A Mefi MC001 E1

A Mefi MC001 E1

Uploaded by

aptureincCopyright:

Available Formats

A Mefi MC001 E1

A Mefi MC001 E1

Uploaded by

aptureincOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

A Mefi MC001 E1

A Mefi MC001 E1

Uploaded by

aptureincCopyright:

Available Formats

Global Spiral TTC™ Fittings

For Use with FC254, FC273, FC273B, FC606,

FC606B, GH466 and GH506 Hose

Global Spiral

TTC Fittings

4-SPIRAL or 6-SPIRAL and hose size

stenciled on socket

Through-the-cover crimp

s

Heavy wall thickness maintained

s

Stress-relief design

s

s

s

One-piece nipple design

Tapered through-hole

Features and

Benefits

FEATURES BENEFITS

Through-the-cover crimp Skiving not required, saves time in assembly

One-piece nipple design Stronger design, no braze joints

One-piece fitting Easier to assemble

Stress-relief design Maximizes durability

Heavy wall thickness Heavy-duty construction for heavy-duty applications

Modern micro-alloy steel Maximizes fatigue life

Tapered through-hole Improves flow characteristics

Global design Global availability

Stenciled socket Hose insertion depth

Operating pressure to 6000 psi Perfect for hydrostatic drives and other demanding applications

Available in -12, -16, -20, -24 & -32 Multiple configurations and jump sizes to fit a wide array of applications

2 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Global Spiral

TTC Fittings

WARNING WARNING

Failure to follow Aeroquip process and product instructions Aeroquip manufactures the terminal ends of our fittings to

and limitations could lead to premature hose assembly fail- the appropriate requirement established by the SAE and

ures, resulting in property damage, serious injury or death. other industry standards. It is possible to order a fitting with

Aeroquip fitting tolerances are engineered to match Aeroquip a terminal end that has a performance rating lower than the

hose tolerances. The use of Aeroquip fittings on hose supplied hose rating. Failure to consider the terminal end performance

by other manufacturers and/or the use of Aeroquip hose with could lead to premature hose assembly failures, resulting in

fittings supplied by other manufacturers, may result in the pro- property damage, serious injury or death.

duction of unreliable and unsafe hose assemblies and is nei-

ther recommended nor authorized by Aeroquip.

Read and understand the operator’s manual before attempt-

ing to operate any equipment.

Aeroquip hereby disclaims any obligation or liability (including

incidental and consequential damages) arising from breach of

contract, warranty, or tort (under negligence or strict liability

theories) should Aeroquip hose, fittings or assembly equip-

ment be used with the hose, fittings or assembly equipment

supplied by another manufacturer, or in the event that product

instructions for each specified hose assembly are not followed.

Hose for Use with

Global Spiral TTC Fittings

FC254

Four spiral wire

Exceeds SAE 100R11, EN 856 4SP

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. Hose O.D.

r r Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

FC254-12

r r r 19,1 0.75 32,0 1.26 435,0 6250 1750,0 25000 279,4 11.00 0,88 0.59

FC254-16 25,4 1.00 38,6 1.52 350,0 5000 1400,0 20000 304,8 12.00 1,03 0.69

FC254-20 31,8 1.25 45,7 1.80 280,0 4000 1120,0 16000 419,1 16.50 1,37 0.92

FC254-24 38,1 1.50 54,1 2.13 210,0 3000 840,0 12000 508,0 20.00 1,82 1.22

FC254-32 50,8 2.00 68,1 2.68 210,0 3000 840,0 12000 635,0 25.00 2,44 1.64

Construction Operating Temperature Range Application

Synthetic rubber tube, 4-spiral –40°C to +121°C [–40°F to +250°F] Hydraulic system service with

wire reinforcement and synthetic petroleum and water-base fluids,

rubber cover. for general industrial use.

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 3

FC273

Four or six spiral wire

SAE 100R13, EN 856 Type R13, ISO 3862 Type R13

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. Hose O.D.

r r Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

FC273-12

r r r 19,1 0.75 32,0 1.26 350,0 5000 1400,0 20000 240,0 9.50 1,56 1.05

FC273-16 25,4 1.00 38,6 1.52 350,0 5000 1400,0 20000 300,0 12.00 1,96 1.32

FC273-20 31,8 1.25 49,8 1.96 350,0 5000 1400,0 20000 420,0 16.50 3,66 2.46

FC273-24 38,1 1.50 57,4 2.26 350,0 5000 1400,0 20000 500,0 20.00 4,70 3.16

FC273-32 50,8 2.00 71,1 2.80 350,0 5000 1400,0 20000 640,0 25.00 7,11 4.78

Construction Operating Temperature Range Application

Synthetic rubber tube, multiple –40°C to +121°C [–40°F to +250°F] Hydraulic system service with

heavy spiral wire (4 wire for -12, - petroleum and water-base fluids,

16; 6 wire for -20, -24 and -32); for general industrial service.

black synthetic rubber cover.

FC273B BRUISER

Ultra-abrasion resistant cover

Four or six spiral wire

SAE 100R13, EN 856 Type R13, ISO 3862 Type R13

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. r r

Hose O.D. Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

FC273B-12

r r r 19,1 0.75 33,3 1.31 350,0 5000 1400,0 20000 240,0 9.50 1,55 1.04

FC273B-16 25,4 1.00 39,9 1.57 350,0 5000 1400,0 20000 300,0 12.00 1,95 1.31

FC273B-20 31,8 1.25 51,3 2.02 350,0 5000 1400,0 20000 420,0 16.50 3,63 2.44

FC273B-24 38,1 1.50 58,9 2.32 350,0 5000 1400,0 20000 500,0 20.00 4,78 3.21

FC273B-32 50,8 2.00 72,6 2.86 350,0 5000 1400,0 20000 640,0 25.00 7,05 4.74

Construction Operating Temperature Range Application Recommended for use on crical

Synthetic rubber tube, multiple –40°C to +121°C [–40°F to +250°F] High abrasion industrial and applications in construction,

heavy spiral wire (4 wire for -12, - hydraulic system applications with forestry, and other off-highway

16; 6 wire for -20, -24 and -32); petroleum and water-based fluids. vehicles. BRUISER outer cover

synthetic rubber intermediate offers unmatched abrasion, chemi-

cover and BRUISER outer cover. cal and environmental protection.

GH506

Four spiral wire

EN 856 4SH

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. Hose O.D.

r r Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

GH506-12*

r r r 19,1 0.75 32,3 1.27 420,0 6090 1680,0 24360 280,0 11.00 1,49 1.00

GH506-16* 25,4 1.00 38,4 1.51 380,0 5510 1520,0 22040 340,0 13.38 2,05 1.38

GH506-20* 31,8 1.25 45,5 1.79 350,0 5075 1400,0 20300 460,0 18.11 2,54 1.71

GH506-24* 38,1 1.50 53,6 2.11 300,0 4350 1200,0 17400 560,0 22.05 3,27 2.20

GH506-32* 50,8 2.00 68,1 2.68 250,0 3625 1000,0 14500 700,0 27.56 4,58 3.08

Construction Operating Temperature Range Application * Also available as an M100 length

Synthetic rubber tube, 4-spiral wire –40°C to +100°C [–40°F to +212°F] Four wire hose for high pressure (GH506-12M100). This P/N is a mini-

reinforcement, synthetic rubber hydraulic systems with petroleum mum 100 feet in length.

cover. and water-base fluids.

4 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

FC606

Six spiral wire

SAE 100R15

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. Hose O.D.

r r Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

FC606-16

r r r 25,4 1.00 41,9 1.65 420,0 6000 1680,0 24000 304,8 12.00 2,66 1.79

FC606-20 31,8 1.25 49,5 1.95 420,0 6000 1680,0 24000 419,1 16.50 3,62 2.43

FC606-24 38,1 1.50 58,4 2.30 420,0 6000 1680,0 24000 508,0 20.00 4,72 3.17

Construction Operating Temperature Range Application

Synthetic rubber tube, 6-spiral –40°C to +121°C [–40°F to +250°F] High-pressure hydraulics,

wire reinforcement, synthetic rub- hydrostatic transmissions.

ber cover.

