Iplv NPLV

Iplv NPLV

Uploaded by

Kamal HaziqCopyright:

Available Formats

Iplv NPLV

Iplv NPLV

Uploaded by

Kamal HaziqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Iplv NPLV

Iplv NPLV

Uploaded by

Kamal HaziqCopyright:

Available Formats

Understanding IPLV/NPLV | ASHRAE Central Florida Chapter

1 of 5

NEXT MEETIN G

RECENT U PDATES

http://ashrae-cfl.org/2010/03/understanding-iplvnplv/

EVENTS

C HAPTER

WR CC

HISTORY

PR OD UCT DIRECTORY

Understanding IPLV/NPLV

HON OR S & AWARDS

Calendar

Posted By admin, On March 1, 2010

May 14

4:30 AM - ASHRAE BOG Meeting

By: John Fabian

The Integrated Part Load Value (IPLV) is a performance characteristic developed by the

Air-Conditioning, Heating and Refrigeration Institute (AHRI). It is most commonly used to

describe the performance of a chiller capable of capacity modulation. Unlike an EER

(Energy Efficiency Ratio) or COP (coefficient of performance), which describes the efficiency

at full load conditions, the IPLV is derived from the equipment efficiency while operating at

various capacities. Since a chiller does not always run at 100% capacity, the EER or COP is

not an ideal representation of the typical equipment performance. The IPLV is a very

important value to consider since it can affect energy usage and operating costs throughout

the lifetime of the equipment. Energy codes such as ASHRAE Standard 90.1 specifies

minimum values for the equipment.

Thu, May 14, 2015, 4:30 AM - 6:00 AM

Highland Manor, East Main Street, Apopka, FL,

United States map

6:00 AM - ASHRAE Meeting: Society President

Tom Phoenix - "Our People, Our Passion, Our

Performance"

Thu, May 14, 2015, 6:00 AM - 8:00 AM

Highland Manor, East Main Street, Apopka, FL,

United States map

Click here to RSVP

Click here for Flier

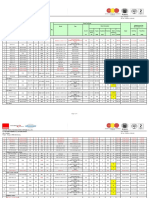

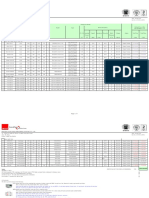

The IPLV is calculated using the efficiency of the equipment while operating at capacities of

100%, 75%, 50%, and 25%. For the purpose of chiller equipment, the operational conditions

are shown in Table 3 of AHRI Standard 550/590-2003. A water cooled chiller, for example,

is required to run at a 44F evaporator LWT with a flow rate of 2.4 gpm/ton. The condenser

EWT will vary depending on the part load capacity utilizing a 3.0 gpm/ton flow rate. If a

chiller is designed to operate at different conditions than specified in Table 3, including lower

water temperature or different flow rate, the efficiency is called a NPLV (non-standard part

load value). Both of these ratings can be calculated using the following equation:

IPLV (or NPLV) = 0.01A+0.42B+0.45C+0.12D

Where:

A = COP or EER @ 100% Load

B = COP or EER @ 75% Load

C = COP or EER @ 50% Load

D = COP or EER @ 25% Load

The derivation of this equation is extensive and includes various assumptions which create a

lengthy discussion. For more information refer to Appendix D, AHRI 550/590-2011.

[Translate]

Water Cooled Chillers Open or Hermetic DrivePart 2

February Meeting Review

24 Comments

Pragya nand says:

April 16, 2015 at 8:02 am

any one tell me ..

how to calcute the minimum inside temperature can be maintain with chilled water system @

evaporator side at 54 F (chilled water in) / 44 F (chilled water out).

plz help me

mdw@kcpl.net.in says:

April 2, 2015 at 5:20 am

Can anybody tell me if some chiller is not delieverng capacity at 100% say requirement 325 TR

29/4/2015 10:48 AM

Understanding IPLV/NPLV | ASHRAE Central Florida Chapter

2 of 5

http://ashrae-cfl.org/2010/03/understanding-iplvnplv/

delievering 310 TR.

