Q Loader Patents

Q Loader Patents

Uploaded by

sjdarkman1930Copyright:

Available Formats

Q Loader Patents

Q Loader Patents

Uploaded by

sjdarkman1930Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Q Loader Patents

Q Loader Patents

Uploaded by

sjdarkman1930Copyright:

Available Formats

US 20040194772A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2004/0194772 A1

(43) Pub. Date:

Hamilton

(54)

MULTIPLE COLUMN HELICAL FEEDER

(76)

Inventor:

Jared L. Hamilton, Weaverville, CA

(US)

(22)

Filed:

10/391,942

Mar. 19, 2003

Publication Classi?cation

(51)

(52)

Int. Cl.7 ...................................................... .. F41A 9/61

US. Cl.

ABSTRACT

A loader stores and loads round objects is presented. The

loader includes a screW and a drive tube. The screW has a

Correspondence Address:

Douglas L. Weller

431 Magnolia Lane

Santa Clara, CA 95051 (US)

(21) Appl. No.:

(57)

Oct. 7, 2004

.............................................................. .. 124/45

11

helical groove. The helical groove Winds in a ?rst direction.

The drive tube has multiple helical grooves on an inner

surface of the drive tube. The multiple helical grooves Wind

in a second direction. The second direction is counter to the

?rst direction. The screW is located Within a center of the

drive tube along a length of the drive tube so that round

objects loaded Within the drive tube are each Within the

helical groove of the screW and Within one of the multiple

helical grooves on the inner surface of the drive tube. When

the drive tube rotates With respect to the screW, round objects

Within the drive tube are constrained to travel along the

helical groove of the screW and along one of the multiple

helical grooves on the inner surface of the drive tube.

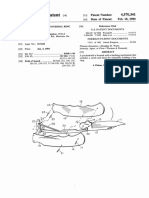

Patent Application Publication

Oct. 7, 2004 Sheet 1 0f 14

FIG. 1

(PRIOR ART)

US 2004/0194772 A1

Patent Application Publication

Oct. 7, 2004 Sheet 2 0f 14

US 2004/0194772 A1

Patent Application Publication

Oct. 7, 2004 Sheet 3 0f 14

FIG. 4 <

34

FIG. 6

US 2004/0194772 A1

Patent Application Publication

Oct. 7, 2004 Sheet 4 0f 14

US 2004/0194772 A1

gm

Z:

i /;

I

________.l

.QE

m

Patent Application Publication

Oct. 7, 2004 Sheet 5 0f 14

US 2004/0194772 A1

Patent Application Publication

Oct. 7, 2004 Sheet 8 0f 14

US 2004/0194772 A1

6E2

m:

@m

om

mm

Patent Application Publication

Oct. 7, 2004 Sheet 9 0f 14

US 2004/0194772 A1

FIG.12

516 435

Patent Application Publication

FIG. 14

FIG. 15

Oct. 7, 2004 Sheet 10 0f 14

US 2004/0194772 A1

Patent Application Publication

Oct. 7, 2004 Sheet 11 0f 14

US 2004/0194772 A1

EN

6Ei

2

Patent Application Publication

Oct. 7, 2004 Sheet 14 0f 14

US 2004/0194772 A1

240

241

241

241

FIG. 22

Oct. 7, 2004

US 2004/0194772 A1

MULTIPLE COLUMN HELICAL FEEDER

BACKGROUND

[0001] The present invention pertains to feeders for round

objects and pertains particularly to a multiple helical feeder.

[0002] Paintball guns are used in games Where participants

?re at one another projectiles consisting of paint enclosed in

an outer layer composed of gel. The paintball guns use

pressuriZed gas to propel paintballs toWards an intended

target.

[0003] Generally, paintballs are stored in a bulk loader.

The bulk loader typically sits on top of the paintball gun and

utiliZes gravity to feed paintballs into the barrel of paintball

gun in preparation for ?ring at a target. Paintball guns are

typically semiautomatic and can be ?red as fast as a user can

pull a trigger. It is necessary, therefore, for bulk loaders to

alloW for quick and consistent loading of paintballs.

[0004] It is not unusual for paint ball guns to occasionally

jam during operation. This can often be remedied, for

example by a user shaking the gun upon detecting that a jam

has occurred. Alternatively, efforts have been made to place

anti-jamming devices Within paintball loaders. See, for

example, US. Pat. No. 5,282,454 issued to Roderick L. Bell,

et al. on Feb. 1, 1994 and US. Pat. No. 6,415,781 B1 issued

to Aldo Perrone on Jul. 9, 2002.

SUMMARY OF THE INVENTION

[0005] In accordance With a preferred embodiment of the

present invention, a loader for storing and loading round

objects is presented. The loader includes a screW and a drive

tube. The screW has a helical groove. The helical groove

Winds in a ?rst direction. The drive tube has multiple helical

grooves on an inner surface of the drive tube. The multiple

helical grooves Wind in a second direction. The second

direction is counter to the ?rst direction. The screW is located

Within a center of the drive tube along a length of the drive

tube so that round objects loaded Within the drive tube are

each Within the helical groove of the screW and Within one

of the multiple helical grooves on the inner surface of the

drive tube. When the drive tube rotates With respect to the

screW, round objects Within the drive tube are constrained to

travel along the helical groove of the screW and along one of

the multiple helical grooves on the inner surface of the drive

tube.

