Complete Heat Treatment Solutions: Projects and Services

Complete Heat Treatment Solutions: Projects and Services

Uploaded by

AbhayaSimhaCopyright:

Available Formats

Complete Heat Treatment Solutions: Projects and Services

Complete Heat Treatment Solutions: Projects and Services

Uploaded by

AbhayaSimhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Complete Heat Treatment Solutions: Projects and Services

Complete Heat Treatment Solutions: Projects and Services

Uploaded by

AbhayaSimhaCopyright:

Available Formats

Projects and Services

Quenchant Testing

Heat treatment Simulations

Finite Element Thermal Analysis

Manufacturing cost reduction program

Lean and Sixsigma consulting

Project Management- Green eld & Brown eld projects

SMT (Self Managed Team) techniques at shop oor level. It improves team culture,

productivity improvement, customer satisfaction and improved motivation to employees

QMS (Quality Management System) - Supplier Qualication process for OEM

QICR- Quality Improvement Cost Reduction

QRQC - Quick response Quality Control

Complete Heat Treatment Solutions

Result of research conducted at IIT Madras in the past

12 years

About Us

ProVaC Manufacturing Technologies Pvt. Ltd. is a "ONE-SHOP STOP" of advanced technology solutions

to various industrial challenges and delivers what it promises.

ProVaC is an integration of Research & Development, Industrial expertise and project

management(Green eld and Brown eld projects) expertise by Doctrates, Industrial experts, Managers

and Engineers. With dedicated application of mind and experience, we haave generated complex

products which delivers simple solution for industrial production issues.

PRODUCTS

1) Reference QuenchProbe

2) ASTM probe

3) Steel Heat Treatment Simulation

4) InverseSoolver

Our basic philosophy is to get integrated into customer process seamlessly and bring the value-added

solutions using advanced Finite element analysis, Mathematical modeling, Development of customised

software tools, manufacturing process simulation, thereby ultimately reducing delivery cost to customer.

We support to various industrial platforms like commercial heat treaters, Quenchant suppliers, Auto,

Aerospace, Railways, Earth moving equipment manufacturers, Defense sector, casting, forging, sheet

metal, machine tool industries, Research institutes, Technical colleges and many more.

w w w. p r o v a c t e c h . c o m

Contact Us:

BENEFITS AT GLANCE:

ProVaC Manufacturing Technologies Pvt. Ltd.

Troubleshoot Heat Treatment problems and lower Manufacturing cost

* Reduce Rework

* Reduce / Eliminate post heat treatment operations

Improve Quality

Enhance Design capability

* Predict the impact of new design or design modication on manufacturing

* Conduct less costly virtual experiments

Regd. Ofce: #1176, 11th Cross,

22nd B main Road, Sector 1,

H.S.R. Layout, Bangalore-560102

Corporate Ofce: 301, Kumara Paradise,

Building No. 3, B.P.Wadia Road

Basavanagudi, Bangalore-560004

ARJUN N

Mobile: +91-9035553216

Email: arjun@provactech.com

MUKUNDA NAIB

Mobile: +91-8553467680

Email: mukunda@provactech.com

Steel Heat Treatment Analysis (TmmFE)

Reference QuenchProbe

Steel Heat Treatment Analysis (TmmFE) is Finite element based software for simulating heat treatment

process and its metallurgical implications for steel parts. With TmmFE you can predict the evolution and

nal volume fractions of metallurgical phases, hardness, and cooling curves at different locations.

Equipment for in-situ Determination of Cooling

Characteristics of Quenchants by Cooling Curve Analysis

With a single temperature measurement Benets:

Compute cooling characteristics of

quenchants

Compute cooling rate variation at the surface

and core

Compute microstructure variation at the

surface and core

Compute hardness variation at the surface

and core

Compute effect of agitation

Select the most suitable quenchant for the

steel

Estimate the heat transfer coefcient during

quenching

In-situ measurement of quenching capacity of

different quenching mediums

Check the 'health' of quenchants with continued

use

Check the effect of agitation level/ow

rate/quenching position in the tank

Check the effect of contamination in quenchants

(water in oil; polymer in oil etc.)