MAY MEETING SIGN UP

w.r.t 310.Please let us know.

Meeting Sign-Up

George Hernandez says:

December 9, 2014 at 12:49 pm

C o py right 2 0 1 5 | P o w e re d by W o rdP re s s | im print t he m e by m udThe m e s

What is the definition of PPLV??? I have a chiller selection with 3 ratings, IPLV, NPLV and

PPLV. Im familiar with IPLV ans NPLV, not PPLV

zamree says:

May 24, 2014 at 9:30 am

IPLV & NPLV is depend on application of No of chiller Compressor to usage, EWT/LWT &

Related to condensing in out temperature.Normally IPLV efficient almost at 100% at chilled

water 44/54F & at 97F LWT condenser., not at Part load.

For fact with use 1 unit bigger compressor capacity IPLV doesnt real shown efficiency were

within Part Load the compressor amp is not down due to a huge motor KW selected cause the

RPM still remain at 2900 but chilled water is already reach 44/54F,IPLV & NPLV is depend on

temperature were condenser temperature from 65F to 97F(100%)

With condensing Temperature from 65 to 97F The table data shown is confuse.

Condensing temperature for tropical area almost 87/97F consistent.. It cant at 65F.

Selected lower IPLV for Higher efficiency is good at only 100%,but must consider on

application,usage of building, no of compressor.I think for good practice for energy saving

multiple compressor is the answer not a single one.

quyume says:

February 18, 2014 at 1:58 pm

1. the evaporator side at 54 F (chilled water in) / 44 F (chilled water out).On the condenser side

in both the modes 100 F (condenser water in)/90 F (condenser water out).

2. the evaporator side at 54 F (chilled water in) / 44 F (chilled water out).On the condenser side

in both the modes 95 F (condenser water in)/85 F (condenser water out).

which option give more efficiency ? what is the basic of selecting condenser for better

efficiency?

pls let me know

bharat bhushan says:

January 22, 2014 at 11:11 am

i have to select one chilling machine from two having IPLV 0.33 and .49, which one is more

efficient. please suggest.

thanks

yasin says:

December 5, 2013 at 8:35 am

thanks

Sagar says:

November 6, 2013 at 1:12 pm

Can any one let know the formula or thumb rule for pressure drop for evaporator and condenser

for 300 TR water cooled screw chiller with 7/12 degree Celsius & 32/36 degree Celsius. Thanks

Ernie Tolentino says:

August 29, 2013 at 4:09 pm

The ASHRAE NPLV based on COP = 3.517/(NPLV based on Kw/ton) since

NPLV based on Kw/Ton = 1/((.01/A)+(0.42/B)+(0.45/C)+(o.12/D))

Where A = kw/ton at 100% capacity

B = kw/ton at 75% capacity

C = kw/ton at 50% capacity

D = kw/ton at 25% capacity

Ernie Tolentino says:

August 29, 2013 at 2:45 pm

COP = 12000/(Kw/ton x 3412) = 3.517/(kw/ton)

1 Ton = 12000 Btu/hr per ton

29/4/2015 10:48 AM

Understanding IPLV/NPLV | ASHRAE Central Florida Chapter

3 of 5

http://ashrae-cfl.org/2010/03/understanding-iplvnplv/

1 Kw = 3412 Btu/hr

E Tolentino says:

August 29, 2013 at 2:10 pm

Kw/Ton = 12000/COP x 3412) = 3.517/COP

RAMON says:

August 16, 2013 at 2:47 pm

No logro entender los conceptos IPLV NPLV PARA QUE SIRVEN

Wasfi says:

January 23, 2013 at 4:43 am

Lower kW/ton that means higher efficiency,IPLV and NPLV both are the reciprocal of COP or

efficiency.

Regards

Glen says:

August 10, 2012 at 7:12 pm

Amit, I would leave the chiller water temperture at a constant 44 degrees and use a mixing

valve to control the higher temperature water for your chilled beams. You will also be better off if

you can keep the condenser water below design. However you cant go too long. I would speak

to your rep because depending on your chiller low condenser water temp can cause issues.

