Degassing Boot Sizing

Degassing Boot Sizing

Uploaded by

Rexx MexxCopyright:

Available Formats

Degassing Boot Sizing

Degassing Boot Sizing

Uploaded by

Rexx MexxOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Degassing Boot Sizing

Degassing Boot Sizing

Uploaded by

Rexx MexxCopyright:

Available Formats

BN-EG-UE109 Guide for Vessel Sizing

Page 1 of 31

BN-EG-UE109 Guide for Vessel Sizing

Table of Contents

1. Scope

2. Introduction

3. Selection Criteria for Vapor-Liquid Separators

4. Design Criteria for Vapor / Liquid Separators

5. Design of Liquid / Liquid Separators

6. Computer Programs

7. Appendices

1. Scope

This document shall be used for the process design of vessels, however, for specific projects, these design rules may be

superseded or modified by client requirements.

Applicable design rules for a specific project shall be specified in the Design Basis and / or the General Information and

Instructions (GII) for the project.

2.Introduction

In general the function of a vessel in a process unit is to either provide hold-up time or to make a separation between the

various phases of a mixed process stream. In this design guide rules are given for the dimensioning of vessels, which are

used for the separation of mixed process streams. They can be divided into two categories:

Vapor / liquid separators, which are used to separate the vapor and liquid part of a mixed stream.

Liquid / liquid separators, which are used to separate the two liquid phases of a mixed stream.

For both types of separators the design rules will be given in this design guide.

3. Selection Criteria for Vapor-Liquid Separators

The configuration of a vapor/liquid separator depends on a number of factors. Before making a vessel design one has to

decide on the configuration of the vessel with respect to among others:

Orientation

Type of feed inlet

Type of internals

Type of heads

Factors that help to make the choice between the various alternatives are discussed in this chapter.

3.1 Orientation of the Vessel

The selection of the orientation of a gas-liquid separator depends on several factors. Both vertical and horizontal vessels

have their advantages. Depending on the application one has to decide on the best choice between the alternatives.

Advantages of a vertical vessel are:

a smaller plot area is required (critical on offshore platforms)

it is easier to remove solids

liquid removal efficiency does not vary with liquid level because the area in the vessel available for the vapor flow

remains constant

generally the vessel volume is smaller

Advantages of a horizontal vessel are:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 2 of 31

it is easier to accommodate large liquid slugs;

less head room is required;

the downward liquid velocity is lower, resulting in improved de-gassing and foam breakdown;

additional to vapor / liquid separation also a liquid / liquid separation can be achieved (e.g. by installing a boot).

The preferred orientation for a number of typical vapor / liquid separation applications are:

Application

Preferred orientation

Reactor Effluent Separator (V/L)

Vertical

Reactor Effluent Separator (V/L/L)

Horizontal

Reflux Accumulator

Horizontal

Compressor KO Drum

Vertical

Fuel Gas KO Drum

Vertical

Flare KO Drum

Horizontal

Condensate Flash Drum

Vertical

Steam Disengaging Drum

Horizontal

3.2 Feed Inlet

3.2.1 Inlet Nozzle

The feed nozzle size and the type of feed inlet device (if any) have an impact on the vapor / liquid separation that can be

achieved. The feed nozzle is normally sized to limit the momentum of the feed. The limitation depends on whether or not a

feed inlet device is installed.

3.2.2 Inlet device

Various inlet devices are available to improve the vapor / liquid separation. Among others the following inlet devices may be

installed:

a deflector baffle

a slotted tee distributor

a half-open pipe

a 90 elbow

a tangential inlet with annular ring

a schoepentoeter

For vertical drums, preferably a deflector baffle or a half open pipe shall be selected. In case of a slug flow regime in the inlet

piping, or if a high liquid separation efficiency is required, a tangential inlet nozzle with annular ring can be used. However, in

case a high liquid removal efficiency is required, the application of a wire mesh demister is preferred.

For horizontal drums normally a 90 elbow or a slotted diverter is installed. In some cases a submerged inlet pipe is installed,

but this shall not be done in the case of a two-phase feed.

Normally the selected inlet device for a horizontal drum shall be:

a 90 elbow or a slotted diverter in case of an all liquid or vapor-liquid feed

a submerged pipe when the feed is a subcooled liquid and the mixing of liquid and blanket gas is to be minimized

two 90 elbow inlets in case of high vapor loads

3.3 Internals

After passing through the feed inlet, the vapor stream will still contain liquid in the form of droplets. The maximum size of

these entrained droplets depends on the vapor upflow velocity. A separation device can reduce this entrainment significantly.

Wire mesh demisters are the most commonly used as separation device. They are used for two reasons:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 3 of 31

To minimize entrainment

Of the drum services having such a requirement, suction drums for reciprocating compressors are the most notable examples

To reduce the size of a vessel

The allowable vapor velocity in a drum can be increased significantly by using a wire mesh demister. So, when sizing is

governed by vapor-liquid separation criteria, this will result in a smaller diameter of the vessel

Major disadvantages of wire mesh demisters are:

They are not suitable for fouling services

Their liquid removal decreases significantly at reduced throughput

Although the size of the vessel often can be reduced by applying a wire mesh demister, there are also many services where

there is normally no demister installed. Reflux accumulators, for example, seldom have mist eliminators.

There are several other types of mist eliminators such as vanes, cyclones, and fiber beds. They are used when conditions

are not favorable for wire mesh screens. Selection criteria for these types of internals are the required efficiency, capacity,

turndown ratio, maximum allowable pressure drop and fouling resistance. These types however will not be further addressed

in this design guide.