BRIEF DESCRIPTION OF THE DRAWINGS

[0006]

FIG. 1 shoWs an eXample of a paintball gun With

[0011] FIG. 6 shoWs paintballs arranged in an outer cap of

a paintball clip in accordance With a preferred embodiment

of the present invention.

[0012] FIG. 7 shoWs a partially assembled paintball clip

in accordance With a preferred embodiment of the present

invention.

[0013]

FIG. 8 shoWs inner cap of a paintball clip attached

to a spring in accordance With a preferred embodiment of the

present invention.

[0014] FIG. 9 shoWs a screW of a paintball clip in accor

dance With a preferred embodiment of the present invention.

[0015] FIG. 10 shoWs a drive tube of a paintball clip in

accordance With a preferred embodiment of the present

invention.

[0016] FIG. 11 and FIG. 12 are cut-aWay vieWs illustrat

ing operation of a paintball clip in accordance With a

preferred embodiment of the present invention.

[0017] FIG. 13 is another cut-aWay vieW illustrating

operation of a paintball clip in accordance With a preferred

embodiment of the present invention.

[0018]

FIG. 14 shoWs a side vieW of a multiple heliX

arrangement of paintballs illustrating the Way paintballs are

stored in a paintball clip in accordance With a preferred

embodiment of the present invention.

[0019] FIG. 15 shoWs a top vieW of the multiple heliX

arrangement of paintballs shoWn in FIG. 13 in accordance

With a preferred embodiment of the present invention.

[0020] FIG. 16 shoWs a close-up of rotation limiter in

accordance With a preferred embodiment of the present

invention.

[0021]

FIG. 17 shoWs an outer cap, ?tted on a contain

ment tube, having multiple ejection holes in accordance With

an alternative embodiment of the present invention.

[0022]

FIG. 18 shoWs a screW having multiple ridges in

accordance With an alternative embodiment of the present

invention.

[0023]

FIG. 19 shoWs a drive tube With straight ridges in

accordance With an alternative embodiment of the present

invention.

[0024]

FIG. 20 shoWs an outer cap ?tted on a containment

tube and having an alternative ejection hole location in

accordance With an alternative embodiment of the present

invention.

a prior art bulk loader.

[0025]

FIG. 21 shoWs a screW in accordance With an

[0007] FIG. 2 shoWs a paintball gun With a paintball

loader in accordance With a preferred embodiment of the

alternative embodiment of the present invention.

present invention.

[0026]

[0008] FIG. 3 shoWs an assembled paintball clip separated

present invention.

FIG. 22 shoWs an inner cap With multiple eXit

holes in accordance With an alternative embodiment of the

from a paintball transportation system in accordance With a

preferred embodiment of the present invention.

[0009] FIG. 4 shoWs a disassembled paintball transporta

tion system in accordance With a preferred embodiment of

the present invention.

[0010] FIG. 5 shoWs a disassembled paintball clip in

accordance With a preferred embodiment of the present

invention.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

[0027] FIG. 1 is a simpli?ed block diagram of a prior art

paintball gun 11. Paintball gun 11 is equipped With a

compressed air container 13 used to supply poWer to propel

paintballs toWards a target. Paintballs are stored in a bulk

loader 12.

Oct. 7, 2004

US 2004/0194772 A1

[0028] FIG. 2 shows bulk loader 12 being replaced With

[0037] FIG. 7 shoWs paintball clip 33 being partially

a paintball loader 21, attached as shown.

assembled. Within drive tube 52, paintballs 45 travel around

screW 53, proceed through one of six openings 71 in inner

cap 55 and through 68 Within outer cap 56.

[0029] Paintball loader 21 is shoWn in FIG. 3. An attach

ment mechanism 35 is used to physically secure paintball

loader 21 to paintball gun 11. Paintballs are stored in a

[0038]

paintball clip 33. During a ?ring session, paintballs exit

cap 55. Associated With each hole 71 is a ?ute denoted by

paintball clip 33 and travel through a delivery tube 34 before

loaded through an elboW joint 31 into paintball gun 11. A

clip holder 32 secures paintball clip 33 in place during use.

Clip holder 32 has a quick release to alloW quick and

ef?cient exchange of paintball clips. As further discussed

ridges 72 Which guide paint balls through holes 71.

beloW, a pin 36 Within clip holder 32 is used to disengage a

[0039]

FIG. 8 shoWs the arrangement of holes 71 in inner

FIG. 9 shoWs screW 53 having a single ridge 92

forming a single groove (channel) 192 along Which paint

balls travel. Square shaft 60 and ridge tip 65 are also shoWn.

spring restraint Within paintball clip 33 When paintball clip

[0040] FIG. 10 shoWs drive tube 52 having six inner

ridges 91 that form six grooves (channels) 191 along Which

33 is attached to clip holder 32.

paintballs travel.

[0030] As shoWn in FIG. 3, the exterior of paintball clip

[0041] As inner cap 55 (shoWn in FIG. 5) and drive tube

33 includes an outer cap 56 and a containment tube 51.

