 & 120

1

4 3 2

Connection dimensions in mm

A = 476.6mm

Connections

1 Pump group

2 Heating flow

3 Heating return

4 Gas valve

5 5

250

350

Required minimum gaps/assembly clearances

For the installation/assembly of the boiler as well as for

carrying out future maintenance tasks, you need the

minimum gaps and assembly clearances given above.

38

41 40

Flue accessories

ecoTEC 80, 100 & 120

ecoTEC

80 100 120

Max.

permissible

length of

concentric flue

24.0m

including

2 x 87 elbows

20.0m

including

2 x 87 elbows

11.0m

including

2 x 87 elbows

Maximum length of flue is reduced by 1.5m for

each additional 87

O

elbow

Maximum length of flue is reduced by 1.0m for

each additional 45

O

elbow

ecoTEC

80 100 120

Max.

permissible

length of

concentric flue

22.0m

including

87 elbow

18.0m

including

87 elbow

9.0m including

87 elbow

Maximum length of flue is reduced by 1.5m for

each additional 87

O

elbow

Maximum length of flue is reduced by 1.0m for

each additional 45

O

elbow

Key

A Vertical flue duct and

terminal (0020166853)

B Pitched roof flashing (0020106409)

C Flue extension pieces:

500mm extension (0020106376)

1000mm extension (0020106377)

2000mm extension (0020106378)

D 45 elbow (2 of) (0020106379)

E Flue support clips -

pack of 5 (0020106381)

Flat roof penetration collar

(not shown) (0020106411)

87 elbow (not shown) (0020106380)

B

C

D

E

A

Key

A - D Horizontal flue terminal (0020166854)

Introducing the new Vaillant cascade rigs, to offer

even more efciency and exibility on outputs.

We are pleased to be able to offer our new range

of cascade rigging, which is an easily expandable

modular system and available for inline, back to back

and corner installations of up to six ecoTEC 46, 65,

80, 100 or 120 wall hung commercial boilers.

For more information, please see our commercial

website www.vaillant.co.uk/commercial or contact

your local Vaillant representative.

43 42

Cascade rigs

ecoTEC 46, 65, 80, 100 & 120

45 44

ecoCRAFT

Floor standing condensing boiler range

The complete solution

Starting at 80kW, the range consists of six models and

enables the closest load matching with modulation

ranges as wide as 17% to 100% on the 160kW boiler.

The ecoCRAFT range has a compact size for its class

with an appliance width of 695mm and is delivered to

site on a single pallet. Its easy manoeuvrability offers

exible siting and a modular heat exchanger design

utilising a single pre-mix burner and fan to achieve

part load efciencies as high as 108.4% (net) enabling

you to maximise the Building Regulations rating with

a class rating for the boiler of NOx class 5.

High Performance

Large output range from 14.1 - 281.4kW (60/4

0

C)

High efciency exceeding Part L2 Building

Regulations 2005

VKK 806, VKK 1206 and VKK 1606 net efciency

108.4% low, 97.8% high

VKK 2006, VKK 2406 and VKK 2806 net efciency

108.2% low, 98.4% high

Sectional heat exchanger with single burner control

allowing boiler modulation ranges of 16.8% - 100%

Adjustable maximum ow temperature from

35 85C

Fully modulating, low NOX pre-mix horizontal ring

burner (class 5) <60mg/kWh

Aluminium/silicon alloy heat exchanger

Easy Installation

Connections

Flow and return 2 male BSP

Gas 1 1 / 2 male BSP

Condensate 21mm

Pro E electrical connections

Modulating primary pump (three sizes available

as accessory)

0 10v compatible for BEMS applications

(via VR 34 accessory)

Compatible with Vaillant VRC 630 cascade controller

Cascade installations via Vaillant eBus

(via VR 32 accessory)

Push t appliance ue outlet

VKK 806, 1206 & 1606 - 150mm

VKK 2006, 2406 & 2806 - 200mm

Flues for this range should be supplied

by a specialist ue company

Flexible siting

Flue categories B23, B23P, C33, C53, C43, C83, C63

Maximum system working pressure 6 bar

Remote safety circuit interlock (24 Volt)

Fully programmable boiler interface to match

system requirements

Compact size for output to enable easy transport

and manoeuvrability

VKK 806, VK 1206 and VK 1606 (HxWxD)

1285 x 695 x 1240

VKK 2006, VK 2406 and VK 2806 (HxWxD)

