Body Electrical System

Body Electrical System

Uploaded by

Leonardo Gómez BernigaCopyright:

Available Formats

Body Electrical System

Body Electrical System

Uploaded by

Leonardo Gómez BernigaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Body Electrical System

Body Electrical System

Uploaded by

Leonardo Gómez BernigaCopyright:

Available Formats

BODY

ELECTRICAL

SYSTEM

Return To Main Table of Contents

GENERAL .................................................................................. 2

FUSIBLE LINKS AND FUSES ................................................... 6

IGNITION SWITCH .................................................................... 7

INSTRUMENTS, GAUGES AND WARNING LAMPS.. ............. 8

MULTIFUNCTION SWITCH ........................................................ 16

LIGHTING SYSTEM.................................................................... 19

DAYTIME RUNNING LIGHT........................................................ 29

AUDIO .......................................................................................... 31

WINDSHIELD WIPER AND WASHER ..................................... 34

CLOCK AND CIGARETTE LIGHTER ...................................... 38

POWER WINDOW....................................................................... 39

POWER DOOR LOCK.................................................................. 43

POWER DOOR MIRROR............................................................. 44

HORN, FUEL FILLER AND TRUNK LID OPENER................. 46

SUN ROOF ................................................................................... 49

E.T.A.C.S..................................................................................... 51

AUTOMATIC TRANSAXLE AND KEY LOCK

CONTROL SYSTEM.................................................................... 56

PASSIVE SEAT BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

90-2 GENERAL

GENERAL

SERVICING THE ELECTRICAL SYSTEM

1. When servicing the electrical system, disconnect the negative

cable from the terminal of the battery.

Caution

1. Before connecting or disconnecting the negative cable,

be sure to turn off the ignition switch and the lighting

switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. For MPI-equipped models, after completion of the work

steps [when the batterys negative (-) terminal is

connected], warm up the engine and allow it to idle

described below, in order to stabilize engine control

conditions, and then check to be sure that the idling is

satisfactory.

Engine coolant temperature : 80-95C (176-203F)

Lamps, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: N or P)

Steering wheel: neutral (center) position

2. If any section of a wiring harness interferes with the edge of a

part, or a corner, wrap the section of the harness with tape or

something similar in order to protect it from damage.

3. When installing any of the vehicle parts, be careful not to pinch

or damage any of the wiring harnesses.

4. If a burned-out fuse is to be replaced, be sure to use only a fuse

of the specified capacity. If a fuse a capacity larger than that

specified is used, parts may be damaged and the danger of fire

also exists.

GENERAL 90-3

5. The sensor, relay, etc, must never be subjected to strong

shocks. Do not allow them to fall and do not throw then when

handling.

6. The electronic parts used in the computer, relays, etc. are

readily damaged by heat. If there is a need for service opera-

tions that may cause the temperature to exceed 80C (176F),

remove the electronic parts beforehand.

7. Loose connectors could troubles. Make sure that the connec-

tors are connected securely.

8. When disconnecting a connector, be sure to pull only the

connector, not the harness.

9. Disconnect connectors which have catches by pressing in the

direction indicated by the arrows in the illustration.

90-4 GENERAL

10. Connect connectors which have catches by inserting the

connectors until a click noise is heard.

11. When using a circuit tester to perform continuity or voltage

checks on connector terminals, insert the test probe from the

harness side.

If the connector is a sealed connector, insert the test probe in

through the hole in the rubber cap for the electrical wires, being

careful not to damage the insulation of the wires continue to

insert the test probe until it contacts the terminal.

CHECKING CABLES AND WIRES

1. Checking the terminal for tightness.

2. Check terminals and wires for corrosion by battery electrolyte,

etc.

3. Check terminals and wires for open circuit or impending open

circuit.

4. Check wire insulation and coating for damage, cracks and

degrading.

5. Check conductive parts of terminals for contact with other

metallic parts

(vehicle body and other parts).

6. Check grounding parts to verify that there is complete continuity

between attaching bolt(s) and vehicle body.

7. Check for incorrect wiring.

8. Check that wirings are so clamped as to prevent contact with

sharp corners of the vehicle body, etc. or hot parts (exhaust

manifold, pipe, etc.)

9. Check that wirings are clamped firmly to secure enough

clearance from the fan pulley, fan belt and other rotating or

moving parts.

10. Check that the wirings between the fixed parts such as the

vehicle body and the vibrating parts such as the engine are

made with adequate allowance for vibrations.

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of the

fuse itself without removing it from the fuse block. The fuse is okay

if the test lamp comes on when its one lead is connected to the test

taps (one at a time) and the other lead is grounded. (Change the

ignition switch position adequately so that the fuse circuit becomes

live.)

GENERAL

90-5

INSTALLATION OF RADIO EQUIPMENT

The computers of the electronic control system has been designed

so that external radio waves will not interfere with their operation.

However, if the antenna or cable of the amateur transceiver etc. is

routed near the computers, it may affect the operation of the

computers, even if the output of the transceiver is no more than

25W.

To protect each of the computers from interference by transmitter

(hum, transceiver, etc.) the following should be observed.

1.

2.

3.

4.

5.

Install the antenna on the roof or rear bumper.

Because radio waves are emitted from the coaxial cable of the

antenna, keep it 200 mm (8 in.) away from the computers and

the wiring harness. If the cable must cross the wiring harness,

route it so that it runs at right angles to the wiring harness.

The antenna and the cable should be well matched, and the

standing-wave ratio* should be kept low.

A transmitter having a large output should not be installed in the

vehicle.

After installation of transmitter, run the engine at idle, emit radio

waves from the transmitter and make sure that the engine is not

affected.

*STANDING-WAVE RATIO

If an antenna and a cable having different impedances are connected,

the input impedance Zi will vary in accordance with the length of the

cable and the frequency of the transmitter, and the voltage distri-

bution will also vary in accordance with the location.

The ratio between this maximum voltage and minimum voltage is

called the standing-wave ratio. It can also be represented by the

ratio between the impedances of the antenna and the cable.

The amount of radio waves emitted from the cable increases as the

standing-wave ratio increases, and this increases the possibility of

the electronic components being adversely affected.

90-6 FUSIBLE LINKS AND FUSES

FUSIBLE LINKS AND FUSES

FUSIBLE LINK

Specifications

Items Specifications

Main fusible link

Sub. fusible link

(Located in engine

compartment relay box)

Rated capacity Circuit

Type

Housing color

60A

20A

Charging

Cooling

Screw-up

Screw-up

Yellow

Blue

Circuit

Item

P/WDW H/LAMP

BATT ECI RAD IGN SW ABS

Rated

capacity

30A 30A 50A 20A 30A 30A 40A

Housing

Pink Pink Red Blue Pink Pink Green

color

Type

Connector type

Inspection

1. Check for a burnt fusible link with an ohmmeter.

2. If a fusible link burns out, there is a short or some other problem

in the circuit.

Carefully determine the cause and correct it before replacing

the fusible link.

NOTE

The fusible link will burnt out within 15 seconds if a higher than

specified current flows through the circuit.

FUSES

Inspection

1. Be sure there is no play in the fuse holders, and that the holders

hold the fuses securely.

2. Are fuse capacities for each circuit correct ?

3. Are there any blown fuse?

If a fuse is to be replaced, be sure to use a new fuse of the

specified capacity. Always determine why the fuse blew first

and completely eliminate the problem before installing a new

fuse.

CAUTION

Never use a fuse of higher capacity than specified.

