0 ratings0% found this document useful (0 votes)

456 viewsLab 3 CAD

Lab 3 CAD

Uploaded by

jzsinghThe document describes an experiment that compares the velocity and acceleration profiles of different types of cams (circular, convex, simple harmonic, and constant acceleration) with two types of followers (flat and dome). Data is presented on the displacement, velocity, and acceleration at various crank angles for each cam profile and follower type. Calculations are also provided as an example for determining the displacement of a convex cam. The objectives are to compare the profiles of the different cam types and understand the velocity and acceleration profiles of simple harmonic and constant acceleration cams.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Lab 3 CAD

Lab 3 CAD

Uploaded by

jzsingh0 ratings0% found this document useful (0 votes)

456 views16 pagesThe document describes an experiment that compares the velocity and acceleration profiles of different types of cams (circular, convex, simple harmonic, and constant acceleration) with two types of followers (flat and dome). Data is presented on the displacement, velocity, and acceleration at various crank angles for each cam profile and follower type. Calculations are also provided as an example for determining the displacement of a convex cam. The objectives are to compare the profiles of the different cam types and understand the velocity and acceleration profiles of simple harmonic and constant acceleration cams.

Original Description:

Machine design lab

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document describes an experiment that compares the velocity and acceleration profiles of different types of cams (circular, convex, simple harmonic, and constant acceleration) with two types of followers (flat and dome). Data is presented on the displacement, velocity, and acceleration at various crank angles for each cam profile and follower type. Calculations are also provided as an example for determining the displacement of a convex cam. The objectives are to compare the profiles of the different cam types and understand the velocity and acceleration profiles of simple harmonic and constant acceleration cams.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

456 views16 pagesLab 3 CAD

Lab 3 CAD

Uploaded by

jzsinghThe document describes an experiment that compares the velocity and acceleration profiles of different types of cams (circular, convex, simple harmonic, and constant acceleration) with two types of followers (flat and dome). Data is presented on the displacement, velocity, and acceleration at various crank angles for each cam profile and follower type. Calculations are also provided as an example for determining the displacement of a convex cam. The objectives are to compare the profiles of the different cam types and understand the velocity and acceleration profiles of simple harmonic and constant acceleration cams.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 16

OBJECTIVE

The objectives of this experiment are as follows:

To compare the profile of the convex, simple harmonic, constant acceleration and

circular cams, with two types of followers, flat follower and dome followers

To know the velocity profile of simple harmonic and constant acceleration cams, with

two types of followers that is, flat follower and dome followers.

To know the acceleration profile of simple harmonic and constant acceleration cam

with two types of followers that is, flat follower and dome followers.