Inspection of quenchants in as-received condition

Applications:

Benets:

Steel Casting Heat Treatment

Steel Forging Heat Treatment

Heat Treatment of machined

Troubleshoot Heat Treatment problems and lower

components

InverseSolver

ASTM Standard Probe

Equipment for Standard Tests for the Determination of Cooling

Characteristics of Quenchants by Cooling Curve Analysis as per

ASTM D6200-01(For Quench Oils) and as per ASTM D648206(For Aqueous Polymer Quenchants with Agitation)

Applications:

Measurement of quenching capacity of different quenching

mediums (oils, polymer solutions etc) as per ASTM D6200-01

for ease of comparison of data worldwide

Selection of proper quenchant based on comparison of

different quenchants

Check the 'health' of quenchants with continued use

Check the effect of agitation on cooling rates

Check the effect of contamination in quenchants (water in oil;

polymer in oil etc.)

Inspection of quenchants in as-received condition

Manufacturing cost

Reduce Rework

Reduce / Eliminate post heat treatment operations

Improve Quality

Enhance Design capability

Predict the impact of new design or design modication

on manufacturing

Conduct less costly virtual experiments

InverseSOLVER is based on a serial algorithm for the Inverse Heat Conduction Problem (IHCP) developed

to estimate the individual ux components at the unknown boundary. In many practical problems the

surface conditions are not known a-prior. In such cases the surface conditions will have to be 'estimated'

under simulated or laboratory conditions.

Applications:

Estimation of heat ux on the heat shields during re-entry of space

vehicles for the Indian Space Research

Estimation of space and time varying multiple heat ux

components at the metal-mold interface during net shape casting

of continuous casting of steel, for a consortium of steel companies

Estimation of space and time varying multiple heat ux

components (six components along the mold wall) at the metalmold interface during continuous casting of thin steel slabs and

lling in aluminum die casting

Estimation of metal-mold interface heat ux during die casting of

cast iron moulds for a leading foundry

Estimation of heat ux due to the welding arc during TIG welding

Estimation of heat ux during quenching of steel specimens

Estimation of heat ux at the metal-mold interface corners of

solidifying aluminum bars and slabs

Estimation of heat ux on the plasma facing components in the

Tokomak.

You might also like

- Continuous Casting of Steel-Institute of Materials, Minerals and MiningDocument188 pagesContinuous Casting of Steel-Institute of Materials, Minerals and MiningKishore Kumar100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Die Casting Process Optimization Using Taguchi Methods: G.P. SyrcosDocument7 pagesDie Casting Process Optimization Using Taguchi Methods: G.P. SyrcosfaisalNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- KasiaDocument68 pagesKasiaAbhayaSimha50% (2)

- ProVaC Catalogue V2Document4 pagesProVaC Catalogue V2AbhayaSimhaNo ratings yet

- Kenneths Resume2003docxDocument2 pagesKenneths Resume2003docxKenneth Lewis Calvin JordanNo ratings yet

- A Low Cost Affordable Viscometer Design For Experimental Fluid Viscosity Verification and Drag Coefficient CalculationDocument13 pagesA Low Cost Affordable Viscometer Design For Experimental Fluid Viscosity Verification and Drag Coefficient CalculationSidharthNo ratings yet

- 5 Years 3 Months: Working Experience: Career ObjectiveDocument4 pages5 Years 3 Months: Working Experience: Career ObjectiveKrantikumar KolliNo ratings yet

- Pradeepkumar M - Assistant Manager-Quality AssuranceDocument4 pagesPradeepkumar M - Assistant Manager-Quality AssuranceArun AggarwalNo ratings yet

- Presssure Die-CastingDocument12 pagesPresssure Die-CastingritaNo ratings yet

- Desalinationplant PDFDocument10 pagesDesalinationplant PDFYoungmin ParkNo ratings yet

- SPM ManufacturerDocument18 pagesSPM ManufacturerenggcontrolsautomationNo ratings yet

- Senior Mechanical Manufacturing Engineer in Lebanon Hanover NH Resume Donald AveryDocument2 pagesSenior Mechanical Manufacturing Engineer in Lebanon Hanover NH Resume Donald AveryDonald AveryNo ratings yet