3.4 Vessel Head

Most vessels have 2:1 elliptical heads, welded to the shell of the vessel. However, in some cases other types of heads are

used. The major alternatives are:

Flat heads

In case of small vertical vessels (diameter less than approximately 30) often a flanged top head is used, which also serves to

provide access to the vessel. Depending on the pressure rating, this type of head can either be flat or elliptical, and shall be

selected in consultation with the mechanical engineer

Hemispherical heads

A hemispherical head should be considered for an extremely large, high-pressure vessel

A dished head should be considered in the case of a large diameter, low-pressure vessel

4. Design Criteria for Vapor / Liquid Separators

4.1 Definition of Levels

In the sizing of vessels the proper definition of hold-up time and liquid levels is important. For the design of vessels the

following shall be used:

Liquid hold-up time

Working volume between High Liquid Level (HLL) and Low Liquid Level (LLL)

HLL

Upper end of the control span

LLL

Lower end of the control span

HLA

High Level Alarm, normally at 90% of the control span

LLL

Low Level Alarm, normally at 10% of the control span

4.2 Vertical Vessels

4.2.1 Diameter of a Vertical Vessel

The design of a vapor-liquid separator is based on the terminal settling velocity of a liquid droplet of specified size, settling

under the influence of gravity. This velocity is given by:

(4.1)

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 4 of 31

where

The vapor handling capacity (Kt) depends on the type of service of the vessel. Typical values are:

Application

Kt

Horizontal KO drum

0.25 fps

0.08 m/s

Vertical KO drum without demister

0.15 fps

0.05 m/s

Vertical KO drum with demister

0.25 fps

0.08 m/s

Flare KO drum (essentially dry

vapor)

0.25 m/s

Flare KO drum (wet vapor)

0.10 m/s

The separator shall be large enough to handle the gas flow rate under the most severe process conditions. For systems,

which have a foaming tendency, such as glycol and amine solutions, a derating factor of 0.7-0.8 shall be used for Kt. A

derating factor of 0.7-0.8 shall also be used for compressor suction knockout drums.

See paragraph 4.6 for the sizing of the demister mat

4.2.2 Height of a Vertical Vessel

The total vessel height is the sum of the following contributions:

1. The height required for the Low Liquid Level (LLL)

The level instrument determines the LLL. For mechanical reasons, the nozzle of this instrument should be at least 150

mm above the bottom tangent line. The level instrument requires an additional 50 mm. Therefore, the LLL is about

200 mm above the bottom TL of a vessel. In case of doubt the instrument engineer shall be consulted on the

minimum required LLL.

2. The height required for the liquid hold-up

The liquid hold-up is defined as the volume between the High Liquid Level (HLL) and the Low Liquid Level (LLL). This

volume consists of the standard hold-up plus additional volume in case of slug or trip-alarm levels. Typical hold-up

times are:

Service

Recommended

hold-up

Feed to distillation column, reactor, heater

5-15

min

Reflux vessel

3-5

min

Flare KO drum

20-30

min

Condensate Flash drum

3-5

min

Fuel Gas KO drum 1)Fuel Gas KO drum

1)

1) As a minimum a Fuel Gas KO drum shall be sized to contain a slug of liquid equivalent to the content of 6 mtr inlet

piping.

If slugs of liquid can be expected, additional volume shall be provided to ensure that the required vapor / liquid

separation can still be achieved.

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 5 of 31

3. The clearance between the High Liquid Level and the inlet nozzle

The clearance between the HLL and the inlet nozzle shall be 0.3 times the vessel diameter, with a minimum of 0.3 m.

4. The diameter of the inlet nozzle

The diameter of the inlet device depends on the inlet flow and on the type of inlet device. See section 4.5.1 for the

sizing criteria of the inlet nozzle.

5. The clearance between the inlet device and the top TL

The required clearance between the inlet nozzle and the top TL depends on the presence of a demister.

Without a demister, the clearance shall be 0.7 times the vessel diameter with a minimum of 0.9 m.

With a demister, the clearance shall be:

0.45 times the vessel diameter, with a minimum of 0.9 m to the demister, plus, 0.1 m for the demister, plus

0.15 times the vessel diameter, with a minimum of 0.15 m for the clearance between the demister and the top TL

The sizing is for a vertical vessel with and without a demister is summarized in figure 4.1.

4.3 Horizontal Vessels

4.3.1 Size of a Horizontal Vessel

The calculation of the diameter and the length of a horizontal vessel can not be separated. The cross-sectional area of the

vapor space is based on a maximum allowable vapor velocity given by equation 4.1. The sizing of a horizontal vapor / liquid

separator is based on a trial-and error method. The sizing method consists of the following steps:

1. Calculate the required liquid volume (Vliq) based on the selected liquid holdup time. The liquid volume is given by:

(4.2)

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 6 of 31

1. As a first estimate, assume that the liquid volume is 60 % of the total volume. Select an L/D ratio and calculate the

vessel diameter. The vessel diameter is given by:

(4.3)

where:

D

the diameter of the vessel (m),

L/D

the ratio between the length and the diameter (-).

If there are no other factors, which determine the L/D ratio of a vessel, the design pressure is normally used to select

this ratio. Recommended L/D ratios are:

2. Select the Low Liquid Level (LLL). Typically the LLL is set at 0.2 m, but it shall be checked with the mechanical

engineer whether this is feasible. Calculate the cross-sectional area below the LLL , using the following set of

equations:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 7 of 31

(4.4)

In Excel a special function is available for this calculation.