Ray Hickey says:

May 22, 2012 at 10:01 am

IPLV or IEER (newest)

The lower the kw/ton or the higher the EER equals the highest efficiency.

Hernando says:

April 13, 2012 at 6:21 pm

In the IPVL, the coefficients are specific for each climatic zone conditions?.

These are the percentage of time that the chiller operate at each load?.

Analizing the indoor and outdoor temperature can I derive these coefficients?.

Regards,

Nando

Amit Kumar says:

April 13, 2012 at 3:12 pm

Dear All,

Very Good Morning,

In one of my projects I am facing one difficulty. Here I have to use chiller in two modes i.e Mode

(1)on the evaporator side at 60.8 F (chilled water out) / 68 F (chilled water in) and Mode (2)on

the evaporator side at 54 F (chilled water in) / 44 F (chilled water out).On the condenser side in

both the modes 96 F (condenser water in)/89 F (condenser water out). Now my question is that

in both the modes can we use the same in /out temp in condenser end or we have to modulate

the same to get the desired temp at diffrent modes of the screw chiller ?

Mode(1)of chiller is being used to feed chilled water to the chilled beams and Mode(2)is used to

feed chilled water to the AHUs for conventional system.

And how does tower relief will help to get the desired result without effecting much on the

efficiency end ?

Outside wet bulb temp is 83 F.

Mode(1)generates 160 TR and Mode(2)generates 240 TR.

What is the minimum temp the condenser should go to get the desired result ?

Can anyone please help regarding the above issues ? I will be available on the below

mentioned mail and contact no.

Regards,

Amit Kumar

mail.voltas@gmail.com

+919910498934

Calvin Li says:

April 10, 2012 at 3:34 am

29/4/2015 10:48 AM

Understanding IPLV/NPLV | ASHRAE Central Florida Chapter

4 of 5

http://ashrae-cfl.org/2010/03/understanding-iplvnplv/

Dear Bill,

Will the weighting of the COP of the formula be changed for different geographic area? Where

could these weighting be found?

Bill says:

April 8, 2012 at 12:58 pm

Robert, yes, water conditions will affect part load performance. Contact your local rep to get

chiller efficiency curves for your particuliar application. At a minimum, they will need to know

your design conditions: Capacity, entering and leaving CW Temp, entering and leaving

condenser temp, and % glycol in either evap or condenser loop (if any). If you are wondering

about an existing chiller, youll want to provide the model and serial number too.

Another important factor is if you want the analysis done using tower relief, which lowers the

tower temperature as the chiller unloads. This assumes the chiller unloading typically coincides

with lower OA wet bulb temperatures. There are AHRI standard values that are typically used

for tower relief.

Heres a link to a document that explains AHRI tower relief, along with additional info on IPLV /

NPLV:

http://trane.com/commercial/library/vol281/en_28-01.pdf

Robert says:

March 4, 2012 at 7:10 pm

will the leaving chilled water temperature(LCHT) and the entering condensing water

temperature (ECWT) affect the part load performance? if yes, what are the other neccesary

data to get chiller curve?

I am more interested in chiller curves. Hope you can help me.

Bill says:

February 23, 2012 at 8:47 pm

The units for IPLV are KW/Ton, which is (energy input / energy output). Thus Lower IPLV =

Higher Efficiency!

FAYAZ says:

February 6, 2012 at 12:48 pm

yes, the higher the value of IPLV, the better the efficiency.

Hans Viggaard says:

January 30, 2012 at 1:46 am

The higher IPLV, the more energy efficient.

Hans

Bruce says:

January 27, 2012 at 10:18 am

Concerning IPLV, the higher the value indicate better efficiency or poorer?