52 rotate With respect to screW 53 (shoWn in FIG. 9), outer

When paintball clip 33 is attached to clip holder 32, clip

cap 56 (shoWn in FIG. 5) and containment tube 51 (shoWn

in FIG. 5), ridges 91 of grooves 191 of inner cap 55 push

holder 32 holds outer cap 56, and thus containment tube 51,

?rmly, preventing disengagement or rotation of outer cap 56

and containment tube 51.

paintballs 45 (shoWn in FIG. 7) along groove 192 (shoWn in

[0031] FIG. 4 shoWs detail about hoW delivery tube 34 is

attached to elboW joint 31 and clip holder 32. Paintballs 45

[0042] FIG. 11 is a cut-aWay portion of paintball clip 33

and clip holder 32. Outer cap 56 is shoWn having been

are shoWn as they Would exit from elboW joint 31.

[0032] FIG. 5 shoWs the disassembled parts of paintball

clip 21. The parts include a containment tube 51, a drive tube

52, a screW 53, a torsion spring 54, an inner cap 55 and an

outer cap 56. Torsion spring 54 is used to store torsion

energy. A compression spring 63 is used to store compres

sion energy betWeen screW 54 and thrust bushing 64. Torsion

spring 54 is attached to inner cap 55 at a square end 57.

[0033] Torsion spring 54 ?ts Within screW 53. When

paintball clip 51 is assembled, a square end 59 of torsion

spring 54 along With a square shaft 60 of screW 53, extends

through a hole 61 in drive tube 52 and is attached to

containment tube 51. This anchors screW 53 and square end

59 of torsion spring 54 to containment tube 51. Also, When

paintball clip 51 is assembled, inner cap is 55 is attached to

FIG. 9) of screW 53 (shoWn in FIG. 9).

snapped over containment tube 51. Inner cap 55 is shoWn

having been snapped Within drive tube 52. Square end 59 of

torsion spring 54 ?ts snugly Within square shaft 60 of screW

53. A square feature 133 of containment tube 51 also ?ts

snugly into square shaft 60 of screW 53. Square end 57 of

torsion spring 54 ?ts snugly Within square shaft 66 of inner

cap 55.

[0043] Torsion spring 54 Within screW 53 rotates inner cap

55 and drive tube 52 With respect to screW 53, outer cap 56

and containment tube 51. The six grooves 191 in drive tube

52 are aligned With the six ?utes on inner cap 55.

[0044] In FIG. 11, drive tube 52 is in a locked position

With respect to containment tube 51. In the locked position

a notch 113 of outer cap 56 is engaged. In FIG. 12, drive

tube 52 is in an unlocked position With respect to contain

drive tube 52 and outer cap 56 is attached to containment

tube 51. ScreW 53 has a single ridge 92 that forms a single

ment tube 51. In the unlocked position, as evidenced by a

groove (channel) 192 along Which paintballs travel until a

containment tube 51, alloWing drive tube 52 to alloW rota

tion around pin 36 With respect to containment tube 51. In

the unlocked position notch 113 of outer cap 56 is disen

gaged. ScreW 53 rotates in synchroniZation With contain

ridge tip 65 is reached.

[0034] When paintball clip 51 is assembled and attached

to clip holder 32, pin 36 (shoWn in FIG. 11) pushes inner cap

52, causing compression spring 63 to compress. The result

ing alignment of inner cap 55 to outer cap 56 alloWs rotation

of inner cap 55 and drive tube 52 With respect to outer cap

56 and containment tube 51. Drive tube 52 is driven by the

stored torsional energy of torsion spring 54. A rotation

limiter 62 alloWs torsion spring 54 to remain preWound to an

initial tension alloWing optimal performance of torsion

spring 54.

[0035] When paintball clip 51 is ?lled With paintballs, it is

the rotation of inner cap 55 and drive tube 52 With respect

to outer cap 56 and containment tube 51 that moves paint

space 114, drive tube 52 is pushed slightly deeper into

ment tube 51 so that the six grooves 191 are used to guide

paintballs 45 along groove 192 of screW 53, alloWing

paintballs to exit drive tube 51.

[0045] As shoWn in FIG. 13, the ?utes bordered by ridges

72 guide paintballs 45 out holes 71 of inner cap 55, along

ejection ramp 69, out of ejection hole 68 of outer cap 56 and

into feed delivery tube 34.

[0046]

FIG. 14 shoWs a side vieW of the multiple column

arrangement of paintballs Within paintball clip 33. Lines 131

represent the alignment of paintballs 45 along groove 192 of

balls out of paintball clip 51 and into delivery tube 34

screW 53 (shoWn in FIG. 9). Lines 132 represent the

alignment of paintballs 45 along grooves 191 of drive tube

(shoWn in FIG. 4).

52 (shoWn in FIG. 10).

[0036] FIG. 6 illustrates the path paintballs 45 take When

exiting paintball clip 33 through outer cap 56. Paintballs 45

[0047]

FIG. 15 shoWs a top vieW of the multiple column

arrangement of paintballs 45 Within paintball clip 33. Hole

folloW ramp 69 around the diameter of outer cap 56 before

130 is the location of screW 53 in relation to the multiple

exiting through a hole 68.

column arrangement of paintballs 45.