- Column Designing ServicesDocument31 pagesColumn Designing Serviceszamit imedNo ratings yet

- MAGMA SimulationFatiqueDocument37 pagesMAGMA SimulationFatiquevmgobinathNo ratings yet

- Process Design Course-PD01Document4 pagesProcess Design Course-PD01Junaid ParkerNo ratings yet

- Air Cooled Heat Exchangers - DecometaDocument8 pagesAir Cooled Heat Exchangers - Decometasammar_10No ratings yet

- DKE Presentation R1.2023Document42 pagesDKE Presentation R1.2023Mr. DNo ratings yet

- Project Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Document2 pagesProject Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Timothy FieldsNo ratings yet

- Application of Numerical Optimization To Aluminum Alloy Wheel CastingDocument9 pagesApplication of Numerical Optimization To Aluminum Alloy Wheel Castingmehrdad abdolahhiNo ratings yet

- Sachin G. Pawar: Professional ReviewDocument5 pagesSachin G. Pawar: Professional ReviewSachinNo ratings yet

- Resume - AMIT - PIPING ENGRDocument4 pagesResume - AMIT - PIPING ENGRSanjeev Kumar100% (1)

- Thermal Design Margins For Heat ExchangersDocument22 pagesThermal Design Margins For Heat Exchangersjdgh1986No ratings yet

- Ragesh Joshi: HyderabadDocument5 pagesRagesh Joshi: HyderabadsriguruNo ratings yet

- Ajit Misra: Professional SnapshotDocument3 pagesAjit Misra: Professional SnapshotRaj LeninNo ratings yet

- Brochure DK 2015 New 1936Document12 pagesBrochure DK 2015 New 1936huyxpkissNo ratings yet

- HeatKal TechnologiesDocument8 pagesHeatKal TechnologiesRahul GawaliNo ratings yet

- Vikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Document2 pagesVikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Kushal ChatterjeeNo ratings yet

- Arul 3 Years - ExpDocument9 pagesArul 3 Years - ExpsvrsamroseNo ratings yet

- Study of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelDocument10 pagesStudy of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelSüleymanŞentürkNo ratings yet

- Cupping Tester: With PC Software For Advance Analysis and Database Creation For ComparisionDocument5 pagesCupping Tester: With PC Software For Advance Analysis and Database Creation For ComparisionrischajayantyNo ratings yet

- EDC Profile 2014Document36 pagesEDC Profile 2014Oktavianus Paul MulalindaNo ratings yet

- Industry & Building: Company ProfileDocument24 pagesIndustry & Building: Company ProfilemurugaraajNo ratings yet

- Company Profile - 20082023 - Exhaust Parts - KNBDocument12 pagesCompany Profile - 20082023 - Exhaust Parts - KNBamit.mandalNo ratings yet

- Design & Simulation SoftwaresDocument46 pagesDesign & Simulation SoftwaresqamarVEX100% (3)

- Test Devices-High Temperature Gas Exhaust Testing-V5Document9 pagesTest Devices-High Temperature Gas Exhaust Testing-V5ceaule1969No ratings yet

- Tejas Gangan - ResumeDocument1 pageTejas Gangan - Resumeabhijit patilNo ratings yet

- SDE Instrumentation 2012Document5 pagesSDE Instrumentation 2012Mohammed Makeen0% (1)

- Hafiz M Abubakar - OriginalDocument4 pagesHafiz M Abubakar - OriginalMuhammad ShehzadNo ratings yet

- The Culminates Engineering ServicesDocument4 pagesThe Culminates Engineering Servicesmbc_enggNo ratings yet

- The Culminates Engineering Services: For Engineering / Design ofDocument4 pagesThe Culminates Engineering Services: For Engineering / Design ofmbc_enggNo ratings yet

- Vpi 41Document3 pagesVpi 41MKOZERDEMNo ratings yet

- Dry Cooling Systems-ServiceDocument13 pagesDry Cooling Systems-ServiceZdravko IvancicNo ratings yet

- Adil CV Latest PDFDocument4 pagesAdil CV Latest PDFMuhammad Adil KhanNo ratings yet