FC606B BRUISER

Ultra-abrasion resistant cover

Six spiral wire

SAE 100R15, ISO 3862 Type R15

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. Hose O.D.

r r Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

FC606B-16

r r r 25,4 1.00 42,9 1.69 420,0 6000 1680,0 24000 304,8 12.00 2,60 1.79

FC606B-20 31,8 1.25 51,6 2.03 420,0 6000 1680,0 24000 419,1 16.50 3,57 2.43

FC606B-24 38,1 1.50 58,9 2.32 420,0 6000 1680,0 24000 508,0 20.00 4,57 3.07

Construction Operating Temperature Range Application Recommended for use on critical

Synthetic rubber tube, 6-spiral –40°C to +121°C [–40°F to +250°F] High-abrasion industrial and applications in construction, forestry,

wire reinforcement, synthetic rub- hydraulic system applications with and other off-highway vehicles.

ber intermediate cover and BRUIS- petroleum and water-based fluids. BRUISER outer cover offers

ER outer cover. unmatched abrasion, chemical, and

environmental protection.

GH466

Six spiral wire

r r

Maximum Minimum Minimum

Operating Burst Bend Weight

Part Number Hose I.D. r r

Hose O.D. Pressure Pressure Radius of Hose

mm in mm in bar psi bar psi mm in Kg/m lbs/ft

GH466-20

r r r 31,8 1.25 49,3 1.94 420,0 6090 1680,0 24000 420,0 16.50 3,48 2.34

GH466-24 38,1 1.50 57,4 2.26 420,0 6090 1680,0 24000 510,0 20.80 4,63 3.11

Construction Operating Temperature Range Application

Synthetic rubber tube, 6-spiral –40°C to +100°C [–40°F to +212°F] Six wire spiral hose for pressure

wire reinforcement, synthetic rub- systems with extreme pressure

ber cover. peaks. For use with petroleum and

water-base fluids.

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 5

Global Spiral A A A

D D L D L

TTC Fittings L

Straight split flange –

45° split flange - K H

90° split flange - H

Code 62 (SAE J518) K

Spiral TTC Fittings for use

with hose: FC254, FC273, FC273B, K

FC606, FC606B, GH466, GH506 Straight Split Flange 45° Elbow Split Flange 90° Elbow Split Flange

1E Fittings for use on 4-wire Code 62 Code 62 Code 62

construction

1Z Fittings for use on 6-wire

construction Flange Hose

Head Hose Insertion

Fitting Part Number Dia. K Ø Size A D Length L H

mm in mm in mm in mm in mm in

Straight split flange – Code 62 (SAE J518)

1E12FH12 41.3 1.62 -12 105,8 4.16 60,8 2.39 45,0 1.77

1E16FH12 47,6 1.88 -12 110,0 4.33 65,0 2.56 45,0 1.77

1E16FH16 47,6 1.88 -16 135,2 5.32 70,2 2.76 65,0 2.56

1Z16FH16 47,6 1.88 -16 135,2 5.32 70,2 2.76 65,0 2.56

1E20FH16 54,0 2.12 -16 132,6 5.22 67,6 2.66 65,0 2.56

1E20FH20 54,0 2.12 -20 148,6 5.85 73,6 2.90 75,0 2.95

1Z20FH16 54,0 2.12 -16 132,6 5.22 67,6 2.66 65,0 2.56

1Z20FH20 54,0 2.12 -20 148,6 5.85 73,6 2.90 75,0 2.95

1E24FH20 63,5 2.50 -20 185,6 7.31 110,6 4.35 75,0 2.95

1Z24FH20 63,5 2.50 -20 185,6 7.31 110,6 4.35 75,0 2.95

1E24FH24 63,5 2.50 -24 189,6 7.46 111,6 4.39 78,0 3.07

1Z24FH24 63,5 2.50 -24 189,6 7.46 111,6 4.39 78,0 3.07

1E32FH24 79,4 3.13 -24 200,6 7.90 122,6 4.83 78,0 3.07

1Z32FH24 79,4 3.13 -24 200,6 7.90 122,6 4.83 78,0 3.07

1E32FH32 79,4 3.13 -32 202,7 7.98 124,7 4.91 78,0 3.07

1Z32FH32 79,4 3.13 -32 202,7 7.98 124,7 4.91 78,0 3.07

45° Split flange - Code 62 (SAE J518)

1E12FHA12 41,3 1.62 -12 125,3 4.93 80,3 3.16 45,0 1.77 27,0 1.06

1E16FHA12 47,6 1.88 -12 136,5 5.37 91,5 3.60 45,0 1.77 32,0 1.26

1E16FHA16 47,6 1.88 -16 161,7 6.37 96,7 3.81 65,0 2.56 32,0 1.26

1Z16FHA16 47,6 1.88 -16 161,7 6.37 96,7 3.81 65,0 2.56 32,0 1.26

1E20FHA16 54,0 2.12 -16 177,4 6.99 112,4 4.43 65,0 2.56 39,0 1.54

1E20FHA20 54,0 2.12 -20 193,4 7.61 118,4 4.66 75,0 2.95 39,0 1.54

1Z20FHA16 54,0 2.12 -16 177,4 6.99 112,4 4.43 65,0 2.56 39,0 1.54

1Z20FHA20 54,0 2.12 -20 193,4 7.61 118,4 4.66 75,0 2.95 39,0 1.54

1E24FHA20 63,5 2.50 -20 206,3 8.12 131,3 5.17 75,0 2.95 45,0 1.77

1Z24FHA20 63,5 2.50 -20 206,3 8.12 131,3 5.17 75,0 2.95 45,0 1.77

1E24FHA24 63,5 2.50 -24 210,3 8.28 132,3 5.21 78,0 3.07 45,0 1.77

1Z24FHA24 63,5 2.50 -24 210,3 8.28 132,3 5.21 78,0 3.07 45,0 1.77

1E32FHA24 79,4 3.13 -24 247,2 9.73 169,2 6.66 78,0 3.07 57,5 2.26

1Z32FHA24 79,4 3.13 -24 247,2 9.73 169,2 6.66 78,0 3.07 57,5 2.26

1E32FHA32 79,4 3.13 -32 249,3 9.81 171,3 6.74 78,0 3.07 57,5 2.26

1Z32FHA32 79,4 3.13 -32 249,3 9.81 171,3 6.74 78,0 3.07 57,5 2.26

90° Split flange - Code 62 (SAE J518)

1E12FHB12 41,3 1.62 -12 120,0 4.72 75,0 2.95 45,0 1.77 59,0 2.32

1E16FHB12 47,6 1.88 -12 131,4 5.17 86,4 3.40 45,0 1.77 71,0 2.80

1E16FHB16 47,6 1.88 -16 156,6 6.17 91,6 3.61 65,0 2.56 71,0 2.80

1Z16FHB16 47,6 1.88 -16 156,6 6.17 91,6 3.61 65,0 2.56 71,0 2.80

1E20FHB16 54,0 2.12 -16 172,4 6.79 107,4 4.23 65,0 2.56 89,0 3.50

1E20FHB20 54,0 2.12 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

1Z20FHB16 54,0 2.12 -16 172,4 6.79 107,4 4.23 65,0 2.56 89,0 3.50

1Z20FHB20 54,0 2.12 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

1E24FHB20 63,5 2.50 -20 201,1 7.92 126,1 4.96 75,0 2.95 104,0 4.09

1Z24FHB20 63,5 2.50 -20 201,1 7.92 126,1 4.96 75,0 2.95 104,0 4.09

1E24FHB24 63,5 2.50 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1Z24FHB24 63,5 2.50 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1E32FHB24 79,4 3.13 -24 243,6 9.59 165,6 6.52 78,0 3.07 138,0 5.43

1Z32FHB24 79,4 3.13 -24 243,6 9.59 165,6 6.52 78,0 3.07 138,0 5.43

1E32FHB32 79,4 3.13 -32 245,7 9.67 167,7 6.60 78,0 3.07 138,0 5.43

1Z32FHB32 79,4 3.13 -32 245,7 9.67 167,7 6.60 78,0 3.07 138,0 5.43

.