3. Calculate the total cross-sectional area required for the liquid by adding to the cross-sectional area below the LLL the

area required for the liquid hold up. The total liquid cross-sectional area is given by:

(4.5)

4. Calculate the HLL, using similar formulas as in step 4, or the special function in Excel. Determine the remaining vapor

cross-sectional area.

5. Calculate maximum allowable vapor velocity using

(4.6)

For horizontal vessels Kt shall be taken as 0.25 fps (0.08 m/s).

6. Check the actual vapor velocity.

Based on the vapor space above the HLL, the actual vapor space must be calculated and compared against the

maximum allowable vapor velocity. In case of a large required vapor area, two vapor inlet nozzles shall be

considered, thereby reducing the required vapor space by 50%.

Based on the application some additional criteria apply:

A. Limitations on HLL

The HLL shall not be higher than 80% of the diameter, with a minimum height of the vapor space of 0.3 m. If a demister is

installed, the minimum height of the vapor space is 0.6 m

B. Space for inlet device

The vapor space must be sufficiently high to accommodate the feed inlet device. At least 150 mm shall be available between

the bottom of the inlet device and the HLL

4.3.2 Feed Inlet Device for Horizontal Vessels

Either a 90elbow, or a half-open pipe can be used as inlet device for a horizontal vessel. A 90elbow is preferred, as they

are easier to fabricate. The following requirements are applicable for 90elbow inlets:

The diameter of the elbow must be the same as the nozzle diameter.

An impingement baffle should be installed opposite to the elbow to protect the drum shell. The baffle diameter should

be twice the inlet nozzle diameter. A thickness of for the baffle plate is recommended.

The minimum distance between the elbow and the HLL is 150 mm (6).

The elbow should be installed as close as possible to the tangent line considering reinforcement and fabrication

requirements (150 mm).

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 8 of 31

Short radius elbows shall be used, with 3 straight pipe inside the drum.

4.3.3 Boot

When there is a chance that the liquid contains some water or other immiscible fluid a boot can be provided to collect the

heavier fluid phase. A boot will only be selected if the following criteria are satisfied:

"De-oiling" of the heavy liquid phase is not important

The ratio of the volumetric flow rates of the heavy and light liquid phase is smaller than 0.2

In all other cases overflow/underflow weirs shall be used for proper liquid/liquid separation.

The sizing of the boot diameter shall satisfy the following criteria:

The boot diameter shall not be more than 0.5 times the vessel diameter

The minimum boot diameter depends on the diameter of the vessel, and shall be as listed below:

Vessel Diameter (mm)

Min. Boot Diameter (mm)

D < 900

300

900<D<1400

400

D>1400

500

The heavy liquid draw-off velocity shall not exceed 80% of the rising velocity of the light liquid. Because of the small size of

the droplets, in most cases the Stokes law can be applied to calculate the rising velocity of the droplets.This results in:

Moreover, the design settling velocity should be limited to 10 inch per minute even if a higher rate is calculated.

The length of a boot shall be based on the following criteria:

Typically, allow about 5 minutes hold up for the heavy phase

The length of the boot (i.e. the distance between the bottom of the vessel and the bottom tangent line of the boot)

should be at least 900 mm

to allow a proper interface level control and to accommodate all the nozzles for the control instruments

The low liquid level for the liquid-liquid interface should be 200 mm above the bottom tangent line. The high liquid

level should be 200 mm below the bottom of the vessel. This results in a distance between the low and high level of

the liquid-liquid interface of at least 500 mm

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 9 of 31

Additional vessel requirements when providing a boot:

The light liquid phase outlet shall extend 100 to 150 mm above the bottom of the vessel, and be equipped with a

vortex breaker

The light liquid phase outlet shall be located downstream of the boot and as close as possible to the tangent line of

the vessel

The boot shall be located on the opposite side form the inlet, as close as possible to the tangent line. The distance is

not determined by process reasons, but by the saddle support. Therefore, contact with the mechanical department is

required

4.4 Additional Criteria

4.4.1 Degassing

When good degassing of liquid is required, the dimensioning of the vessel shall also satisfy criteria for the separation of gas

bubbles out of the liquid phase. Because of the small size of the bubbles, in most liquids the Stokes law can be applied to

calculate the rising velocity of the bubbles. This results in:

For vertical vessels it shall be ensured that the downward liquid velocity in the vessel doesn't exceed the calculated rising

velocity of the bubbles.

For horizontal vessels it shall be ensured that the residence time below the low liquid level will allow the selected minimum

size bubble to travel the distance between the vessel bottom and the low liquid level.

4.4.2 Foaming

In case the liquid handled has a tendency to foam, the design shall take this into consideration. Although there is no solid

basis to do so, the following can be used as a guide:

For horizontal vessels, add the height of the foam above the high liquid level, to allow for the reduced vapor space for

vapor/liquid disengagement. (typically 0.3 mtr or 1 ft)

For vertical vessels, Company limits the downwards liquid velocity to:

(4.10)

4.5 Sizing of Nozzles

4.5.1 Feed Inlet Nozzle

The internal nozzle diameter may be taken equal to that of the feed pipe, but also the following momentum criteria shall be

satisfied:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 10 of 31

Other momentum criteria are applicable for high vacuum units or other units where the inlet velocity can be very high

because of the low gas density.

4.5.2 Vapor Outlet Nozzle

The diameter of the gas outlet nozzle should normally be equal to that of the outlet pipe, but also the following criterion shall

be satisfied:

In High Vacuum Units this criterion may result in a high outlet velocity, leading to a pressure drop which is too high. In that

case, the gas outlet nozzle shall be sized such that the pressure drop requirements between column and downstream system

are met.