DATA, OBSERVATION AND RESULTS

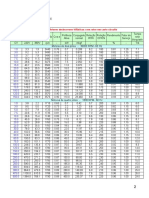

FOR CIRCULAR CAM

Crank Angle,

Displacement, x(mm) Theoretical

displacement,(mm) Dome Flat

0 0 0.1 0.000

10 0.2 0.5 0.200

20 0.6 1.2 0.800

30 1.1 2.2 1.800

40 1.9 3.4 3.100

50 2.9 4.7 4.600

60 3.9 6.2 6.300

70 5.2 7.9 8.000

80 6.85 9.7 9.800

90 8.55 11.3 11.600

100 10.3 13.1 13.200

110 12.1 14.5 14.600

120 13.7 15.9 16.000

130 15.3 17.1 17.100

140 16.7 18.2 18.000

150 18.0 18.9 18.700

160 19.0 19.4 19.200

170 19.5 19.5 19.500

180 19.7 19.4 19.700

190 19.5 18.9 19.500

200 18.9 18.2 19.200

210 17.9 17.2 18.700

220 16.7 15.9 18.000

230 15.2 14.5 17.100

240 13.55 13.0 16.000

250 11.85 11.2 14.600

260 9.9 9.5 13.200

270 8.1 7.7 11.600

280 6.5 6.2 9.800

290 5.0 4.8 8.000

300 3.7 3.5 6.300

310 2.6 2.3 4.600

320 1.7 1.4 3.100

330 0.9 0.6 1.800

340 0.5 0.2 0.800

350 0.2 0.1 0.200

360 0 0 0.000

FOR CONVEX CAM

Crank Angle,

Displacement, x(mm) Theoretical

displacement,(mm) Dome Flat

0 0 0 0.00

10 0.1 0 0.00

20 0.1 0 0.00

30 0.1 0 0.00

40 0.15 0 0.00

50 0.05 -0.1 0.00

60 0.05 -0.1 0.00

70 0.05 -0.2 0.00

80 0.05 -0.2 0.00

90 0 -0.3 0.00

100 0.1 0 0.00

110 0.7 1.2 0.00

120 1.75 3.0 0.00

130 3.2 5.4 0.00

140 5.2 8.4 0.00

150 7.9 11.8 0.00

160 11.5 16.0 0.00

170 16.1 18.5 0.00

180 19.5 19.2 0.00

190 17.4 18.9 0.19

200 12.4 17.0 0.79

210 8.7 13.0 1.83

220 5.6 9.3 3.38

230 3.3 6.2 5.52

240 1.7 3.7 8.39

250 0.7 1.7 12.11

260 0.05 0.3 16.78

270 -0.15 -0.3 22.43

280 -0.2 -0.3 16.78

290 -0.1 -0.2 12.11

300 -0.1 -0.2 8.39

310 0 -0.1 5.52

320 0 -0.1 3.38

330 0.5 -0.1 1.83

340 0.05 0 0.79

350 1 0 0.19

360 0 0 0

FOR SIMPLE HARMONIC CAM

Crank Angle,

Displacement, x(mm) Theoretical

displacement,(mm) Dome Flat

0 0 0 0.000

10 0.2 0.2 0.152

20 0.75 1.0 0.603

30 1.55 2.0 1.340

40 2.6 3.2 2.340

50 3.95 4.8 3.572

60 5.45 6.2 5.000

70 6.7 7.8 6.580

80 8.5 9.6 8.264

90 10.3 11.2 10.000

100 12.0 12.8 11.736

110 13.6 14.3 13.420

120 15.1 15.5 15.000

130 16.4 16.7 16.428

140 17.6 17.7 17.660

150 18.5 18.5 18.660

160 19.2 19.1 19.397

170 19.6 19.4 19.848

180 19.75 19.5 20.000

190 19.55 19.4 19.848

200 19.05 19.1 19.397

210 18.3 18.4 18.660

220 17.4 17.6 17.660

230 16.1 16.7 16.428

240 14.7 15.5 15.000

250 13.1 14.1 13.420

260 11.4 12.6 11.736

270 9.7 11.0 10.000

280 8.5 9.4 8.264

290 6.4 7.9 6.580

300 4.9 6.2 5.000

310 3.6 4.8 3.572

320 2.4 3.4 2.340

330 1.3 2.2 1.340

340 0.6 1.1 0.603

350 0.2 0.3 0.152

360 0 0 0.000

FOR CONSTANT ACCELERATION CAM

Crank Angle,

Displacement, x(mm) Theoretical

displacement,(mm) Dome Flat

0 0 0 0.00

10 0.25 0.2 0.12

20 0.65 0.7 0.49

30 1.3 1.6 1.11

40 2.2 2.8 1.98

50 3.3 4.2 3.09

60 4.1 5.8 4.44

70 6.2 7.8 6.05

80 8.2 10.0 7.90

90 13.0 11.8 10.00

100 12.3 13.5 12.10

110 14.1 15.1 13.95

120 15.7 16.5 15.56

130 16.9 17.6 16.91

140 18.1 18.6 18.02

150 18.95 19.4 18.89

160 19.6 19.9 19.51

170 20.0 20.2 19.88

180 22.0 20.4 20.00

190 20.5 20.2 19.88

200 19.65 19.9 19.51

210 19.05 19.3 18.89

220 18.25 18.6 18.02

230 17.1 17.6 16.91

240 15.8 16.5 15.56

250 14.2 15.6 13.95

260 12.3 13.5 12.10

270 10.2 11.8 10.00

280 8.2 10.0 7.90

290 6.2 8.0 6.05

300 4.55 6.1 4.44

310 3.25 4.4 3.09

320 2.15 3.0 1.98

330 1.25 1.7 1.11

340 0.65 0.8 0.49

350 0.25 0.2 0.12

360 0 0 0.00

VELOCITY AND ACCELERATION PROFILE FOR SIMPLE HARMONIC AND

CONSTANT ACCELERATION CAMS.