Thanks,

Bruce

Leave a Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Website

Comment

You may use these HTML tags and attributes: <a href="" title=""> <abbr title=""> <acronym

title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s>

<strike> <strong>

29/4/2015 10:48 AM

Understanding IPLV/NPLV | ASHRAE Central Florida Chapter

5 of 5

http://ashrae-cfl.org/2010/03/understanding-iplvnplv/

Post Comment

29/4/2015 10:48 AM

You might also like

- Chapter 9 Heat Form 2 KSSMDocument7 pagesChapter 9 Heat Form 2 KSSMNadhirah Kamarudin80% (5)

- NEC FR-358 Instruction ManualDocument12 pagesNEC FR-358 Instruction Manualekim444666No ratings yet

- Carrier Recommended Minimum CW Fluid Loop VolumeDocument1 pageCarrier Recommended Minimum CW Fluid Loop VolumeRyan Carter100% (2)

- KRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODocument4 pagesKRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODo MinhNo ratings yet

- Chiller System BMS PDFDocument42 pagesChiller System BMS PDFYahya Salem100% (1)

- Case Study: CSTR Dynamics Via Linearization: 1. Representation of Multivariable SystemsDocument8 pagesCase Study: CSTR Dynamics Via Linearization: 1. Representation of Multivariable SystemsΜιχάλης ΝικολάουNo ratings yet

- Understanding NPLV / IPLVDocument4 pagesUnderstanding NPLV / IPLVmitasyahu100% (1)

- Sumair Project Report PPT HVACDocument37 pagesSumair Project Report PPT HVACRishabh SinghNo ratings yet

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- Variable Refrigerant FlowDocument6 pagesVariable Refrigerant FlowRahul PrajapatiNo ratings yet

- Hvac Boq-07082014Document18 pagesHvac Boq-07082014Kohilan NahivNo ratings yet

- Chap 10 HvacDocument30 pagesChap 10 HvacVikrant HaribhaktaNo ratings yet

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- تقرير تدريب صيفي لواء الدين مظفرDocument23 pagesتقرير تدريب صيفي لواء الدين مظفرlalaNo ratings yet

- Chiller PDFDocument20 pagesChiller PDFredaNo ratings yet

- Hvac OtDocument4 pagesHvac OtshreyaNo ratings yet

- COIL Selection Formulas PDFDocument3 pagesCOIL Selection Formulas PDFWalter100% (1)

- Ishrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaDocument35 pagesIshrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaAnurag JoshiNo ratings yet

- Coil Selection ReportDocument1 pageCoil Selection ReportMohsin Shaikh100% (1)

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- AHUDocument5 pagesAHUksahunkNo ratings yet

- Ceiling Cassette Chilled Water Fan Coil Unit - Koppel PDFDocument2 pagesCeiling Cassette Chilled Water Fan Coil Unit - Koppel PDFatramanathanNo ratings yet

- Benefits and Design Tipsfor ChillersDocument4 pagesBenefits and Design Tipsfor ChillersSharon LambertNo ratings yet

- ESP CalculationDocument4 pagesESP CalculationKhalidNo ratings yet

- Afdb Abuja Hvac Boq - Lot2-1Document48 pagesAfdb Abuja Hvac Boq - Lot2-1Dee RajaNo ratings yet

- Hvac Formulas PDFDocument25 pagesHvac Formulas PDFManish SinghNo ratings yet

- Cooling Load Rule of Thumb PDFDocument36 pagesCooling Load Rule of Thumb PDFmaungNo ratings yet

- Multi V 4 Vs Water Cooled ChillerDocument28 pagesMulti V 4 Vs Water Cooled ChillerThameem Ansari100% (1)

- Making Them Work: Primary-Secondary Chilled Water SystemsDocument9 pagesMaking Them Work: Primary-Secondary Chilled Water Systemspsn_kylmNo ratings yet

- Swimming Pool Heater SizingDocument1 pageSwimming Pool Heater SizingAmeer Abbas100% (1)

- Chilled Water System Sequence of OperationDocument3 pagesChilled Water System Sequence of OperationdimasNo ratings yet

- Ishrae PDFDocument39 pagesIshrae PDFShivraj SawantNo ratings yet

- How Do You Convert BTU To CFM?Document6 pagesHow Do You Convert BTU To CFM?sanjay975No ratings yet

- SRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationsDocument13 pagesSRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationssumitNo ratings yet