4.5.3 Liquid Outlet nozzle

The diameter of the liquid outlet nozzle shall be chosen in relation to the outlet line size selected, and is often based on a

liquid velocity of 1 m/s. As liquid circulating above the liquid outlet nozzle may result in vortex formation, the design shall

include measures to avoid this. This can be done in two ways:

Allow adequate liquid height above the outlet nozzle. For checking the required minimum liquid height above the

outlet nozzle see graphs in Appendix I.

Install a vortex breaker

Normally vortex breakers are provided on outlet nozzles that serve as outlet to a pump.

4.5.4 Manway

The size of a manway is usually 24, unless internal devices require larger size for installation. If the vessel diameter is 30 or

less, a flanged head may be considered in stead of a manway. For mechanical reasons manways should be smaller than one

-half of the vessel inside diameter.

As an alternative to a manway, smaller vessels can be provided with an inspection hole, which is normally 8.

4.5.5 Vents and Drains

As defined in the Engineering Guide for the Preparation of Engineering Flow Diagrams (BN-EG-UE208), para. 5.2.4 the size

of vents and drains on vessels shall be:

Vessel volume

Drain Connection

Vent Connection

Up to 17 m3

17 to 200 m3

200 to 400 m3

400 to 700 m3

700 m3 and above

Additional to vents and drains vessels may be provided with steam out and utility connections. Normally these connections

are 2.

4.5.6 Nozzle Identification

If not specifically defined for the project, the nozzles on a vessel shall be identified as follows:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 11 of 31

Process nozzles

N1, N2, N3 etc.

Instrument nozzles

K1, K2, K3 etc., where multiple nozzles for a single instrument

shall be identified K1A\B\C etc

Manways

M1, M2 etc.

Relief Valves

RV1, RV2 etc.

Vents

V1,V2 etc.

Drains

D1, D2 etc.

Steam out connections

SO

Utility connections

UC

4.6 Mist Eliminators

In case a high liquid separation efficiency is required, a mist eliminator can be installed to ensure the removal of smaller liquid

droplets. Also a mist eliminator can be installed to reduce the size of a vertical vapor / liquid separator. Normally a demister

pad is installed as mist eliminator.

Important: In case a vessel is provided with a demister pad, the relief valve protecting the vessel shall be mounted upstream

of the demister pad to reduce the change of blockage in the relief valve inlet and to reduce pressure drop.

4.6.1 Sizing of Demister Pads

The demister pad is sized based on a maximum allowable vapor velocity through the pad, given by vendor rules. A typical

sizing rule for demister pads is given by equation 4.13 however for separators operating under vacuum conditions vendor

information shall be consulted.

The demister thickness is normally 100 mm or 4.

4.6.2 Demisters in Vertical Vapor / Liquid Separators

For vertical vessels the details on demister installation and vessel sizing are given in para. 4.2.

4.6.3 Demisters in Horizontal Vapor / Liquid Separators

For horizontal vessels the following applies for the use of demister pads.Horizontally installed demister pads:

The minimum clearance between the top of the vessel and the demister pad is the larger of 12 or half the length of

the longer side of the pad.

The design of the vessel remains the same as for a horizontal vessel without mist eliminator. except for the minimum

length, which is not specified from inlet to outlet nozzle but from inlet to demister pad.

In case the separation efficiency of the vessel should be very high, two vertical and one horizontal demister can be

installed in the vapor phase. The vessel requires an inlet nozzle at each end, terminated by an elbow or a half-open

pipe, and one vapor outlet nozzle at the center of the vessel. This setup reduces the required cross-sectional vapor

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 12 of 31

area by 50%. However, with small low-pressure vessels, the savings from the smaller diameter may be offset by the

cost of the vertical demisters and the extra inlet.

For vertically installed demister pads:

The minimum thickness of the demister pad is 6

The demister pad should extend from the top of the vessel to 0.1 m above the bottom. The area between the mat and

the bottom of the vessel shall allow free passage of liquid.

The distance between the inlet device and the front face of the demister mat shall be at least 0.6 m or 0.5 times the

vessel diameter

The distance between the downstream side of the outlet nozzle and the rear face of the demister mat shall be at least

0.5D.

5. Design of Liquid / Liquid Separators

Normally, liquid / liquid separation is achieved in a horizontal vessel, providing adequate residence time to properly separate

the required droplet size from both the liquid phases. The most commonly used types are:

Completely filled vessels with liquid draw-off via nozzles at the top and bottom of the vessel

Vessels also providing vapor space, with overflow and underflow baffles, which are separating the liquid / liquid

separation compartment from compartments for liquid draw-off

The former type of separator is used when there is no chance of vapor formation, while the latter is used when there is a

chance of vapor formation.

Rules for the design of coalescor type liquid / liquid separators, where the separation is enhanced by internals (e.g. plate

packs, wire mesh), are not given in this design guide. Design rules for this type of separator shall be based on vendor

information.

5.1 Liquid-Filled Separators

The sizing of a liquid filled liquid / liquid separator is based on the required residence time for:

separating small droplets of light fluid from the heavy phase fluid

separating small droplets of heavy fluid from the light phase fluid

Based on the type of application, one of the two above mentioned criteria may be skipped.