IGNITION SWITCH

IGNITION SWITCH

INSPECTION

1. Separate the connector located under the steering column.

2. Inspect the switch continuity between the terminals.

3. If continuity is not as specified, replace the switch.

NOTE

O-0 indications that there is continuity between the terminal.

RO : Round the locking bar

RE : Return the locking bar

L : Lock

F : Free

INSTRUMENTS, GAUGES AND WARNING LAMPS

INSTRUMENTS, GAUGES AND WARNING LAMPS

INSTRUMENT CLUSTER

SPECIFICATIONS OF INDICATOR AND WARNING LAMPS

Items

Indicator lamps

Direction indicator (LH/RH)

Battery charging

Oil pressure

Brake failure

Door warning

Rear window defogger

Check engine

High beam

Low washer (Canada)

Low fuel

Safety belt

ABS warning

SERVICE STANDARD

Specification (wattage) Items Specification (wattage)

Trunk lid ajar

Illumination lamps

A/T position indication

P

R

N

D

L

OD OFF

1.2 W

3.4 W

1.2 W

1.2 W

1.2 W

1.2 W

1.2 W

1.2 W

INSTRUMENTS, GAUGES AND WARNING LAMPS 90-9

Fuel sender

Water temperature gauge

Water temperature sender

Voltage gauge

Oil pressure gauge

Oil pressure sender

TIGHTENING TORQUE

Float position

Resistance (Q)

Allowable error (Q)

Temperature (C)

Angle

Tolerance

Temperature (C)

Resistance (Q)

Voltage (V)

Angle

Allowable error (V)

Pressure (Kg/cm

2

)

Angle

Resistance (Q)

Pressure (Kg/cm

2

)

Resistance (Q)

F 1.2 E

3 32.5 110

2 4 7

60 85 110 125

-30 -7 -7 +30

+ 2 + 2

- 3 - 3

1.5

60 85 110 125

128 49.5 24.9 14.8

8 10 12 14 16

-30 -16 0 16 30

0.5 0.5 0.6

0.3

2.7

7 10

-32.5

-21.5

16 32.5

3 4

0.3 2.7 7 10

310 25 195 16 49 12 20 8

Items

Coolant temperature sender

Oil sender pressure

Oil switch pressure

Nm

10-12

8-12

8-12

Specifications

Kg.cm

100-200

80-120

80-120

Ib.ft

7-9

6-9

6-9

90-10

INSTRUMENTS, GAUGES AND WARNING LAMPS

COMPONENTS

INSTRUMENTS, GAUGES AND WARNING LAMPS 90-11

PRINTED CIRCUIT BOARD

CIRCUIT DIAGRAM

90-12

INSTRUMENTS, GAUGES AND WARNING LAMPS

COMPONENT CHECK

Speedometer

1. Using a speedometer tester, inspect the speedometer for

allowable indicating error and check the operation of the

odometer.

NOTE

Tire wear and tire over or under inflation will increase the

indication error.

2. Check the speedometer for pointer vibration and abnormal

noises.

NOTE

Pointer vibration can be caused by a loose or dry

speedometer cable.

Speedometer cable

Insert the cable until the stopper properly fits into the speedometer

groove.

CAUTION

Poor installation of the cable may cause a fluctuating pointer,

noise and a damaged harness inside the instrument panel.

Tachometer

1. Connect a tachometer and start the engine.

2. Compare the tester and tachometer indications.

If the difference is excessive, replace the tachometer.

CAUTION

1) Reversing the connections of the tachometer will

damage the transistor and diodes.

2) When removing or installing the tachometer, be careful

not to drop it or subject it to severe shock.

INSTRUMENTS, GAUGES AND WARNING LAMPS

90-13

Fuel gauge

1. Lift up the vehicle and disconnect the connector of the fuel

gauge from the fuel sender .2. Ground to the harness side

connector via (terminals 3) the 12V, 3.4W bulb.

3. Turn the ignition key to the ON position.

4. Check to be sure that the test bulb flashes and that the indicator

moves.

Fuel sender resistance

1. Measure (with the float as the F position and at the E

position) the resistance between ground and the sender terminal

for the fuel gauge.

Standard specification : Point F :

3 2

Point E : 110-17R

2. Also check that the resistance changes smoothly when the float

is moved to F and E.

Fuel level sensor

1. Connect the sender with a test lamp (12V, 3.4W) to the battery

and immerse it in water.

2. The lamp should be off while the thermistor is beneath the

water, and should illuminate when the sender is taken out of the

water.

NOTE

If there is a malfunction, replace the fuel sender as an

assembly.

CAUTION

After completing this test, wipe the sender dry and

install it in the fuel tank.

WATER TEMPERATURE GAUGE

1. Disconnect the wiring connector from the water temperature

sender in the engine compartment.

2. Ground to the harness side connector via the 12V, 2.3W bulb.

3. Turn the ignition key to the ON position.

4. Check to be sure that the test bulb flashes and that the indicator

moves.

90-14 INSTRUMENTS, GAUGES AND WARNING LAMPS

Water temperature sender

1. Using an ohmmeter, measure the resistance between the

terminal and ground.

2. If the resistance value is not as shown in the table below,

replace the temperature sender.

Temperature C (F) 60 (140) 110 (230)

Resi st ance Sz 125

24

Oil pressure sender

1. Check the engine oil level. Add oil if insufficient, or replace it if

the connection is bad.

2. Measure the resistance changes by connecting an ohmmeter

between a good ground (vehicle body) and the terminal of the

sender.

3. Refer to service standard.

Oil pressure switch

Specifications

Type

Contact points

Lighting oil pressure

0.3 kg/cm

2

(4.27 psi)

If operation is not as specified, replace the oil pressure switch.

Voltage gauge

1. Connect the voltmeter in parallel with the volt gauge.

2. The voltmeter indication should be equal to the volt gauge.

Voltage (V)

8 10 12 14 16

Allowable error (V) - 0.5 0.5 -

0.6

Brake warning lamp and switch

The brake fluid level sensor or the parking brake switch is switched

ON, and the brake warning lamp illuminates, when, with the ignition

switch at the ON position, the brake fluid level is at or below the

specified level, or the parking brake lever is pulled.

NOTE

The brake fluid level sensor is built into the master cylinder

reservoir cap.

INSTRUMENTS, GAUGES AND WARNING LAMPS 90-15

Parking brake switch

The parking brake switch is a push type and located under the

parking brake lever. To adjust, move the switch mount up and down

with the parking brake lever released all the way.

Door switch

Remove the door switch and check for continuity between the

terminals.

If continuity is not as specified, replace the door switch

90-16 MULTIFUNCTION SWITCH

MULTIFUNCTION SWITCH

COMPONENTS

M05-1 M05-2

REMOVAL AND INSTALLATION

1. Remove the steering wheel.

2. Remove the steering column lower and upper shroud.

MULTIFUNCTION SWITCH

3. Remove the multifunction switch mounting screws.

4. Disconnect the harness connector.

CAUTION

Make sure the wire leads are not being pulled when you

move the lever.

Check that lever works freely without binding.

5. Installation is the reverse order of removal.

OPERATION CHECK

Check the continuity between the terminals while operating the

switch.