Crank Angle,

Constant Acceleration Harmonic

velocity

(mm/deg)

Acceleration,

(mm/deg

2

)

velocity

(mm/deg)

Acceleration,

(mm/deg

2

)

0 0.0 2.0 0.0 10.000

10 25 2.0 1.736 9.848

20 4.9 2.0 3.420 9.397

30 7.4 2.0 5.000 8.660

40 9.9 2.0 6.428 7.660

50 12.3 2.0 7.660 6.428

60 14.8 2.0 8.660 5.000

70 17.3 2.0 9.397 3.420

80 19.8 2.0 9.848 1.736

90 22.2 2.0 10.000 0.000

100 19.8 -2.0 9.848 -1.736

110 17.3 -2.0 9.397 -3.420

120 14.8 -2.0 8.660 -5.000

130 12.3 -2.0 7.660 -6.428

140 9.9 -2.0 6.428 -7.660

150 7.4 -2.0 5.000 -8.660

160 4.9 -2.0 3.420 -9.397

170 2.5 -2.0 1.736 -9.848

180 0.0 -2.0 0.000 -10.000

190 -2.5 -2.0 -1.736 -9.848

200 -4.9 -2.0 -3.420 -9.397

210 -7.4 -2.0 -5.000 -8.660

220 -9.9 -2.0 -6.428 -7.660

230 -12.3 -2.0 -7.660 -6.428

240 -14.8 -2.0 -8.660 -5.000

250 -17.3 -2.0 -9.397 -3.420

260 -19.8 -2.0 -9.848 -1.736

270 -22.2 -2.0 -10.000 0.000

280 -19.8 2.0 -9.848 1.736

290 -17.3 2.0 -9.397 3.420

300 -14.8 2.0 -8.660 5.000

310 -12.3 2.0 -7.660 6.428

320 -9.9 2.0 -6.428 7.660

330 -7.4 2.0 -5.000 8.660

340 -4.9 2.0 -3.420 9.397

350 -2.5 2.0 -1.736 9.848

360 0.0 2.0 0.000 10.000

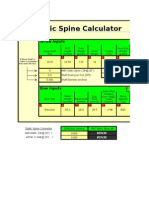

SAMPLE CALCULATION

1) Convex

- For the first 180 degrees, the theoretical value for displacement is 0.

- The theoretical is 10 until 180 then start from 10 until 90 and decreasing till 0

For = 10

sin = 35 sin (180-)

55

= 35 sin (180-10)

55

= 0.1105

= 6.344

= -

= 10-6.344

= 3.656

OE = 55 sin

sin (180-)

= 55 sin 3.656

sin 170

= 20.195

X = OE 20

= 20.195 20

= 0.195mm

2) Harmonic

For = 10

= angular velocity in rad/sec, in our case = 1 rad/sec

x = R(1-cos)

= 10 (1-cos 10)

= 0.1519mm

v = (Rsin)

= 1 ( 0.01 sin 10)

= 1.7365 x 10

-3

mm/sec

= 1.7365 mm/sec

a =

2

(Rcos )

= 1 (0.01 cos 10)

= 9.848 x 10

-3

m/sec

2

= 9.848 mm/sec

2

3) Constant Acceleration

For 0 to 90

x = [(/15)/3.6]

= [ (10/15)/3.6]

= 0.123 mm

v = dx/d

= d[(/15)/3.6]

d

= (2/15

2

)/3.6

= 0.02469 mm/sec

a = dv/d

= d (2/15

2

)/3.6

d

= (2/15

2

)/3.6

= 2.469 x 10

-3

mm/sec

2

For 91 to 180

x = 20 [(180-/15)

2

/3.6]

= 20 [(180-100/15)

2

/3.6]