The sizing of this type of liquid / liquid separator is based on trial and error and requires the following steps:

1. Select vessel dimensions and interface levels (min. and max.)

Initial vessel dimensions can be selected based on an overall liquid residence time, e.g. 15 minutes. Initial high and low

interface levels can be selected to get a hold-uptime for the larger of the two phases of approximately 3 minutes (for control

purposes), and about identical hold-up times for both phases, with the interface at the normal level.

2. Calculate the droplet settling velocity for both phases

Because of the small size of the droplets, in most cases the Stokes law can be applied to calculate the settling velocity of the

droplets. This results in:

(5.1)

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 13 of 31

The required residence time must be calculated for both phases, to allow the selected droplet size to travel between the

interface and the top or bottom of the vessel. These residence times must be compared with the actual residence time of both

phases at the interface. Because of the shape of the vessel, it is required to check the required residence time of both phases

against the actual at various interface levels, e.g. at the low and high interface level.

Based on the outcome of the calculations a new set of (high and low) interface levels can be selected, or a new size vessel.

5.2 Liquid-Liquid Separators with Vapor Compartment

A liquid / liquid separator with a vapor compartment is well known, and often used as the accumulator of an ejector based

vacuum system. The sizing of these horizontal vessels includes the sizing based on vapor / liquid separation as described

before and the sizing of the liquid / liquid separation. In this section only the sizing for liquid / liquid separation is discussed. In

case there is only a very small amount of vapor flowing through the vessel, the High Liquid Level shall be taken at max. 80%

of the diameter of the vessel.

The liquid / liquid separators with a vapor compartment have three liquid compartments, one for the liquid / liquid separation

and one each for the hold-up of the separated light and heavy phase. These compartments are separated by overflow and

underflow baffles, which ensure a proper hold up time of the two phases in the separating compartment.

Also the sizing of this type of liquid / liquid separator is based on trial and error and requires the following steps:

1. Select vessel dimensions

Initial vessel dimensions can be selected based on an overall liquid residence time, e.g. 15 minutes with a HLL at 80% of the

vessel diameter.

2. Select the heavy phase overflow baffle height and calculate the resulting interface

By selecting the height of the heavy phase overflow baffle the liquid / liquid interface can be calculated based on a pressure

balance, using the following equation:

H1 x h = Hh x h + (H2-Hh) x l

Where:

H1 the height of the heavy phase overflow baffle

H2 the height of the light phase overflow baffle

Hh the height of the heavy phase in the separation compartment

h the density of the heavy fluid (kg/m3)

l the density of the light fluid (kg/m3)

As a starting value for H1 take it approximately 200 mm below H2.

3. Position the baffles

The overflow baffles must be positioned to get adequate hold up in the overflow compartments for proper control of the

outgoing fluid. Normally a hold up of approximately three minutes between a HLL and LLL is adequate.The distance between

heavy phase underflow and overflow normally is 200 mm, however this shall be checked to minimize pressure drop.

4. Check the liquid / liquid separation

To check the liquid / liquid separation the droplet settling velocity for both phases must be calculated. Because of the small

size of the droplets, in most cases the Stokes law can be applied to calculate the settling velocity of the droplets. This results

in:

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 14 of 31

(5.2)

where

Vd settling velocity of the droplet (m/s)

g gravitational constant (9.81 m/s2)

Dd the droplet diameter (m)

h the density of the heavy fluid (kg/m3)

l the density of the light fluid (kg/m3)

c the dynamic viscosity of the continuous phase (Pa s)

Based on the calculated interface level and settling velocities the required residence time for the light and heavy fluid must be

calculated and compared with the actual residence times.

Based on the outcome of the calculations some of the assumed values have to be adjusted. In case there are only minor

differences between the actual and required residence times, adjustment of the overflow and underflow baffles (in height

and / or location) will be sufficient, in the case of larger differences, the overall size of the vessel will have to be adjusted.

Because of the fixed overflow baffles, the interface level will change with changes in fluid densities. As this affects the

separation, the design shall be checked for possible changes in these densities. For the same reason it is recommended to

have the top of the heavy fluid overflow baffle adjustable (e.g. +/- 100 mm)

5. Check vapor / liquid separation

As a final check on the dimensions, the vapor / liquid separation must be checked based on the vapor residence time and the

settling velocity of the light fluid droplets to be removed from the vapor.

6. Computer Programs

Various computer applications have been developed for the sizing of vapor \ liquid separators. These are:

6.1 Depsep

This program has been developed to size vapor \ liquid separators based on the "Company" rules. A typical output is given in

Appendix IV.

6.2 Separator

This program, originally a Lotus 123 spreadsheet, has been developed to size vapor \ liquid separators based on "Company"

rules.

Some typical outputs are given in Appendix V.

6.3 Excel Functions

In Excel a number of special functions have been developed to calculate vessel characteristics. Among other the following

functions have been developed:

6.3.1 Horizontal Vessel Liquid Volume

Calculates the volume of liquid in a horizontal vessel based on vessel diameter, vessel length, liquid level and type of head.

6.3.2 Horizontal Vessel Liquid Level

Calculates the liquid level in a horizontal vessel based on:

Vessel Diameter

Vessel Length

Liquid Volume

Type of Head

(For a quick estimate refer to the 'Tools' section of the Red-Bag website.)