Oct. 7, 2004

US 2004/0194772 A1

[0048] The multiple column arrangement of paintballs 45

allows for a signi?cantly reduced amount of Work (distance

equivalent to poWering rotation of the screW With respect to

the drive tube. Alternatively, the poWer for rotation of the

times friction) as the balls travel through paintball clip 33.

drive tube With respect to the screW can be supplied manu

This is because, as paintballs 45 travel around groove 192 of

screW 53, the paintballs are divided into siX helical columns,

divided by siX grooves 191 that simultaneously advance

paintballs 45 With respect to drive tube 52. As the paintballs

45 advance along the heliX formed by ridge 92, paintballs 45

simultaneously advance along the siX columns formed by

grooves 191. The resulting shorter path paintballs 45 travel

With respect to drive tube 52 results in minimal Work

(distance times friction) as paintballs 45 advance Within

drive tube 52.

[0049]

FIG. 16 shoWs a close-up of rotation limiter 62.

[0050] Various alternative embodiments of the invention

can also be utiliZed. For eXample, instead of a single ejection

hole in the outer cap, multiple ejection holes can be used.

This is illustrated in FIG. 17 Where an outer cap 203, ?tted

on a containment tube 202, has multiple ejection holes 204

Which are used to eject paintballs.

ally by a user.

[0056] The foregoing discussion discloses and describes

merely exemplary methods and embodiments of the present

invention. As Will be understood by those familiar With the

art, the invention may be embodied in other speci?c forms

Without departing from the spirit or essential characteristics

thereof. For eXample, While the preferred embodiment of the

present invention is described With regard to loading paint

balls into a paintball gun, the ideas presented can be used

effectively for loading round objects into any type of device.

Accordingly, the disclosure of the present invention is to be

illustrative, but not limiting, of the scope of the invention,

Which is set forth in the folloWing claims.

I claim:

1. A loader for storing and loading round objects, the

loader comprising:

a screW having a helical groove, the helical groove

[0051] For eXample, the screW can have multiple ridges

and multiple grooves instead of a single ridge and a single

Winding in a ?rst direction; and,

groove. This is illustrated in FIG. 18 Where a screW 220 is

a drive tube having multiple helical grooves on an inner

shoWn to have a ridge 221 With a ridge tip 223, and a ridge

222 With a ridge tip 224. Ridge 221 and ridge 222 form tWo

surface of the drive tube, the multiple helical grooves

Winding in a second direction, the second direction

being counter to the ?rst direction, the screW being

located Within a center of the drive tube along a length

of the drive tube so that round objects loaded Within the

separate grooves: a grove 225 and a groove 226.

[0052] In another alternative embodiment of the present

invention, the ridges of drive tube can be straight lines

resulting in vertical columns. This is illustrated in FIG. 19

Where ridges 221 of a drive tube 220 are straight. Never

theless, in the preferred embodiments, the ridges are helical

drive tube are each Within the helical groove of the

screW and Within one of the multiple helical grooves on

the inner surface of the drive tube;

52 is selected so that each roW of paintballs 45 around ridge

92 interlocks With the previous roW and the folloWing roW

of paintballs around ridge 92. This can be seen in the

Wherein When the drive tube rotates With respect to the

screW, round objects Within the drive tube are con

strained to travel along the helical groove of the screW

and along one of the multiple helical grooves on the

inner surface of the drive tube.

2. A loader as in claim 1 additionally comprising:

resulting interlocking pattern of paintballs 45 shoWn in FIG.

a containment tube Within Which the drive tube is placed,

in form as shoWn in FIG. 10. This alloWs for more ef?cient

packing of paintballs 45 Within paintball clip 33. Speci?

cally, the slope of ridges 91 (shoWn in FIG. 10) on drive tube

13.

[0053]

the containment tube remaining stationary Within

In other alternative embodiments, the containment

tube can be eliminated and the screW can be rotated With

respect to the screW When the drive tube is rotated With

respect to the screW.

respect to a drive tube having helical (or straight) grooves as

3. A loader as in claim 1 additionally comprising:

described herein. It is intended that the statement the screW

a containment tube Within Which the drive tube is placed,

rotates With respect to the drive tube is equivalent to the

statement the drive tube rotates With respect to the screW.

[0054]

FIG. 20 shoWs an embodiment of the present

invention With an outer cap 231 ?tted over a containment

tube 230. A drive tube (similar to drive tube 52 shoWn in

FIG. 5) rotates With respect to a screW 233, shoWn in FIG.

21. An inner cap 240, shoWn in FIG. 22, has multiple eXits

holes 241. In this embodiment, paintballs travel along a

groove 235 of screW 233, go up a ramp 234 and eXit inner

cap 240 through one of eXit holes 241 and then eXits outer

cap 231 through a side hole 232.

[0055] While in various embodiments of the present

invention, a torsion spring is used to poWer rotation of the

drive tube With respect to the screW, other devices can be

used to provide poWer. For eXample, pressuriZed gas or an

the containment tube remaining stationary Within

respect to the screW When the drive tube rotates With

respect to the screW; and,

an outer cap that attaches to the containment tube, the

outer cap including a ramp that guides round objects

out of the loader through a hole in the outer cap.

4. A loader as in claim 1 additionally comprising:

an inner cap that attaches to the drive tube, the inner cap

including multiple ?utes, one ?ute for each of the

multiple helical grooves on the inner surface of the

drive tube, the ?utes guiding round objects out of the

drive tube through holes in the inner cap.