- Cooling Tower Efficiency CalculationsDocument3 pagesCooling Tower Efficiency CalculationsPramod SharmaNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- Converting KW Ton To COP or EERDocument2 pagesConverting KW Ton To COP or EERswsw2011No ratings yet

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 pagesSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRNo ratings yet

- Heat Load CalculationDocument24 pagesHeat Load CalculationpradeepqNo ratings yet

- Air Handling Units: CatalogueDocument157 pagesAir Handling Units: Cataloguevarshneyrk@rediffmail.comNo ratings yet

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- Prinston Smart Engineers InternshipDocument33 pagesPrinston Smart Engineers InternshipCalvin bNo ratings yet

- Hot Water Heater Sizing Guidelines: I. DefinitionsDocument8 pagesHot Water Heater Sizing Guidelines: I. DefinitionsMac ShaikNo ratings yet

- Testing and Balancing AcsDocument10 pagesTesting and Balancing Acsroshan jaiswalNo ratings yet

- Cooling Tower InfoDocument78 pagesCooling Tower Infopitong_manning100% (1)

- Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDFDocument56 pagesDaikin VRV III (Selection Installation Proceedure) Technical Data Book PDFHarveen Singh100% (1)

- DX Split ChecklistDocument2 pagesDX Split ChecklistdesignselvaNo ratings yet

- Chilled Water PipingDocument6 pagesChilled Water Pipingunicornmep100% (1)

- Chilled Water Pump Head CalculationDocument18 pagesChilled Water Pump Head CalculationPeshoMagdyNo ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Proper Engine Room VentilationDocument2 pagesProper Engine Room VentilationAsok AyyappanNo ratings yet

- ASHRAE 90-1 New Centrifugal Chiller Equation For 2010Document2 pagesASHRAE 90-1 New Centrifugal Chiller Equation For 2010Víctor RojasNo ratings yet

- 84-Asked Quotation For VRF Air Conditioning SystemDocument4 pages84-Asked Quotation For VRF Air Conditioning SystemaliakhterattariNo ratings yet

- PIBCV Danfoss AB-QM Tender SpecificationDocument2 pagesPIBCV Danfoss AB-QM Tender SpecificationJames ChanNo ratings yet

- DDC Basics HogerDocument37 pagesDDC Basics HogerharimadhavNo ratings yet

- Ishrae Variable Volume Pumping SystemDocument14 pagesIshrae Variable Volume Pumping SystemAidrus AliNo ratings yet

- HVAC IkW Per TRDocument1 pageHVAC IkW Per TRV S PRASAD Chief Engineer, CPWD - TrivandrumNo ratings yet

- Air Changes Per HourDocument5 pagesAir Changes Per Hourاحمد الجزار2007No ratings yet

- AHU Design GuideDocument37 pagesAHU Design Guidesachin100% (1)

- 1Document3 pages1ntt_121987No ratings yet

- NPLV CalcuationDocument4 pagesNPLV CalcuationjdkafdaasdkNo ratings yet

- Calculate COP and IPLV From EER - Cove - Tool Help CenterDocument2 pagesCalculate COP and IPLV From EER - Cove - Tool Help CenterWASSIM SUNNANo ratings yet

- FPS Equipment & Specifications Fire-Fighting System Item Specifications Standards ReferenceDocument6 pagesFPS Equipment & Specifications Fire-Fighting System Item Specifications Standards ReferenceKamal HaziqNo ratings yet

- FPS, DR, SN, CWP ProvisionsDocument21 pagesFPS, DR, SN, CWP ProvisionsKamal HaziqNo ratings yet

- FPS Equipment & Specifications Fire-Fighting System Item Specifications Standards ReferenceDocument6 pagesFPS Equipment & Specifications Fire-Fighting System Item Specifications Standards ReferenceKamal HaziqNo ratings yet

- Siapa Tahu Nama Penuh Bagi Adfp Dan Actp?: SoalanDocument17 pagesSiapa Tahu Nama Penuh Bagi Adfp Dan Actp?: SoalanKamal HaziqNo ratings yet

- HTFS - General Introduction To The Thermal Design of Shell & Tube Type Heat ExchangersDocument57 pagesHTFS - General Introduction To The Thermal Design of Shell & Tube Type Heat Exchangersehsan_baheri100% (1)