6 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Global Spiral A A A

TTC Fittings D L D L D L

Straight split flange –

45° split flange - K H

H

90° split flange -

K

Code 61 (SAE J518)

Spiral TTC Fittings for use K

with hose: FC254, FC273, Straight Split Flange 45° Elbow Split Flange 90° Elbow Split Flange

FC273B, FC606, FC606B, Code 61 Code 61 Code 61

GH466, GH506

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire

construction

Flange Hose

Head Hose Insertion

Fitting Part Number Dia. K Ø Size A D Length L H

mm in mm in mm in mm in mm in

Straight split flange - Code 61 (SAE J518)

1E12FL12 38,1 1.50 -12 99,5 3.92 54,5 2.15 45,0 1.77

1E16FL12 44,4 1.75 -12 96,1 3.78 51,1 2.01 45,0 1.77

1E16FL16 44,4 1.75 -16 121,3 4.78 56,3 2.22 65,0 2.56

1Z16FL16 44,4 1.75 -16 121,3 4.78 56,3 2.22 65,0 2.56

1E20FL16 50,8 2.00 -16 125,5 4.94 60,5 2.38 65,0 2.56

1E20FL20 50,8 2.00 -20 141,5 5.57 66,5 2.62 75,0 2.95

1Z20FL20 50,8 2.00 -20 141,5 5.57 66,5 2.62 75,0 2.95

1E24FL20 60,3 2.38 -20 163,8 6.45 88,8 3.50 75,0 2.95

1E24FL24 60,3 2.38 -24 167,8 6.61 89,8 3.54 78,0 3.07

1Z24FL24 60,3 2.38 -24 167,8 6.61 89,8 3.54 78,0 3.07

1E32FL24 71,4 2.81 -24 170,9 6.73 92,9 3.66 78,0 3.07

1E32FL32 71,4 2.81 -32 173,0 6.81 95,0 3.74 78,0 3.07

1Z32FL32 71,4 2.81 -32 173,0 6.81 95,0 3.74 78,0 3.07

45° Split flange - Code 61 (SAE J518)

1E12FLA12 38,1 1.50 -12 125,3 4.93 80,3 3.16 45,0 1.77 27,0 1.06

1E16FLA12 44,4 1.75 -12 136,5 5.37 91,5 3.60 45,0 1.77 32,0 1.26

1E16FLA16 44,4 1.75 -16 161,7 6.37 96,7 3.81 65,0 2.56 32,0 1.26

1Z16FLA16 44,4 1.75 -16 161,7 6.37 96,7 3.81 65,0 2.56 32,0 1.26

1E20FLA16 50,8 2.00 -16 177,4 6.99 112,4 4.43 65,0 2.56 39,0 1.54

1E20FLA20 50,8 2.00 -20 193,4 7.61 118,4 4.66 75,0 2.95 39,0 1.54

1Z20FLA20 50,8 2.00 -20 193,4 7.61 118,4 4.66 75,0 2.95 39,0 1.54

1E24FLA20 60,3 2.38 -20 206,3 8.12 131,3 5.17 75,0 2.95 45,0 1.77

1E24FLA24 60,3 2.38 -24 210,3 8.28 132,3 5.21 78,0 3.07 45,0 1.77

1Z24FLA24 60,3 2.38 -24 210,3 8.28 132,3 5.21 78,0 3.07 45,0 1.77

1E32FLA24 71,4 2.81 -24 247,2 9.73 169,2 6.66 78,0 3.07 57,5 2.26

1E32FLA32 71,4 2.81 -32 249,3 9.81 171,3 6.74 78,0 3.07 57,5 2.26

1Z32FLA32 71,4 2.81 -32 249,3 9.81 171,3 6.74 78,0 3.07 57,5 2.26

90° Split flange - Code 61 (SAE J518)

1E12FLB12 38,1 1.50 -12 120,0 4.72 75,0 2.95 45,0 1.77 59,0 2.32

1E16FLB12 44,4 1.75 -12 131,4 5.17 86,4 3.40 45,0 1.77 71,0 2.80

1E16FLB16 44,4 1.75 -16 156,6 6.17 91,6 3.61 65,0 2.56 71,0 2.80

1Z16FLB16 44,4 1.75 -16 156,6 6.17 91,6 3.61 65,0 2.56 71,0 2.80

1E20FLB16 50,8 2.00 -16 172,4 6.79 107,4 4.23 65,0 2.56 89,0 3.50

1E20FLB20 50,8 2.00 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

1Z20FLB20 50,8 2.00 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

1E24FLB20 60,3 2.38 -20 201,1 7.92 126,1 4.96 75,0 2.95 104,0 4.09

1E24FLB24 60,3 2.38 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1Z24FLB24 60,3 2.38 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1E32FLB24 71,4 2.81 -24 243,6 9.59 165,6 6.52 78,0 3.07 138,0 5.43

1E32FLB32 71,4 2.81 -32 245,7 9.67 167,7 6.60 78,0 3.07 138,0 5.43

1E32FLB32 71,4 2.81 -32 245,7 9.67 167,7 6.60 78,0 3.07 138,0 5.43

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 7

Global Spiral A A A

TTC Fittings D L D L D L

Spiral TTC Fittings for use

H H

with hose: FC254, FC273, K

FC273B, FC606, FC606B, K

K

GH466, GH506

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire Cat Flange Cat Flange Cat Flange

construction Straight 22.5° Elbow 30° Elbow

Compatible only with D-rings

P/N FF90319.

Flange Hose

Head Hose Insertion

Fitting Part Number Dia. K Ø Size A D Length L H

mm in mm in mm in mm in mm in

Caterpillar - Straight split flange

1E12CT12 41,3 1.62 -12 111,3 4.38 66,3 2.61 45,0 1.77

1E16CT12 47,6 1.88 -12 114,7 4.51 69,7 2.74 45,0 1.77

1E16CT16 47,6 1.88 -16 139,9 5.51 74,9 2.95 65,0 2.56

1Z16CT16 47,6 1.88 -16 139,9 5.51 74,9 2.95 65,0 2.56

1E20CT16 54,0 2.12 -16 136,5 5.37 71,5 2.81 65,0 2.56

1E20CT20 54,0 2.12 -20 152,5 6.00 77,5 3.05 75,0 2.95

1Z20CT16 54,0 2.12 -16 136,5 5.37 71,5 2.81 65,0 2.56

1Z20CT20 54,0 2.12 -20 152,5 6.00 77,5 3.05 75,0 2.95

1Z24CT20 63,5 2.50 -20 187,3 7.37 112,3 4.42 75,0 2.95

1Z24CT24 63,5 2.50 -24 191,3 7.53 113,3 4.46 78,0 3.07

1Z32CT24 79,4 3.13 -24 202,3 7.96 124,3 4.89 78,0 3.07

1Z32CT32 79,4 3.13 -32 204,4 8.05 126,4 4.98 78,0 3.07

Caterpillar - 22.5° Split flange

1E12CTD12 41,3 1.62 -12 137,9 5.43 92,9 3.66 45,0 1.77 13,7 0.54

1E16CTD16 47,6 1.88 -16 174,8 6.88 109,8 4.32 65,0 2.56 15,3 0.60

1Z16CTD16 47,6 1.88 -16 174,8 6.88 109,8 4.32 65,0 2.56 15,3 0.60

1E20CTD16 54,0 2.12 -16 191,9 7.56 126,9 5.00 65,0 2.56 17,8 0.70

1Z20CTD20 54,0 2.12 -20 207,9 8.19 132,9 5.23 75,0 2.95 17,8 0.70

1Z24CTD20 63,5 2.50 -20 220,1 8.67 145,1 5.71 75,0 2.95 19,4 0.76

1Z24CTD24 63,5 2.50 -24 224,1 8.82 146,1 5.75 78,0 3.07 19,4 0.76

Caterpillar - 30° Split flange

1E12CTF12 41,3 1.62 -12 135,7 5.34 90,7 3.57 45,0 1.77 19,1 0.75

1E16CTF16 47,6 1.88 -16 172,4 6.79 107,4 4.23 65,0 2.56 21,6 0.85

1Z16CTF16 47,6 1.88 -16 172,4 6.79 107,4 4.23 65,0 2.56 21,6 0.85

1E20CTF16 54,0 2.12 -16 189,1 7.45 124,1 4.89 65,0 2.56 25,3 1.00

1Z20CTF20 54,0 2.12 -20 205,1 8.08 130,1 5.12 75,0 2.95 25,3 1.00

1Z24CTF20 63,5 2.50 -20 217,1 8.55 142,1 5.59 75,0 2.95 27,7 1.09

1Z24CTF24 63,5 2.50 -24 221,1 8.70 143,1 5.63 78,0 3.07 27,7 1.09

1Z32CTF24 79,4 3.13 -24 260,5 10.26 182,5 7.19 78,0 3.07 34,8 1.37

1Z32CTF32 79,4 3.13 -32 262,6 10.34 184,6 7.27 78,0 3.07 34,8 1.37

Cat Flange D-Ring** PART A B C D E

NUMBER REF REF REF REF REF

D C INCH MM INCH MM INCH MM INCH MM INCH MM

E FF90319-12 1.27 32,3 1.00 25,4 .20 5,1 .10 2,5 .135 3,4

FF90319-16 1.52 36,6 1.25 31,8 .20 5,1 .10 2,5 .135 3,4

B A FF90319-20 1.77 45,0 1.50 38,1 .20 5,1 .10 2,5 .135 3,4

FF90319-24 2.03 51,6 1.76 44,7 .20 5,1 .10 2,5 .135 3,4

FF90319-32 2.78 70,6 2.52 64,0 .20 5,1 .10 2,5 .135 3,4

Temperature range: -40°F to +212°F.