5. A loader as in claim 1 additionally comprising:

a containment tube Within Which the drive tube is placed,

electric motor can be used to poWer rotation of the drive tube

the containment tube remaining stationary Within

With respect to the screW. It is considered that poWering

rotation of the drive tube With respect to the screW is

respect to the screW When the drive tube rotates With

respect to the screW;

Oct. 7, 2004

US 2004/0194772 A1

an inner cap that attaches to the drive tube, the inner cap

multiple helical grooves on the inner surface of the

including multiple ?utes, one ?ute for each of the

drive tube, the ?utes guiding paintballs out of the drive

tube through holes in the inner cap; and,

multiple helical grooves on the inner surface of the

drive tube, the ?utes guiding round objects out of the

drive tube through holes in the inner cap; and,

a spring placed Within a holloW area of the inner screW,

the spring having a ?rst end af?Xed to at least one of the

screW and the containment tube, and a second end

attached to the inner cap, the spring for providing

torsion tending to cause the drive tube to rotate With

respect to the screW.

6. A loader as in claim 1 additionally comprising:

a spring placed Within a holloW area of the inner screW,

the spring having a ?rst end af?Xed to at least one of the

screW and the containment tube, and a second end

attached to the inner cap, the spring for providing

torsion tending to cause the drive tube to rotate With

respect to the screW.

9. A paintball gun comprising:

a paintball loader for storing and loading paintballs, the

paintball loader including:

a containrnent tube Within Which the drive tube is placed,

the containment tube rernaining stationary Within

respect to the screW When the drive tube rotates With

respect to the screW;

an outer cap that attaches to the containment tube, the

outer cap including a ramp that guides round objects

out of the loader through a hole in the outer cap;

an inner cap that attaches to the drive tube, the inner cap

including multiple ?utes, one ?ute for each of the

multiple helical grooves on the inner surface of the

drive tube, the ?utes guiding round objects out of the

drive tube through holes in the inner cap; and,

a spring placed Within a holloW area of the screW, the

spring having a ?rst end affixed to at least one of the

screW and the containment tube, and a second end

attached to the inner cap, the spring for providing

torsion tending to cause the drive tube to rotate With

respect to the screW.

7. A loader as in claim 1 Wherein the round objects are

paintballs.

8. Apaintball loader for storing and loading paintballs into

a paintball gun, the paintball loader comprising:

a screW having a helical groove, the helical groove

Winding in a ?rst direction;

a drive tube having multiple helical grooves on an inner

surface of the drive tube, the multiple helical grooves

Winding in a second direction, the second direction

being counter to the ?rst direction, the screW being

located Within a center of the drive tube along a length

of the drive tube so that paintballs loaded Within the

drive tube are each Within the helical groove of the

screW and Within one of the multiple helical grooves on

the inner surface of the drive tube, Wherein When the

drive tube rotates With respect to the screW, paintballs

Within the drive tube are constrained to travel along the

helical groove of the screW and along one of the

multiple helical grooves on the inner surface of the

drive tube;

a containrnent tube Within Which the drive tube is placed,

the containment tube rernaining stationary Within

respect to the screW When the drive tube rotates With

respect to the screW;

an outer cap that attaches to the containment tube, the

outer cap including a ramp that guides paintballs out of

the paintball loader through a hole in the outer cap;

an inner cap that attaches to the drive tube, the inner cap

including multiple ?utes, one ?ute for each of the

a screW having a helical groove, the helical groove

Winding in a ?rst direction, and

a drive tube having multiple helical grooves on an inner

surface of the drive tube, the multiple helical grooves

Winding in a second direction, the second direction

being counter to the ?rst direction, the screW being

located Within a center of the drive tube along a

length of the drive tube so that paintballs loaded

Within the drive tube are each Within the helical

groove of the screW and Within one of the multiple

helical grooves on the inner surface of the drive tube;

Wherein When the drive tube rotates With respect to the

screW, paintballs Within the drive tube are constrained

to travel along the helical groove of the screW and along

one of the multiple helical grooves on the inner surface

of the drive tube.

10. A method for loading round objects into a device, the

method comprising the folloWing steps:

(a) placing the round objects into a drive tube, a screW

Within the drive tube having a helical groove, the

helical groove Winding in a ?rst direction, the drive

tube having multiple helical grooves on an inner sur

face of the drive tube, including the folloWing substep:

(a.1) loading the round objects Within the drive tube so

that each round object is Within the helical groove of

the screW and Within one of the multiple helical

grooves on the inner surface of the drive tube; and,

(b) rotating the drive tube With respect to the screW,

causing the round objects Within the drive tube to travel

along the helical groove of the screW and along one of

the multiple helical grooves on the inner surface of the

drive tube in a direction to eXit the drive tube.

11. Arnethod as in claim 10 Wherein step (b) includes the

folloWing substep:

keeping a containrnent tube, Within Which the drive tube

is placed, stationary Within respect to the screW When

the drive tube rotates With respect to the screW.

12. A method as in claim 10 Wherein step (b) includes the

folloWing substeps:

keeping a containrnent tube, Within Which the drive tube

is placed, stationary Within respect to the screW When

the drive tube rotates With respect to the screW; and,

guiding the round objects along a ramp through a hole in

an outer cap, the ramp being part of the outer cap and

the outer cap being attached to the containment tube.

Oct. 7, 2004

US 2004/0194772 A1

13. Arnethod as in claim 10 wherein step (b) includes the

following substep:

using ?utes on an inner cap to guide the round objects out

of the drive tube through holes in the inner cap, the

inner cap attaching to the drive tube and having one

?ute for each of the multiple helical grooves on the

inner surface of the drive tube.

