VGP01 Routine Visual Inspection

VGP01 Routine Visual Inspection

Uploaded by

Riaz AhmedCopyright:

Available Formats

VGP01 Routine Visual Inspection

VGP01 Routine Visual Inspection

Uploaded by

Riaz AhmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

VGP01 Routine Visual Inspection

VGP01 Routine Visual Inspection

Uploaded by

Riaz AhmedCopyright:

Available Formats

Print Form

Routine Visual Inspections (VGP 4.1.1)

Form

VGP 01

Checklist Part 1

Inspections of all areas addressed in this permit are to be carried out weekly, or per voyage, whichever is

more frequent.

This in spection must incl ude all deck, machinery, cargo ar eas and all other acce ssible areas where

chemicals, oils, dry cargo or other materials are stored, mixed, and used, whether or not the areas have

been used since the last inspection.

At a minimu m, the r outine inspecti on must verify that requirem ents of secti on 2.1 are b eing met and

document any instances of non-compliance

These routine inspections should be conducted on a schedule that coincides with other routine vessel

inspections

Areas Free of Potential Pollutant

Location

Garbage

(Y/N)

Raw

Materials

Deck

Cargo Spaces

Machinery Spaces

Boiler Area

Steering Gear

Storage Areas - Deck

Storage Areas E.R.

Storage Areas - Accom

Chemical Storage

Galley

(Enter other areas covered in blank rows in table)

(Y/N)

Oil/Oily

Waste (Y/N)

Other

(Y/N)

Corr Act

Ref No.

Compliance with Section 2.1 Limits (refer to VGP 2.1)

Y/N

If No, Corr

Act Ref No.

Material Stowage (2.1.1) requirements are being met

Toxic and Hazardous Material (2.1.2) in Protected Stowage

Fueling Operations (2.1.3) Control Measures in Place

No Discharge of Oil or Oily Mixture

All Discharges Comply with all Applicable US Regulations (2.1.5)

A ships watc h must inclu de visu al m onitoring of th e water around and behi nd the v essel for vi sible

sheens, du st, chemical s, abnormal d iscoloration or foaming , and other in dicators of pollutants or

constituents of concern or iginating from the vessel. Pa rticular attention should be paid to deck runoff,

ballast water, and bilgewater.

It is confirmed that:

All ships watchkeepers are aware of the monitoring requirements above

All visible pollution prevention mechanisms are in place and in proper working order.

All monitoring, training, and inspections are logged according to permit requirements.

Date/Time Inspection:

Inspectors Name (s)/Signature (S):

.

.

Masters Signature

Routine Visual Inspections Checklist Part 2 (Quarterly Sampling)

At least onc e per quar ter, discharge streams not readily visible (if accessible) must be sampled. This will

generally apply to discharge such as bilgewater or graywater, discharged below the water line.

The samples are to be in spected for any signs of vi sible pollutants or constituents of concern, including

discoloration, visible sheens, suspended solids, floating solids, foam, or changes to clarity.

If signs of oil, other pollutants, or other constituents of concern are discovered exceeding the applicable

effluent limit, the steps taken to prevent the con tinued disch arge of these pollutants or constituents of

concern and what corrective actions were taken to remediate the problem(s) must be recorded.

Note: Sampling of readily visible discharges is not required, but is recommended if the insp ector cannot

easily view their discharg e charac teristics (such as cl arity or discoloration, presence of oily sheens,

presence of foams, etc.). All discharges must comply with the effluent limits in Part 2.

Date /

Time

Discharge

Sampled

Visible Pollutant Inspection (Y/N)

Discoloration Visib

le Sheen

Solids

Foam

Other

Corr Act

Ref. No.

Date/Time Inspection:

Inspectors Name (s)/Signature (S)

Masters Signature

You might also like

- 00 NPDES Record Book Filling Instructions and IndexDocument3 pages00 NPDES Record Book Filling Instructions and IndexNeeraj SNo ratings yet

- D20 ECDIS - Gyro Input FailureDocument1 pageD20 ECDIS - Gyro Input FailureRiaz Ahmed67% (3)

- PDF Grupos Etnicos Lesson Plan Spanish Speakers IDocument7 pagesPDF Grupos Etnicos Lesson Plan Spanish Speakers Iapi-247302176No ratings yet

- Oil Record Book Part IIDocument52 pagesOil Record Book Part IIRosario Sisniegas100% (1)

- T24 Setting Up A Nostro AccountDocument10 pagesT24 Setting Up A Nostro Accountlolitaferoz100% (2)

- Hempadur Quattro Base 1763650630 En-UsDocument12 pagesHempadur Quattro Base 1763650630 En-UsBill MillNo ratings yet

- BP - Survey Vessel XS6001Document10 pagesBP - Survey Vessel XS6001Kurniawan PriambodoNo ratings yet

