ABC Full Project

Uploaded by

Vinayaka McCopyright:

Available Formats

ABC Full Project

Uploaded by

Vinayaka McOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ABC Full Project

Uploaded by

Vinayaka McCopyright:

Available Formats

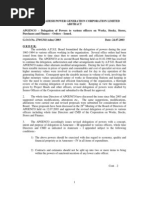

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

INDEX

Sr.No.

CONTENTS

Executive summary

Industry Profile

Organization profile

Research Methodology

Data Collection

Conceptual Framework

Analysis

Findings

Suggestions

10

Conclusion

11

Bibliography

Page No.

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

EXECUTIVE SUMMARY

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

EXECUTIVE SUMMARY

A study report on ACTIVITY BASED COSTING AS A MEASURE OF

IMPROVING THE COST STRUCTURE OF SAI PACKING LTD,MYSORE,

a project undertaken at SAI PACKING LTD,MYSORE.

Activity-Based Costing (ABC) represents an alternative paradigm to traditional cost

accounting system and it often provides more accurate cost information for decision

making such as product pricing, product mix, and make-or buy decisions. ABC

models the causal relationships between products and the resources used in their

production and traces the cost of products according to the activities through the use

of appropriate cost drivers.

In this project, the costing system followed by SAI PACKING

LTD,MYSORE is compared with ABC in terms of the effects on the product costs

that are carried out to highlight the difference between two costing methodologies.

By using this methodology, a valuable insight into the factors that cause the cost is

provided, helping to better manage the activities of the company.

According to the study, SAI PACKING LTD,MYSORE follows

traditional method for costing that assigns overheads directly to the product. Cost of

the product UC Range series 4 end cover is found out by Activity Based costing and

is compared with the traditional method followed by SAI PACKING

LTD,MYSORE to arrive at the cost of the above product. The study states that the

product is being over cost by the company.

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

SAI PACKING LTD,MYSORE should go for Activity Based costing as

it understands true profitability of the customers, products, or services and also helps

in identifying areas where the cost can be reduced or efficiencies can be increased.

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

INDUSTRY PROFILE

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

INDUSTRY PROFILE

Manufacturing Industry

Manufacturing industry refers to those industries which involve in the

manufacturing and processing of items and indulge in either creation of new

commodities or in value addition. The manufacturing industry accounts for a

significant share of the industrial sector in developed countries. The final products

can either serve as a finished good for sale to customers or as intermediate goods

used in the production process.

Manufacturing industries are the chief wealth producing sectors of an economy.

These industries use various technologies and methods widely known as

manufacturing

process

management.

Manufacturing

industries

are

broadly

categorized into engineering industries, construction industries, electronics industries,

chemical industries, energy industries, textile industries, food and beverage

industries,

metalworking

industries,

plastic

industries,

etc.

Manufacturing industries are important for an economy as they employ a huge share

of the labor force and produce materials required by sectors of strategic importance

such as national infrastructure and defense. However, not all manufacturing industries

are beneficial to the nation as some of them generate negative externalities with huge

social costs. The cost of letting such industries flourish may even exceed the benefits

generated by them.

Indias manufacturing base, which is the fourth-largest among emerging economies,

is among the fastest growing and has seen more investments as a proportion of gross

domestic product than any country except China. Employment opportunities in the

manufacturing industry have declined comparatively. Manufacturing industry

analysis also suggests that in some countries like China, technological know how has

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

to be developed. Despite the fact that China is ranked fourth in the manufacturing

productivity, due to technological lacunae, it is not being able to compete in the world

market. Also needed are professionals well versed in the technological know how.

The Government has taken several initiatives to accelerate growth in this sector and

improve competitiveness of Indian industry in general and manufacturing in

particular.

Technology up gradation schemes for various sectors such as small scale

industries, textiles, food processing etc.;

Industrial infrastructure up gradation programmes on cluster basis;

Easier access to inputs at competitive prices and rationalization and reduction in

duty rates.

Encouragement to foreign technology collaborations and liberalization of FDI in

manufacturing activities.

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

ORGANIZATION PROFILE

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

ORGANIZATIONAL PROFILE

Company profile

Sri Sai Packaging was established in 2002 in mysore, Karnataka and is now rated

among the leading Corrugated Box Manufacturers, karnataka. Under the leadership of

our Owner, Mr. Shiv sai, we are becoming the talk of the market as reliable

Corrugated Boxes Manufacturers and Suppliers. These Wholesale Corrugated Boxes

are used in various industries for packaging and wrappingandwoodencartonboxes.

Infrastructure

We have a well-established infrastructure which is equipped with the latest high tech

machinery. The machinery helps in the on-time production of all our products. We

also have a spacious warehouse which is well arranged to store bulk products.

Team

We have a team of highly qualified and dedicated professionals. These professionals

are well versed with the latest technology. They work in coordination to produce the

desired products. The logistics team takes care of on-time delivery of these products.

QualityAssurance

We test for all our raw materials before production. The products go through rigorous

test at every stage from manufacturing to packaging and delivery. All our products

are thoroughly checked by our quality controllers to let the flawless products reach

the clients.

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Name of Owner : Mr. Shiv sai

Year of Establishment : 2002

Nature of Business : Manufacturer & Supplier

Packaging Products manufactured by us are known for their strength and durability.

Our range of Packaging Products includes Corrugated Boxes. These Packaging

Products are widely used in various industries like Automotive, Pharmaceutical,

Cosmetic, Ceramic and many more for transportations and storage purposes. Our

Packaging Products are well cushioned to give them shock resistance characteristics

keeping the product inside them safe. We also offer customization of Corrugated

Boxes. Our Packaging Products last long when compared to others. These Packaging

Products are available in various sizes.

Qualitative And Eco-Friendly Wooden Products

Sai packaing does not need any introduction in the field of Manufacturing and

Supplying of Wooden Boxes and Crates. The company has an active presence with

substantial client base which is spread not only in karnataka but in the other markets

as well. The assortment of Wooden Products offered by us includes Wooden Pallets,

Euro Pallets, Wooden Packaging Boxes, Heavy Wooden Packaging Boxes, Wooden

Crates, Wooden Packing Cases and various others.

A quality and performance driven company, we have been striving hard to offer

immaculate quality. By adhering to the principle of consistency in the business

protocol, the products range that we offer is superior in quality and at par with

international standards. We have a well established business network that helps in the

smooth and effective functioning of the business. The positive feedbacks from clients

have also played a vital role in adding latest features to the wooden boxes and pallets.

10

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Last but not the least; we are also looking forward to establish and maintain long

lasting relationship with our esteemed clients.

Organizational Strategy

A definite organizational strategy has to be in place before beginning the

process of identifying actual costs within the manufacturing process, as well as

implementing a plan once those costs are identified.

Although a small company or a company with only a product or two may be

able to dive right into ABC analysis and implementation, a larger organization must

do some careful planning before beginning. Sometimes, a pilot project using only

product or department is an ideal place to start. This allows the ABC pilot project

team to get some experience as well as hopefully providing some semi-rapid results

that can be utilized in the short-term, thereby proving the effectiveness of the method.