6.3.3 Vertical Vessel Liquid Volume

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 15 of 31

Calculates the volume of liquid in a vertical vessel based on:

Vessel Diameter

Vessel Length

Liquid Level

Type of Head

6.3.4 Vertical Vessel Liquid Level

Calculates the liquid level in a horizontal vessel based on:

Vessel Diameter

Vessel Length

Liquid Volume

Type of Head

6.3.5 Segmental Area from Elevation

Calculates the cross sectional area of a horizontal vessel below a given level based on:

Vessel diameter

Level height

7. Appendices

I

Graphs

II

Typical Vessel Calculations

III

Typical Data Sheet

IV

DEPSEP Output

SEPARATOR Output

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 16 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 17 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 18 of 31

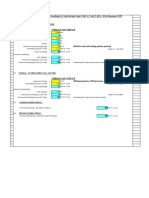

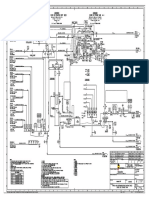

Typical Vessel Calculations

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 19 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 20 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 21 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 22 of 31

PROCESS DATA SHEETS FOR:

B211

Benzeen Destillaat Vat

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 23 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 24 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 25 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 26 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 27 of 31

DEPSEP OUTPUT

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 28 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 29 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 30 of 31

SEPARATOR OUTPUT

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

BN-EG-UE109 Guide for Vessel Sizing

Page 31 of 31

http://www.red-bag.com/jcms/engineering-guides/337-bn-eg-ue109-guide-for-vessel-sizin...

2/14/2013

You might also like

- Liquid/Liquid and Gas/Liquid/Liquid Separators - Type Selection and Design RulesDocument3 pagesLiquid/Liquid and Gas/Liquid/Liquid Separators - Type Selection and Design RulescassindromeNo ratings yet

- Fine Tune Relief Calculations For Supercritical FluidsDocument10 pagesFine Tune Relief Calculations For Supercritical FluidsPeter PerezNo ratings yet

- Slug Catcher Design GuideDocument7 pagesSlug Catcher Design GuideShyBokx100% (3)

- DRS - Operation & Control PhilosophyDocument5 pagesDRS - Operation & Control PhilosophyAnand GNo ratings yet

- CFD Methodology For Liquid Pressure Recovery PredictionsDocument9 pagesCFD Methodology For Liquid Pressure Recovery PredictionsAshok SureshNo ratings yet

- Real Separator Guide - HysysDocument23 pagesReal Separator Guide - Hysysfri_13thNo ratings yet

- API STD 521-Control Valve FailureDocument1 pageAPI STD 521-Control Valve Failuremuhammad_asim_10100% (1)

- Flaresim Manual (2008)Document452 pagesFlaresim Manual (2008)thesimpleguy6No ratings yet

- Slugging in A Flare HeaderDocument34 pagesSlugging in A Flare Headercepong89No ratings yet

- Gas Pipeline Blowdown TimeDocument3 pagesGas Pipeline Blowdown Timeankur2061No ratings yet

- RP44 3Document81 pagesRP44 3polaris44100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Tanks Breathing CalculationDocument1 pageTanks Breathing CalculationRexx Mexx0% (1)

- Iraq Oil and Gas Final Tender Protocol - Round1Document67 pagesIraq Oil and Gas Final Tender Protocol - Round1Rexx Mexx100% (1)

- LP Flare Network Calculation Rev - E0Document18 pagesLP Flare Network Calculation Rev - E0Rexx Mexx100% (3)

- Modal Workout 2.0 v2 PDFDocument45 pagesModal Workout 2.0 v2 PDFAdi Darmawan100% (10)

- Principles of Separation: Production and Test SeparatorsDocument28 pagesPrinciples of Separation: Production and Test SeparatorsهانيزايدNo ratings yet

- Natural Gas Quality Enhancement: Training Report ONDocument20 pagesNatural Gas Quality Enhancement: Training Report ONRajkishan GuptaNo ratings yet

- Slug Catcher SizingDocument6 pagesSlug Catcher SizingrezaNo ratings yet

- Read Me Chapter 4: Pages 4 - 7 Show The VB 3.0 Display ScreensDocument7 pagesRead Me Chapter 4: Pages 4 - 7 Show The VB 3.0 Display ScreensLeonardo Chávez0% (2)

- Gas Line VelocityDocument3 pagesGas Line Velocityputrude100% (1)

- Template (Vessel Sizing-2phase)Document2 pagesTemplate (Vessel Sizing-2phase)mNo ratings yet

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview Techniquesyamsul100% (1)

- Guidelines For The Safe and Optimum Design ofDocument9 pagesGuidelines For The Safe and Optimum Design ofMoca PhoenixNo ratings yet

- PDM-P-CS-002 - HP Prod SeparatorDocument6 pagesPDM-P-CS-002 - HP Prod Separatorfirman adiyantoNo ratings yet

- Project Standards and Specifications Pig Catcher Package Rev01Document9 pagesProject Standards and Specifications Pig Catcher Package Rev01hiyeonNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- Low Pressure Gas Piping Pressure Loss CalculationDocument1 pageLow Pressure Gas Piping Pressure Loss CalculationJohn ANo ratings yet

- E PR 460Document37 pagesE PR 460khorzooNo ratings yet

- Calculation and Design of Separators (VS)Document18 pagesCalculation and Design of Separators (VS)Bhuran Akshay100% (1)

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Blowdown Calculation Inventory - Subsea FlowlineDocument13 pagesBlowdown Calculation Inventory - Subsea FlowlineNK0% (1)

- Chemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFDocument4 pagesChemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFvenkatrangan2003100% (1)

- ENGINEERING DESIGN GUIDELINES Slug Catcher Rev Web PDFDocument26 pagesENGINEERING DESIGN GUIDELINES Slug Catcher Rev Web PDFkhajacheNo ratings yet