Material: Nitrile (Buna-N)

**To be used only with Cat Flange.

8 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Global Spiral D

A

L

A A A

D L D L D L

TTC Fittings

Spiral TTC Fittings for use H H

H

with hose: FC254, FC273, H

FC273B, FC606, FC606B, K

GH466, GH506 K K

K

1E Fittings for use on 4-wire

construction Cat Flange Cat Flange Cat Flange Cat Flange

1Z Fittings for use on 6-wire 45° Elbow 60° Elbow 67.5° Elbow 90° Elbow

construction

Compatible only with D-rings

P/N FF90319.

Flange Hose

Head Hose Insertion

Fitting Part Number Dia. K Ø Size A D Length L H

mm in mm in mm in mm in mm in

Caterpillar - 45° Split flange

1E12CTA12 41,3 1.62 -12 129,2 5.08 84,2 3.31 45,0 1.77 30,9 1.22

1E16CTA12 47,6 1.88 -12 139,8 5.50 94,8 3.73 45,0 1.77 35,3 1.39

1E16CTA16 47,6 1.88 -16 165,0 6.50 100,0 3.94 65,0 2.56 35,3 1.39

1Z16CTA16 47,6 1.88 -16 165,0 6.50 100,0 3.94 65,0 2.56 35,3 1.39

1E20CTA16 54,0 2.12 -16 180,2 7.10 115,2 4.54 65,0 2.56 41,8 1.65

1E20CTA20 54,0 2.12 -20 196,2 7.72 121,2 4.77 75,0 2.95 41,8 1.65

1Z20CTA16 54,0 2.12 -16 180,2 7.10 115,2 4.54 65,0 2.56 41,8 1.65

1Z20CTA20 54,0 2.12 -20 196,2 7.72 121,2 4.77 75,0 2.95 41,8 1.65

1Z24CTA20 63,5 2.50 -20 207,5 8.17 132,5 5.22 75,0 2.95 46,2 1.82

1Z24CTA24 63,5 2.50 -24 211,5 8.33 133,5 5.26 78,0 3.07 46,2 1.82

1Z32CTA24 79,4 3.13 -24 248,4 9.78 170,4 6.71 78,0 3.07 58,7 2.31

1Z32CTA32 79,4 3.13 -32 250,5 9.86 172,5 6.79 78,0 3.07 58,7 2.31

Caterpillar - 60° Split flange

1E12CTG12 41,3 1.62 -12 148,1 5.83 103,1 4.06 45,0 1.77 42,3 1.66

1E16CTG16 47,6 1.88 -16 189,3 7.45 124,3 4.89 65,0 2.56 48,7 1.92

1Z16CTG16 47,6 1.88 -16 189,3 7.45 124,3 4.89 65,0 2.56 48,7 1.92

1E20CTG16 54,0 2.12 -16 212,4 8.36 147,4 5.80 65,0 2.56 59,3 2.33

1Z20CTG20 54,0 2.12 -20 228,4 8.99 153,4 6.04 75,0 2.95 59,3 2.33

1Z24CTG20 63,5 2.50 -20 246,4 9.70 171,4 6.75 75,0 2.95 66,6 2.62

1Z24CTG24 63,5 2.50 -24 250,4 9.86 172,4 6.79 78,0 3.07 66,6 2.62

1Z32CTG24 79,4 3.13 -24 303,2 11.94 225,2 8.87 78,0 3.07 87,3 3.44

1Z32CTG32 79,4 3.13 -32 305,3 12.02 227,3 8.95 78,0 3.07 87,3 3.44

Caterpillar - 67.5° Split flange

1E12CTE12 41,3 1.62 -12 142,2 5.60 97,2 3.83 45,0 1.77 48,2 1.90

1E16CTE16 47,6 1.88 -16 182,5 7.18 117,5 4.62 65,0 2.56 55,8 2.20

1Z16CTE16 47,6 1.88 -16 182,5 7.18 117,5 4.62 65,0 2.56 55,8 2.20

1E20CTE16 54,0 2.12 -16 204,1 8.04 139,1 5.48 65,0 2.56 68,1 2.68

1Z20CTE20 54,0 2.12 -20 220,1 8.67 145,1 5.71 75,0 2.95 68,1 2.68

1Z24CTE20 63,5 2.50 -20 237,0 9.33 162,0 6.38 75,0 2.95 76,8 3.02

Caterpillar - 90° Split flange

1E12CTB12 41,3 1.62 -12 120,0 4.72 75,0 2.95 45,0 1.77 64,5 2.54

1E16CTB12 47,6 1.88 -12 131,4 5.17 86,4 3.40 45,0 1.77 75,7 2.98

1E16CTB16 47,6 1.88 -16 156,6 6.17 91,6 3.61 65,0 2.56 75,7 2.98

1Z16CTB16 47,6 1.88 -16 156,6 6.17 91,6 3.61 65,0 2.56 75,7 2.98

1E20CTB16 54,0 2.12 -16 172,4 6.79 107,4 4.23 65,0 2.56 92,9 3.66

1E20CTB20 54,0 2.12 -20 188,4 7.41 113,4 4.46 75,0 2.95 92,9 3.66

1Z20CTB16 54,0 2.12 -16 172,4 6.79 107,4 4.23 65,0 2.56 92,9 3.66

1Z20CTB20 54,0 2.12 -20 188,4 7.41 113,4 4.46 75,0 2.95 92,9 3.66

1Z24CTB20 63,5 2.50 -20 201,1 7.92 126,1 4.96 75,0 2.95 105,7 4.16

1Z24CTB24 63,5 2.50 -24 205,1 8.07 127,1 5.00 78,0 3.07 105,7 4.16

1Z32CTB24 79,4 3.13 -24 243,6 9.59 165,6 6.52 78,0 3.07 139,6 5.50

1Z32CTB32 79,4 3.13 -32 245,7 9.67 167,7 6.60 78,0 3.07 139,6 5.50

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 9

Global Spiral A A A

TTC Fittings D L D L D L

Spiral TTC Fittings for use

with hose: FC254, FC273,

FC273B, GH506 H H

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire

construction

BSPP Swivel BSPP Swivel BSPP Swivel

Straight 45° Elbow 90° Elbow

Hose

Hose Insertion

Fitting Part Number Thd. Size A D Length L H

mm in mm in mm in mm in

BSP/JIS Female swivel (BF)

1E12BF12 G 3/4 -12 83,0 3.27 38,0 1.50 45,0 1.77

1E16BF12 G1 -12 81,7 3.22 36,7 1.44 45,0 1.77

1E16BF16 G1 -16 106,9 4.21 41,9 1.65 65,0 2.56

1E20BF16 G 11/4 -16 104,9 4.13 39,9 1.57 65,0 2.56

1E20BF20 G 11/4 -20 120,9 4.76 45,9 1.81 75,0 2.95

1E24BF24 G 11/2 -24 153,5 6.04 75,5 2.97 78,0 3.07

1Z24BF24 G 11/2 -24 153,5 6.04 75,5 2.97 78,0 3.07

1E32BF32 G2 -32 159,5 6.28 81,5 3.21 78,0 3.07

1Z32BF32 G2 -32 159,5 6.28 81,5 3.21 78,0 3.07

BSP/JIS Female swivel, 45° elbow (BFA)