- Korea Shipowners' AssociationDocument6 pagesKorea Shipowners' AssociationRiaz AhmedNo ratings yet

- VGP Logbook - Sample EntriesDocument13 pagesVGP Logbook - Sample EntriesRiaz AhmedNo ratings yet

- ECDIS - Failure of Secondary Means of NavigationDocument1 pageECDIS - Failure of Secondary Means of NavigationRiaz AhmedNo ratings yet

- D18 ECDIS - Speed Log Input FailureDocument1 pageD18 ECDIS - Speed Log Input FailureRiaz Ahmed100% (1)

- D17 ECDIS - GPS Input FailureDocument1 pageD17 ECDIS - GPS Input FailureRiaz Ahmed100% (1)

- Mondavi Case StudyDocument3 pagesMondavi Case StudysroghenNo ratings yet

- Anthology of Russian Folk EpicsDocument31 pagesAnthology of Russian Folk EpicsMisterAntlers100% (1)

- Assignment On Negotiable Instruments ActDocument6 pagesAssignment On Negotiable Instruments ActBitthal Sharma0% (1)

- Uscg Chem PDFDocument65 pagesUscg Chem PDFjbjacksparrowNo ratings yet

- USCG Foreign Freight Vessel Examiner JobAidDocument18 pagesUSCG Foreign Freight Vessel Examiner JobAidLNG OUGARTANo ratings yet

- Bahamas CircularDocument8 pagesBahamas CircularPrasad BangaruNo ratings yet

- Survey Report For: Cargo Ship Safety Construction Certificate (CSSC)Document14 pagesSurvey Report For: Cargo Ship Safety Construction Certificate (CSSC)tacoriandNo ratings yet

- Section 3 - Oil To Sea Interface Log: Date: 1 - Jun - 2011 Fleet Management Ltd. Revision: 0 Revision: 0Document1 pageSection 3 - Oil To Sea Interface Log: Date: 1 - Jun - 2011 Fleet Management Ltd. Revision: 0 Revision: 0ravilullaNo ratings yet

- PreparationDocument36 pagesPreparationLakshmikanthNo ratings yet

- Engine Room CraneDocument22 pagesEngine Room CraneNarendra KatdareNo ratings yet

- Handover Notes Master Nov 2021Document5 pagesHandover Notes Master Nov 2021Sriram SridharNo ratings yet

- IECex CertificateDocument5 pagesIECex CertificateLai HuynhNo ratings yet

- Confined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Document24 pagesConfined Space Safe Practice: (2000) Rev.1 (October 2003) Rev.2 (April 2007)Karwan Dilmany100% (1)

- DNV Machinery CM Guidance 2008Document13 pagesDNV Machinery CM Guidance 2008Andre100% (1)

- Tankler FamilirazationDocument135 pagesTankler Familirazationkurtmus100% (1)

- SIRE Inspections On Oil TankersDocument5 pagesSIRE Inspections On Oil Tankersrahmat jamilNo ratings yet

- Aux Engine SCREENDocument12 pagesAux Engine SCREENimedNo ratings yet

- FFD - 4 - Maintenance Manual PDFDocument15 pagesFFD - 4 - Maintenance Manual PDFKaleb Z king webNo ratings yet

- M4 - Engine Room Plan MaintenanceDocument8 pagesM4 - Engine Room Plan MaintenanceMd FaesNo ratings yet

- 10 1 BWMDocument4 pages10 1 BWMLuu Quang HoaNo ratings yet

- ExxonMobil VPQ Review Form1Document27 pagesExxonMobil VPQ Review Form1qualiman1No ratings yet

- BMA Bulletin 73 Periodic Bottom Inspection of Passenger ShipsDocument11 pagesBMA Bulletin 73 Periodic Bottom Inspection of Passenger ShipspRADEEP sNo ratings yet

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliNo ratings yet

- Guidance Notes For Machinery Survey Arrangements Including The ExaminaDocument30 pagesGuidance Notes For Machinery Survey Arrangements Including The ExaminaAbu HaidarNo ratings yet

- Normam04 r1 enDocument73 pagesNormam04 r1 enVladimir PintoNo ratings yet

- IGS Ballast Tanks Guide - E-May12Document37 pagesIGS Ballast Tanks Guide - E-May12André CarvalhoNo ratings yet

- Periodic Servicing of Lifeboats and Rescue BoatsDocument37 pagesPeriodic Servicing of Lifeboats and Rescue BoatsDalibor Mimica100% (1)

- 2007 Circular 10 Lifting GearDocument4 pages2007 Circular 10 Lifting Gearmask_goldNo ratings yet

- FO-I-11 AB Instructions For Flag State Inspectors Rev 17Document24 pagesFO-I-11 AB Instructions For Flag State Inspectors Rev 17JackNo ratings yet