14. Arnethod as in claim 10 Wherein step (b) includes the

folloWing substeps:

keeping a containrnent tube, Within Which the drive tube

is placed, stationary Within respect to the screW When

the drive tube rotates With respect to the screW;

using ?utes on an inner cap to guide the round objects out

of the drive tube through holes in the inner cap, the

inner cap attaching to the drive tube and having one

?ute for each of the multiple helical grooves on the

inner surface of the drive tube; and,

guiding the round objects along a ramp through a hole in

an outer cap, the ramp being part of the outer cap and

the outer cap being attached to the containment tube.

15. Arnethod as in claim 10 Wherein step (b) includes the

folloWing substeps:

keeping a containrnent tube, Within Which the drive tube

is placed, stationary Within respect to the screW When

the drive tube rotates With respect to the screW;

using ?utes on an inner cap to guide the round objects out

of the drive tube through holes in the inner cap, the

inner cap attaching to the drive tube and having one

?ute for each of the multiple helical grooves on the

inner surface of the drive tube;

guiding the round objects along a ramp through a hole in

an outer cap, the ramp being part of the outer cap and

the outer cap being attached to the containment tube;

and,

using a spring to provide torsion to cause the drive tube

to rotate With respect to the screW, the spring being

placed Within a holloW area of the screW, the spring

having a ?rst end affixed to at least one of the screW and

the containment tube, and a second end attached to the

inner cap.

16. Arnethod as in claim 10 Wherein the round objects are

paintballs.

17. A paintball loader for storing and loading paintballs

into a paintball gun, the paintball loader including:

a screW having a helical groove, the helical groove

Winding in a ?rst direction; and,

a drive tube having multiple colurnn grooves on an inner

surface of the drive tube, the screW being located Within

a center of the drive tube along a length of the drive

tube so that paintballs loaded Within the drive tube are

each Within the helical groove of the screW and Within

one of the multiple colurnn grooves on the inner surface

of the drive tube;

Wherein When the drive tube rotates With respect to the

screW, paintballs Within the drive tube are constrained

to travel along the helical groove of the screW and along

one of the multiple colurnn grooves on the inner surface

of the drive tube.

18. Apaintball loader as in claim 17 Wherein the multiple

colurnn grooves on the inner surface of the drive tube spiral

around the inner surface of the drive tube.

19. Apaintball loader as in claim 17 Wherein the multiple

colurnn grooves on the inner surface of the drive tube do not

spiral around the inner surface of the drive tube.

20. Apaintball loader as in claim 17 Wherein the screW has

an additional helical groove.

21. A paintball loader as in claim 17 Wherein the helical

groove is one of multiple helical grooves of the screW.

*

You might also like

- DIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)Document21 pagesDIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)fritzthecat5296% (26)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 pagesThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs94% (124)

- US5421114 DerringerDocument12 pagesUS5421114 Derringeruntersberg92% (13)

- Design, Fabrication and Analysis of Fibonacci TurbineDocument5 pagesDesign, Fabrication and Analysis of Fibonacci TurbinearcaldartNo ratings yet

- The Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)Document16 pagesThe Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)BangBoomBang91% (69)

- QB78 DisassemblyDocument8 pagesQB78 Disassemblysjdarkman1930100% (2)

- Chironis Nicholas P.-Spring Design and ApplicationDocument349 pagesChironis Nicholas P.-Spring Design and ApplicationJLLIMPE3116100% (1)

- eBOOK - Poor Man's RPG PDFDocument156 pageseBOOK - Poor Man's RPG PDFsjdarkman1930100% (10)

- The Construction and Operation of The Air Gun. Vol. 1Document111 pagesThe Construction and Operation of The Air Gun. Vol. 1sjdarkman193067% (3)

- BARRETT 2013 - Product - Brochure PDFDocument30 pagesBARRETT 2013 - Product - Brochure PDFsjdarkman1930100% (1)

- US6443044Document10 pagesUS6443044Sadia MoinNo ratings yet

- Ep 0679137B1Document11 pagesEp 0679137B1daveNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Document23 pagesUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- European Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Document12 pagesEuropean Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Amir BahramiNo ratings yet

- 2011 Ball Hitting Trainer US20110183781A1Document10 pages2011 Ball Hitting Trainer US20110183781A1Nguyen LeNo ratings yet

- X III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2Document9 pagesX III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2djsfNo ratings yet

- Indian Patent SpecificationDocument15 pagesIndian Patent Specificationrajeev ranjan patelNo ratings yet

- Composite Bridge Plug System (US Patent 6796376)Document16 pagesComposite Bridge Plug System (US Patent 6796376)PriorSmartNo ratings yet

- Ep2957811a1 PDFDocument14 pagesEp2957811a1 PDFMohamed MohamedNo ratings yet

- United States Patent: Berej Noi Et AlDocument6 pagesUnited States Patent: Berej Noi Et AlwewewewNo ratings yet

- United States PatentDocument8 pagesUnited States PatentBarmak CheraghiNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Inventii ConstructiiDocument21 pagesInventii ConstructiiAdriana Daniela SanduNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument8 pagesUnited States Patent: (10) Patent N0.: (45) Date of PatentwererNo ratings yet

- Us7201104 PDFDocument7 pagesUs7201104 PDFThamuze UlfrssonNo ratings yet

- Reverse Energy Bow Patent US 7743760 B2Document8 pagesReverse Energy Bow Patent US 7743760 B2Doukhobor100% (1)