1E12BFA12 G 3/4 -12 121,0 4.76 76,0 2.99 45,0 1.77 26,0 1.02

1E16BFA12 G1 -12 130,4 5.13 85,4 3.36 45,0 1.77 30,0 1.18

1E16BFA16 G1 -16 155,6 6.13 90,6 3.57 65,0 2.56 30,0 1.18

1E20BFA16 G 11/4 -16 166,9 6.57 101,9 4.01 65,0 2.56 34,0 1.34

1E20BFA20 G 11/4 -20 182,6 7.19 107,9 4.25 75,0 2.95 34,0 1.34

1E24BFA24 G 11/2 -24 208,2 8.20 130,2 5.13 78,0 3.07 43,0 1.69

1Z24BFA24 G 11/2 -24 208,2 8.20 130,2 5.13 78,0 3.07 43,0 1.69

1E32BFA32 G2 -32 242,8 9.56 164,8 6.49 78,0 3.07 51,0 2.01

1Z32BFA32 G2 -32 242,8 9.56 164,8 6.49 78,0 3.07 51,0 2.01

BSP/JIS Female swivel, 90° elbow (BFB)

1E12BFB12 G 3/4 -12 114,5 4.51 69,5 2.74 45,0 1.77 57,0 2.24

1E16BFB12 G1 -12 125,6 4.94 80,6 3.17 45,0 1.77 68,0 2.68

1E16BFB16 G1 -16 150,8 5.94 85,8 3.38 65,0 2.56 68,0 2.68

1E20BFB16 G 11/4 -16 163,7 6.44 98,7 3.89 65,0 2.56 79,0 3.11

1E20BFB20 G 11/4 -20 179,7 7.07 104,7 4.12 75,0 2.95 79,0 3.11

1E24BFB24 G 11/2 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1Z24BFB24 G 11/2 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1E32BFB32 G2 -32 245,7 9.67 167,7 6.60 78,0 3.07 133,0 5.24

1Z32BFB32 G2 -32 245,7 9.67 167,7 6.60 78,0 3.07 133,0 5.24

NOTE: The JIS parallel thread and BSPP connection are interchangeable.

10 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Global Spiral A A A

TTC Fittings D L D L D L

Spiral TTC Fittings for use

with hose: FC254, FC273,

FC273B, FC606, FC606B, H

H

GH466, GH506

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire DKOS Swivel DKOS Swivel DKOS Swivel

construction Straight 45° Elbow 90° Elbow

Hose

Tube Hose Insertion

Fitting Part Number Thd. O.D. Size A D Length L H

mm in mm in mm in mm in

DKO Female swivel, heavy duty (DS)

1E20DS12 M36 x 2 25 -12 98,4 2.10 53,4 3.87 45,0 1.77

1E25DS12 M42 x 2 30 -12 96,6 3.80 51,6 2.03 45,0 1.77

1E25DS16 M42 x 2 30 -16 121,8 4.80 56,8 2.24 65,0 2.56

1Z25DS16 M42 x 2 30 -16 121,8 4.80 56,8 2.24 65,0 2.56

1E32DS16 M52 x 2 38 -16 122,3 4.82 57,3 2.26 65,0 2.56

1E32DS20 M52 x 2 38 -20 138,3 5.44 63,3 2.49 75,0 2.95

1Z32DS16 M52 x 2 38 -16 122,3 4.82 57,3 2.26 65,0 2.56

1Z32DS20 M52 x 2 38 -20 138,3 5.44 63,3 2.49 75,0 2.95

DKO Female swivel, heavy duty, 45° elbow (DSA)

1E20DSA12 M36 x 2 25 -12 130,3 5.13 85,3 3.36 45,0 1.77 32,0 1.26

1E25DSA12 M42 x 2 30 -12 139,4 5.49 94,4 3.72 45,0 1.77 35,0 1.38

1E25DSA16 M42 x 2 30 -16 164,6 6.48 99,6 3.92 65,0 2.56 35,0 1.38

1Z25DSA16 M42 x 2 30 -16 164,6 6.48 99,6 3.92 65,0 2.56 35,0 1.38

1E32DSA16 M52 X 2 38 -16 177,3 6.98 112,3 4.42 65,0 2.56 39,0 1.54

1E32DSA20 M52 x 2 38 -20 193,3 7.61 118,3 4.66 75,0 2.95 39,0 1.54

1Z32DSA16 M52 X 2 38 -16 177,3 6.98 112,3 4.42 65,0 2.56 39,0 1.54

1Z32DSA20 M52 x 2 38 -20 193,3 7.61 118,3 4.66 75,0 2.95 39,0 1.54

DKO Female swivel, heavy duty, 90° elbow (DSB)

1E20DSB12 M36 x 2 25 -12 120,0 4.72 75,0 2.95 45,0 1.77 65,0 2.56

1E25DSB12 M42 X 2 30 -12 131,4 5.19 86,4 3.40 45,0 1.77 76,0 2.99

1E25DSB16 M42 x 2 30 -16 156,8 6.17 91,8 3.61 65,0 2.56 76,0 2.99

1Z25DSB16 M42 x 2 30 -16 156,8 6.17 91,8 3.61 65,0 2.56 76,0 2.99

1E32DSB16 M52 X 2 38 -16 172,4 6.79 107,4 4.23 65,0 2.56 89,0 3.50

1E32DSB20 M52 x 2 38 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

1Z32DSB16 M52 x 2 38 -16 172,4 6.79 107,4 4.23 65,0 2.56 89,0 3.50

1Z32DSB20 M52 x 2 38 -20 188,4 7.41 113,4 4.46 75,0 2.95 89,0 3.50

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 11

Global Spiral A A A

D L

TTC Fittings D L D L

Spiral TTC Fittings for use

with hose: FC254, FC273, H

FC273B, FC606, FC606B, H

GH466, GH506

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire ORS Swivel ORS Swivel ORS Swivel