- 30wknm15 Week30 2015Document119 pages30wknm15 Week30 2015Kunal Singh100% (1)

- USCG Foreign Tank Vessel Exam. Book No. 1Document13 pagesUSCG Foreign Tank Vessel Exam. Book No. 1ch3g44No ratings yet

- P A ManualDocument65 pagesP A ManualARE YOU TECH CRAZYNo ratings yet

- Chevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPDocument32 pagesChevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPNamal FernandoNo ratings yet

- Marine Notice 2023 04 Pilot Transfer Arrangements June 2023 002Document11 pagesMarine Notice 2023 04 Pilot Transfer Arrangements June 2023 002SHIPMANAGEMENT FETRANNo ratings yet

- Pub Flag State RequirementsDocument14 pagesPub Flag State RequirementsOmar F. Mauco100% (1)

- Directorate General of Shipping, Govt. of India: Assessment Check ListDocument2 pagesDirectorate General of Shipping, Govt. of India: Assessment Check ListChetanNo ratings yet

- Liberia Form InspectionDocument8 pagesLiberia Form Inspectionrichard icalaNo ratings yet

- RX 415 ManualDocument33 pagesRX 415 ManualMH PartisanNo ratings yet

- Occasional Survey ReportDocument9 pagesOccasional Survey ReportManish SoodNo ratings yet

- Sithonia-Ffe Cert-2021-NewDocument94 pagesSithonia-Ffe Cert-2021-Newmohammed2sohyouniNo ratings yet

- 2013ownerchklist ForeigngovDocument169 pages2013ownerchklist Foreigngovcarlosmesq100% (1)

- Presentation 20 Mar 2014 NIHK VettingDocument72 pagesPresentation 20 Mar 2014 NIHK VettingNang D. Vu100% (1)

- Tokyo MOU Deficiency CodesDocument16 pagesTokyo MOU Deficiency CodesWirote ArcheepkosolNo ratings yet

- NK - IMSBC Code For AluminaDocument25 pagesNK - IMSBC Code For AluminaKhoai Sai GonNo ratings yet

- Ship Energy Efficiency Management Plan - Mepc 213 - 63 - SummaryDocument2 pagesShip Energy Efficiency Management Plan - Mepc 213 - 63 - SummaryV S Ramesh RaoNo ratings yet

- rightship上船前培训课件(中英文)培训部Document52 pagesrightship上船前培训课件(中英文)培训部Steven Tan100% (1)

- Owner Response KTR 10june19 MarineSuptDocument10 pagesOwner Response KTR 10june19 MarineSuptronnie seaman100% (1)

- Cg-840 Hull Inspection BookDocument38 pagesCg-840 Hull Inspection Bookgreatenick.nbNo ratings yet

- Chek List Ilo MLC GuideDocument18 pagesChek List Ilo MLC GuideFédyHamdiNo ratings yet

- CRONUS-Z Specs 20022020Document2 pagesCRONUS-Z Specs 20022020zba2No ratings yet

- SGN 084 (A) - Cyber Security For Ships PDFDocument2 pagesSGN 084 (A) - Cyber Security For Ships PDFvangeliskyriakos8998No ratings yet

- K-Gauge Hla 600: Independent High Level and Overfill Alarm SystemDocument4 pagesK-Gauge Hla 600: Independent High Level and Overfill Alarm SystemPavel ViktorNo ratings yet

- Checklist For Port State Control: - ISPS CheckDocument5 pagesChecklist For Port State Control: - ISPS CheckTan DatNo ratings yet

- MarPol Annex VI Reg 16-18 PresentationDocument48 pagesMarPol Annex VI Reg 16-18 PresentationZtik PeraltaNo ratings yet

- Annual Report PSCDocument27 pagesAnnual Report PSCEmoxie X - Stabyielz100% (1)

- Iec60092-502sup ZONAS CLASIFICADADocument6 pagesIec60092-502sup ZONAS CLASIFICADAacastanopadilla4100No ratings yet

- OSV Rules SingaporeDocument24 pagesOSV Rules Singaporeronny-suNo ratings yet

- VGP02 Annual Insp CLDocument2 pagesVGP02 Annual Insp CLZIAUL KARIMNo ratings yet

- Ship Maintenance Business Process Level 1Document17 pagesShip Maintenance Business Process Level 1Fareza MNo ratings yet

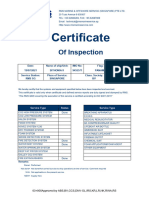

- SGSClinker OmanDocument1 pageSGSClinker OmanRiaz AhmedNo ratings yet

- Ship BreakingDocument99 pagesShip BreakingRiaz Ahmed100% (1)

- At A Glance Ship Berthing Data For CPADocument1 pageAt A Glance Ship Berthing Data For CPARiaz AhmedNo ratings yet