Lighting switch (M05-1/*M05-2)

Dimmer and passing switch (M05-1)

Turn signal switch (M05-1)

Wiper and washer switch (M05-2)

MULTIFUNCTION SWITCH

Automatic speed control (cruise) switch (M05-2)

LIGHTING SYSTEM 90-19

LIGHTING SYSTEM

SPECIFICATIONS North America Australia

Head lamp

Front combination lamps

Turn signal lamp

Front position lamp

Rear combination lamps (outside)

Turn signal lamp

Stop and tail lamp

Rear combination lamps (inside)

Stop(Fog, Australia only) and tail lamp

Back-up lamp

Interior lamps

Luggage and glove box lamp

Room lamp

Door lamp

High mounted stop lamp

Licence plate lamp

Flasher unit

Turn signal blinking frequency

Hazard warning blinking frequency

60/45 W

28/8 W

5 W

27 W

27/8 W

27/8 W

27 W

5 W

10 W

5 W

17 W

8 W

85 10 C/M at 12.8 V

80 12 C/M at 12.8 V

60/55 W

21 W

4 W

21 W

21/5 W

21/ -w

21 W

5 W

10 W

5 W

17 W

5 W

90-20 LIGHTING SYSTEM

HEAD LAMP AIMING

Pre-aiming instructions

1. Test dimmer switch operation.

2. Observe operation of high beam indicator lamp mounted in the

instrument cluster.

3. Inspect for badly rusted of faulty head lamp assemblies.

These conditions should be corrected before a satisfactory

adjustment can be made.

4. Place the vehicle on a level floor.

5. Bounce the front suspension through three (3) oscillations by

applying body weight to the bumper.

6. Check and correct tire inflation pressures.

7. Rock vehicle sideways to allow vehicle to assume its normal

position.

8. If the fuel tank is not full, place a weight in the trunk of the vehicle

to simulate the weight of a full tank.

9. There should be no other load in the vehicle other than that of

the driver or substituted weight of approximately 75 kg (165

Ibs.) placed in the drivers position.

10. Thoroughly clean the head lamp lenses.

Compensating the aimers for floor slope

The floor level offset dial must coincide with the floor slope for

accurate aiming. Calibration fixtures are included with the aimers.

1.

2.

3.

4.

5.

6.

Attach one calibration fixture to each aimer. Fixtures will easily

snap into position on the aimer when properly positioned.

Place the aimers at the center line of each wheel on one side

of the vehicle. Unit A must be placed at the rear wheel with the

target facing forward. Unit B must be placed at the front wheel

with the target facing rearward.

Adjust the thumb screw on each calibration fixture by turning

either clockwise or counter-clockwise until the level vial bubble

registers in a centered, level position.

Look into the top port hole of Unit A. Turn the horizontal knob

until the split image is aligned.

Transfer the plus or minus reading indicated on the horizontal

dial to the floor level offset dial on each aimer.

Press the floor level dial inward to set reading.

Remove the calibration fixtures from both units.

LIGHTING SYSTEM 90-21

Testing aimer calibration

The aimer calibration may be off due to extended use.

Calibration fixtures used in conjunction with the aimers can be

used to check and adjust the aimer.

Turn the thumb adjusting screw on each calibration fixture until

it is approximately the same distance as the supporting posts.

Attach the calibration fixtures to each unit with the level vials on

1.

2.

3.

top.

4.

5.

6.

Locate a true vertical plate glass window or smooth surface and

position the aimers three to five feet apart so that the split image

targets can be located in the viewing ports.

Set the floor level dial to zero.

Rotate the thumb adjusting screws on each calibration fixture

until the level vials on the fixtures are centered.

With both calibration level vials centered, turn the vertical dial

knobs on each aimer until the aimer level vials are centered. If

the aimer vertical dial pointers read between 1/2 up and 1/2 down,

the aimers are within allowable vertical tolerance, Recalibrate

the units if they are beyond these limits.

Vertical dial pointer reading (on each aimer) . . . . . . . . . . . . . . . . . . . . .

1/2 up to 1/2 down

7. Adjust the horizontal dial knob on each aimer until the split

image targets align. If the aimer horizontal dial pointers read

between 1 left and 1 right, the aimers are within allowable

tolerance limits. Recalibrate the units if beyond these limits.

Horizontal dial pointer reading (on each aimer) . . . . . . . . . . . . . . . . . .

1 left to 1 right

Mounting aimers

1. Remove the calibration fixture from the each unit.

2. As shown in the figure, install the articulating vacuum cup

assembly (A), vacuum extension plate (B) and small universal

adaptor (C) to each unit.

90-22 LIGHTING SYSTEM

3. Make the length of the adjustable rod as shown in the figure.

4. Position the aimers on the head lamps pushing the piston

handle forward, engaging the rubber suction cup. Immediately

pull back the piston handle until it is locked in place.

NOTE

Steel inserts are molded into position on the adaptor to

insure accuracy. These inserts should be in contact with

the three guide points on the lamps when the aimers are

properly positioned.

Horizontal adjustment

1. Set the horizontal dial to zero.

2. Check to see that the split image target lines are visible in the

viewing port. If necessary, rotate each aimer slightly to locate

the target.

3. Turn the horizontal screw on the side of the head lamp until the

split image of target line appears in the mirrors as one solid line.

To remove backlash, make the final adjustment by turning

adjusting screw in a clockwise direction.

4. Repeat the last three steps on the apposite head lamp.

Vertical adjustment

1. The vertical dial should be set a zero. (For passenger vehicles,

0 setting is generally required. For special settings, consult

local state laws.)

2. Turn the vertical adjusting screw until the level bubble is

centered between the lines.

3. Repeat the last two steps on the opposite head lamp.

4. Re-check the target alignment on both aimers and readjust the

horizontal aimer if necessary.

5. Remove the aimers by pressing Vacuum release button

located on the piston handle.

LIGHTING SYSTEM 90-23

Aiming with screen

Head lamp aiming preparation

Place the vehicle on a level floor 7.6 m (25 feet) apart from the

aiming screen or a light-colored wall. Four lines of adhesive tape

are required on the screen or wall:

1. Position a vertical piece of tape so that it is aligned with the

vehicle center line.

2. Position a horizontal piece of tape with reference to the center

line of the head lamp.

3. Position a vertical piece of tape on the screen for vertical

adjustment, adjust the side screw for horizontal adjustment.

Visual head lamp adjustment

1. A properly aimed low beam will appear on the aiming screen

7.6m (25 feet) in front of the vehicle. The shaded area as shown

in the illustration indicates a high intensity zone.

2. Adjust the low beam head lamps to match the low beam pattern

of the right and left head lamps.

NOTE

If the visual head lamp adjustment at low beam is made, the

adjustment at high beam is not necessary.

REPLACEMENT OF LAMPS

Head lamp/Front position lamp

1. Disconnect the battery negative terminal.

2. After loosening the nut, pull out the front combination lamp (turn

signal lamp incorporated)

Tightening torque of front combination lamp mounting nut

. . . . . . . . . . . . . . . . . . . . . . . . 0.5-1.0 Nm (5-10 kg.cm, 0.4-0.7 Ib.ft)

3. Remove the radiator grille.

Tightening torque of radiator grille mounting screw

. . . . . . . . . . . . . . . . . . . . . . 0.5-1.0 Nm (5-10 kg.cm, 0.4-0.7 Ib.ft)

Verti cal center l i ne ahead of l ef t headl i ght

Hi gh i ntensi ty area

Vehi cl e axi s

Verti cal center l i ne ahead of ri ght headl i ght

Hei ght of l i ght centers

Hi gh i ntensi ty area

LIGHTING SYSTEM

4. Remove the headlamp assembly with transverse filler by

loosening the 4 mounting bolts.