= 12.099mm

v = dx/d

= d [20 [(180-/15)

2

/3.6]]/ d

= 4/9 /405

= 0.1975 mm/sec

a = dv/d

= d(4/9 /405)/ d

= -1/405

= -2.469 x 10

-3

mm/sec

2

For 181 to 270

x = 20 [(-180/15)

2

/3.6]

= 20 [(190-180/15)

2

/3.6]

= 19.88 mm

v = dx/d

= d[20 [( -180/15)

2

/3.6]] / d

= 4/9 - /405

= -0.1975 mm/sec

a = dv/d

= d(4/9 - /405)/ d

= -2.469 x 10

-3

mm/sec

2

For 271 to 360

x = [(360-/15)

2

/3.6]

= [(360-280/15)

2

/3.6]

=7.9 mm

v = dx/d

= d[(360-/15)

2

/3.6]/ d

= -8/9 + /405

= -0.148 mm/sec

a = d(-8/9 + /405) / d

= 1 /405

= 2.469 x 10

-3

mm/sec

2

ANALYSIS

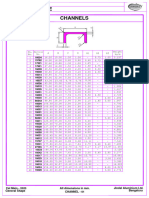

1) Graph of Displacement against Crank Angle for Circular Cam

2) Graph of Displacement against Crank Angle for Convex Cam

0

5

10

15

20

25

0 100 200 300 400

Displacement,

mm

Crank Angle,

Graph of Displacement vs Crank Angle for

Circular Cam

Dome

Flat

-5

0

5

10

15

20

25

0 50 100 150 200 250 300 350 400

Displacement,

mm

Crank Angle,

Graph of Displacement against Crank Angle for

Convex Cam

Dome

Flat

3) Graph of Displacement against Crank Angle for Simple Harmonic Cam

4) Graph of Displacement against Crank Angle for Constant Acceleration Cam

0

5

10

15

20

25

0 50 100 150 200 250 300 350 400

Displacement,mm

Crank Angle,

Graph of Displacement against Crank Angle for

Simple Harmonic Cam

Dome

Flat

0

5

10

15

20

25

0 50 100 150 200 250 300 350 400

Displacement,m

m

Crank Angle,

Graph of Displacement against Crank Angle for

Constant Acc. Cam

Dome

Flat

5) Graph of Velocity Against Crank Angle for Simple Harmonic and Constant

Acceleration Cams

6) Graph of Acceleration against Crank Angle for Simple Harmonic and Constant

Acceleration Cams

-25

-20

-15

-10

-5

0

5

10

15

20

25

0 50 100 150 200 250 300 350 400

Velocity, mm/deg

Crank Angle,

Graph of Velocity vs Crank Angle

Simple

Harmonic

Constant

Acceleration

-15

-10

-5

0

5

10

15

0 50 100 150 200 250 300 350 400

Acceleration,

mm/deg

2

Crank Angle,

Graph of Acceleration against Crank Angle

Simple

harmonic

Constant

Acceleration

DISCUSSION

1) The graph of circular cam, convex cam, simple harmonic motion and constant

acceleration cams with dome tappet follower shows same type of graph. All the graph

almost shares same shape. Its a quadratic shaped graph. The lowest displacement is

0 meanwhile the maximum displacement was at 19.7, 19.5 19.75 and 22.0

respectively. The graphs pattern was increasing until 180 where the highest

displacement occurs and then the pattern decreases until displacement reach 0. For

convex cam, the graph possess the same shape but with steeper gradient and the graph

started to rise at angle of significantly at angle of 30.

Meanwhile, the graph of circular cam, convex cam and simple harmonic motion cam

with flat tappet follower also shows the same pattern with the graph of dome tappet

follower. The highest point of the graph is 19.3, 19.4 and 19.1 respectively.

The graph for velocity against angle for simple harmonic motion cam was a quadratic

graph with two cycles. The highest value that was recorded was 10 mm/deg while the

lowest that was recorded was 10 mm/deg. The graph for Constant acceleration cam

nearly possessed the quadratic graph with two cycles but the graph was steeper. The

highest value was 22.2 mm/deg and lowest point was -22.2 mm/deg.