construction Straight 45° Elbow 90° Elbow

Hose

Hose Insertion

Fitting Part Number Thd. Size A D Length L H

mm in mm in mm in mm in

Female ORS swivel, straight

1EA12FR12 13/16-12 -12 95,9 3.77 50,9 2.00 45,0 1.77

1EA16FR12 17/16-12 -12 84,6 3.33 39,6 1.56 45,0 1.77

1EA16FR16 17/16-12 -16 119,5 4.71 54,5 2.15 65,0 2.56

1ZA16FR16 17/16-12 -16 119,5 4.71 54,5 2.15 65,0 2.56

1EA20FR16 111/16-12 -16 106,4 4.19 41,4 1.63 65,0 2.56

1EA20FR20 111/16-12 -20 136,7 5.38 61,7 2.43 75,0 2.95

1EA24FR24 2-12 -24 126,9 5.00 48,9 1.93 78,0 3.07

1ZA20FR16 111/16-12 -16 106,4 4.19 41,4 1.63 65,0 2.56

1ZA20FR20 111/16-12 -20 136,7 5.38 61,7 2.43 75,0 2.95

1ZA24FR24 2-12 -24 126,9 5.00 48,9 1.93 78,0 3.07

Female ORS swivel, 45° elbow

1EA12FRA12 13/16-12 -12 118,9 4.68 73,9 2.91 45,0 1.77 24,0 0.94

1EA16FRA12 17/16-12 -12 128,4 5.05 83,4 3.28 45,0 1.77 28,0 1.10

1EA16FRA16 17/16-12 -16 153,4 6.04 88,4 3.48 65,0 2.56 28,0 1.10

1ZA16FRA16 17/16-12 -16 153,4 6.04 88,4 3.48 65,0 2.56 28,0 1.10

1EA20FRA16 111/16-12 -16 163,9 6.45 98,9 3.89 65,0 2.56 31,0 1.22

1EA20FRA20 111/16-12 -20 179,8 7.08 104,8 4.13 75,0 2.95 31,0 1.22

1ZA20FRA16 111/16-12 -16 163,9 6.45 98,9 3.89 65,0 2.56 31,0 1.22

1ZA20FRA20 111/16-12 -20 179,8 7.08 104,8 4.13 75,0 2.95 31,0 1.22

Female ORS swivel, 90° elbow

1EA12FRB12 13/16-12 -12 114,5 4.51 69,5 2.74 45,0 1.77 58,0 2.28

1EA16FRB12 17/16-12 -12 125,6 4.94 80,6 3.17 45,0 1.77 71,0 2.80

1EA16FRB16 17/16-12 -16 150,6 5.93 85,6 3.37 65,0 2.56 71,0 2.80

1ZA16FRB16 17/16-12 -16 150,6 5.93 85,6 3.37 65,0 2.56 71,0 2.80

1EA20FRB16 111/16-12 -16 163,7 6.45 98,7 3.89 65,0 2.56 78,0 3.07

1EA20FRB20 111/16-12 -20 179,6 7.07 104,6 4.12 75,0 2.95 78,0 3.07

1ZA20FRB16 111/16-12 -16 163,7 6.45 98,7 3.89 65,0 2.56 78,0 3.07

1ZA20FRB20 111/16-12 -20 179,6 7.07 104,6 4.12 75,0 2.95 84,0 3.07

12 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Global Spiral A A A

TTC Fittings D L D L D L

Spiral TTC Fittings for use

with hose: FC254, FC273, H

FC273B, FC606, FC606B,

GH466, GH506 H

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire

SAE 37° (JIC) Swivel SAE 37° (JIC) Swivel SAE 37° (JIC) Swivel

construction Straight 45° Elbow 90° Elbow

Hose

Hose Insertion

Fitting Part Number Thd. Size A D Length L H

mm in mm in mm in mm in

SAE 37° (JIC) Swivel

1EA12FJ12 11/16-12 -12 104,2 4.10 59,2 2.33 45,0 1.77

1EA16FJ12 15/16-12 -12 106,6 4.20 61,6 2.43 45,0 1.77

1EA16FJ16 15/16-12 -16 131,8 5.19 66,8 2.63 65,0 2.56

1ZA16FJ16 15/16-12 -16 131,8 5.19 66,8 2.63 65,0 2.56

1EA20FJ16 15/8-12 -16 133,7 5.26 68,7 2.70 65,0 2.56

1EA20FJ20 15/8-12 -20 149,7 5.89 74,7 2.94 75,0 2.95

1ZA20FJ20 15/8-12 -20 149,7 5.89 74,7 2.94 75,0 2.95

1EA24FJ20 17/8-12 -20 167,5 6.59 92,5 3.64 75,0 2.95

1ZA24FJ20 17/8-12 -20 167,5 6.59 92,5 3.64 75,0 2.95

1EA24FJ24 17/8-12 -24 171,5 6.75 93,5 3.68 78,0 3.07

1ZA24FJ24 17/8-12 -24 171,5 6.75 93,5 3.68 78,0 3.07

1EA32FJ32 21/2-12 -32 186,0 7.32 108,0 4.25 78,0 3.07

1ZA32FJ32 21/2-12 -32 186,0 7.32 108,0 4.25 78,0 3.07

SAE 37° (JIC) Swivel, 45° elbow

1EA12FJA12 11/16-12 -12 121,9 4.80 76,9 3.03 45,0 1.77 27,0 1.06

1EA16FJA12 15/16-12 -12 133,4 5.25 88,4 3.48 45,0 1.77 33,0 1.30

1EA16FJA16 15/16-12 -16 158,6 6.25 93,6 3.69 65,0 2.56 33,0 1.30

1EA20FJA16 15/8-12 -16 170,2 6.70 105,2 4.14 65,0 2.56 37,0 1.46

1EA20FJA20 15/8-12 -20 186,2 7.33 111,2 4.38 75,0 2.95 37,0 1.46

1ZA20FJA20 15/8-12 -20 186,2 7.33 111,2 4.38 75,0 2.95 37,0 1.46

1EA24FJA24 17/8-12 -24 208,2 8.20 130,2 5.13 78,0 3.07 43,0 1.69

1ZA24FJA24 17/8-12 -24 208,2 8.20 130,2 5.13 78,0 3.07 43,0 1.69

SAE 37° (JIC) Swivel, 90° elbow

1EA12FJB12 11/16-12 -12 114,5 4.51 69,5 2.74 45,0 1.77 58,0 2.28

1EA16FJB12 15/16-12 -12 125,6 4.94 80,6 3.17 45,0 1.77 71,0 2.80

1EA16FJB16 15/16-12 -16 150,8 5.94 85,8 3.38 65,0 2.56 71,0 2.80

1EA20FJB16 15/8-12 -16 163,9 6.45 98,9 3.89 65,0 2.56 82,0 3.23

1EA20FJB20 15/8-12 -20 179,9 7.08 104,9 4.13 75,0 2.95 82,0 3.23

1ZA20FJB20 15/8-12 -20 179,9 7.08 104,9 4.13 75,0 2.95 82,0 3.23

1EA24FJB24 17/8-12 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

1ZA24FJB24 17/8-12 -24 205,1 8.07 127,1 5.00 78,0 3.07 104,0 4.09

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 13

Global Spiral A

TTC Fittings D L

Spiral TTC Fittings for use

with hose: FC254, FC273,

FC273B, FC606, FC606B,

GH466, GH506

1E Fittings for use on 4-wire

construction Male Pipe

1Z Fittings for use on 6-wire

construction

Hose

Hose Insertion

Fitting Part Number Thd. Size A D Length L HEX

mm in mm in mm in

Male Pipe (MP)

1EA12MP12 3/ -14 NPTF -12 98,7 3.89 53,7 2.12 45,0 1.77 11/4

4

1EA16MP16 1-111/2 NPTF -16 125,4 4.94 60,4 2.38 65,0 2.55 11/2

1ZA16MP16 1-111/2 NPTF -16 125,4 4.94 60,4 2.38 65,0 2.55 11/2

1EA20MP20 1 /4-111/2 NPTF

1 -20 144,8 5.70 69,8 2.75 75,0 2.95 17/8

1ZA20MP20 11/4-111/2 NPTF -20 144,8 5.70 69,8 2.75 75,0 2.95 17/8

1EA24MP24 11/2-111/2 NPTF -24 150,6 5.93 72,6 2.86 78,0 3.07 2

1ZA24MP24 11/2-111/2 NPTF -24 150,6 5.93 72,6 2.86 78,0 3.07 2

1EA32MP32 2-111/2 NPTF -32 153,2 6.03 75,2 2.96 78,0 3.07 25/8

1ZA32MP32 2-111/2 NPTF -32 153,2 6.03 75,2 2.96 78,0 3.07 25/8

Male Pipe (AP)*

1EA12AP12 3/ -14 API -12 109,4 4.31 64,5 2.54 45,0 1.77 11/4

4

1EA16AP16 1-111/2 API -16 136,0 5.36 71,1 2.80 65,0 2.56 11/2

1EA20AP20 11/4-111/2 API -20 155,3 6.12 80,5 3.17 75,0 2.95 17/8

1ZA20AP20 11/4-111/2 API -20 155,3 6.12 80,5 3.17 75,0 2.95 17/8

1EA24AP24 11/2-111/2 API -24 161,2 6.35 83,2 3.28 78,0 3.07 2

1ZA24AP24 11/2-111/2 API -24 161,2 6.35 83,2 3.28 78,0 3.07 2

1EA32AP32 2-111/2* API -32 164,2 6.47 86,2 3.40 78,0 3.07 25/8

1ZA32AP32 2-111/2* API -32 164,2 6.47 86,2 3.40 78,0 3.07 25/8

*Conforms to API 5B thread standard for male pipe fittings.

14 EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005

Assembly Note: These target settings for Aeroquip crimp machines are

provided to aid in establishing actual settings. While the set-

Instructions tings on this chart will give crimp diameters close to, or at the

1/8" (3mm) specified value, the machine operator must check to verify

the actual diameter. Before using these target settings, the

4-SPIRAL -12

crimp machine must be properly calibrated. Consult your

Aeroquip equipment manual for calibration procedures.