(Tarr) According to the OSD Comptroller iCenter website, which provides financial

services information for the Department of Defense, there are four steps to ABC

implementation:

1. Identify activitiesperform an in-depth analysis of the operating processes of

each responsibility segment. Each process may consist of one or more

activities required by outputs.

2. Assign resource costs to activitiesthis is sometimes called "tracing."

Traceability refers to tracing costs to cost objects to determine why costs were

incurred. DoD categorizes costs in three ways:

a. Directcosts that can be traced directly to one output. Example: the

material costs (varnish, wood, paint) to build a chair.

b. Indirectcosts that cannot be allocated to an individual output; in

other words, they benefit two or more outputs, but not all outputs.

11

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Examples: maintenance costs for the saws that cut the wood, storage

costs, other construction materials, and quality assurance.)

c. General & Administrativecosts that cannot reasonably be associated

with any particular product or service produced (overhead). These

costs would remain the same no matter what output the activity

produced. Examples: salaries of personnel in purchasing department,

depreciation on equipment, and plant security.

3. Identify outputsidentify all of the outputs for which an activity segment

performs activities and consumes resources. Outputs can be products,

services, or customers (persons or entities to whom a federal agency is

required to provide goods or services).

4. Assign activity costs to outputsassign activity costs to outputs using activity

drivers. Activity drivers assign activity costs to outputs based on individual

outputs consumption or demand for activities. For example, a driver may be

the number of times an activity is performed (transaction driver) or the length

of time an activity is performed (duration driver). (OSD Comptroller iCenter)

12

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

TYPES OF THE WOODEN CARTON BOXES

LIST OF CUSTOMERS

Cummins Generator Technologies, India

Motorsense, U.K

Cummins Generator Technologies, Mexico

Fasco Motors, USA

ABB Ltd, Bangalore

OITS Elevator company, India

Trident Power craft Pvt.Ltd, Hubli

13

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Kirloskar Electric co. Hubli

Mallik Engineering , Bangalore

Telco Construction Equipment, Dharwad

14

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

ACTIVITY BASED COSTING FOLLOWED IN SAI PACKING LTD

15

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

16

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

17

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

18

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

19

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

RESEARCH METHODOLOGY

20

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

RESEARCH METHODOLOGY

The Study:

The present study is an attempt to understand and ascertain the costing method

followed in Sai packing ltd,mysore and to compare it with the costing method

Activity Based Costing.

Objectives of the study:

To study the functions and operations of the organization

To know and understand the existing costing method followed by SAI

PACKING LTD,MYSORE.

To identify activities involved in manufacturing of wooden carton 4x6.

To identify cost of the activities involved in manufacturing the product

wooden carton 4x6.

To allocate the cost for the activities.

To find the cost per unit of the product wooden carton 4x6.

To compare existing costing method followed by SAI PACKING

LTD,MYSORE with Activity Based Costing.

Scope of the study:

The scope of this study is to know and understanding the various processes and

activities involved in manufacturing Industries especially in SAI PACKING

LTD,MYSORE. It involves finding out the cost per unit of the product wooden

carton 4x6 by following Activity based Costing.

21

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Need for the study:

The theoretical aspects of ACTIVITY BASED COSTING provide the framework of

the study. A conceptual and the practical approach is the need of the hour. Hence the

field study becomes as essential part of the curriculum. Thus this project study

conducted to integrate theoretical and practical aspects of Activity based costing in

the organization.

DATA COLLECTION

Primary Data

Following are the sources of primary data collected.

Much of the information was collected from the cost accountant of SAI

PACKING LTD,MYSORE .

Frequent discussions were made with other employees of the company.

Met few senior level executive of the firm.

Secondary Data

Secondary data was collected through last years balance sheet of SAI

PACKING LTD,MYSORE.

Books on cost accounting were referred.

Company website

22

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Limitations of the study:

The study is limited to SAI PACKING LTD,MYSORE only.

In order to maintain confidentiality some information could not be

disclosed by sai packaing ltd.

23

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

CONCEPTUAL FRAMEWORK

24

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

About cost structure

The expenses that a

firm must take into account whenmanufacturing a product or providing a service.

Types of coststructures include transaction costs, sunk costs, marginal

costs and fixed costs. The cost structure of the firm is theratio of

fixed costs to variable costs.

Historical development of activity based costing

Traditionally, cost accountants had arbitrarily added a broad percentage of analysis

into the indirect cost. In addition, activities include actions that are performed both by

people and machine. However, as the percentages of indirect or overhead costs rose,

this technique became increasingly inaccurate, because indirect costs were not caused

equally by all products. For example, one product might take more time in one

expensive machine than another productbut since the amount of direct labor and

materials might be the same, additional cost for use of the machine is not being

recognized when the same broad 'on-cost' percentage is added to all products.

Consequently, when multiple products share common costs, there is a danger of one

product subsidizing another.

ABC

is

based

on

George

Staubus'

Activity Costing

and

Input-Output

Accounting. The concepts of ABC were developed in themanufacturing sector of the

United States during the 1970s and 1980s. During this time, the Consortium for

Advanced Management-International, now known simply as CAM-I, provided a

formative role for studying and formalizing the principles that have become more

formally known as Activity-Based Costing.

Robin Cooper and Robert S. Kaplan, proponents of the Balanced Scorecard, brought

notice to these concepts in a number of articles published in Harvard Business

Review beginning in 1988. Cooper and Kaplan described ABC as an approach to

solve the problems of traditional cost management systems. These traditional costing

25

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

systems are often unable to determine accurately the actual costs ofproduction and of

the costs of related services. Consequently managers were making decisions based on

inaccurate data especially where there are multiple products.

Instead of using broad arbitrary percentages to allocate costs, ABC seeks to identify

cause and effect relationships to objectively assign costs. Once costs of the activities

have been identified, the cost of each activity is attributed to each product to the

extent that the product uses the activity. In this way ABC often identifies areas of

high overhead costs per unit and so directs attention to finding ways to reduce the

costs or to charge more for costly products.

Activity-based costing was first clearly defined in 1987 by Robert S. Kaplan and W.

Bruns as a chapter in their book Accounting and Management: A Field Study

Perspective. They initially focused on manufacturing industry where increasing

technology and productivity improvements have reduced the relative proportion of

the direct costs of labor and materials, but have increased relative proportion of

indirect costs. For example, increased automation has reduced labor, which is a direct

cost, but has increased depreciation, which is an indirect cost.

Like manufacturing industries, financial institutions have diverse products and

customers, which can cause cross-product, cross-customer subsidies. Since personnel

expenses represent the largest single component of non-interest expense in financial

institutions, these costs must also be attributed more accurately to products and

customers. Activity based costing, even though originally developed for

manufacturing, may even be a more useful tool for doing this.

Activity-based costing was later explained in 1999 by Peter F. Drucker in the

book Management Challenges of the 21st Century. He states that traditional cost

accounting focuses on what it costs to do something, for example, to cut a screw

thread; activity-based costing also records the cost of not doing, such as the cost of

waiting for a needed part. Activity-based costing records the costs that traditional cost

accounting does not do.

The overhead costs assigned to each activity comprise an activity cost pool.