- Us 4505480Document3 pagesUs 4505480trtry34No ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- Us 4004514Document3 pagesUs 4004514dgfsduuwioNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Tank ErectionDocument20 pagesTank ErectionPlok Caca piiii100% (5)

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- Apron FeederDocument12 pagesApron FeederMidDeL'Orme100% (1)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0373744 A1Document18 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0373744 A1kahj juliNo ratings yet

- EP0773421A2Document9 pagesEP0773421A2Jacob MillerNo ratings yet

- Unlted States Patent (19) (11) Patent Number: 5,335,579Document8 pagesUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerNo ratings yet

- EP3032176B1Document16 pagesEP3032176B1kataloglaNo ratings yet

- World Intellectual Property Organization International Publication NumberDocument30 pagesWorld Intellectual Property Organization International Publication NumberAcc1337No ratings yet

- Iii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772Document10 pagesIii Iihiii: United States Patent (19) 11 Patent Number: 5,732,772abodolkuhaaNo ratings yet

- روولور 2Document5 pagesروولور 2abbasnjjarkhatirkolai57No ratings yet

- United States Patent: Zamirowski Et A1. (10) Patent N0.: (45) Date of PatentDocument29 pagesUnited States Patent: Zamirowski Et A1. (10) Patent N0.: (45) Date of PatentSoma GhoshNo ratings yet

- United States Patent: (12) Booker Et A) - (10) Patent N0.: (45) Date of PatentDocument13 pagesUnited States Patent: (12) Booker Et A) - (10) Patent N0.: (45) Date of Patentmaulik_20_8No ratings yet

- Post 6 36083 SA Repeating DerringerDocument18 pagesPost 6 36083 SA Repeating Derringerbadlabmouse0% (1)

- Us20140196515 PDFDocument23 pagesUs20140196515 PDFnangkarak8201No ratings yet

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- United States Patent (19) : Gazalel, 72 8Document7 pagesUnited States Patent (19) : Gazalel, 72 8Mihai RobertNo ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document14 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)werwer44345No ratings yet

- United States Patent: Noveske (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Noveske (10) Patent N0.: (45) Date of Patentduffy5555No ratings yet

- European Patent Application C25D 7/00, C25D 3/04,: Chrome Plated Engine ValveDocument10 pagesEuropean Patent Application C25D 7/00, C25D 3/04,: Chrome Plated Engine ValveMasum RavaniNo ratings yet

- EP17726231NWB1Document24 pagesEP17726231NWB1Ana Julia Mayumi PupinNo ratings yet

- Us 4023499Document4 pagesUs 4023499ererNo ratings yet

- Us 5153374Document5 pagesUs 5153374ererNo ratings yet

- United States Patent: Vodinh (10) Patent N0.: (45) Date of PatentDocument12 pagesUnited States Patent: Vodinh (10) Patent N0.: (45) Date of PatentJames LindonNo ratings yet

- US20100236390A1Document9 pagesUS20100236390A1Sundararaja SwamidossNo ratings yet

- United States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)Document7 pagesUnited States Patent: (75) Inventor: Bart Gerard Boucherie, Izegem (BE)AGUAVIVANJNo ratings yet

- United States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005Document10 pagesUnited States Patent: Perlo Et Al. (45) Date of Patent: Dec. 20, 2005tristanNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2008/0135032 A1Document7 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2008/0135032 A1montyviaderoNo ratings yet

- Patent DraftingDocument6 pagesPatent Draftingabhilasha singhNo ratings yet

- United States Patent: Bartlett Patent No.: Date of PatentDocument34 pagesUnited States Patent: Bartlett Patent No.: Date of PatentSameh El-SabbaghNo ratings yet

- EP0229675B1Document10 pagesEP0229675B112348No ratings yet

- 撞针选择的枪 PDFDocument9 pages撞针选择的枪 PDFJin SongNo ratings yet

- PARKER & WHIPPLE CO. and Another v. YALE CLOCK Co. and OtherDocument13 pagesPARKER & WHIPPLE CO. and Another v. YALE CLOCK Co. and OtherScribd Government DocsNo ratings yet

- Sistema de PropulsãoDocument50 pagesSistema de PropulsãoEwerton MonteiroNo ratings yet

- Long Tail BoatDocument71 pagesLong Tail Boatceaseless_way100% (1)

- Cetme: Special Purpose Assault MACHINEGUN 5.56x45Document24 pagesCetme: Special Purpose Assault MACHINEGUN 5.56x45Jon MorenoNo ratings yet

- Double Stack Mag 22LR US8776419Document21 pagesDouble Stack Mag 22LR US8776419sjdarkman19300% (1)

- Us7739821 PDFDocument12 pagesUs7739821 PDFsjdarkman1930100% (1)

- G0355Document52 pagesG0355sjdarkman1930100% (1)

- The Construction and Operation of The Air Gun. Vol. 2 PDFDocument85 pagesThe Construction and Operation of The Air Gun. Vol. 2 PDFsjdarkman1930100% (7)

- Simple Homemade Pistol Pit-Bull-1Document22 pagesSimple Homemade Pistol Pit-Bull-1sjdarkman1930100% (2)

- Sas12 Shotgun ExplodedDocument8 pagesSas12 Shotgun Explodedsjdarkman1930No ratings yet