B

1E Fittings for use on 4-wire

construction

1Z Fittings for use on 6-wire

Fig. 1 construction

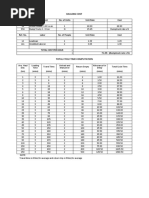

CRIMP FT1209 FT1340

HOSE FITTING DIAMETER AND AND

DASH PART “B” FT1307 FT1360 FT1390 GT9050 GT9050

SIZE NUMBER ± 0.15MM TARGET TARGET TARGET DIE TARGET

PREFIX (± .006 IN) CRIMP CAGE FIG. SETTINGS SETTINGS SETTING NUMBER SETTING

FC254

-12 1E12 36.5 (1.437) FT1209-200-82 1 0.552 756 281 M360 064

-16 1E16 45.4 (1.787) FT1209-200-46 1 0.655 815 252 M450 050

-20 1E20 53.2 (2.094) FT1209-200-14 1 0.023 453 430 M510 220

-24 1E24 61.2 (2.409) FT1390-200-20 1 0.325 626 345

-32 1E32 73.6 (2.898) FT1390-200-23 1 0.467 707 305

FC273 and FC273B

-12 1E12 36.7 (1.445) FT1209-200-82 1 0.524 740 289 M360 084

-16 1E16 45.4 (1.787) FT1209-200-46 1 0.655 815 252 M450 050

-20 1Z20 57.1 (2.248) FT1209-200-15 1 0.328 628 344 M550 204

-24 1Z24 64.1 (2.524) FT1390-200-16 1 0.382 658 329

-32 1Z32 79.1 (3.114) FT1390-200-21 1 0.417 679 319

FC606 and FC606B

-16 1Z16 49.1 (1.933) FT1209-200-46 1 0.108 502 406 M480 100

-20 1Z20 56.2 (2.213) FT1209-200-15 1 0.470 709 304 M550 120

-24 1Z24 64.1 (2.525) FT1390-200-16 1 0.376 654 330 M550 120

GH466

-20 1Z20 56.9 (2.240) FT1209-200-15 1 0.371 652 332 M550 184

-24 1Z24 64.3 (2.531) FT1390-200-16 1 0.343 636 340

GH506

-12 1E12 36.2 (1.425) FT1209-200-82 1 0.595 780 269 M360 034

-16 1E16 44.9 (1.768) FT1209-200-46 1 0.726 855 232 M420 272

-20 1E20 53.5 (2.106) FT1209-200-14 1 0.059 474 420 M510 250

-24 1E24 60.4 (2.378) FT1390-200-20 1 0.453 699 309

-32 1E32 73.6 (2.898) FT1390-200-23 1 0.467 707 305

Assembly Instructions 1. Cut hose to proper length 2. Select proper crimp cage

by subtracting appropriate and machine settings, then

fitting “D” dimensions crimp to specified diameter.

from overall assembly • To achieve full flat crimp

length. locate back edge of sock-

• To determine hose inser- et approximately 1/8"

tion length (L), align end (3mm) from back edge of

of hose to top of sten- crimp jaws as shown in

ciled part number (locat- Figure 1.

ed on the socket taper)

and mark hose where

the socket ends.

• Install fittings onto hose

until socket edge aligns

4-SPIRAL -12

with mark.

FT1390 Crimp Machine

Requires FT1209-200 and FT1390-200

series crimp cages for Global Spiral

TTC Fittings

EATON Aeroquip Global Spiral TTC™Fittings Catalog A-MEFI-MC001-E1 August 2005 15

Eaton Eaton Eaton

14615 Lone Oak Road 20 Rosamond Road Dr.-Reckeweg-Str. 1

Eden Prairie, MN 55344 Footscray D-76532 Baden-Baden

USA Victoria 3011 Germany

Tel: 952 937-9800 Australia Tel: (49) 7221 682-0

Fax: 952 974-7722 Tel: (61) 3 9319 8222 Fax: (49) 7221 682-788

www.hydraulics.eaton.com Fax: (61) 3 9318 5714

© 2005 Eaton Corporation

All Rights Reserved

Printed in USA

Document No. A-MEFI-MC001-E1

Supersedes A-MEFI-MC001-E

August 2005

You might also like

- The Earthbuilders' Encyclopedia (Second Edition, 2001) Joseph M. TibbetsDocument319 pagesThe Earthbuilders' Encyclopedia (Second Edition, 2001) Joseph M. TibbetsKarela Geiger100% (1)

- Knowing and Teaching Elementary MathematicsDocument8 pagesKnowing and Teaching Elementary MathematicsFarhaliza HassimNo ratings yet

- Okb Top SeriesDocument4 pagesOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- ECT Chillers Service and Operation Manual V 3 6 PMDocument83 pagesECT Chillers Service and Operation Manual V 3 6 PMspidershad0% (2)

- 7000 Series Field Operations Manual PDFDocument45 pages7000 Series Field Operations Manual PDFmanzanaNo ratings yet

- Stray Current Corrosion in Submersible PumpsDocument5 pagesStray Current Corrosion in Submersible PumpsMachineryengNo ratings yet

- cp1210 SpecsDocument2 pagescp1210 Specsyoucef alimNo ratings yet

- Catalogo EatonDocument464 pagesCatalogo EatonKatherine Morey AponteNo ratings yet

- Freyssibar enDocument12 pagesFreyssibar enDario MarcoraNo ratings yet

- Đầu Ống Thủy LựcDocument16 pagesĐầu Ống Thủy LựcNguyen Le Thanh VuNo ratings yet

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Triple Crown A-HOOV-TB001-E v10 HRDocument9 pagesTriple Crown A-HOOV-TB001-E v10 HRIGOR ARSENIONo ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- Catalogue Seal Oil CoolerDocument28 pagesCatalogue Seal Oil CoolerSharad KokateNo ratings yet

- 2.5 Inch 6-Spiral Hose: Eaton EC466-40Document8 pages2.5 Inch 6-Spiral Hose: Eaton EC466-40Autieri AutieriNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- Converting Excavator Buckets From J-Series Base Assemblies To The K-SeriesDocument28 pagesConverting Excavator Buckets From J-Series Base Assemblies To The K-Seriespacman2803No ratings yet

- Goldeniso BrochureDocument10 pagesGoldeniso BrochureJose Ramon Rivas MoralesNo ratings yet

- Victaulic Data IGSDocument15 pagesVictaulic Data IGSmas queretaroNo ratings yet

- Rammer DemolitiontoolsDocument36 pagesRammer Demolitiontoolsoguzhan.akselNo ratings yet

- CP Range: Redefining Flow ControlDocument8 pagesCP Range: Redefining Flow ControlSmootherNo ratings yet

- 200706-PD-Overview-for Distributor TrainingDocument96 pages200706-PD-Overview-for Distributor TrainingChester Dalitso MwanzaNo ratings yet

- CR 9 KCDocument4 pagesCR 9 KCLiviu ToaderNo ratings yet

- En TrellflexoilvrDocument2 pagesEn Trellflexoilvrgysytpknm8No ratings yet

- Cat XT ES Hose: The New Standard in Hose PerformanceDocument2 pagesCat XT ES Hose: The New Standard in Hose PerformanceJuan ValdesNo ratings yet

- Pump Installation and Maintenance: Learning OutcomeDocument6 pagesPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatNo ratings yet

- Kuri CONQUERORDocument16 pagesKuri CONQUERORJosh WhiteNo ratings yet

- 12 Pages Book LetDocument12 pages12 Pages Book LetHiresomannavar MahanteshNo ratings yet

- VSL Threadbar SystemsDocument16 pagesVSL Threadbar SystemsNguyen Chau LanNo ratings yet

- Bandas - Alliance2009Document435 pagesBandas - Alliance2009Nelson Gabriel Gallo C.No ratings yet

- CI5000ENGDocument7 pagesCI5000ENGKaliya PerumalNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Mud Pump Consumables - enDocument24 pagesMud Pump Consumables - enflasher_for_nokia100% (1)

- Airmaster HVAC Ducting BrochureDocument12 pagesAirmaster HVAC Ducting BrochureWaseem NaamoNo ratings yet

- Montabert Silver Clip RangeDocument6 pagesMontabert Silver Clip RangeGeorge Kwamina AnamanNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- 9865 0171 01 COP SC19 COP SC19X BrochureDocument4 pages9865 0171 01 COP SC19 COP SC19X BrochureАлександр ПравосудовNo ratings yet

- Sensor Nivel Murphy LS200Document3 pagesSensor Nivel Murphy LS200Sergio PluchinskyNo ratings yet

- 9865 0049 01a COP MD20 BrochureDocument4 pages9865 0049 01a COP MD20 Brochurewaldycotrina105No ratings yet

- Cop Md20Document4 pagesCop Md20Isaac AliagaNo ratings yet

- TERA Joint-Floor Joint System PDFDocument16 pagesTERA Joint-Floor Joint System PDFClaudioNo ratings yet

- Varec 4210A CatalogDocument4 pagesVarec 4210A Catalogking4lifeNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- M/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsDocument8 pagesM/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsBahador YazdiNo ratings yet

- CP PlateCompactorsDocument2 pagesCP PlateCompactorsScott GuimondNo ratings yet

- DTW 1213 Protective FABRIC Sleeve For Single Hydraulic HosesDocument4 pagesDTW 1213 Protective FABRIC Sleeve For Single Hydraulic HosesGANESH GNo ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Us-Ecm-Ps-Aa 0816Document4 pagesUs-Ecm-Ps-Aa 0816Junior Ramirez ReyesNo ratings yet

- FRD Product LineDocument8 pagesFRD Product Linegiapy0000No ratings yet

- Epiroc Drill StringDocument4 pagesEpiroc Drill StringEDI HARTANTO100% (1)