26

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

ABOUT ACTIVITY BASED COSTING

Cost accounting approach concerned with matching costswith activities (called cost

drivers) that cause those costs. It is a more sophisticated kind of absorptioncosting and

replaces labor based costing

system.

ABC states that

(1)products consume activities, (2) it is the activities (and not the products) that

consume resources, (3) activities are the cost drivers, and (4) that activities are not

necessarily based on the volume of production. Instead of allocating costs to cost

centers (such

and indirect

as manufacturing, marketing,

costs to

activities

such

finance),

as processing an

ABC allocates direct

order,

attending

to

a customercomplaint, or setting up a machine. A subset of activity based management

(ABM), it enables management to better understand (a) how and where the firm

makes aprofit, (b) indicates where money is being spent and (c) which areas have the

greatest potential for cost reduction.Developed by professors Robert Kaplan and

Robin Cooper of Harvard University in late 1980's.

Activity Based Costing (ABC) is an accounting technique that allows an organization

to determine the actual cost associated with each product and service produced by the

organization without regard to the organizational structure. It is developed to provide

more-accurate ways of assigning the costs of indirect and support resources to

activities, business processes, products, services, and customers. ABC systems

recognize that many organizational resources are required not for physical production

of units of product but to provide a broad array of support activities that enable a

variety of products and services to be produced for a diverse group of customers. The

goal of ABC is not to allocate common costs to products. The goal is to measure and

then price out all the resources used for activities that support the production and

delivery of products and services to customers.

Concept of Activity-Based-Costing:

An organization performs activities to do its business. These activities define the kind

of business you are in: a ship owner has an activity to unpack boats; an accounting

27

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

firm prepares tax returns; a manufacturer produces products; a council delivers

services; a university teaches students. All activities consume resources. It is the

consumption of these resources that adds to overhead costs.

The basis of Activity Based Costing is look at the activities required to produce the

cost of the product or service. The activities consume resources and the cost of these

can be calculated. The amount of activity required for each product and service is

determined, hence the real cost can be determined.

Activity Based Costing Definition

ABC can be defined by the following equation:

C/A = HD + M + E + S

where C/A = Estimated cost per activity

H = Number of labor hours required to perform the activity one time

D = Wages per labor hour

M = Material costs required to perform the activity one time

E = Equipment costs to perform the activity one time

S = Subcontracting costs to perform the activity one time

The total cost for performing the activity will be based on the number of times the

activity is performed during a specific time frame.

28

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

What's in ABC?

The activity is the work that is done.

The resource is what the activity uses to do the work e.g. people, equipment,

and services. Resources cost money.

The cost of the activity depends on the quantity of resources used to

accomplish the activity.

The cost driver for an activity is the factor that influences the amount of the

resources that will be consumed by this activity.

Example: the activity is delivering goods. The costs of this activity include the

truck drivers' wages, fuel, depreciation of the truck, insurance, etc. The

quantities of the resources that will be consumed by this activity are influenced

by the number of deliveries made per year. Hence the cost driver could be the

number of deliveries. A cost driver is designed to allocate the delivery activity

cost pool to the cost objects.

The activity driver measures how much of the activity is used by the cost

object. Example: Product A is delivered once a month, whereas product B is

delivered once a week. Products A and B require a different number of

deliveries, hence the cost of the delivery activity should be assigned to each

product on the basis of the number of deliveries each uses.

The cost object is whatever it is you wish to cost. It could be a product,

service, process, job or customer.

While traditional costing arbitrarily allocates overhead costs, ABC traces overhead

costs by looking at the activities that each product and service calls upon. With ABC

the products consume the activities. It is the activities that cost money.

29

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Why use Activity-Based-Costing?

Activity-Based-Costing is necessary for the following reasons.

Understand true profitability of your customers, products, or services

Quantify the cost of non-value added activities such as errors and

reworks

Identify opportunities to reduce costs and/or increase efficiency

Obtain actionable information to negotiate price increases for

unprofitable clients

Stratify overhead costs so they can be managed more effectively.

The ABC framework

Activity based costing has been claimed as a method of arriving at more accurate

costs, often in order to set selling prices. In a market economy, the idea of selling

prices based on costs is dangerous, with serious consequences for a business

30

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

competitive stance. With the variety of conventions and concepts used in cost

determination, there are no absolutes in determining product costs, hence the

objective of accurate costs is diluted. However, the technique of ABC is being seen

more as a cost-distortion alarm; more as an attention directing tool; more as a cost

management tool.

Activity Based Costing is a methodology for understanding the activities, processes,

services and products of a business; understanding what drives the cost of these

activities and processes; and thus reducing the non-value-adding activities/processes.

The Elements of ABC can be described in the following model:

The ABC CROSS:

COST ASSIGNMENT VIEW

RESOURCES

31

RESOURCE

DRIVERS

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

COST

DRIVERS

ACTIVITIES

ACTIVITY

DRIVERS

OBJECTS

OF WORK

PERFORMANCE

MEASURES

Resource Drivers are the link between resources and activities assigning cost form the

financial statements.

Activity Driver is the factor used to assign cost from an activity to a object of work,

for instance, if making a sales call is the activity then the frequency of sales calls to a

specific customer/client would be the activity driver.

Object of Work is the specific objective at the end of a process, for instance, a

product, a satisfied customer/client.

Cost Drivers are factors that cause changes in the performance of activities and create

increased consumption of resource. Fundamentally there are two types of Cost

Drivers. The Structural Cost Drivers are viz. Scale, Scope, Experience, Technology

and Complexity. The Exceptional Cost Drivers are viz. Work Force Involvement,

Total Quality Management, Capacity Utilization, Plant Layout, Electricity, Product

Configuration and Exploiting Value Chain Linkages.

Activities comprise of units or work or task. For example purchase of raw materials,

activities involved in manufacturing etc.

ABC categorizes the activities into:

Unit level activities:

32

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Performed each time a unit is produced.

Consumed in direct proportion to the number of units produced.

E.g. Direct materials, Energy costs, direct labour, etc.

Batch related activities:

Performed each time a batch of goods is produced.

Consumed in direct proportion the number of batches produced.

Fixed for all units within a batch.

E.g. set up resources, purchasing resources.

Product sustaining activities:

Performed to support and sustain different products/services on the product

life cycle.

Consumption varies with the variety of products/services and the stage of the

Product Life Cycle the products/services are in.

E.g. designing the product.

Facility sustaining activities:

Performed for supporting the happening of the above three types of activities

and providing the platform/infrastructure.

These are generally fixed for a certain scale/scope of operations over a period

of time.

E.g. Administration, plant maintenance, accounting, etc.

These costs are deducted lump sum from operating margins of all product

lines.

ABC establishes inputs and outputs to and from each activity, Inputs to one activity

may be outputs from another and there could also be interactive relationships among

activities.