5. Disconnect the headlamp connector.

6. Disconnect the transverse filler from headlamp assembly.

7. Installation is the reverse order of removal.

Tightening torque of headlamp mounting bolt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Nm (30-50 kg.cm, 2.2-3.6 Ib.ft)

Outside rear combination lamp

1. Disconnect the negative terminal from the battery.

2. Open the trunk lid.

3. With rear luggage cover opened, loosen the 4 mounting nuts.

Tightening torque of rear combination (outside)

lamp-mounting nut

. . . . . . . . . . . . . . . . . . . . . . . . 2.0-25Nm (20-25 kg.cm, 1.5-1.8 Ib.ft)

4. After disconnecting the connector, remove the lamp assembly.

5. Installation is the reverse order of removal.

Inside rear combination lamp

1. Disconnect the negative terminal from the battery.

2. Remove the inside rear combination lamp cover.

3. Remove the inside rear combination mounting nuts.

Tightening torque of rear combination (inside)

lamp mounting nut

. . . . . . . . . . . . . . . . . . . . . . . . . . 2.0-2.5 Nm (20-25 kg.cm, 1.5-1.8 Ib.ft)

LIGHTING SYSTEM 90-25

4. After-disconnecting the connector, remove the lamp assembly.

5. Installation is the reverse order of removel.

High Mounted Stop Lamp

1. Disconnect the battery negative terminal.

2. Using a screw driver, detach 2 blanking covers on both sides of

the lamp.

3. Loosening the mounting screws.

4. Remove the lamp assembly from the rear package tray trim

5. Disconnect the connector from harness.

6. Installation is the reverse order of removal.

Overhead Console Lamp (Vehicles with sunroof)

1. Disconnect the battery negative terminal.

2. Using a screw driver, detach the overhead console lamp lens.

3. Remove the lamp assembly from the head lining by loosening

2 screws.

4. Disconnect the connector from the roof harness.

5. Installation is the reverse order of removal.

90-26

LIGHTING SYSTEM

Door lamp

1. Disconnect the battery negative terminal.

2. Remove the door lamp while inserting the screw driver.

3. Disconnect the connector from door harness.

4. Installation is the reverse order of removal.

INSPECTION OF COMPONENTS

Relay

1. Remove the head lamp and taillamp relay from engine

compartment relay box.

2. Check for continuity between the terminals.

NOTE

1. M indicates that there is a continuity between the

terminals.

2. -0 indicates power supply connection.

Flasher unit

1. Remove the flasher unit from the relay box in passenger

compartment.

2. Connect the positive (+) lead from the battery to terminal 3 and

the negative (-) lead to terminal 2.

3. Connect the two turn signal lamps parallel to each other to

terminal 1 and 2, check that the bulbs turn on and off.

NOTE

The turn signal lamps should flash 60 to 120 times per

minute.

If one of the front or rear turn signal lamps has an open

circuit, the number of flashes will be more than 120 per

minute.

If the operation is not as specified, replace the flasher unit.

LIGHTING SYSTEM

Hazard switch

1. Disconnect the battery negative terminal.

2. Remove the hazard switch from the cluster facia panel RH side.

3. Disconnect the connector from the instrument harness.

4. Operate the switch and check for continuity between terminals

by using an ohmmeter.

Rheostat

1. Disconnect the battery negative terminal.

2. Remove the rheostat from crash pad side panel.

3. Disconnect the connector from instrument harness.

4. Check for intensity

If the light intensity of the lamps changes smoothly without any

flickering when the rheostat is turned, it can be assumed that

the rheostat is functioning properly.

Luggage compartment lamp switch

1. Disconnect the battery negative terminal.

2. Remove the luggage compartment lamp switch from the trunk

lid striker.

3. Disconnect the connector from rear harness.

90-28 LIGHTING SYSTEM

4. Check for continuity between terminal and body while pushing

the rod.

Switch rod condition Continuity

Pushed (OFF)

Non-conductive (- Q)

Released (ON)

Conductive (0 Q)

DAYTIME RUNNING LIGHT 90-29

DAYTIME RUNNING LIGHT (DRL)

DAYTIME RUNNING LIGHT

OPERATION CHECK

Check that the lights are normally operated with following timing

chart.

Timing chart

AUDIO

AUDIO

REMOVAL AND INSTALLATION

Radio unit

1. Remove the center lower crash pad facia panel.

2. Remove the radio unit from the lower crash pad main assembly

by loosening the mounting screws.

3. Disconnect the connector and antenna receptacle from main

harness and antenna feed wire.

4. Installation is the reverse order of removal.

Front speaker

1. Detach the speaker grille.

2. Remove the speaker mounting bolts.

3. Remove the speaker assembly.

4. Installation is the reverse order of removal.

Rear speaker

1. Remove the speaker mounting nuts.

2. Disconnect the wiring connector.

3. Replace in reverse order of the preceding steps.

Automatic antenna

1. Remove the luggage side trim.

90-32

2. Remove the antenna mounting nuts and tapping screw

for ground.

3. Disconnect the wiring connector and antenna cable.

4. Remove the antenna assembly.

5. Replace in reverse order of the preceding steps.

SERVICE INSTRUCTIONS

Fuse replacement

Be sure to use a specified fuse when replacing a in-line fuse, for

radio unit.

Radio unit grade Fuse ratings

Base model 1A&3A

Others 3A & 5A

CAUTION

Substituting with a higher capacity fuse or connecting without

a fuse may result in damage to the unit.

Tape head and capstan cleaning

1. To obtain optimum performance, clean the head and capstan

as often as necessary, depending upon frequency of use and

tape cleanness.

2. To clean the tape head and capstan, use a cotton swab dipped

in ordinary rubbing alcohol.

Wipe the head and capstan.

Speaker checking

1. Check the speaker by using an ohmmeter

If an ohmmeter indicates the impedance of the speaker when

checking between the speaker (+) and speaker (-) of the same

channel, the speaker is okay.

2. If clicking sound is emitted from the speaker when the

ohmmeter plugs touch the speaker terminals, the speaker is

okay.

Automatic antenna inspection

AUDIO

90-33

Connect the motor terminals directly to the battery and check that

the motor operates smoothly. Next, reverse the polarity and check

that the motor operates smoothly in the reverse direction.

90-34 WINDSHIELD WIPER AND WASHER

WINDSHIELD WIPER AND WASHER

SPECIFICATIONS

Item

Wiper motor

10 kg.cm load speed/current

Low

High

40 kg.cm load speed/current

Low

High

Wiper blade

Wiping angle

Drivers/passengers side

Wiper blade length

Drivers/passengers side

Windshield washer

Motor type

Pump type

Rated current

Flow rate

Over load capacity (continuous operation)

With water

Without water

Specification

48-56 rpm/ Max. 3.5 A

64-78 rpm/ Max. 4.5 A

40-48 rpm/ Max. 5.5 A

56-68 rpm/ Max. 7.0 A

87.2/100

500 mm/456 mm

DC ferrite magnet type

Centrifugal type

Max. 3.8 A

Min. 1320 cc/min.

Max. 60 sec.

Max. 20 sec.

TIGHTENING TORQUE

Nm kg.cm Ib.ft

Wiper motor mounting bolt 7-11 70-110 5.06-7.96

Wiper arm mounting nut 18-22 180-220 13.02-15.91

Wiper linkage mounting bolt 4-6 40-60 2.89-4.34

WINDSHIELD WIPER AND WASHER

90-35

COMPONENTS

Windshield Wiper

Ai r i nl et garni sh

Windshield Washer

90-36 WINDSHIELD WIPER AND WASHER

SERVICE POINT OF REMOVAL

Front deck panel

Remove the mounting screws and pry up the front deck panel and

remove it.