- CV of Globe Valves Gate Valves and Check ValvesDocument2 pagesCV of Globe Valves Gate Valves and Check ValvesFred Faber100% (3)

- A New Approach For Sizing Finger Slug CatcherDocument15 pagesA New Approach For Sizing Finger Slug CatcherHaryadi100% (1)

- Velocity and Pressure Drop in PipesDocument5 pagesVelocity and Pressure Drop in PipesManojkumar ThilagamNo ratings yet

- Heat Exchanger Tube RuptureDocument3 pagesHeat Exchanger Tube RuptureKarthik Sakthivel100% (1)

- Ajuste de GOR en HysysDocument1 pageAjuste de GOR en HysysAnonymous jqevOeP7No ratings yet

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rg100% (1)

- Kataoka 1983Document9 pagesKataoka 1983Nguyễn Thị Kim PhượngNo ratings yet

- Finger Type Slug CatcherDocument41 pagesFinger Type Slug CatcherIrfaan Taufiiqul Rayadi100% (2)

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDocument15 pagesBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradNo ratings yet

- API 12L - Heater TreaterDocument6 pagesAPI 12L - Heater TreaterwahyuriansyahNo ratings yet

- Design, Operation and Maintenance of Lact UnitsDocument3 pagesDesign, Operation and Maintenance of Lact UnitsJose gonzalezNo ratings yet

- Design Philosophy-Process PipingDocument3 pagesDesign Philosophy-Process PipingWade ColemanNo ratings yet

- OLGA 7-NotesDocument10 pagesOLGA 7-NotesraminabkNo ratings yet

- Rupture Disk EquationsDocument13 pagesRupture Disk EquationsMehta MehulNo ratings yet

- Ognition PSV Sizing Calculation SpreadsheetDocument2 pagesOgnition PSV Sizing Calculation SpreadsheetJoseph Paul IlaganNo ratings yet

- Gas Blow-By From A Production Separator To Tank PDFDocument7 pagesGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- Article On Finger Type Slug CatcherDocument15 pagesArticle On Finger Type Slug Catcherhasifpp2013No ratings yet

- What Has Changed in API 521 6EDDocument19 pagesWhat Has Changed in API 521 6EDgateauxboy100% (1)

- PSV Sizing - Blocked Outlet GasDocument1 pagePSV Sizing - Blocked Outlet GasSilas Onyekwe50% (2)

- BN-EG-UE109 Guide For Vessel SizingDocument29 pagesBN-EG-UE109 Guide For Vessel SizingSachin ChavanNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument28 pagesBN-EG-UE109 Guide For Vessel Sizingeulalio_méndezNo ratings yet

- Vessel DesignDocument43 pagesVessel Designhomiez99No ratings yet

- Vertical SeparatorDocument38 pagesVertical SeparatorSaidFerdjallahNo ratings yet

- BN Eg UE109 Vessel SizingDocument40 pagesBN Eg UE109 Vessel Sizingbadelitamarius100% (1)

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument36 pagesBN-EG-UE109 Guide For Vessel SizingAjith KumarNo ratings yet

- BN-EG-UE109 Guide for Vessel SizingDocument43 pagesBN-EG-UE109 Guide for Vessel SizingLuis MarshNo ratings yet

- Separator Vessel: Ms. Shreya SahajpalDocument6 pagesSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalNo ratings yet

- Two-Phase and Three-Phase SeparatorDocument40 pagesTwo-Phase and Three-Phase Separatormargaretramos100% (1)

- Hydraulic Cal - Tanks Vent To FlareDocument1 pageHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- CORP-FRM-HSE-006 - 1 DNO Quick Risk V4.0Document1 pageCORP-FRM-HSE-006 - 1 DNO Quick Risk V4.0Rexx MexxNo ratings yet

- Thermal Fluid Heaters: Model HHC and VHCDocument4 pagesThermal Fluid Heaters: Model HHC and VHCRexx MexxNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Volcanic Alliance Bro 200311 PDFDocument4 pagesVolcanic Alliance Bro 200311 PDFRexx MexxNo ratings yet

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDocument4 pagesTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNo ratings yet

- Thermal Fluid Heaters: 75,000 TO 40 MM BTU/HRDocument16 pagesThermal Fluid Heaters: 75,000 TO 40 MM BTU/HRRexx MexxNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- KU-TWK-40-PR-PID-0018-27-dwg - A - Condensate HeaderDocument1 pageKU-TWK-40-PR-PID-0018-27-dwg - A - Condensate HeaderRexx MexxNo ratings yet

- Alternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseDocument5 pagesAlternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseRexx MexxNo ratings yet

- SEM-9486E Boiler Feed Water Chemical TreatmentDocument19 pagesSEM-9486E Boiler Feed Water Chemical TreatmentRexx MexxNo ratings yet

- Desalter Operation OptimizationDocument3 pagesDesalter Operation OptimizationRexx MexxNo ratings yet

- 00251121DPFM02101 - EXCO01 - 01 - Crude Oil Storage TankDocument1 page00251121DPFM02101 - EXCO01 - 01 - Crude Oil Storage TankRexx Mexx100% (1)

- SEM-9521E Vibrating ScreenDocument16 pagesSEM-9521E Vibrating ScreenRexx Mexx100% (1)

- SEM-9518E Truck ScaleDocument7 pagesSEM-9518E Truck ScaleRexx MexxNo ratings yet

- Packed Tower Internals GuideDocument56 pagesPacked Tower Internals GuideRexx Mexx100% (2)