Hierarchy of Activities and Activity based profitability analysis

Sales Revenue

33

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Less: Unit-level products cost

(Material, Power Costs, Other identifiable costs)

=

unit level contribution

Less: Batch related costs

(Sets-ups, material movements, purchase orders, inspection)

=

batch level contribution

Less: Product line costs

(Process engineering, product specifications, order change notices)

=

product line contribution

Less: Consumer and market related costs

=

customer level contribution

Less: Facility sustaining cost

(Plant management , rent , rates, and taxes, etc.,)

=

net profit

Note: Unit level and batch contribution analysis facilitate short-term decision relating

to products and complexity analysis. Product line contribution helps in product line

decisions. Customer level contribution helps in customer and market related

decisions. Facility sustaining cost are period cost are period which are fixed in nature.

STAGES OR STEPS INVOLVED IN ACTIVITY BASED COSTING.

Step 1: Identify the various activities within the organization. Activities comprise of

units of work or task. For example purchase of material is an activity consisting of

34

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

series of task like purchase requisition, advertisement, inviting quotations,

identification of suppliers, issuing purchase orders, follow up etc.

Step 2: Relate the overheads to the activity using resource cost drivers

a) Over heads will be related to support and primary activities.

b) For this purpose, resource cost drivers will be used.

c) All costs will be identified under the activities, thus creating activity cost

pools.

Step 3: Apportion the cost to support activities over the primary activities on suitable

basis.

a) This is very much like reapportionment of service department expenses to

production departments.

b) Cost of support activities are spread over to primary activities to collect costs

only under them.

c) The base is the cost driver which is the measure of how the support activities

are used.

Step 4: Determine the activity cost drivers for activity/cost pools.

a) Activity cost drivers used to relate the overheads collected in the cost pools

to cost objects should be determined.

b) This is based on the factor that drives the consumption of the activity.

c) For example, in production scheduling, the driver will be the number of

batches ordered.

Step 5: Calculate Activity cost driver rate = Total cost of activity

Activity cost driver

a) Activity cost driver rates are computed for each activity.

35

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

b) The rates will be multiplied by the different amounts of each activity that

each product/other cost object consumes so as to ascertain its cost.

c) This rate can be used to ascertain cost of the product (as in traditional

absorption costing) and to ascertain cost of other cost objects such as

customers/customer segments and distribution channels.

d) Cost drivers are selected based on three criteria:

e) (1) Causal relation. Ideally, choose a cost driver that causes the cost. This is the

best cost

f) drive available.

g) (2) Benefits received. Choose a cost driver to assign costs in proportion to

benefits

h) received.

i) (3) Reasonableness or fairness. When the first two criteria fail, assign costs on the

basis

j) of fairness or reasonableness.

k) For any indirect cost, a predetermined rate can be computed as follows:

l) Predetermined rate = Estimated indirect cost

m) Estimated volume of allocation base

n) .

o) For activity-based costing, the first stage consists of activities. Each activity has

an

p) associated cost pool and requires a cost driver rate using the formula above.

q) The second stage in a two-stage system using activity-based costing allocates

costs to

r) products by multiplying the cost driver rates by the number of units of the cost

driver (i.e.,

s) volume of activities) consumed in each product..

t) The distinctive feature of activity-based costing is that it recognizes that

overhead costs

u) are caused by activities and that activities may not be caused solely by volume,

but by

v) other types of activities. Cost drivers for the activities should reflect the cost

incurrence

36

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

w) in the activity, even if cost is not caused by volume.

Aims of model

With ABC, a company can soundly estimate the cost elements of entire products

ACTIVITIES and services. That may help inform a company's decision to either:

Identify and eliminate those products and services that are unprofitable and lower

the prices of those that are overpriced (product and service portfolio aim)

Or identify and eliminate production or service processes that are ineffective and

allocate processing concepts that lead to the very same product at a better yield

(process re-engineering aim).

In a business organization, the ABC methodology assigns an organization's

resource costs through

activities

to

the products andservices provided

to

its

customers. ABC is generally used as a tool for understanding product and customer

cost and profitability based on the production or performing processes. As such, ABC

has predominantly been used to support strategic decisions such as pricing,

outsourcing, identification and measurement of process improvement initiatives.

Prevalence

Following initial enthusiasm, ABC lost ground in the 1990s, to alternative metrics,

such as Kaplan's balanced scorecard and economic value added. An independent

2008 report concluded that manually driven ABC was an inefficient use of resources:

it was expensive and difficult to implement for small gains, and a poor value, and that

37

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

alternative methods should be used.[2] Other reports show the broad band covered

with the ABC methodology.[3]

Alternatives

Lean accounting methods have been developed in recent years to provide relevant

and thorough accounting, control, and measurement systems without the complex and

costly methods of manually driven ABC. However lean accounting is a snapshot

concept for capturing just partial derivatives or differentials of selected cost

functions. Lean accounting takes an opposite direction from ABC by working to

eliminate peculiar cost allocations rather than apply complex methods of resource

allocation.

Lean accounting is primarily used within lean manufacturing. The approach has

proven useful in many service industry areas including healthcare, construction,

financial services, governments, and other industries.

Application of Theory of constraints (TOC) is analysed in a study showing interesting

aspects of productive coexistence of TOC and ABC application. Identifying cost

drivers in ABC is described as somewhat equivalent to identifying bottlenecks in

TOC. However the more thorough insight into cost composition for the inspected

processes justifies the study result: ABC may deliver a better structured analysis in

respect to complex processes, and this is no surprise regarding the necessarily spent

effort for detailed ABC reporting.

Methodology

Methodology of ABC focuses on cost allocation in operational management. ABC

helps to segregate

Fixed cost

Variable cost

Overhead cost

38

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

The split of cost helps to identify cost drivers, if achieved. Direct labor and materials

are relatively easy to trace directly to products, but it is more difficult to directly

allocate indirect costs to products. Where products use common resources differently,

some sort of weighting is needed in the cost allocation process. The cost driver is a

factor that creates or drives the cost of the activity. For example, the cost of the

activity of bank tellers can be ascribed to each product by measuring how long each

product's transactions (cost driver) takes at the counter and then by measuring the

number of each type of transaction. For the activity of running machinery, the driver

is likely to be machine operating hours. That is, machine operating hours drive

labour, maintenance, and power cost during the running machinery activity.

Application in routine business

ABC has proven its applicability beyond academic discussion. ABC is applicable

throughout company financing, costing and accounting:

ABC is a modeling process applicable for full scope as well as for partial views.

ABC helps to identify inefficient products, departments and activities.

ABC helps to allocate more resources on profitable products, departments and

activities.

ABC helps to control the costs at any per-product-level level and on a

departmental level.

ABC helps to find unnecessary costs that may be eliminated.

ABC helps fixing the price of a product or service with any desired analytical

resolution.

A reports summarizes reasons for implementing ABC as mere unspecific and mainly

for case study purposes (in alphabetical order):

Better Management

Budgeting, performance measurement

Calculating costs more accurately

Ensuring product /customer profitability

39

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Evaluating and justifying investments in new technologies

Improving product quality via better product and process design

Increasing competitiveness or coping with more competition

Management

Managing costs

Providing behavioral incentives by creating cost consciousness among employees

Responding to an increase in overheads

Responding to increased pressure from regulators

Supporting other management innovations such as TQM and JIT systems

Beyond such selective application of the concept, ABC may be extended to

accounting, hence proliferating a full scope of cost generation in departments or

along product manufacturing. Such extension, however requires a degree of

automatic data capture that prevents from cost increase in administering costs.