The graph of acceleration against simple harmonic motion cam was a cos graph. The

starting point and ending point of the graph is at 10.00 mm/deg

2

. The lowest point in

the graph was at 10.00mm/deg. The graph for constant acceleration was in adifferent

shape with the maximum acceleration was 2.00 mm/deg

2

and the minimum

acceleration was 2.00 mm/deg

2

.

2) Based on the graphs plotted for displacement versus angle of experiment for the

constant acceleration, circular, convex and harmonic cams, it has almost the same

shape as the theoretical calculated ones, which is a quadratic shaped graphs. When the

cam rises, the follower is driven away from the cam axis by the increasing radius of

the cam profile at the point of contact. When the cam falls, the follower continues to

maintain contact with the cam profiles whose radius is continually decreasing at the

point of contact. In the case of the constant acceleration cam, the velocity increases

linearly to a maximum at middle section and then decreases to zero at the end of the

section with respect to time. This causes the acceleration to positive and uniform over

the first half of the section up to the point of maximum velocity where it

instantaneously reverses directions to become negative and uniform over the

remaining half of the section. The motion of the simple harmonic cam is in a way

where the displacement is the projection of a point on a circle to a reference line. For

this kind of motion, the maximum velocity occurs in the middle of the time section,

whereas, the acceleration is greatest at both ends of the time section and least in the

middle of the time section. The constant acceleration cam on the other hand has a

smaller maximum acceleration compared with simple harmonic cam but has sudden

changes at the start, the middle and the end of the rise motion. The simple harmonic

cam has a gradual change in acceleration except at the start and end of cam rotation.

For velocity, it is the opposite, the constant acceleration cam has a higher maximum

velocity compared with the simple harmonic cam but at 180 the velocity will sharply

decrease which causes a discontinuity in the acceleration graph.

The experiment that we conducted has some errors that might have been caused by

equipment error or human error. One of the apparatus used had some problems with

the calibration. For example when we set the cam to 0, it wasnt actually 0 and the

increments also had errors. The cam also was not totally centered due to long usage,

and had some free play which caused some errors.

3) Importance of Cam Gears in Internal Combustion Engines is that, a cam is an

important component of an internal combustion engine .Especially in an overhead-

camshaft engine, the cam controls the opening and closing of valves. There are

separate camshafts for fuel inlet and exhaust valves .How it works: the engine

crankshaft has a gear or sprocket fitted to its one end. A second shaft, called a

camshaft, is placed close by which also has a gear or sprocket. Both gears are joined

by a chain. Two turns of the crankshaft give one turn of the camshaft. Resting on the

camshaft is a pushrod which moves up-and-down or backwards-and-forwards as the

camshaft turns. Fitted on the top of the pushrod is a pivoted arm or rocker. One end of

the rocker pushes down on the valve as the other is lifted by the pushrod. To return

the valve to the closed position a coil spring is fixed to the top. This then gives the

opening and closing system for the engine fuel supply. In the whole system explained

above, function of cam gears is to keep the camshaft rotating properly.

CONCLUSION

As a conclusion, it was found that the tappet motion for all the cam used was found to

exhibit the similar profiles Although there might be some errors due to human error,

instrument error but does not affect the overall result. It was also found that the flat follower

produced to stable reading compare to dome follower due to the shape of the follower.

The circular, harmonic and convex cams were found to possess different characteristics. Even

though the profiles of the circular and harmonic cam did not show any significant differences,

but the velocity and acceleration of these profiles suggest otherwise. The circular cam has a

rapid velocity changes and much higher acceleration than the harmonic cam which instead

exhibits a much slower velocity changes but achieved the highest velocity than the circular

cam.

REFERENCES

1) Department of Mechanical Engineering. 2014. Machine Design & CAD Lab

Manual. University Tenaga Nasional. Pp 22-27.

2) Robert L.Norton. 1999. Design of Machinery. Second Edition. Massachhusetts :

McGraw-Hill. Pp274.