Air inlet cover

Remove the air inlet cover while pressing the tab.

Wiper motor

1. Loosen the wiper motor assembly mounting bolts, and then

remove the wiper motor assembly.

2. Disconnect the wiper motor from linkage and the motor

assembly, and then remove the linkage.

CAUTION

Because the installation angle of the crank arm and the

motor has been set, do not remove them unless it is

necessary to do so. If they should be removed, remove

them only after marking their mounting positions.

Wiper, blade

1. Pull out the rubber and backing blade from the stopper side.

2. Remove the backing blade from the rubber.

SERVICE POINT OF INSTALLATION

Wiper arm

Mount the wiper arms onto the pivot shaft so that the stopping

position of the wiper blades is in agreement with the standard

specifications.

Standard specifications (distance between the blade tip and

the front deck panel) : 30 3 mm (1.2 0.12 in.)

WINDSHIELD WIPER AND WASHER 90-37

INSPECTION OF COMPONENTS

Wiper motor speed operation

1. Remove the connector from the wiper motor.

2. Attach the positive (+) lead from the battery to terminal 1 and the

negative (-) lead to terminal 5.

3. Check that the motor operates at low speed.

4. Connect the positive (+) lead from the battery to terminal 1 and

the negative (-) lead to terminal 6.

5. Check that the motor operates at high speed.

Wiper motor automatic stop operation

1. Operate the motor at low speed.

2. Stop the motor operation anywhere except at the off position

by disconnecting terminal 5.

3. Connect terminals 5 and 2.

4. Attach the positive (+) lead from the battery to terminal 1.

5. Check that the motor stops running at the off position.

Washer motor operation

1. With the washer motor connected to the washer tank, fill the

washer tank with water.

2. Connect battery positive (+) and negative (-) cables to terminals

2 and 1 respectively to see that the washer motor runs and

water is pumped.

Washer fluid contact point

1. Check the washer fluid contact point.

2. Adjust the washer fluid contact point by using a metal wire to

move the washer nozzle ball.

3. If the amount of washer fluid sprayed is too small, check for

clogged, bent or crushed washer tube.

90-38 CLOCK AND CIGARETTE LIGHTER

CLOCK AND CIGARETTE LIGHTER

SPECIFICATIONS

Item

Specification

Clock

Time accuracy

Current consumption

Cigarette lighter

Maximum input

Return time

Break temperature of thermal fuse

Within 2 sec/day (at DC 13V)

Max. 150 mA (at DC 13V)

120 W

13 5 sec (after pushing the lighter in)

138-151C (278.4-303.4F)

REPLACEMENT OF CLOCK

1. Remove the 4 screws and pull out the cluster.

2. Disconnect the wiring connector.

3. Remove the digital clock assembly by unscrewing the 2 screws.

CAUTION

The clock is composed of delicate electronic components

containing a crystal oscillator, transistor, etc. and should

be handled with care. Specialized technical skill is needed

to repair the internal mechanism of this clock. Do not

attempt to disassemble it. If the clock itself is

malfunctioning, replace the entire assembly.

INSPECTION OF CIGARETTE LIGHTER

1. Take out the plug.

2. Examine the element spot connection for remnants of tobacco

and other materials.

3. Using an ohmmeter, check for the continuity of the element.

Cautions for use of the cigarette lighter socket as auxiliary

power.

1. When using a plug-in type of accessory, do not use anything

with a load of more than 120W.

2. It is recommended that only the lighter be inserted into the

holder.

POWER WINDOW

POWER WINDOW

REPLACEMENT OF POWER WINDOW MOTOR

Removal

1. Using a screwdriver, remove the clip shown in the illustration to

remove the regulator handle. (Manual type only)

2. Remove the quadrant inner cover.

3. Remove the rearview mirror mounting screws and then remove

the rear view mirror.

Disconnect the remote control connector. (Electric type only)

9 0 - 4 0 POWER WINDOW

4. Remove the safety lock knob.

Remove the screws from the inside handle bezel and arm rest

5. Insert a screwdriver between the trim fasteners and door panel

to pry it loose.

Disconnect the connectors. (Power Window Motor, Power

Window Main Switch, Door Lock Actuator, Outside Mirror and

Trunk Lid Opener Switch)

6. Remove the door trim seal.

7. Detach the regulator assembly.

8. Disconnect the power window motor from the regulator

assembly.

CAUTION

When loosening the mounting screws of the regulator and

the motor assembly, the compressed force of the regulator

spring may cause the regulator arm to spring up.

Installation

Installation is the reverse order of removal.

CAUTION

When installing the door trim seal, butyl tape should not be

placed over door trim fastener mounting area.

POWER WINDOW

INSPECTION OF COMPONENTS

Power window regulator motor

Connect the motor terminals directly to the battery and check that

the motor operates smoothly. Next, reverse the polarity and check

that the motor operates smoothly in the reverse direction. If the

operation is abnormal, replace the motor.

Power window relay

Check for continuity between the terminals 2 and 4.

While power is not supplied : No continuity

While power is supplied : Continuity

Power window main switch

1. Disconnect the power window main switch.

2. Operate the switch, and check for continuity between the

terminals.

3. If continuity is not as specified, replace the switch.

Window lock switch

POWER WINDOW

Power window sub-switch

1. Operate the switch, and check for the continuity between the

terminals.

2. If continuity is not as specified, replace the switch.

POWER DOOR LOCK

POWER DOOR LOCK

INSPECTION OF COMPONENTS

Door lock control actuator

1. Disconnect the actuator connector from the wiring harness.

2. Apply battery voltage (DC 12 V) to each terminal as shown in

the table below and confirm that the actuator makes

corresponding operation.

Door lock control relay

1. After tracing the problem to the control relay, replace it with a

new one. Check for proper operation.

2. If system operates properly, the original control relay is faulty.

90-44

POWER DOOR MIRROR

POWER DOOR MIIRROR

COMPONENTS

INSPECTION OF COMPONENTS

Mirror switch

1. Remove the outside mirror switch on the rear console.

2. Disconnect the connector from the harness.

3. Operate the switch and check for continuity between the

terminals. If continuity is not as specified, replace the mirror

switch.

POWER DOOR MIRROR 90-45

Mirror actuator

Apply battery voltage to each terminal as shown in the table and

confirm that the mirror operates properly.

90-46 HORN, FUEL FILLER DOOR AND TRUNK LID OPENER

HORN, FUEL FILLER DOOR AND TRUNK LID OPENER

SPECIFICATIONS

Item

Horn

Type

Current consumption

Sound level

Basic frequency

Low pitch

High pitch

Fuel filler door opener

Exciting current

Trunk lid opener

Current consumption

Circuit breaker

Trip time

Recovery time

HORN

Removal and installation

1. Disconnect the negative cable of the battery.

2. Remove the horn attaching bolt (on the radiator support panel).

3. Disconnect the horn connector from engine harness.

4. Remove the horn.

Specification

Plate type

Max. 3.5 A (at DC 12V)

105 5 dB (at DC 12V, 2m)

360 20 Hz (at DC 12V)

420 20 Hz (at DC 12V)

Max. 15A (at DC 12V)

Max. 12A (at DC 12V)

4-9 sec.

5 sec

Sound level adjustment

Operate the horn, and adjust the tone to a suitable level (by

turning the adjusting screw).

CAUTION

After the adjustment, apply a small amount paint around the

screw head to keep it from loosening.