Activity Based Costing Pros & Cons

Pros

Identifies Non-Value Added Activities

Identifies cost savings opportunities (untraceable costs)

Provides very detailed cost/profitability information

Differentiates complex versus simple processes

More data can lead to more information = better decisions

Cons

Very costly to implement and maintain

Historical in nature (same as traditional absorption costing)

Detail versus Accuracy (GIGO)

Discourages novel approachs to processes

Encourages activity

Assumes equal and proportionate benefits result from common activity

Steps to implement Activity-Based costing

40

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

1. Identify and assess ABC needs - Determine viability of ABC method within an

organization.

2. Training requirements - Basic training for all employees and workshop

sessions for senior managers.

3. Define the project scope - Evaluate mission and objectives for the project.

4. Identify activities and drivers - Determine what drives what activity.

5. Create a cost and operational flow diagram How resources and activities are

related to products and services.

6. Collect data Collecting data where the diagram shows operational

relationship.

7. Build a software model, validate and reconcile.

8. Interpret results and prepare management reports.

9. Integrate data collection and reporting.

Integrating EVA and PBC

Recently, Mocciaro Li Destri, Picone & Min (2012) proposed a performance and

cost measurement system that integrates the EVA criteria with Process Based Costing

(PBC). Authors note that activity-based costing system is introspective and focuses

on a level of analysis which is too low. On the other hand, they undescore the

importance to consider the cost of capital in order to bring strategy back into

performance measures.

Limitations

41

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Applicability of ABC is bound to cost of required data capture. That drives the

prevalence to slow processes in services and administrations, where staff time

consumed per task defines a dominant portion of cost. Hence the reported application

for production tasks do not appear as a favorized scenario.

ABC Implementation Issues:

Another refinement in product costing that often accompanies implementation of

ABC focuses on step of the five-step product costing sequence: identify the direct

costs associated with the cost object. The refinement involves the following. For a

given cost object, the company attempts to identify costs currently treated as

overhead that have not beenbut can betraced directly to the cost object. In other

words, costs are moved from the overhead cost pool to the direct cost category. For

example, an accounting firm might take certain office-support expenses formerly

treated as overhead, such as printing and copying, and start tracking and assigning

these costs to specific jobs (audits, tax engagements, etc.) for internal reporting and

profitability analysis (but not necessarily for client billing purposes).

The successful implementation of ABC usually requires participation by managers

from non-accounting functions, such as production and marketing. Because ABC

focuses on activities, and activities often cut across departments and functional areas,

implementing ABC can improve lines of communication and cooperation within the

company. On the other hand, more accurate cost allocation does not, by itself, reduce

costs. The initial move from a traditional costing system to ABC usually shifts

overhead costs from some products to other products, with some managers winning

and some losing. Some companies have found that hiring an outside consulting

firm to assist with the ABC adoption facilitates obtaining buy-in by managers and

employees throughout the company. Perhaps partly for this reason, ABC

implementation has become an important consulting product for accounting firms and

for many consulting firms.

42

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Although ABC should provide the company more accurate information, it is not a

panacea; some companies that invested time and money implementing ABC did not

realize the benefits they expected. Some of these companies have reverted to simpler,

more traditional costing systems.

ACTIVITY BASED COSTING ADVANTAGES

More accurate costing of products/services, customers, distribution channels.

Better understanding overheads.

Easier to understand for everyone.

Utilizes unit cost rather than just total cost.

Integrates well with Six Sigma and other continuous improvement programs.

Makes visible waste and non-value added.

Enables costing of processes, supply chains, and value streams

Activity Based Costing mirrors way work is done

Facilitates benchmarking.

ACTIVITY BASED COSTING DISADVANTAGES

More time consuming to collect data.

Cost of buying, implementing and maintaining activity based system.

Makes waste visible which some executives and managers don't want their

boss to see.

43

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

How does Activity Based Costing differ from traditional cost accounting systems?

Most traditional costing systems utilize a single basis, (e.g. direct labor) to distribute

the indirect costs to all products and services. This method of allocating indirect costs

commonly results in erroneous cost data. Often products which have high volume

(and high labor cost) are over costed. Likewise, the cost of lower volume products are

often understated, and many of the indirect costs of these products are overlooked.

Rather than relying on a single basis to distribute costs, ABC assigns costs to

activities and products based on how the costs (resources) are actually consumed by

the process or product. By moving away from traditional cost allocation methods and

using improved ABC methods of tracing and assignment, ABC provides managers

with a clearer picture of cost of processes and the profitability of customers and

products.

ABC Output ABM Decision Making Tools

Product and Customer Profitability

Revenues

Less Traceable Costs

Excess Revenues over Traceable Costs

Less Untraceable Costs

(Total Costs less Traceable Costs)

Operating Income

Departmental Efficiency

Actual Costs Incurred versus Traceable Costs Assigned

If Traceable > Actual, department was efficient

If Traceable < Actual, department was inefficient

Strengths and Weaknesses

While the thought behind ABC makes sense, and the results would be of great

benefit for many companies, there are still some inherent problems with the

methodology.

44

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

In some instances, costs can be defined, but where and how to assign them can

be extremely difficult. An example would be the salary of the companys CEO. This

is difficult to assign because there is no solid method of doing so. (Wikipedia.org)

Just because a cost cannot be assigned to a product or products does not mean that the

ABC method is seriously flawed and should be abandoned. According to Robert

Kaplan, one of the founding fathers of ABC, small inconsistencies are acceptable.

The objective is to be approximately right. (Kaplan and Anderson)

A strength of ABC, as has been mentioned throughout this paper, is having a

better understanding of what indirect or overhead costs go into the cost of a product.

Knowing exactly how much time and materials go into a product from all areas

instead of just the ones that are obvious is of great value to any organization. It leads

to more efficient processing in the manufacturing process, which in turn leads to

greater profits through realization of cost savings.

Specific Applications

There are too many specific applications of ABC to be listed here, but it will

suffice to say that many industries could see benefits from implementing an ABC

method, or at the very least identifying actual costs within a process.

One interesting example I found through my research was how United States

shipyards were being compared to Northern European shipyards in their conversion

from mainly military use to commercial shipbuilding. A large part of this study

required determining hidden costs within the process that are the result of bloat and

financial sloppiness that are inherent in the fulfillment of government contracts.

(Kvaerner Masa Marine INC Annapolis MD)

Conclusion

In conclusion, we can see that the methodology behind Activity-Based Costing

is sound, and can result in sometimes great savings to a company willing to take the

time, effort and expense to implement a plan. Although there are some pitfalls to the

process, with perseverance and a solid commitment from management, ABC can be

of great benefit to a manufacturing company.

45

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

ANALYSIS

46

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

DETAILS OF THE PRODUCT

Product name: wooden carton 4x6

Raw Material Requirements for the product

1) wooden sheet of length 1250*2500*1.2mm

2) Weight of the sheet is 30kg

3) 21 cartons can be prepared from one sheet.