1285 x 695 x 1550

Modulating pumps

Range of dedicated modulating pumps available

Pre-congured electronics matched as close as

possible to each boiler requiring minimal or no

adjustment

Designed to modulate their water ow in relation

to the boiler output therefore allowing the boiler

to produce more condensation and reduce

running costs

Simply plugs into the boiler control box using the

leads supplied

Easy service and repair

Simple case assembly and removal

Quality and reliability

Removable condensate siphon trap

Air inlet lter to maintain clean air for combustion

Integral boiler frost protection

2-year standard guarantee

additional 3-years available

47 46

ecoCRAFT range

55 54 49 48

ecoCRAFT range

Case study - St Marys School

Client:

St Marys School, Astley

Contractor:

Tudor (NW) Ltd

Project:

Commercial heating refurbishment

Tudor (NW) Ltd has successfully installed Vaillant

commercial boilers on a number of projects at different

locations over the years so we were condent to

put forward our products as rst choice for the

refurbishment of St Marys Secondary School in

Astley, Manchester.

Meeting the challenge

St Marys is a very large voluntary aided Catholic

Secondary School built in the 1960s with approximately

1,600 pupils aged between 11 and 18. Due to the large

size of the school there are two plant rooms located

in the basement. Before the refurbishment took place,

these plant rooms housed a total of seven standard

efciency boilers.

Providing the solution

The system was very old and had to be cleaned

thoroughly before any new boilers could be installed.

Eight ecoCRAFT high efciency boilers were installed

between the two plant rooms; four with an output

of 240kW and four with an output of 280kW. As a

further precaution against dirt build up in the system, a

Spirotech SpiroCross combined low loss header/air and

dirt separator, was also supplied by Vaillant and installed.

Due to the added complication of the plant rooms

being located in a basement, the boilers had to be

lowered into it. This was made easier by the fact the

ecoCRAFT boiler casing unclips from the boiler frame,

which could then be used to x the lifting gear.

Enjoying the benet

The eight ecoCRAFTs now successfully meet the hot

water and heating requirements of the school.

Arthur Naylor, managing director of Tudor (NW) Ltd,

the installer responsible, commented:

Complex projects require a trusted partner and

Vaillant is just that. Outstanding products backed up by

terric pre and after-sales service give both my team

and our clients complete condence of a awless

install and reassurance of long term service.

14

8

9

8

10

11

12 13

Variable temperature

mixing circuit HK2

Variable temperature

direct circuit HK1

Hot water circuit

VRC 470

VRC 693

outdoor sensor

VR 61/2 wiring

centre

VR 81/2

19

18

17

1

4

7 6

2

15

16

3

11

51 50

ecoCRAFT range

System design

H

K

2

c

irc

u

it

m

ix

in

g

v

a

lv

e

BUS 230 volt

E N L E N L E N L E N L E N

LP / ZP HK2-P

m

a

in

s

in

p

u

t

c

o

n

n

e

c

tio

n

e

B

U

S

Lowvoltage terminals 230 mains voltage terminals

Vaillant VR 61/2 Extension Module

VF2

2 1

HK2

o

p

e

n

clo

se HK1-P

H

K

1 c

irc

u

it

p

u

m

p

H

K

2

c

irc

u

it

P

u

m

p

H

K

2

c

irc

u

it

s

e

n

s

o

r

VRC edge

connector X41

0 F

B

D

C

F

A

F

R

F0 1 2 7 8 9 - + L N E 3 4 5

L N E L N E

X6 X13

BUS 24 volt 230 volt

ecoTEC 466 & 656 / ecoCRAFT boiler terminals

safety

circuit

boiler

enable

230 mains voltage terminals Lowvoltage terminals

VRC 693

outdoor

sensor

V

R

10

lo

w

lo

s

s

h

e

a

d

e

r s

e

n

s

o

r

Hot water secondary

circulation pump

(set ecoTEC parameter

d.26 to No 1)

Vaillant VR81

For use on HK2 set address to A2

C

y

lin

d

e

r

p

rim

a

ry

p

u

m

p

L

P

o

r s

e

c

p

u

m

p

Z

P

Please note:

The default setting in the VRC 470 program

for the LP/ZP output is ZP which will switch

on the cylinder secondary pump. If this

connection is to be used for the cylinder

primary pump (as shown), then the LP/ZP

relay connection setting in the installer level

systemconfiguration screen for hot water will

need to be set to LP

Cylinder Pump

Cylinder

sensor

Cylinder sensor

connector inside

boiler plug must be

cut off and joined

using connector block

2 & C

Cylinder high limit thermostat

(uniSTOR cylinders only remove wire link)

Pump 1 Pump 2

Vaillant VRC 470 controller

If used with VR61 and two heating zones this must

be wall mounted to control the temperature of the

heating circuit.

Strap sensor

to flowpipe

after pump for

this circuit

Note:

1. All electrical connections to the equipment must be in accordance

with current IEE Wiring Regulations.

2. For drawing clarity, some earth wires have been omitted;