- Sel Brochure Hyd Flexible Spiral Hoses EnglishDocument6 pagesSel Brochure Hyd Flexible Spiral Hoses EnglishAnes HamoudaNo ratings yet

- LS200 HDDocument3 pagesLS200 HDMartin LorenzattoNo ratings yet

- Tri Cone BitsDocument16 pagesTri Cone BitsPeter ForrestNo ratings yet

- Specialty Turbine Flowmeters: NufloDocument2 pagesSpecialty Turbine Flowmeters: NufloJose CameloNo ratings yet

- Rotary Dosing Valve WebDocument5 pagesRotary Dosing Valve WebsaasmexNo ratings yet

- XK Streamflex - Hydraulic Hoses Catalogue - Dec2020Document10 pagesXK Streamflex - Hydraulic Hoses Catalogue - Dec2020Xonken MfgNo ratings yet

- Development of AerofoilDocument6 pagesDevelopment of Aerofoilvaisakp777No ratings yet

- GOA - Casino - Revised BOQDocument6 pagesGOA - Casino - Revised BOQShashikant GatkalNo ratings yet

- Arvis Brochure Plain BearingsDocument28 pagesArvis Brochure Plain BearingsJavierNo ratings yet

- Sami Konf ProgramDocument3 pagesSami Konf ProgramaptureincNo ratings yet

- SchoolLibrary Today TomorrowDocument35 pagesSchoolLibrary Today TomorrowaptureincNo ratings yet

- Hate Crime StatsDocument2 pagesHate Crime StatsaptureincNo ratings yet

- Incidents and Offenses: Hate Crime Statistics, 2006Document5 pagesIncidents and Offenses: Hate Crime Statistics, 2006aptureincNo ratings yet

- Incidents and Offenses: Hate Crime Statistics, 2006Document5 pagesIncidents and Offenses: Hate Crime Statistics, 2006aptureincNo ratings yet

- MDocument179 pagesMaptureincNo ratings yet

- Conference Report: The 7th Conference of Parliamentarians of The Arctic RegionDocument32 pagesConference Report: The 7th Conference of Parliamentarians of The Arctic RegionaptureincNo ratings yet

- Minifacts About NorwayDocument64 pagesMinifacts About NorwayΌλγα ΛυμπεροπούλουNo ratings yet

- Gilles BerhaultDocument2 pagesGilles BerhaultaptureincNo ratings yet

- Slac Pub 10973Document23 pagesSlac Pub 10973aptureincNo ratings yet

- Internet Corporation For Assigned Names and Numbers (Icann) : Objectives and Main ActivitiesDocument9 pagesInternet Corporation For Assigned Names and Numbers (Icann) : Objectives and Main ActivitiesaptureincNo ratings yet

- New Approaches To The Synthesis of Highly HDS Active Silica-Supported Nickel Phosphide CatalystsDocument1 pageNew Approaches To The Synthesis of Highly HDS Active Silica-Supported Nickel Phosphide CatalystsaptureincNo ratings yet

- Concordia Study April 2006Document56 pagesConcordia Study April 2006aptureinc100% (1)

- Peer Reviewed Articles: Bibliography Molecular/Genetic Analysis of GliomaDocument10 pagesPeer Reviewed Articles: Bibliography Molecular/Genetic Analysis of GliomaaptureincNo ratings yet

- The Environment in The NewsDocument38 pagesThe Environment in The NewsaptureincNo ratings yet

- European Diving Junior Championships: (Update: 27 September 2003)Document6 pagesEuropean Diving Junior Championships: (Update: 27 September 2003)aptureincNo ratings yet

- AppendixfDocument11 pagesAppendixfaptureincNo ratings yet

- Ambulance Report 2006Document25 pagesAmbulance Report 2006aptureincNo ratings yet

- Feb 08 Mar 08 Events Att and Activities PT 1Document2 pagesFeb 08 Mar 08 Events Att and Activities PT 1aptureincNo ratings yet

- A11 Alison Sunday RoverDocument1 pageA11 Alison Sunday RoveraptureincNo ratings yet

- AD NHS Staff Survey 2006 RYF FullDocument39 pagesAD NHS Staff Survey 2006 RYF FullaptureincNo ratings yet

- Summer 07 Days OutDocument4 pagesSummer 07 Days OutaptureincNo ratings yet

- Book C No CoversDocument83 pagesBook C No CoversaptureincNo ratings yet

- Knowledge Accelerator Xi R2: Xcelsius 4.5Document3 pagesKnowledge Accelerator Xi R2: Xcelsius 4.5aptureincNo ratings yet

- Digestaug 06Document8 pagesDigestaug 06aptureincNo ratings yet

- PowerAnalytics2 0 Xcelsius 03-04-08Document2 pagesPowerAnalytics2 0 Xcelsius 03-04-08aptureincNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- PHILIPDocument3 pagesPHILIPXDXDXDNo ratings yet

- Cameron - Installation ProceduresDocument110 pagesCameron - Installation Proceduresmsu6383100% (9)

- Yevu 2019Document30 pagesYevu 2019Bilal DawoodNo ratings yet

- Fan Coil UnitsDocument4 pagesFan Coil UnitsAbdul SamadNo ratings yet

- Deformation of SolidsDocument17 pagesDeformation of SolidscrpNo ratings yet

- Usace EM - 1110-3-131Document45 pagesUsace EM - 1110-3-131Alexandre ArnoldNo ratings yet

- U-4 - Design of Riveted Joint - SRMDocument87 pagesU-4 - Design of Riveted Joint - SRMsiddharth GautamNo ratings yet

- Rfi 013 06052023 - LWDocument2 pagesRfi 013 06052023 - LWmanoNo ratings yet

- Basement Study MaterialDocument19 pagesBasement Study MaterialParitosh JambhaleNo ratings yet

- Accumulator: Surge PressuresDocument5 pagesAccumulator: Surge PressuresMubashir KhanNo ratings yet

- Format of Bridge Report Dated 29.08.2020Document8 pagesFormat of Bridge Report Dated 29.08.2020lenkapradipta2011No ratings yet

- Assignment No. 2 Reflection On Virtual Plant Visits - Cement, Steel, Timber, and Concrete and Webinar v.2Document1 pageAssignment No. 2 Reflection On Virtual Plant Visits - Cement, Steel, Timber, and Concrete and Webinar v.2John Rhey Almojallas BenedictoNo ratings yet

- Resource Costs: Labour, Materials and PlantDocument7 pagesResource Costs: Labour, Materials and PlantmohamedNo ratings yet

- Geotechnical INvestigationDocument34 pagesGeotechnical INvestigationWaqas HassanNo ratings yet

- Cera Fibroflex - Brochure 20Document2 pagesCera Fibroflex - Brochure 20Patricia ClarkNo ratings yet

- Saej 2800 V 001Document5 pagesSaej 2800 V 001kyletgerberNo ratings yet

- getPDF JSPDocument5 pagesgetPDF JSPrafNo ratings yet

- Awh Armaturen-Werk Halle GMBH: Ball Float Steam TrapDocument14 pagesAwh Armaturen-Werk Halle GMBH: Ball Float Steam Traprahimi mohamadNo ratings yet

- Precast and Prestressed Folded Plate SlabsDocument10 pagesPrecast and Prestressed Folded Plate SlabsMuna ChiNo ratings yet

- College of Engineering and Architecture Civil Engineering Department On The Job Training Summer 2019 Weekly Accomplishment ReportDocument1 pageCollege of Engineering and Architecture Civil Engineering Department On The Job Training Summer 2019 Weekly Accomplishment ReportMary PaquibotNo ratings yet

- Dicotech PQD Epoxy & Flooring 23dec2020Document223 pagesDicotech PQD Epoxy & Flooring 23dec2020Mohammad Huzefa KanNo ratings yet

- Opensees Geotechnical Capabilities and ApplicationsDocument31 pagesOpensees Geotechnical Capabilities and ApplicationsMahmoud ElkhedrNo ratings yet

- Hauling Cost: Ref. No. Equipment No. of Units Unit Rate CostDocument54 pagesHauling Cost: Ref. No. Equipment No. of Units Unit Rate CostLindoNo ratings yet

- Instrument Installation: NIOEC-SP-70-02Document23 pagesInstrument Installation: NIOEC-SP-70-02Mohammad AminiNo ratings yet

- The Glass Accessories From HdsafeDocument153 pagesThe Glass Accessories From HdsafeHdsafe Glass door manufactureNo ratings yet