- Ashrae Journal Upgrading Chilled Water SystemDocument10 pagesAshrae Journal Upgrading Chilled Water SystemperezismaelNo ratings yet

- Ik2m 158 03 Lyd 2001Document1 pageIk2m 158 03 Lyd 2001Burhanudin BurhanudinNo ratings yet

- Broshure 1302677599Document4 pagesBroshure 1302677599Sawsan Anna KhNo ratings yet

- Ag5 2002Document134 pagesAg5 2002rasheedillikkalNo ratings yet

- Pcua14-03 Daikin Applied ProductsDocument8 pagesPcua14-03 Daikin Applied ProductsadesNo ratings yet

- MS Samsung Ar5000 Non Inverter AirconditionerDocument2 pagesMS Samsung Ar5000 Non Inverter AirconditionerMacSparesNo ratings yet

- Chapter 1 Vapor Power Cycles - CompleteDocument97 pagesChapter 1 Vapor Power Cycles - CompleteAdnan NimachwalaNo ratings yet

- EBR9900 - BuiltinKitInstructions - GB DE FR NL IT ESDocument17 pagesEBR9900 - BuiltinKitInstructions - GB DE FR NL IT ESAnonymous PL3wzykNo ratings yet

- VRV General KnowledgeDocument55 pagesVRV General Knowledgekikiichtiar03No ratings yet

- Supersedes DIN V 18599-1:2005-07Document66 pagesSupersedes DIN V 18599-1:2005-07LB100% (1)

- Climate Design of Building Using PassiveDocument24 pagesClimate Design of Building Using Passivepurged_160151093_920No ratings yet

- M. Arch. Syllabus FinalDocument50 pagesM. Arch. Syllabus FinalMohitSoodNo ratings yet

- 08 - 4 FDB PPT - ComfortDocument41 pages08 - 4 FDB PPT - ComfortJayachandran KNo ratings yet

- 5MKM100RVMV Multi NX R32 Data Engineering EDAVN121718Document1 page5MKM100RVMV Multi NX R32 Data Engineering EDAVN121718Permana PutraNo ratings yet

- S.4 Physics - Measuring The Specific Latent HeatDocument6 pagesS.4 Physics - Measuring The Specific Latent Heatrazanmk961214No ratings yet

- General RAC 2024 Catalogue - CET SeriesDocument2 pagesGeneral RAC 2024 Catalogue - CET SeriesAtishNo ratings yet

- Shell and Tube Heat Exchanger Design PreparedDocument6 pagesShell and Tube Heat Exchanger Design PreparedEmebu SamuelNo ratings yet

- Turbo Air ManualDocument46 pagesTurbo Air Manualsillyfruits99No ratings yet

- Air ConditioningDocument3 pagesAir ConditioningSRIJASH ARYANNo ratings yet

- PipelineStudio Gas Simulator Module Quality - Tracking - English - AllDocument15 pagesPipelineStudio Gas Simulator Module Quality - Tracking - English - AllgcarreongNo ratings yet

- Catalogo 2015 FullDocument116 pagesCatalogo 2015 FullRicardo Álvarez PérezNo ratings yet

- MEC551 Assignment - Design June2017Document6 pagesMEC551 Assignment - Design June2017Muhd Syafiq OthmanNo ratings yet

- Thermo Lecture 6 - Air-ConditioningDocument84 pagesThermo Lecture 6 - Air-ConditioningRosina AdhikariNo ratings yet

- Study of Steam Condensation On A Single Vertical TubeDocument27 pagesStudy of Steam Condensation On A Single Vertical Tubemahbub1332No ratings yet

- ME 366-Heat Transfer Lecture Notes (January - 20 - 2022)Document146 pagesME 366-Heat Transfer Lecture Notes (January - 20 - 2022)somenewguyonthewebNo ratings yet

- Balance Point of Compressor and Capillary TubeDocument13 pagesBalance Point of Compressor and Capillary TubeMonojit KonarNo ratings yet