3) Cam and Tappet Experiment.2008.

http://webcabinet.tripod.com/Assignment/camandtappet.htm

You might also like

- Rocker Bogie CalculationsDocument13 pagesRocker Bogie Calculationsravi100% (3)

- Ariane7 Theoretical Manual: Ariane7 C BV (1991-2007) Is Distributed by Bureau VeritasDocument87 pagesAriane7 Theoretical Manual: Ariane7 C BV (1991-2007) Is Distributed by Bureau VeritasjackiemaddyNo ratings yet

- Universiti Tenaga Nasional: College of EngineeringDocument20 pagesUniversiti Tenaga Nasional: College of EngineeringRubaveeran GunasegaranNo ratings yet

- Tabela 1 - Caracteristicas Dos MotoresDocument2 pagesTabela 1 - Caracteristicas Dos MotoresRVVG20011No ratings yet

- Tension Force Calculation Sheet For Steel Bolts PDFDocument1 pageTension Force Calculation Sheet For Steel Bolts PDFVỸ TRẦNNo ratings yet

- (Torsion Test) : Strength Lab Report Experiment #2Document27 pages(Torsion Test) : Strength Lab Report Experiment #2john rozz bbNo ratings yet

- End Caps: 10 Bar 20 Bar 14 Bar 16 BarDocument1 pageEnd Caps: 10 Bar 20 Bar 14 Bar 16 BarjavierNo ratings yet

- Bharat Bijlee Electric Motors PricelistDocument21 pagesBharat Bijlee Electric Motors Pricelistaslam_bechemNo ratings yet

- Valve Face-to-Face FTF Dimension - HABONIM - 2017Document4 pagesValve Face-to-Face FTF Dimension - HABONIM - 2017compas.oeilNo ratings yet

- Handbook of ElectromotorDocument16 pagesHandbook of ElectromotorfrdnNo ratings yet

- NAS2 Liquefaction SPT 1998NCEER N SPTDocument1 pageNAS2 Liquefaction SPT 1998NCEER N SPTHanafiahHamzahNo ratings yet

- AERO3000 Equation ListDocument19 pagesAERO3000 Equation ListlalalallkjdlfjlkNo ratings yet

- Crank Report ZullalyaanumnaqiuDocument5 pagesCrank Report ZullalyaanumnaqiuDKMF1054 MUHAMMAD SALMANNo ratings yet

- P202301 PR B CS STD 0001Document16 pagesP202301 PR B CS STD 0001Nitin SakpalNo ratings yet

- JBNKHHDocument3 pagesJBNKHHJoel De Filippis MagriniNo ratings yet

- Installation Instructions: Alignment, Sleeve Seating and Torque Wrench Use Are Critical To Coupling OperationDocument2 pagesInstallation Instructions: Alignment, Sleeve Seating and Torque Wrench Use Are Critical To Coupling OperationcakendriNo ratings yet

- HKS Datasheet M-DA-H-F5 ENDocument3 pagesHKS Datasheet M-DA-H-F5 ENAbdukayyum JililNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Ukuran Nominal Nominal OD Tebal Dinding (T) S.8 S.10 S.12,5 S.16 S.20 S.25 MM Inch MM MM MM MM MM MM MMDocument15 pagesUkuran Nominal Nominal OD Tebal Dinding (T) S.8 S.10 S.12,5 S.16 S.20 S.25 MM Inch MM MM MM MM MM MM MMpipaswallowNo ratings yet

- EXP2Document38 pagesEXP2ngothihonghanh13No ratings yet

- EXP2Document38 pagesEXP2ngothihonghanh13No ratings yet

- Confined ConcreteDocument136 pagesConfined Concretepratik vharambaleNo ratings yet

- Traveled Way Width: 6.6 MetersDocument10 pagesTraveled Way Width: 6.6 MetersRichard Dean SantosNo ratings yet

- Base Sub Base - TSBDocument102 pagesBase Sub Base - TSBoliver lopezNo ratings yet

- Draft Survey CalculationDocument20 pagesDraft Survey CalculationAlex QuinteroNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- Section17ConversionTablesDocument20 pagesSection17ConversionTablesBalraj .GNo ratings yet

- Analog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierDocument11 pagesAnalog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierSanjai SenthilNo ratings yet