- IMPORT (Load) : Sub - Total Workable VSSLDocument1 pageIMPORT (Load) : Sub - Total Workable VSSLRiaz AhmedNo ratings yet

- Of Vessels: Dated: Berthing Position & PerformanceDocument2 pagesOf Vessels: Dated: Berthing Position & PerformanceRiaz AhmedNo ratings yet

- VGP Final Permit2013Document194 pagesVGP Final Permit2013Riaz AhmedNo ratings yet

- Frequently Asked Questions Update 20 Feb 2009Document1 pageFrequently Asked Questions Update 20 Feb 2009Riaz AhmedNo ratings yet

- VGP Final Permit2013Document194 pagesVGP Final Permit2013Riaz AhmedNo ratings yet

- VGP Faq 1Document3 pagesVGP Faq 1Riaz AhmedNo ratings yet

- VGP 2013 Annual ReportDocument9 pagesVGP 2013 Annual ReportRiaz AhmedNo ratings yet

- Ecdis - Primary Ecdis FailureDocument1 pageEcdis - Primary Ecdis FailureRiaz AhmedNo ratings yet

- SAF16 - Critical Operations Checklist: Ships Name: Department Checklist NoDocument1 pageSAF16 - Critical Operations Checklist: Ships Name: Department Checklist NoRiaz AhmedNo ratings yet

- (Ibn Al-Jawzi) Devils Deception (Talbis Iblis)Document70 pages(Ibn Al-Jawzi) Devils Deception (Talbis Iblis)shkmd100% (1)

- Event Space Rental Agreement and Contract 5aab99851723ddbd6a79429bDocument5 pagesEvent Space Rental Agreement and Contract 5aab99851723ddbd6a79429bMary Ann Farcon VelascoNo ratings yet

- NikeDocument11 pagesNikeNikita Agrawal100% (1)

- The Johns Hopkins University PressDocument35 pagesThe Johns Hopkins University Pressnajib yakoubiNo ratings yet

- Sop For Procedure For BreakdownDocument4 pagesSop For Procedure For BreakdownYATHISH BABUNo ratings yet

- Tessie A. LarozaDocument3 pagesTessie A. LarozaTess C. AlumbroNo ratings yet

- Mihir J Patel Student ID: 200448420 ENG 100-071 Mid-Term ExamDocument8 pagesMihir J Patel Student ID: 200448420 ENG 100-071 Mid-Term ExamMihir PatelNo ratings yet

- Appointed and Reserved Seats For Women in Papua New Guinea by Orovu SepoeDocument22 pagesAppointed and Reserved Seats For Women in Papua New Guinea by Orovu SepoeADBGAD100% (1)

- X-Pin Code File Hyderabad Snid Sep-24Document206 pagesX-Pin Code File Hyderabad Snid Sep-24sadafsh745No ratings yet

- Activity Partnership Formation and OperationDocument8 pagesActivity Partnership Formation and OperationSharon AnchetaNo ratings yet

- VP 021LC972 InvoicesDocument4 pagesVP 021LC972 InvoicesVaishnav RaiNo ratings yet

- TOEFL Castellano.Document9 pagesTOEFL Castellano.Sexto InfNo ratings yet

- Aa Big IndexDocument2 pagesAa Big IndexKristinDaigleNo ratings yet

- Greek Theater PDFDocument60 pagesGreek Theater PDFapi-254476897100% (1)

- SilverLining and YOUNGO Adapt WG PartnershipDocument4 pagesSilverLining and YOUNGO Adapt WG PartnershipKyleNo ratings yet

- Print ApplicationDocument1 pagePrint ApplicationSmarttNo ratings yet

- Pema Chödrön-Perfect Just As You AreDocument4 pagesPema Chödrön-Perfect Just As You Are7ThorHimmel0% (1)

- 4 Revenue From Contracts With Customers (PFRS 15)Document11 pages4 Revenue From Contracts With Customers (PFRS 15)Mark TaysonNo ratings yet

- Stakeholder Interview Questions 1Document2 pagesStakeholder Interview Questions 1api-459019391No ratings yet

- Garcia Vs SesbrenoDocument8 pagesGarcia Vs SesbrenokhailcalebNo ratings yet

- CabinetDocument8 pagesCabinetmirmoinul100% (1)

- Ordinance Urinating NewDocument2 pagesOrdinance Urinating NewMarites RagadiNo ratings yet

- Bullying (DanaKopt)Document43 pagesBullying (DanaKopt)bmcastroooNo ratings yet

- Beyond MeatDocument14 pagesBeyond MeatNguyen Thu TraNo ratings yet

- Ef Intermediate Audio 6a 3,36Document4 pagesEf Intermediate Audio 6a 3,36Veronica FacioNo ratings yet

- Elderly InterviewDocument2 pagesElderly InterviewSayami Sato (Rhawnie)No ratings yet