4) Sheets required to prepare 1000 units is 48sheets.

5) Cost of sheet per kg 37Rs.

6) Weight of a Cover

= 30kg/21

=1.42kg

7) Gross Material cost per unit

= 1.42 x Rs55

= Rs78.1/Cover

8) Process Generated Scrap

=0.65 kgs

9) Scrap rate

=Rs12/kg

10) Revenue generated from scrap = 0.65 x 10

= Rs 6.5

11) Net material cost

= 78.1 6.5

= Rs71.6

47

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

COSTING FOLLOWED BY THE COMPANY

Product: wooden carton 4x6

Number of units produced = 300000 cartons p.a

Particulars

Total

Cost/unit

cost(in Rs)

(in Rs)

DIRECT COST

Direct Material (Raw Material Consumed)

3,05,73,918

Direct Wages

18,93,573

Direct Expenses

45,65,266

Prime Cost

3,70,32,757

123.4

31,45,069

10.48

FACTORY OVERHEADS

fuel oil & lubricant

1,58,029

Depreciation on machinery

8,04,853

Repairs and maintenance

3,91,235

Insurance

56,147

Rates and Taxes

2,61,532

Indirect material

14,73,273

Factory cost

ADMINISTRATIVE OVERHEADS

Printing and stationary

69,255

Postage and telegram

18,929

Newspapers and magazines

5,964

Professional charges

27,619

Office furniture

5,646

Leave with wages

7,095

Telephone expenses

1,75,338

Salary to partners

14,60,000

48

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Vehicle maintenance

72,347

Sundry expenses

84,809

Salary to staff

2,59,203

21,86,205

Cost Of Goods Sold

7.28

SELLING AND DISTRIBUTION

Advertisement expenses

Traveling expenses

3,410

1,82,480

Sales Promotion expenses

Packing charges

5,500

4,97,360

6,88,750

4,30,52,781

143.50

PROFIT

52,81,095

17.6

SALES

4,83,33,876

161.1

Cost Of Sales

49

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

CALCULATION OF COST PER UNIT BY ACTIVITY BASED COSTING

1) Purchase of Raw material

Activity

Sub Activity

Cost Driver

Purchase

Raw material transport

Weight of product

Loading and unloading

Weight of product

Storage

Weight of product

Material cost

Weight of product

a) Raw material transport charges :

Weight of the goods 5000kgs (for the specified component) of sheet wooden

Delivered from J.P Nagar mysore to SAI PACKING LTD,MYSORE = Rs.600.00

Therefore charges per unit

= Rs600/5000kgs

= Rs0.12/kg

Cost of per carton

=1.42kg x Rs0.12

=Rs0.1704/carton

b) Loading and unloading Charges = Rs300.00/ton

5 Ton x Rs300

= Rs1500.00

Therefore charges for per unit

= Rs1500/5000kgs

= Rs0.20/kg

Cost per carton

=1.42 x Rs0.20

=Rs0.284/carton

50

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

c) Storage charges

= space required 10 x 5ft

Rent 20000/month

Building area

= 10000sq ft

Storage Cost

=50sq ft x Rs2.00

=Rs100.00/- p.m

Storage cost per day

=Rs100/26Days

=Rs3.84/day

Storage cost per Cover

=Rs3.84/1000Covers

=Rs0.00384/cover

d) Material cost

= 5000kgs x Rs 71.28 (exclusive of

transport and loading and unloading

charges)

= Rs3,56,400

=5000kgs/1.42wt per kg

=3521 Covers

=Rs3,56,400/3521cartons

=Rs101.22 scrap

=Rs101.22 Rs6.5

=Rs94.72/cartons

51

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Total cost incurred for purchase of raw material

Activity

Sub Activity

Purchase

Raw material transport

Loading and unloading

Cost

Rs0.1704/carton

Rs0.284/carton

Storage

Rs0.00384/carton

Material cost

Rs 94.72/carton

Rs95.17

Total

52

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

2) Manufacturing cost

Activity

Sub Activity

Manufacturing

Shearing

Activity Driver

Combination of man and

machine hour

Combination of man and

Circle cutting

machine hour

Combination of man and

Deep drawing

machine hour

Combination of man and

Trimming

machine hour

Combination of man and

Piercing

machine hour

2) Manufacturing cost

Number

Process

labo

Wages

per day

Hours

Circle

cutting

Deep

drawing

300/wo

rker

150

150

&135

Cost

per sq

of

Cost of

Hp per

occupie

Covers

Machin

machin

d by the ft

per 8

hrs

Shearing

Space

1000

500000

800

100000

0.5

800

800000

53

machin

100 sq

Rs2

ft

50 sq ft

Rs 2

100sq ft Rs 2

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Trimming

150

500

300000

Piercing

150

900

400000

80sq ft

Rs 2

50 sq ft

Rs 2

COST OF EACH PROCESS

1) Shearing

a) Man cover rate:

= wages/number of Covers

= Rs900/1000Covers

= 0.9/Cover rate

b) Machine cover rate

=cost of machine x depreciation

=Rs500000 x 10% depreciation

=Rs50000 p.a

=Rs50000/300days

= Rs166.6per day

=Rs166.6/1000Covers

=Rs0.17/Cover

c) Space occupied by

= 100 Sq ft x Rs 2 per sq ft

the machine

= Rs200 p.m

= Rs200/26days

=Rs7.69/day

=Rs7.69/1000Covers

=Rs 0.00769/Cover

d) calculation of electricity

54

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Monthly electricity bill

= 31,266

Monthly power consumption = 45hp

Therefore,

Rs31,266/45hp = Rs694.8 per hp/ month

Power Consumption

= 5hp

For 5hp = Rs694.8 x 5hp

Electricity bill per month

= Rs3,474

= Rs3474.00

= Rs3474/26days

=133.61/day

=133.61/1000

=Rs0.1336/Cover

Fuel oil & lubricants

= Rs1,58,028 p.a

= Rs 158028/ 300days

= Rs 526.76/day

= Rs 526.76/25machines

=Rs21.07/machine

=21.07/1000Covers

=0.021/Cover

Total Cost of shearing activity

Activity

Sub Activity

Shearing

Man cover rate

Machine cover rate

55

Cost

Rs0.9/carton

Rs0.17/carton

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Space occupied by the

Rs0.00769/ carton

machine

electricity

Rs0.1336/ carton

Fuel oil & lubricants

Rs0.021/ carton

Rs 1.232/ carton

Total

2. Circle cutting

a) Man cover rate

=wages/number of Covers

= Rs150/800 carton

=Rs0.1875/ carton

b) Machine cover rate

=Rs100000 x 10% depreciation

=Rs10000 p.a

=Rs 10000/300days

=Rs33.33/per day

=Rs33.33/800 carton

=Rs0.0416/ carton

c) Space occupied by

= 50Sq ft x Rs 2 per sq ft

the machine

= Rs100 p.m

= Rs100/26days

=Rs3.84/day

=Rs3.84/800 carton

=Rs 0.0048/ carton

56

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

e) calculation of electricity

Monthly electricity bill

= Rs31,266

Monthly power consumption = 45hp

Therefore,

Rs31,266/45hp = Rs694.8 per hp/ month

Power Consumption

= 0.5hp

For 0.5hp = Rs694.8 x 0.5hp

Electricity bill per month

= Rs347.4

= Rs347.4

= Rs347.4/26days

=13.36/day

=13.36/800 carton

=Rs0.0167/ carton

Fuel oil & lubricants

= Rs1,58,028 p.a

= Rs 158028/ 300days

= Rs 526.76/day

= Rs 526.76/25machines

=Rs21.07/machine

=21.07/800 carton

=0.026/ carton

Total Cost of circle cutting activity

Activity

Sub Activity

Circle cutting

Man cover rate

Cost

Rs0.1875/ carton

Machine cover rate

Rs0.0416/ carton

Space occupied by the

Rs0.0048/ carton

machine

57

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

electricity

Rs0.0167/ carton

Fuel oil & lubricants

Rs0.026/ carton

Rs0.2766/ carton

Total

58

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

3. Deep drawing

a) Man hour rate

=wages/number of Covers

= Rs285/800 carton

=Rs0.3562/ carton

b) Machine hour rate

=Cost of machine x Depreciation

=Rs800000 x 10% depreciation

=Rs80000 p.a

= Rs80000/300days

=Rs266.67/per day

=Rs266.67/800 carton

=Rs0.333/ carton

c) Space occupied by

= 100Sq ft x Rs 2 per sq ft

the machine

= Rs200 p.m

= Rs200/26days

=Rs7.69/day

=Rs7.69/800 carton

=Rs0.0096/ carton

d) calculation of electricity

Monthly electricity bill

= Rs31,266

Monthly power consumption = 45hp

Therefore,

Rs31,266/45hp = Rs694.8 per hp/ month

59

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Power Consumption

= 7hp

For 7hp = Rs694.8 x 7hp

Electricity bill per month

= Rs4863.6

= Rs4863.6

= Rs4863.6/26days

=187.06/day

=187.06/800 carton

=Rs0.233/ carton

Fuel oil & lubricants

= Rs1,58,028 p.a

= Rs 158028/ 300days

= Rs 526.76/day

= Rs 526.76/25machines

=Rs21.07/machine

=21.07/800 carton

=0.026/ carton

60

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Total Cost of deep drawing activity

Activity

Sub Activity

Deep Drawing

Man cover rate

Cost

Rs0.3562/ carton

Machine cover rate

Rs0.333/ carton

Space occupied by the

Rs0.0096/ carton

machine

electricity

Rs0.233/ carton

Fuel oil & lubricants

Rs0.026/ carton

Rs 0.9578/ carton

Total

4. Trimming

a) Man hour rate

=Wages/number of Covers

= Rs150/500 carton

=Rs0.3/ carton

b) Machine hour rate

=Cost of machine x depreciation

=Rs300000 x 10% depreciation

=Rs30000 p.a

= Rs30000/300days

=Rs100/per day

=Rs100/500 carton

=Rs0.2/ carton

61

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

c) Space occupied by

= 80Sq ft x Rs 2 per sq ft

the machine

= Rs160 p.m

= Rs160/26days

=Rs6.15/day

=Rs6.15/500 carton

=Rs 0.012/ carton

d) calculation of electricity

Monthly electricity bill

= Rs31,266

Monthly power consumption

= 45hp

Therefore,

Rs31,266/45hp = Rs694.8 per hp/ month

Power Consumption

= 3hp

For 3hp = Rs694.8 x 3hp

= Rs2084.4

Electricity bill per month

= Rs2084.4

= Rs2084.4/26days

=80.16/day

=80.16/500 carton

=Rs0.16/ carton

Fuel oil & lubricants

= Rs1,58,028 p.a

= Rs 158028/ 300days

= Rs 526.76/day

= Rs 526.76/25machines

=Rs21.07/machine

=21.07/500 carton

62

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

=0.042/ carton

Total Cost of trimming activity

Activity

Sub Activity

Trimming

Man cover rate

Cost

Rs0.3/ carton

Machine cover rate

Rs0.125/ carton

Space occupied by the

Rs0.012/ carton

machine

electricity

Rs0.16/ carton

Fuel oil & lubricants

Rs0.042/ carton

Rs 0.639/ carton

Total

5. Piercing

a) Man hour rate

=Rs 150/900 carton

=0.166/ carton

b) Machine hour rate

=400000 x 10% depreciation

=40000 p.a

= 40000/300days

=133.33/per day

=133.33/900 carton

=0.148/ carton

c) Space occupied by

= 50Sq ft x Rs 2 per sq ft

the machine

= Rs100 p.m

63

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

= Rs100/26days

=Rs3.84/day

=Rs3.84/900 carton

=Rs 0.0042/ carton

d) calculation of electricity

Monthly electricity bill

= Rs31,266

Monthly power consumption = 45hp

Therefore,

Rs31,266/45hp = Rs694.8 per hp/ month

Power Consumption

= 3hp

For 3hp = Rs694.8 x 3hp

= Rs2084.4

Electricity bill per month

= Rs2084.4

= Rs2084.4/26days

=80.16/day

=80.16/900 carton

=Rs0.089/ carton

Fuel oil & lubricants

= Rs1,58,028 p.a

= Rs 158028/ 300days

= Rs 526.76/day

= Rs 526.76/25machines

=Rs21.07/machine

=21.07/900 carton

=0.023/ carton

Total Cost of piercing activity

64

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Activity

Sub Activity

Piercing

Man cover rate

Cost

Rs0.166/ carton

Machine cover rate

Rs0.148/ carton

Activity

Sub Activity

Cost

Manufacturing

Shearing

Rs1.232/ carton

Circle cutting

Rs0.2766/ carton

Deep drawing

Rs 0.9578/ carton

Trimming

Rs 0.639/ carton

Piercing

Rs0.468/ carton

Rs3.5734/ carton

Total

Space occupied by the

Rs0.042/ carton

machine

electricity

Rs0.089/ carton

Fuel oil & lubricants

Rs0.023/ carton

Rs0.468/ carton

Total

65

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Total Cost of the processes

3) Inspection

Inspection rate 10% of number of units produced per day

1000 carton x 10% = 100 carton to be inspected

1) Salary of the inspector

= Rs8000/month

Time required to inspect

Per day salary

= 1 hour

= Rs8000/26days

=Rs307.69/day

Per hour salary

=Rs 307.69/8hRs

= Rs 38.46/hr

Wages to the inspector

= 1hr x Rs38.46

= Rs38.46/hr

2) Cost of instruments required to inspect

= Rs 8500

Expected life of instrument is one year

Instruments charges per month

= Rs8500/12months

= Rs708.33/month

Per day charges

= Rs708.33/26 days

= Rs 27.24/day

Per hour charges

= Rs27.24/8hrs

= Rs3.4/hr

66

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

3) Calibration charges per year

Per month charges

= Rs900

= Rs900/12months

= Rs75/month

Per day charges

= Rs75/26days

= Rs3/day

Per hour charges

= Rs3/8hr

=Rs0.375/hr

Total of inspection activity

Activity

Sub Activity

Inspection

Salary of the inspector

instruments required to

inspect

Calibration

Cost

Rs38.46/hr

Rs3.4/hr

Rs0.375/hr

Rs42.23/hr

Total

Cost of Per

Cover

67

Rs 0.0422/ carton

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

4) Painting

.