- Ekulama1 Hydrostatic Testing Procedure - Rev 2Document15 pagesEkulama1 Hydrostatic Testing Procedure - Rev 2eke23No ratings yet

- Brentwood Cooling Tower Products - Rev2Document12 pagesBrentwood Cooling Tower Products - Rev2Kaushal100% (1)

- Saransh Chemical Engineer ResumeDocument3 pagesSaransh Chemical Engineer ResumeprashantsahNo ratings yet

- Akarmak Autoclaves PDFDocument28 pagesAkarmak Autoclaves PDFAnonymous Hy5Ir9QXNo ratings yet

- Mechanical Constraints On Thermal Design of Shell and Tube ExchangersDocument26 pagesMechanical Constraints On Thermal Design of Shell and Tube Exchangersjdgh1986No ratings yet

- Fall15 TPDocument60 pagesFall15 TPignaciomarinNo ratings yet

- Why Burn in Boards Is Crucial in Semiconductor ManufacturingDocument5 pagesWhy Burn in Boards Is Crucial in Semiconductor ManufacturingjackNo ratings yet

- Hydroprocessing DepropanizerDocument12 pagesHydroprocessing DepropanizerSathish KumarNo ratings yet

- Up Dated CV of D K Jena - DNV GLDocument15 pagesUp Dated CV of D K Jena - DNV GLParag WadekarNo ratings yet

- Open To Relocation Overseas & Anywhere in IndiaDocument4 pagesOpen To Relocation Overseas & Anywhere in IndiaamitrdttecNo ratings yet

- Resume Sample PDFDocument4 pagesResume Sample PDFamitrdttecNo ratings yet

- Sudhakar Babu M PPC ManagerDocument7 pagesSudhakar Babu M PPC ManagerMr. RAJASEKHARNo ratings yet

- PSP Kırma Eleme Genel Katalog PDFDocument40 pagesPSP Kırma Eleme Genel Katalog PDFbulentbulutNo ratings yet

- 1 s2.0 S1110016820304798 MainDocument11 pages1 s2.0 S1110016820304798 MainDương MinhNo ratings yet

- CV of Raj (Dec'23)Document3 pagesCV of Raj (Dec'23)ahiadarshNo ratings yet

- HOD C& I Workshop Nov 2010finalDocument20 pagesHOD C& I Workshop Nov 2010finalsiddharth507No ratings yet

- Brochure v2012 1Document33 pagesBrochure v2012 1Miguel A. GarciaNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Shaiva Kshetraas As Per Thirtha PrabandhaDocument16 pagesShaiva Kshetraas As Per Thirtha PrabandhaAbhayaSimhaNo ratings yet

- Apollo Fruit ProductsDocument13 pagesApollo Fruit ProductsAbhayaSimhaNo ratings yet

- Product Research Report: Reprinted With Permission From Kerri Rosenzweit, Glen Allen, VADocument1 pageProduct Research Report: Reprinted With Permission From Kerri Rosenzweit, Glen Allen, VAAbhayaSimhaNo ratings yet

- MIC IP Starlight 700 Special enUS 23996947211Document5 pagesMIC IP Starlight 700 Special enUS 23996947211AbhayaSimhaNo ratings yet

- Session 5Document4 pagesSession 5AbhayaSimhaNo ratings yet

- 625 Elec HybridDocument4 pages625 Elec HybridAbhayaSimhaNo ratings yet

- Introduction To Android App Development: Opersys IncDocument59 pagesIntroduction To Android App Development: Opersys IncAbhayaSimhaNo ratings yet

- Part 3 CMD Ermerging Markets India Armin BruckDocument23 pagesPart 3 CMD Ermerging Markets India Armin BruckAbhayaSimhaNo ratings yet

- Videsha Gamana Nishedha PDFDocument118 pagesVidesha Gamana Nishedha PDFAbhayaSimhaNo ratings yet

- Sunflag Iron & Steel Company Limited: Continuous CastingDocument30 pagesSunflag Iron & Steel Company Limited: Continuous Castingamit gajbhiye100% (2)

- Prevention of Scum Formation and Entrapment in High Carbon Steel BilletsDocument9 pagesPrevention of Scum Formation and Entrapment in High Carbon Steel BilletsRavi KanheNo ratings yet