- Single Lip Cutter D-BitDocument2 pagesSingle Lip Cutter D-Bitsjdarkman1930No ratings yet

- 6DZE1 Rifle Making in The Great Smokey MountainsDocument21 pages6DZE1 Rifle Making in The Great Smokey MountainsRobert Powell100% (4)

- Making and Using Reamers: Part 1Document50 pagesMaking and Using Reamers: Part 1angelines123No ratings yet

- Off Set CenterDocument1 pageOff Set CenterFrenchwolf420No ratings yet

- Model 99 Exploded ViewDocument1 pageModel 99 Exploded ViewtophunterNo ratings yet

- Mk18 Mod1 SBR RifleDocument21 pagesMk18 Mod1 SBR Riflesjdarkman1930No ratings yet

- Enfield No4 Bolt DisassemblyDocument20 pagesEnfield No4 Bolt Disassemblydeolexrex100% (3)

- A Method of Making Reamers PDFDocument10 pagesA Method of Making Reamers PDFsjdarkman193050% (2)

- Breechloading Flintlock PDFDocument12 pagesBreechloading Flintlock PDFsjdarkman1930100% (1)

- RAP4 T68 Paintball Patent US8578921Document32 pagesRAP4 T68 Paintball Patent US8578921sjdarkman1930No ratings yet

- Off Grid RefrigerationDocument2 pagesOff Grid Refrigerationsjdarkman1930No ratings yet

- Breechloading - Flintlock Notes PDFDocument2 pagesBreechloading - Flintlock Notes PDFsjdarkman1930No ratings yet

- Icy Ball ManualDocument6 pagesIcy Ball Manualsjdarkman1930No ratings yet

- Machine Mate Inc - Full List of CNC CodesDocument5 pagesMachine Mate Inc - Full List of CNC CodesEr Zorawar SinghNo ratings yet

- GenEndo Product PPT For DentistsDocument21 pagesGenEndo Product PPT For DentistsSasidharKaipaNo ratings yet

- Envelope Method of GearingDocument4 pagesEnvelope Method of GearingNgọc Vi CaoNo ratings yet

- Module 4 TorsionDocument62 pagesModule 4 TorsionPRINZE SEREGUINENo ratings yet

- Helical Springs - SoMDocument2 pagesHelical Springs - SoMSpeed GrayNo ratings yet

- 2024_Multi-objective optimization of a double helical coil heat exchanger using response surface method and genetic algorithmDocument15 pages2024_Multi-objective optimization of a double helical coil heat exchanger using response surface method and genetic algorithmsudhansu sekhar mishraNo ratings yet

- Magnetic Effect of Current 1 MMDocument48 pagesMagnetic Effect of Current 1 MMnamitjain98No ratings yet

- Special CurvesDocument15 pagesSpecial CurvesIsSid100% (1)

- KTM Unit-7Document76 pagesKTM Unit-7pateldhruv707No ratings yet

- Question Bank For Strenght of Materials Semester - 4: Fill in The BlanksDocument46 pagesQuestion Bank For Strenght of Materials Semester - 4: Fill in The BlanksgchgNo ratings yet

- PDFsam - B 389 - 81 (2016)Document4 pagesPDFsam - B 389 - 81 (2016)mike.jensen0581No ratings yet

- Engineering Drawing: by N. D. BhattDocument6 pagesEngineering Drawing: by N. D. Bhatt71 KaranNo ratings yet

- Definition For SpringDocument18 pagesDefinition For SpringamanpurushothNo ratings yet

- Ce6306 Strength of Materials L T P CDocument1 pageCe6306 Strength of Materials L T P CmunijackNo ratings yet

- 12 Loci Applications 2020 Manual of Engineering DrawingDocument16 pages12 Loci Applications 2020 Manual of Engineering Drawing96xbntwjymNo ratings yet

- TERMINOLOGY OF WORM GEARS F AnalaysisDocument6 pagesTERMINOLOGY OF WORM GEARS F Analaysisdawit100% (2)

- Yarn StructureDocument10 pagesYarn Structurebub12345678No ratings yet

- Content PDF 1Document15 pagesContent PDF 1jesbmnNo ratings yet

- Physical Modelling of The Behaviour of Helical Anchors: June 2016Document20 pagesPhysical Modelling of The Behaviour of Helical Anchors: June 2016Oxiris QuitianNo ratings yet

- Spur Gear FundamentalsDocument11 pagesSpur Gear FundamentalsMiguel ArduzNo ratings yet

- A Cad Approach To Helical Groove Machining.Document17 pagesA Cad Approach To Helical Groove Machining.RihabChommakhNo ratings yet

- Module-7 Thin and Thick CylinderDocument52 pagesModule-7 Thin and Thick CylinderRahul SinghNo ratings yet

- VoluMill NX GuideDocument26 pagesVoluMill NX GuidedragoblaztrNo ratings yet

- Ac7114-3 Rev oDocument30 pagesAc7114-3 Rev omrigesh vermaNo ratings yet

- Helical Spring DesignDocument7 pagesHelical Spring DesignsohamkoliNo ratings yet

- Helical Sweeps Creo 3Document6 pagesHelical Sweeps Creo 3brpnaidu2157No ratings yet

- Gao 2015 ReviewDocument15 pagesGao 2015 ReviewTiannan DengNo ratings yet