HORN, FUEL FILLER DOOR AND TRUNK LID OPENER 90-47

FUEL FILLER DOOR OPENER

COMPONENTS

INSPECTION OF COMPONENTS

Fuel filler door opener

1. Remove the luggage compartment side trim.

2. Open the fuel filler door.

3. Loosen the three bolts securing the fuel filler door opener and

then disconnect the wiring connector.

4. Check for continuity between terminals 1 and 2. If there is no

continuity, replace the fuel filler door opener.

Fuel filler door opener switch

Operate the switch, and check for continuity between the terminals.

If continuity is not as specified, replace the switch.

90-48 HORN, FUEL FILLER DOOR AND TRUNK LID OPENER

TRUNK LID OPENER

COMPONENTS

INSPECTION OF COMPONENTS

Trunk lid opener

1. Remove the trunk lid opener and check continuity between the

terminal a and b.

2. If there is no continuity, replace the opener assembly.

Trunk lid opener switch

Remove the trunk lid opener switch and check continuity between

the terminals.

SUN ROOF

SUN ROOF

SPECIFICATIONS

Item

Sun roof motor

No load speed/current

Lock current

Sun roof relay

Rated load

Exciting current

Sun roof motor switch

Type of operation

Rated load

INSPECTION OF COMPONENTS

Sun roof motor

1. Remove the overhead console lamp.

2. Disconnect the motor connector from sun roof harness.

3. Apply DC 12V to the 0.85 YR wire and ground the 0.85Y wire.

4. Check that the motor turns in the direction to tilt up and closed

position,

5. Reverse the connections and check that the motor turns from

open, to closed, to tilt up position.

Specification

Max. 180 rpm/Max. 6 A

Max. 35 A

Motor 6 A/Lock 15 A

Max. 250 mA

Push on and self-return

1 A

SUN ROOF

Sun roof relay

Check for continuity between the terminals.

Sun roof switch

1. Using an ohmmeter, check for continuity between terminals.

2. If the continuity is not as specified, replace the switch.

E.T.A.C.S. 90-51

E.T.A.C.S. (Electronic Time and Alarm Control System)

SPECIFICATIONS

ETACS unit

Rated load

Variable intermittent wiper

Rear defogger timer

Seat belt warning

Key illumination & delay out room lamp

Door lock actuator (lock, unlock)

Chime bell

Leakage current

Rear window defogger glass

Power consumption

DC 12V, 6A (Inductive load)

DC 12V, 200 mA (Inductive load)

DC 12V, 1.2W (Lamp load)

DC 12V, 1.2W, 10W (Lamp load)

DC 12V, 200 mA (Inductive load)

DC 13.5V, 350 mA (inductive load)

Max. 4 mA (at 12.8V)

185 10 W (Per sheet)

COMPONENTS

90-52

E.T.A.C.S.

OPERATION CHECK OF COMPONENTS

While operating the components, check whether the operations are

normal with timing chart.

Variable intermittent wiper

1. Time specification

T 1 : Max. 0.5 sec.

T 2 : Time of wiper motor 1 rotation.

T 3 : 1.5 0.7 sec. (VR=OkQ) ~ 10.5 3 sec. (VR=50 kQ)

2. Variable resistance (VR) : 0I ~ 50 kQ

Washer

1. Time specification

T 1 : 0.4 ~ 1.2 sec

T 2 : 2.0 ~ 4.7 sec

2. This function should be operated preferentially even though the

variable intermittent wiper is operating.

Rear window defogger

1. Time specification

T 1 : Min. 0.5 sec.

T 2 : 10 3 min.

Seat belt warning

1. Time specification

T 1 :6 sec.

T 2 : 6 1 sec.

T 3, T 4 : 0.3 0.1 sec.

Door lock actuator

1. Time specification

T 1 : 0.5 sec.

E.T.A.C.S. 90-53

Ignition key hole illumination

1. Time specification

T 1 : 6 sec.

T 2 : 016 sec.

Delayed out room lamp

T 1 : 2 sec.

T 2 : 4 sec.

T 3 : 014 sec.

Door warning

1. Time specification

T 1, T 2 : 0.3 0.1 sec.

Ignition key reminder

1. Time specification

T 1 : 5.0 sec.

INSPECTION OF COMPONENTS

E.T.A.C.S. unit

1. After tracing the problem to the control unit, replace it with a new

one. Check for proper operation.

2. If system operates properly, the original control unit is faulty.

90-54 E.T.A.C.S.

Rear window defogger switch

1. Disconnect the defogger switch connector from the wiring

harness.

2. Operate the switch, and check the continuity between the

terminals.

3. If continuity is not as specified, replace with new one.

Printed heater line

CAUTION

Wrap tin foil around the end of the voltmeter test lead to

prevent damaging the heater line. Apply finger pressure on the

tin foil, moving the tin foil along the grid line to check for open

circuits.

1. Turn on the defogger switch and use a voltmeter to measure the

voltage of each heater line at the glass center point. If a voltage

of approximately 6V is indicated by the voltmeter, the heater

line of the rear window is considered satisfactory.

2. If a heater line is burned out between the center point and (+)

terminal, voltmeter indicates 12 volts.

3. If a heater line is burned out between the center point and (-)

terminal, the voltmeter indicates 0 volt.

E.T.A.C.S.

4. To check for open circuits, slowly move the test lead in the

direction that the open circuit seems to exist. Try to find a point

where a voltage is generated or changes to OV. The point where

the voltage has changed is the open-circuited point.

5. Use an ohmmeter to measure the resistance of each heater line

between a terminal and the center of a grid line and between the

same terminal and the center of one adjacent heater line after

another with defogger OFF. The section involving a broken

heater line indicates resistance twice as that in other section. In

the affected section, move the test lead to a position where

resistance sharply changes.

Repair of broken heater line

Provide the following items:

1. Conductive paint.

2. Paint thinner.

3. Making tape.

4. Silicone remover.

5. Thin brush

Wipe the glass adjacent to the broken heater line, clean with

silicone remover and attach the masking tape as shown. Shake

the conductive paint container well, and apply three coats with

a brush at intervals of about 15 minutes apart. Remove the tape

and allow sufficient time for drying before applying power.

For a better finish, scrape away excess deposits with a knife

after completely dried. (allow 24 hours)

CAUTION

After repairing, clean the glass with a soft dry cloth or wipe

along the grid line with a slightly moistened cloth.

90-56 AUTOMATIC TRANSAXLE AND KEY LOCK CONTROL SYSTEM

AUTOMATIC TRANSAXLE AND KEY LOCK CONTROL SYSTEM

COMPONENTS

A. Below front of center console

B. Shift lever assembly

C. Ignition key

D. Shift lever assembly

A. Control unit

C. Key lock solenoid

B. A/T solenoid

D. P-position switch

AUTOMATIC TRANSAXLE AND KEY LOCK CONTROL SYSTEM

90-57

SYSTEM OPERATION CHECK

Key lock system

1. Check that the ignition key cannot be turned to LOCK (OFF)

position, when the position of the shift lever is not in P position.

2. Check that the ignition key turns to the LOCK (OFF) position,

when the shift lever is set to the P position.

A/T shift lock system

1. Check that under the following conditions, the shift lever cannot

be moved from the P position to any other position.

IGNITION KEY POSITION : ON

BRAKE PEDAL : NOT DEPRESSED

BUTTON : PRESSED

2. Check that under the following conditions, the shift lever can be

moved from the P position to other position.

IGNITION KEY POSITION : ON

BRAKE PEDAL : DEPRESSED

BUTTON : PRESSED

AUTOMATIC TRANSAXLE AND KEY LOCK CONTROL SYSTEM

Timing Chart

INSPECTION OF COMPONENTS

Automatic Transaxle Solenoid

1. Remove the solenoid connector.

2. Using an ohmmeter, measure the resistance between termi-

nals.