- SEM-9483E Bag FilterDocument13 pagesSEM-9483E Bag FilterRexx MexxNo ratings yet

- SEM-9487E Breather ValveDocument8 pagesSEM-9487E Breather ValveRexx Mexx100% (1)

- SEM-9522E Water TreatmentDocument81 pagesSEM-9522E Water TreatmentRexx MexxNo ratings yet

- SEM-9513E Safety ValveDocument11 pagesSEM-9513E Safety ValveRexx MexxNo ratings yet

- Sem-9480e 0 (Depressuring)Document26 pagesSem-9480e 0 (Depressuring)Rexx Mexx100% (2)

- Blowdown CalculationDocument6 pagesBlowdown CalculationRexx Mexx100% (2)

- EXPT. 1 Common Laboratory OperationsDocument8 pagesEXPT. 1 Common Laboratory Operationsjazzmin dulceNo ratings yet

- Peasaran Et Al 2001 Bound Test and ARDL CointegratDocument33 pagesPeasaran Et Al 2001 Bound Test and ARDL CointegratemilNo ratings yet

- Overview VES Visual Enterprise SolDocument10 pagesOverview VES Visual Enterprise SolmspranavNo ratings yet

- (FREE PDF Sample) Microscopy Methods in Nanomaterials Characterization. A Volume in Micro and Nano Technologies Sabu Thomas EbooksDocument62 pages(FREE PDF Sample) Microscopy Methods in Nanomaterials Characterization. A Volume in Micro and Nano Technologies Sabu Thomas Ebooksbasimslovesx100% (4)

- Leica Disto s910 User Manual 805080 808183 806677 en PDFDocument55 pagesLeica Disto s910 User Manual 805080 808183 806677 en PDFVina AnggrainiNo ratings yet

- Grass CutterDocument17 pagesGrass CutterraviNo ratings yet

- MATH F311 (Introduction To Topology) : BITS PilaniDocument21 pagesMATH F311 (Introduction To Topology) : BITS PilaniJatin BackupNo ratings yet

- Report - A06 - PD2 (Chapter 1 To 9) LatestDocument611 pagesReport - A06 - PD2 (Chapter 1 To 9) LatestPuan MizilaNo ratings yet

- Spansion S25FL256S - 32MB SPI FlashromDocument149 pagesSpansion S25FL256S - 32MB SPI FlashromcockNo ratings yet

- Soy Automotive Technology Midterm ExamDocument5 pagesSoy Automotive Technology Midterm ExamJOHN STEVEN SOYNo ratings yet

- Table of SpecificationDocument1 pageTable of SpecificationAngelica Manalo PerezNo ratings yet

- 2 EuclidDocument25 pages2 EuclidLorie Mae MicarisNo ratings yet

- Heat Treatment and Fruit RipeningDocument17 pagesHeat Treatment and Fruit RipeningirfanNo ratings yet

- Air Pollution Control Measures For Hot Dip Galvanizing KettlesDocument9 pagesAir Pollution Control Measures For Hot Dip Galvanizing KettlesPradeep KumarNo ratings yet

- Probleme Controversate de Morfologie Si Sintaxa A Limbii EnglezeDocument45 pagesProbleme Controversate de Morfologie Si Sintaxa A Limbii EnglezeandreeagainaNo ratings yet

- Chemical Engineering Science: X: Yen-Hsun Tseng, Swomitra K. Mohanty, John D. Mclennan, Leonard F. Pease IiiDocument8 pagesChemical Engineering Science: X: Yen-Hsun Tseng, Swomitra K. Mohanty, John D. Mclennan, Leonard F. Pease IiiAnita BudiNo ratings yet

- 2014 - Elsevier - A Review of Biometric Technology Along With Trends and ProspectsDocument16 pages2014 - Elsevier - A Review of Biometric Technology Along With Trends and ProspectsRajalakshmi MohandhossNo ratings yet

- 48x8 Scrolling Matrix Led Display Using Arduino Controller - AllDocument21 pages48x8 Scrolling Matrix Led Display Using Arduino Controller - AllVenkatesh SubramanyaNo ratings yet

- Distance Protection RelayDocument2 pagesDistance Protection RelayThirumalNo ratings yet

- Hale UavDocument29 pagesHale UavTanveer AliNo ratings yet

- Hangman Source Code With JavaDocument6 pagesHangman Source Code With JavaYosep WijayaNo ratings yet

- Chapter 3 Class SlidesDocument58 pagesChapter 3 Class SlidesmattNo ratings yet

- Stainless Steel Production by IfDocument4 pagesStainless Steel Production by IfAbhinav TiwariNo ratings yet

- Philips 39pfl3708-f8 Chassis Pl13.10Document53 pagesPhilips 39pfl3708-f8 Chassis Pl13.10Edilberto Avila100% (1)

- M2 Unit 4Document67 pagesM2 Unit 4makingfortimepass420No ratings yet

- Math Xi Set A First Term 2080 FinalDocument4 pagesMath Xi Set A First Term 2080 Finalrajshgupta01No ratings yet

- BIG-IP Global Traffic ManagerDocument6 pagesBIG-IP Global Traffic ManagerpavankalluriNo ratings yet

- AuxinsDocument16 pagesAuxinsICPH 2021No ratings yet

- Complete Download Start Programming Using HTML CSS and JavaScript 1st Edition Iztok Fajfar (Author) PDF All ChaptersDocument60 pagesComplete Download Start Programming Using HTML CSS and JavaScript 1st Edition Iztok Fajfar (Author) PDF All Chapterseddiealand73100% (11)