- Guide Totinplate PDFDocument124 pagesGuide Totinplate PDFPrakhar MishraNo ratings yet

- Development & Production Strategies of SAIL Steel Plants in 12th Plan PeriodDocument31 pagesDevelopment & Production Strategies of SAIL Steel Plants in 12th Plan PeriodAbhijeet BhagavatulaNo ratings yet

- Vizag Steel PlantDocument27 pagesVizag Steel Plantpramod_k67% (6)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyNo ratings yet

- Design and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaDocument4 pagesDesign and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaKvvPrasadNo ratings yet

- Astm A788Document10 pagesAstm A788Lucas Prezotto Puertas ErnandesNo ratings yet

- PassionForProcesse en 04-13Document20 pagesPassionForProcesse en 04-13Mutas MattaNo ratings yet

- Southwire Shaft FurnaceDocument2 pagesSouthwire Shaft FurnaceГеоргий Романов100% (1)

- CONTINUOUS CASTING ColloquiumDocument18 pagesCONTINUOUS CASTING ColloquiumakritiNo ratings yet

- Eng Plant 2 1 1 0Document22 pagesEng Plant 2 1 1 0Parewa ScorpNo ratings yet

- Inclusion in Cast SteelDocument42 pagesInclusion in Cast SteelAnonymous w6v7JWfr5100% (1)

- Impact of Refractories Corrosion On Industrial Processes: 4.1. Steel MakingDocument93 pagesImpact of Refractories Corrosion On Industrial Processes: 4.1. Steel MakingniviNo ratings yet

- RefwinDocument51 pagesRefwinSaptarshi SenguptaNo ratings yet

- Contoh Model Matematika Dalam Heat TransferDocument39 pagesContoh Model Matematika Dalam Heat TransferADITYA RAHMANNo ratings yet

- ECCC2014 - 8th European Continuous Casting Conference - ReportDocument61 pagesECCC2014 - 8th European Continuous Casting Conference - ReportHarlei Pereira de RezendeNo ratings yet

- Bs en 10025 2Document13 pagesBs en 10025 2Valesh MonisNo ratings yet

- Numerical Calculation of Fluid Flow in A Continuous Casting TundishDocument8 pagesNumerical Calculation of Fluid Flow in A Continuous Casting TundishGökhan TurhanNo ratings yet

- Da News 145Document52 pagesDa News 145saibal_silNo ratings yet

- Lecture Casting InSteelCon 2007Document8 pagesLecture Casting InSteelCon 2007radynasrNo ratings yet

- Control of Columnar-To-Equiaxed Transition in Continuous Casting of 16% CR Stainless SteelDocument6 pagesControl of Columnar-To-Equiaxed Transition in Continuous Casting of 16% CR Stainless SteelkesharNo ratings yet

- Cleanliness of Low Carbon Aluminum-Killed Steels During Secondary Refining ProcessesDocument17 pagesCleanliness of Low Carbon Aluminum-Killed Steels During Secondary Refining ProcessesPhuNguyenVanNo ratings yet

- Mold Oscillation and Negative Strip Time PDFDocument14 pagesMold Oscillation and Negative Strip Time PDFPrakash Sarangi100% (1)

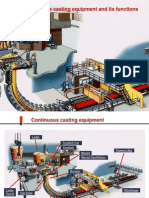

- JSW Casting EquipDocument23 pagesJSW Casting EquipArnab GhoshNo ratings yet

- Q-Robot Cast For Ladle Area: Reaching New Levels of Automation and Safety in Continuous CastingDocument12 pagesQ-Robot Cast For Ladle Area: Reaching New Levels of Automation and Safety in Continuous CastingAntonio Adalto AltomaniNo ratings yet

- Classification Foundries Acc Moulding ProcessesDocument20 pagesClassification Foundries Acc Moulding ProcessesIngDiaz730% (1)

- Introduction PTKP UI Industrial Visit 2017 NandyoDocument25 pagesIntroduction PTKP UI Industrial Visit 2017 NandyorahmanhadiNo ratings yet

- Steel Melting ShopDocument21 pagesSteel Melting ShopAnjan Dey0% (1)