Standard resistance : 12 - 16 i2

3. Attach the positive (+) lead from the battery to terminal 1. and

the negative (-) lead to terminal 2.

4. Check that an operation noise can be heard from the solenoid.

PASSIVE SEAT BELT (U.S.A.)

PASSIVE SEAT BELT (For U.S.A.)

SPECIAL SERVICE TOOL

Tool

(Number and name)

Illustration

09888-33000

Diagnostic controller

COMPONENTS

Use

Reading diagnosis

You might also like

- 2000 VW Passat Wiring DiagramsDocument55 pages2000 VW Passat Wiring Diagramsjuan carlos siqueiros ochoaNo ratings yet

- Hyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Document35 pagesHyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Jan KowalskiNo ratings yet

- NAVEDTRA 14030A - Aviation Electronics Technician (ATO) Jun2015Document309 pagesNAVEDTRA 14030A - Aviation Electronics Technician (ATO) Jun2015lynx437100% (2)

- Abrites Diagnostics For Ford Mazda User ManualDocument60 pagesAbrites Diagnostics For Ford Mazda User ManualOscar RodriguezNo ratings yet

- Tle - Ict - CSS: Quarter 3 - Module 1 Types and Parts of ComputersDocument14 pagesTle - Ict - CSS: Quarter 3 - Module 1 Types and Parts of ComputersRichard Garcia80% (5)

- WAPU Overhaul BZBDocument8 pagesWAPU Overhaul BZBNedim ErkocevicNo ratings yet

- Passat CC No. 39 / 1: Current Flow DiagramDocument7 pagesPassat CC No. 39 / 1: Current Flow DiagramBin WangNo ratings yet

- Electro-Mechanical Parking Brake, ComponentDocument7 pagesElectro-Mechanical Parking Brake, ComponentPopa MihaiNo ratings yet

- Peugeot Obd CodesDocument4 pagesPeugeot Obd Codesmrx200No ratings yet

- Mexican Beetle 1600 I Ignition TimingDocument17 pagesMexican Beetle 1600 I Ignition TimingmartinNo ratings yet

- Scoda Fabia Tdi Classl455 1 Cfwa MalDocument28 pagesScoda Fabia Tdi Classl455 1 Cfwa MalИгорь ЯсюкNo ratings yet

- mK5 Jetta BrakesDocument45 pagesmK5 Jetta Brakesvixentd100% (2)

- Bose Cinemate 15 ManualDocument124 pagesBose Cinemate 15 Manual석우No ratings yet

- Installation and Operations Guide: Flg-ModbusDocument28 pagesInstallation and Operations Guide: Flg-ModbusFrancisco100% (1)

- Daewoo Matiz - Hydraulic BrakesDocument14 pagesDaewoo Matiz - Hydraulic BrakesadrianNo ratings yet

- Slide/tilt Sunroof: Volkswagen New BeetleDocument21 pagesSlide/tilt Sunroof: Volkswagen New BeetleHéctor Morales OrtegaNo ratings yet

- VW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)Document49 pagesVW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)NPNo ratings yet

- VW ManualDocument28 pagesVW ManualImanol SantsNo ratings yet

- 85 KW Motronic, Engine Code BHYDocument18 pages85 KW Motronic, Engine Code BHYArdillon15No ratings yet

- Current Flow Diagram: Airbags and Belt Tensioners For Driver and Front PassengerDocument3 pagesCurrent Flow Diagram: Airbags and Belt Tensioners For Driver and Front PassengerRoberto BlazquezNo ratings yet

- Megane General Electrical LayoutDocument9 pagesMegane General Electrical LayoutPepe MoralesNo ratings yet

- Opel Motronic2.5 PDFDocument5 pagesOpel Motronic2.5 PDFjesrafNo ratings yet

- Charging 2001-04 PDFDocument19 pagesCharging 2001-04 PDFoz23No ratings yet

- b6 97 EngDocument104 pagesb6 97 EngdanielvasilievNo ratings yet

- SBT Electrical Distribution Centre - E87, E90, E91, E92Document2 pagesSBT Electrical Distribution Centre - E87, E90, E91, E92Engsolution LdaNo ratings yet

- CD 05 VW Jetta GLI (Manual) 1624Document27 pagesCD 05 VW Jetta GLI (Manual) 1624Umar DeenNo ratings yet

- Air Condition (AEH+AKL+AGN+AGU+APN+AQY+AGP+AQM+AGR+ALH)Document5 pagesAir Condition (AEH+AKL+AGN+AGU+APN+AQY+AGP+AQM+AGR+ALH)Melissa WillisNo ratings yet

- 1999 System Wiring Diagrams Volkswagen - PassatDocument45 pages1999 System Wiring Diagrams Volkswagen - PassatDragos MunteanuNo ratings yet

- En SSP 340 The Passat 2006 Electrical System 1Document19 pagesEn SSP 340 The Passat 2006 Electrical System 1molnar nicu100% (1)

- Abrites Diagnostics For Renault Dacia User ManualDocument47 pagesAbrites Diagnostics For Renault Dacia User ManualTomi OzzyNo ratings yet

- '07-'14 Mercedes-Benz C-Class (W204 - S204 - C204) Fuse Box DiagramDocument20 pages'07-'14 Mercedes-Benz C-Class (W204 - S204 - C204) Fuse Box Diagramtech.nagendranNo ratings yet

- Keyless Entry System: Wiring Diagram of The Main UnitDocument1 pageKeyless Entry System: Wiring Diagram of The Main UnithamayunNo ratings yet

- VW T4 Automatic Gearbox Adapter Kit InstallationDocument2 pagesVW T4 Automatic Gearbox Adapter Kit InstallationLuke HazelgroveNo ratings yet

- Manual RT5 EngDocument19 pagesManual RT5 EngmytheuzenNo ratings yet

- Infodiag 213Document14 pagesInfodiag 213ArturHeiseNo ratings yet

- Abrites Diagnostics For VAG User Manual HTMLDocument14 pagesAbrites Diagnostics For VAG User Manual HTMLismael pimentelNo ratings yet

- Passat No. 15/1: Air-ConditioningDocument5 pagesPassat No. 15/1: Air-ConditioningvoltohmartNo ratings yet

- Diesel GateDocument41 pagesDiesel Gateanon_934477879100% (1)

- The Sharan: 2006 Model YearDocument25 pagesThe Sharan: 2006 Model YearwytalikNo ratings yet

- 3NS7wij4Ny2H9G17yy9ikD1v1Ka2nYuO - Engine Management 2017-2018 - Reduced PDFDocument564 pages3NS7wij4Ny2H9G17yy9ikD1v1Ka2nYuO - Engine Management 2017-2018 - Reduced PDFProducciones3NNo ratings yet

- 2 g4 1.9L ALH Autom TrsDocument13 pages2 g4 1.9L ALH Autom TrsDan Paşca100% (2)

- CAN-bus Interface Steering Wheel Control Interface-Box CX-301 Harnesses Vehicle-Specific CX-0xx Harnesses Device-Specific (Optional) ARC-1xxDocument12 pagesCAN-bus Interface Steering Wheel Control Interface-Box CX-301 Harnesses Vehicle-Specific CX-0xx Harnesses Device-Specific (Optional) ARC-1xxeldi_ye100% (1)

- GPL Golf 6Document22 pagesGPL Golf 6Iordan Adrian100% (1)