- Valves and Fittings Losses in Equivalent Feet of Pipe: Y-StrainerDocument3 pagesValves and Fittings Losses in Equivalent Feet of Pipe: Y-Strainerthilina lakhithaNo ratings yet

- FlarenetTempExcel1 (151024)Document33 pagesFlarenetTempExcel1 (151024)Tekk ImNo ratings yet

- Balmoral RWH HH Direct ManualDocument2 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- Parameter CalculatorDocument6 pagesParameter CalculatorAnkit GuptaNo ratings yet

- Hydro BonjeanDocument34 pagesHydro Bonjeanarqhab walzthyNo ratings yet

- Bolted Joint DesignDocument12 pagesBolted Joint DesignsivagulfNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFkossaNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFHaniNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFK C M SarlNo ratings yet

- Tabelle Gewicht RundstahlDocument1 pageTabelle Gewicht RundstahlAzur OmranNo ratings yet

- Poids Fer Rond PDFDocument1 pagePoids Fer Rond PDFSallam HikmaNo ratings yet

- IT Grade - WikipediaDocument2 pagesIT Grade - WikipediaVratislav Němec ml.No ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFFerdinand HOUNYEMENo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFCécé Charles KoliéNo ratings yet

- Poids Fer Rond PDFDocument1 pagePoids Fer Rond PDFSallam HikmaNo ratings yet

- Tabelle Gewicht RundstahlDocument1 pageTabelle Gewicht RundstahlAmin ThabetNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFSaidDiasNo ratings yet

- Tabelle Gewicht Rundstahl PDFDocument1 pageTabelle Gewicht Rundstahl PDFSofiane BNNo ratings yet

- Soumitomo Fender Catalogue PDF FreeDocument44 pagesSoumitomo Fender Catalogue PDF FreeIman BatmanghelichiNo ratings yet

- Data Uji Puntir Kelompok 2 AnjayyDocument4 pagesData Uji Puntir Kelompok 2 AnjayyFreddy GilbertNo ratings yet

- Sagian Brick Masonry RWDocument26 pagesSagian Brick Masonry RWmumarbsc7244No ratings yet

- Llogaritja Hidraulike e Kanaleve SEG - 3Document2 pagesLlogaritja Hidraulike e Kanaleve SEG - 3Armend AvdiuNo ratings yet

- CMM - Isoyeta de 10Document1 pageCMM - Isoyeta de 10Henry AkdNo ratings yet

- Channels-PnwhzgJn 240616 131939Document11 pagesChannels-PnwhzgJn 240616 131939Vibhu WadhawanNo ratings yet

- Design of BeamsDocument5 pagesDesign of BeamsSrishti Project ConsultantsNo ratings yet

- SDF DataDocument8 pagesSDF DataGreat ProfessionalNo ratings yet

- Joins Universel PDFDocument7 pagesJoins Universel PDFmecano1No ratings yet

- Low Voltage Power Cable Technical Data A.C. Resistance, Reactance and Impedance Rated Voltage: 600/1000VDocument2 pagesLow Voltage Power Cable Technical Data A.C. Resistance, Reactance and Impedance Rated Voltage: 600/1000VSemih Cem İlikNo ratings yet

- Hjda 2009-2 R1 (Jar)Document2 pagesHjda 2009-2 R1 (Jar)Anonymous ciu3QEjuSNo ratings yet

- Dynamic Spine Calculator Rev 7-18-10Document20 pagesDynamic Spine Calculator Rev 7-18-10Dominique Ayn BarlarNo ratings yet

- Angular Moment and Its ConservationDocument25 pagesAngular Moment and Its Conservationnikhilbandi0304No ratings yet

- Effect of Stirrups (PARTE 01) PDFDocument18 pagesEffect of Stirrups (PARTE 01) PDFDanNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationSIL PROJECTSNo ratings yet

- Viscosities of NewtonianDocument9 pagesViscosities of NewtonianMuzammil IqbalNo ratings yet

- Response To A Ramp Function LoadDocument11 pagesResponse To A Ramp Function LoadBhind NijjarNo ratings yet