1) Cost of paint and thinner

Paint Rs250/ltr

Thinner Rs150/ltr

Divided in the ratio of 75:25

Cost of Paint

= Rs250 x 75/100

=Rs 187.5

Cost of Thinner

= Rs150 x 25/100

=Rs 37.5

Cost of mixture total

= Rs187.5 + Rs37.5

= Rs225

Total Area of component covered by the mixture is 45 sq ft

Area of the a component

= 1.72 sq ft

Covers that can be painted = 45sq ft/1.72sq ft

= 26Covers

Cost of paint per cover

=Rs225/ 26 carton

= Rs8.6/ carton

2) Labour cost

People required for painting

=2

Wages per day

= Rs 320

Covers painted in one day

= 200 carton

Cost per cover

= Rs320/200 carton

=Rs1.6/ carton

68

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

3) Paint booth operation cost

Deprecation

= Rs300000

= 20% of the cost

=Rs 300000 x 20%

= Rs60000p.a

Per month

= Rs60000/12months

=Rs5000p.m

Per day

= Rs5000/26days

= Rs192.3/day

Cost of per covers

=Rs 192.3/200 carton

=Rs0.961/carton

4) Power charges Rs 5500/month

Total Power consumption

=20hp

Therefore,

Rs5500/20hp

=Rs275per hp/month

Power consumption

=5hp

For 5hp

=5hp x Rs275

Electricity bill per month for 5hp =Rs1375

Per day charges

= Rs1375/26days

= Rs53/day

Per cover charges

=Rs53/200 carton

=Rs0.265/ carton

69

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

5) Area of painting booth

= 60 x 20ft

Rent

= 20000 p.m

Built area

= 10000sq ft

Rent per sq ft

= Rs30000/10000sq ft

= Rs3/sq ft/month

Cost of area

= 1200sq ft x Rs3

= Rs 3600

Per day charges

=Rs3600/26

= Rs138.46/day

Per cover

=Rs138.46/200 carton

= Rs0.692/ carton

Area of the Cover = 1.72sq ft

Cost of per cover = Rs12.11 x 1.72sq ft

= Rs20.82/ carton

Total cost of painting activity

Activity

Sub Activity

Painting

Cost of paint and thinner

Cost

Rs8.6

Labour cost

Rs1.6

Paint booth operation cost

Rs0.961

Power charges

Rs0.265

Area of painting booth

Rs0.692

Rs12.11/sq ft

70

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Total

Cost of Per

Rs20.82/ carton

carton

5) Dispatching

1) Packing charges :

Packing material required: --Cost of wooden box = Rs 3000 (inclusive transportation cost, taxes)

Cost of plastic wire = Re 1.50/ carton

Cost of paper = Re1.00/ carton

Number of Covers packed per box = 200 carton

Rs3000 + (Re1.50 x 200) + (Re1.00 x 200) = Rs3500

2) Labour

People required = 3

5 boxes packed per day

Wages

= Rs200 + Rs150 + Rs150

= Rs500/day

Wages per box

= Rs500/5boxes

= Rs100/box

Total

=Rs 3500 + Rs100

= Rs 3600

Per Cover

= Rs3600/200 carton

=Rs18/ carton

Total of dispatching Activity

71

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

Activity

Sub Activity

Despatching

Packing charges

Cost

Rs3500

labour

Rs100

Rs3600/box

Total

Rs18/ carton

Cost Per

carton

COST PER UNIT OF THE PRODUCT

ACTIVITIES

1

Amount

COST/ carton

in Rs

Amt in Rs

PURCHASE OF RAW

95.017

MATERIALS

2

MANUFACTURING

Shearing

1.232

Circle cutting

0.2766

Deep drawing

0.9578

Trimming

0.639

Piercing

0.468

Total

3.5734

INSPECTION

0.0422

PAINTING

19.90

DESPATCHING

18.00

GRAND

TOTAL

72

136.68

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

FINDINGS

73

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

FINDINGS

1. SAI PACKING LTD, MYSORE are specialized in deep drawn components

that cater the electrical, elevator, home appliances automobile industry and the

defense.

2. SAI PACKING LTD, MYSORE follows traditional method of costing.

3. The product carton is over costed.

4. According to traditional costing the cost of the cover is Rs.143.50

5. According to Activity Based costing the cost of the cover is Rs136.68

6. According to costing followed by SAI PACKING LTD, MYSORE they first

identify the cost then they go for producing the product rather than identifying

the activities first.

7. Appropriate variable overheads are identified to individual products through

ABC.

8. All levels of activities in the manufacturing cost hierarchy viz unit level, batch

level, product level and facility level have been identified.

9. Cost drivers for the activities have been identified.

10. SAI PACKING LTD, MYSORE relates overheads to cost centers which are

not realistic to the behavior of costs.

11. To get a realistic analysis of cost behavior, the overheads have been properly

related to cost drivers.

74

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

SUGGESTIONS

75

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

SUGGESTIONS

1. SAI PACKING LTD, MYSORE should adopt Activity Based costing in

their organization.

2. As ABC integrates well with Six Sigma and continuous improvement

programs the company can achieve minimum rejection rate.

3. To arrive at the actual cost of the product, overheads should not be directly

assigned to the cost center which is basically done in traditional costing.

4. Instead of focusing more on cost reduction they should focus more on cost

control.

5. SAI PACKING LTD, MYSORE can adopt cost control strategy where in the

company can begin by evaluating non-labor expenses which can be controlled.

6. Labor and employment costs are a source of considerable expense and should

be constantly monitored.

7. If it is possible to amalgamate two jobs into one, make some jobs part time,

use temporary contract labor, outsourcing to specialists, consider if some other

choice of labor cost saving is available.

8. SAI PACKING LTD, MYSORE should follow an open style with clear and

concise objective for the successful implementation of ABC.

9. Organization-wide awareness should be extended to convince the participants

to change, as well as effecting the change.

10. Overheads are part of running a business but can be controlled. Everything

from cleaning materials to the cost of vehicle operation , machine

maintenance, consumable materials and staff employment costs can, and must

be kept as low as possible.

76

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

CONCLUSION

77

Activity Based Costing as a measure of improving the cost structure at SAI

PACKING LTD, MYSORE

CONCLUSION

ABC utilizes the activity concept and by using the activities, ABC can successfully

link the product costs to production knowledge. How a product is produced, how

much time is needed to perform an activity and finally how much money is absorbed

by performing this task are answered by the help of ABC studies. This method is a

dynamic tool for continuous improvement. With ABC to its benefit, any enterprise

will have a built in competitive cost advantage and can continuously add value to

both its stakeholders and customers.

Therefore, Activity-Based Costing measures the costs and profits of an organization

based on the activities performed within that organization. By focusing on processes

that contribute to revenues and business operations, ABC can accurately determine

how each process relates back to specific products, customers, or services. This can