- VolvoDocument1 pageVolvoAnonymous OFfJVrQY60% (1)

- EECTCH98Document79 pagesEECTCH98Harry JacobsonNo ratings yet

- Peugeot 807 ManualDocument234 pagesPeugeot 807 ManualV GergNo ratings yet

- BobinasDocument8 pagesBobinasbernalgutierrezNo ratings yet

- VW Wiring Diagram Symbols and ReadDocument7 pagesVW Wiring Diagram Symbols and ReadrikuelleNo ratings yet

- Yacc Module For Opel Astra G MidDocument17 pagesYacc Module For Opel Astra G MidPrudencio L. Serviano IIINo ratings yet

- Autoscan Grason WAUZZZ8E32A120922 227730km 141504miDocument3 pagesAutoscan Grason WAUZZZ8E32A120922 227730km 141504miVoicu FlorinNo ratings yet

- VW CAN BT Installation Instructions WEBSITE August 2010Document9 pagesVW CAN BT Installation Instructions WEBSITE August 2010Luiz Malta MontenegroNo ratings yet

- 968 Fuse Box ChartDocument1 page968 Fuse Box Chartdamon wNo ratings yet

- Kalos - 1.4 16V DataDocument3 pagesKalos - 1.4 16V DataNatalija Nata JovanovicNo ratings yet

- Arac Listesi Kme Direkt Enjeksiyon - 1Document11 pagesArac Listesi Kme Direkt Enjeksiyon - 1yassine zitouniNo ratings yet

- Mr395 Laguna Motor f9q enDocument328 pagesMr395 Laguna Motor f9q enAlexandru sNo ratings yet

- Toyota Avensis Electronic Parking Brake SystemDocument8 pagesToyota Avensis Electronic Parking Brake SystemAnastas TashevNo ratings yet

- (TM) Volkswagen Manual de Taller Volkswagen Passat 2006 en Ingles PDFDocument300 pages(TM) Volkswagen Manual de Taller Volkswagen Passat 2006 en Ingles PDFVartic Lilia100% (1)

- VW Vento 2.5 Lts BTK 2008 AbsDocument8 pagesVW Vento 2.5 Lts BTK 2008 Absnicamarcos100% (1)

- AirbagDocument8 pagesAirbagMartynas RamanauskasNo ratings yet

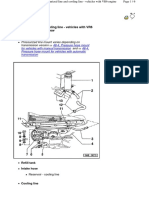

- VW Passat B4 - Pressurized Line and Cooling Line - Vehicles With VR6 EngineDocument6 pagesVW Passat B4 - Pressurized Line and Cooling Line - Vehicles With VR6 EngineNPNo ratings yet

- Revoflash 3 r19 Vag Ecu List v08 05Document6 pagesRevoflash 3 r19 Vag Ecu List v08 05Gasper Ceballos100% (1)

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideFrom EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideNo ratings yet

- Reyes, Andrian G. Multi Dwelling Electrical Plan BSCE 2-1 Engineering UtilitiesDocument4 pagesReyes, Andrian G. Multi Dwelling Electrical Plan BSCE 2-1 Engineering UtilitiesAndrian Reyes0% (1)

- Final Report PBL PJDocument18 pagesFinal Report PBL PJAdityaNo ratings yet

- 1 Pasco Fysikkatalog 2010 DataloggingDocument109 pages1 Pasco Fysikkatalog 2010 DataloggingBryan Andi SitumorangNo ratings yet

- Lucas 2MC Capacitor TestsDocument6 pagesLucas 2MC Capacitor Testsderryuk100% (1)

- Motor Driver From Micorchip Is Automotive AEC-Q100-Qualified, Highly Integrated and Compact Provides High Performance and High CurrentDocument3 pagesMotor Driver From Micorchip Is Automotive AEC-Q100-Qualified, Highly Integrated and Compact Provides High Performance and High CurrentKelvin CooperNo ratings yet

- Low Cost String PotDocument2 pagesLow Cost String PotmelquicedecNo ratings yet

- Lte MCQ PDFDocument3 pagesLte MCQ PDFking khan100% (1)

- The Azerbaijani Experiences in Digital Substation Deployment. How Process Bus and IEC 61850 Addresses Utility RequirementsDocument18 pagesThe Azerbaijani Experiences in Digital Substation Deployment. How Process Bus and IEC 61850 Addresses Utility Requirementspo ghNo ratings yet

- Emergency Power SystemsDocument30 pagesEmergency Power Systemsrand.campbell@pgnmail.com100% (1)

- Hanwha Q Cells Data Sheet Qplus L-g4.1 330-340 2015-09 Rev02 Na PrintDocument2 pagesHanwha Q Cells Data Sheet Qplus L-g4.1 330-340 2015-09 Rev02 Na Printนครินทร์ นักเดินทางตัวเล็กNo ratings yet

- Module I: Electromagnetic Waves: Lectures 10-11: Multipole RadiationDocument18 pagesModule I: Electromagnetic Waves: Lectures 10-11: Multipole RadiationBibhuti DasNo ratings yet

- Low-Pass Filter ButterworthDocument14 pagesLow-Pass Filter ButterworthBhuvan GuptaNo ratings yet

- DDR5 Vs DDR4 - All The Design Challenges & Advantages - RambusDocument4 pagesDDR5 Vs DDR4 - All The Design Challenges & Advantages - Rambussantosh soodNo ratings yet

- ISS 1 KameraDocument2 pagesISS 1 KamerameiniarNo ratings yet

- AGC-4 Operator's Manual 4189340690 UK - 2012.07.13Document21 pagesAGC-4 Operator's Manual 4189340690 UK - 2012.07.13Felipe LimaNo ratings yet

- Fire Pump SpecificationDocument5 pagesFire Pump SpecificationThiru AnanthNo ratings yet

- Service Manual Power Supply Unit Panasonic KX-TDA0103X - Sup3Document178 pagesService Manual Power Supply Unit Panasonic KX-TDA0103X - Sup3RusLanCkNo ratings yet

- B Tech +Electrical+Syllabus-3Document110 pagesB Tech +Electrical+Syllabus-3ashuy.1303No ratings yet

- ABC, An Effective Tool For Harmonic EliminationDocument17 pagesABC, An Effective Tool For Harmonic Eliminationshridhar kulkarniNo ratings yet

- Datasheet MIN TL-XDocument2 pagesDatasheet MIN TL-XJM COPANo ratings yet

- Visio-SWCS - Control Block Diagram Rev.02Document2 pagesVisio-SWCS - Control Block Diagram Rev.02nautelNo ratings yet

- Psa Question Bank 2Document9 pagesPsa Question Bank 2Krishnakumar IesNo ratings yet

- 1) Karthik S 1BH15EC003 2) Darshan R 1BH16EC003 3) Rupini R 1BH16EC014 1) Auto Temperature Detector For Entrance Covid SafetyDocument7 pages1) Karthik S 1BH15EC003 2) Darshan R 1BH16EC003 3) Rupini R 1BH16EC014 1) Auto Temperature Detector For Entrance Covid SafetyPuneethHjNo ratings yet

- E38 Immobiliser System EWS3Document4 pagesE38 Immobiliser System EWS3naamikekwekuaduNo ratings yet

- Data SheetDocument13 pagesData Sheethukam pariharNo ratings yet

- Balanza de Recolección Technical - Reference-Manual - bm330-1 - bm323-1Document48 pagesBalanza de Recolección Technical - Reference-Manual - bm330-1 - bm323-1MatíasNo ratings yet