- Experiment 201: Work, Energy, and PowerDocument5 pagesExperiment 201: Work, Energy, and PowerKeith ManansalaNo ratings yet

- LR Bachelor 2013 enDocument63 pagesLR Bachelor 2013 enmrslayerdudeNo ratings yet

- Morino - 1986 Helmholtz Decomposition Revisited Vorticity Generation and Trailing Edge ConditionDocument26 pagesMorino - 1986 Helmholtz Decomposition Revisited Vorticity Generation and Trailing Edge ConditionproscribdNo ratings yet

- The Main Cause of Vibration: 1 MisalignmentDocument8 pagesThe Main Cause of Vibration: 1 MisalignmentHopedejene DejeneNo ratings yet

- Motion in A Straight Line - DPP 01 (Of Lec 02) - Arjuna JEE 2.0 2024Document2 pagesMotion in A Straight Line - DPP 01 (Of Lec 02) - Arjuna JEE 2.0 2024yadavsatyam8415No ratings yet

- Introduction To Fluid Statics and Manometers OutlineDocument8 pagesIntroduction To Fluid Statics and Manometers OutlineVerin VericuetoNo ratings yet

- An 18.0 KG Box Is Released On A Incline and Accelerates at 0.300 M/s - What Is The Coefficient of Friction?Document14 pagesAn 18.0 KG Box Is Released On A Incline and Accelerates at 0.300 M/s - What Is The Coefficient of Friction?electric droneNo ratings yet

- WEEK 1 Base and Derived UnitsDocument6 pagesWEEK 1 Base and Derived Unitsannmarie100% (1)

- Unit 6 (Design & Detailing of Beams)Document32 pagesUnit 6 (Design & Detailing of Beams)prabhu81100% (1)

- SFD & BMDDocument21 pagesSFD & BMDSayan ChowdhuryNo ratings yet

- Journal of Constructional Steel ResearchDocument15 pagesJournal of Constructional Steel ResearchAntenasmNo ratings yet

- Field, Force, Energy and Momentum in Classical ElectrodynamicsDocument351 pagesField, Force, Energy and Momentum in Classical ElectrodynamicsBhat SaqibNo ratings yet

- Experiment 6: Heat Effects Laboratory ReportDocument9 pagesExperiment 6: Heat Effects Laboratory ReportLyca BorejonNo ratings yet

- EMD Mcqs Unit I & IIDocument15 pagesEMD Mcqs Unit I & II222363No ratings yet

- Crastin PBT and Rynite PET Design Info Module IV PDFDocument67 pagesCrastin PBT and Rynite PET Design Info Module IV PDFashkansoheyl100% (1)

- IAT-I Question Paper With Solution of 18ME63 Heat Transfer May-2021-Shashank DubeyDocument15 pagesIAT-I Question Paper With Solution of 18ME63 Heat Transfer May-2021-Shashank Dubey080 Priyanshu mishraNo ratings yet

- AB VECTOR + NLM + FRICTION (QSN BANK) - StudentDocument18 pagesAB VECTOR + NLM + FRICTION (QSN BANK) - Studentdipanjan.sadhukhan.1885No ratings yet

- Line Sizing Spreadsheets-GeneralDocument8 pagesLine Sizing Spreadsheets-GeneralFavoriteNo ratings yet

- Physical Sciences GR 12 Improvement Resources Memorandum Combined Level 1-3Document80 pagesPhysical Sciences GR 12 Improvement Resources Memorandum Combined Level 1-3benzorankhoneNo ratings yet

- Advanced Mechanical VibrationsDocument2 pagesAdvanced Mechanical VibrationsSohan Rao100% (1)

- Lab 4 Potential and Kinetic Energy F1069Document5 pagesLab 4 Potential and Kinetic Energy F1069Aimy SufeaNo ratings yet

- Bmee202p Mechanics-Of-Solids-Lab Lo 1.0 70 Bmee202pDocument2 pagesBmee202p Mechanics-Of-Solids-Lab Lo 1.0 70 Bmee202pShin ChanNo ratings yet

- Science SEA SoundDocument15 pagesScience SEA SoundgouniyalsunilduttNo ratings yet