Saic A 2011

Saic A 2011

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

Saic A 2011

Saic A 2011

Uploaded by

Anonymous 4e7GNjzGWOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saic A 2011

Saic A 2011

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

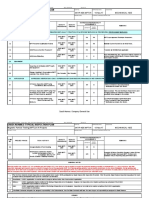

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2010)

Rev 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation

SAIC-A-2011

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

31-Mar-10

DATE APPROVED

QR NUMBER

MECH-

31-Aug-11

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

Test Preparation - General Requirements ... USE SATR-A-2001, 2002, 2003, 2004, 2005 & SATR-A-2006 as req'd.

A1

Pressure Test Package meets Attachment 1 minimum content

requirements. (Reviewed/approved/signed). See SAIC-A-2003.

Note 1: Package contents were reviewed carefully.

Note 2: Document deficiencies are noted in package for action.

SAEP-1160,

Section 8

A2

Pre-Test Punchlisting is complete (per procedure). All "A" items are

cleared & accepted* (*Test Pkg Flow Chart is also signed off)

Note: "A" items are Pre-test Punchlist items that must be complete prior

to safe pressure testing of systems per approved procedure.

SAEP-1160,

Section 8

A3

Permanent Flange set installations are documented/accepted.

Note: Flanges that will not be disturbed after the pressure test are

marked/identified and tightened & QC records are per approved

procedure & available. See also SAIC-L-2014 & SATR-L-2001.

SAEP-1160,

Section 8

A4

System Flushing and internal Cleanliness is complete. Test Package

Flow chart is signed-off. New systems and equipment in Plants were

cleaned per approved procedures per SAES-L-350.

SAES-A-004,

Para. 8.1.2

A5

Component Safeguards (temporary removals/test exclusions) exist for

new systems to prevent damage caused by filling, venting, draining,

flushing or testing. These are itemized on Reinstatement and Pre-Test

Checklists and are found in Test Pkgs/Procedures.

See Safeguards listed in Attachment 2.

SAES-A-004,

Section 8

A6

Temporary supports shall be installed prior to hydrostatic testing, and

flushing of the piping if they were determined to be required per SAES-L150.

SAES-A-004,

Para. 8.5.2

A7

Expansion joints and spring hangers or spring supports are provided with

temporary restraints where needed to prevent excessive travel or

deformation under the test loads. (Field Verify)

SAES-L-150,

Para. 6.4

A8

All joints including welded joints are accesible and left exposed for visual

leak detection during the strength test. External coating and priming of

such joints are not allowed unless approved.

Note: This excludes joints subject to 24-hr recorded test

SAES-L-150,

Para. 7.3

A9

Work permit is obtained for pressure testing and associated work within

restricted areas, as per G.I. 2.100, Work Permit System.

G.I.-2.102,

Para. 5.1.6

A10

Equipment & appurtenances (Attachments, auxilliary equipment, etc) that

are not adequate for test pressures are isolated from test.

Provisions made to ensure that no over pressuring can occur in

equipment that is not being tested

G.I.-2.102,

Para. 5.1.7

A11

If an isolation valve is used for a test boundary, in lieu of test blind,

ensure that no overpressurization damage can occur in any equipment

beyond the isolation valve (due to valve leak-by) by:

a) Reduction of test pressure (rule = 1.1 times valve press rating)

b) Open isolation valve drain (or nearest adjacent low-point drain)

c) Relief valves placed on both sides of isolation valve. (Para. 7.3)

d) Personnel are posted during testing to identify any valve leak-by.

e) Personnel control/stop pressurization (Valve leak-by evidence).

See Remarks Section (Safety Note 1)

G.I.-2.102,

Para. 5.1.7,

SAES-A-004

Para 8.3

A12

MSDS or Chemical Hazard Bulletins is available/reviewed for all

chemicals handled (corrosion inhibitor, bactericide, chlorine, oxygen

scavenger, etc). Written procedure to safely handle chemicals during

testing & to ensure proper disposal after testing is approved.

G.I.-2.102,

Para. 5.1.9

Page 1 of 5

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2010)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation

PROJECT TITLE

ITEM

No.

Rev 4

DATE APPROVED

SAIC-A-2011

31-Aug-11

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

A 13

Personal protective equipment (PPE) is available and utilized as

shown on these sheets and bulletins for chemical handling.

G.I.-2.102,

Para. 5.2.1

A 14

Access/Egress for Test areas is marked & warning signs posted to alert

approaching personnel of pressure testing activities.

G.I.-2.102,

Para. 5.1.11

A 15

Where a road parallels within 30 m (100 ft.) of an aboveground pipeline

being tested, traffic shall be diverted or stopped during the test. If this is

not practical, the area Loss Prevention offices should be contacted to

confirm that the test can be conducted safely.

G.I.-2.102,

Para. 5.1.11

If non-Saudi Aramco facilities will be exposed in a pressure test of SA

A 16 facilities, the proponent organization of the test shall so inform the Saudi

Aramco Affairs representative prior to the test.

G.I.-2.102,

Para. 5.1.12

A 17

31-Mar-10

SAIC NUMBER

Copy of the approved pressure testing procedure & the GI-2.102 are

available at site. Test Personnel are safety trained/experienced.

Verification of Actual Test Set-up & SIS Sheet Data:

B1

Test Set-up* matches actual test arrangement (drawings).

Note 1: *Pressure Test Diagram with an appropriate Legend for

symbols, Test Manifold Arrangement (& pressure hoses/piping) show all

high points (vents), low points (drains), gage locations & provide

documentation that attests to the actual test as performed. In event of

testing accident, Loss Prevention Dept must be able to use diagrams &

sketches to recreate actual test set-up/conditions.

Note 2: Testing of multiple lines (test pkgs) on projects can be done by

proper hose arrangement, filling & venting to save time. Sketch & show

the actual hose arrangement(s) in test packages. Correct any errors in

arrangement found, initial & date sketches.

SAEP-1160,

Section 8

Bullet Item 2

B2

SIS Sheet Data (pressure, limiting factor, medium & temperature) is

checked* for accuracy against the test application and is correct.

*Note: Human error (test package calcs) is common. Inspectors

responsible for testing are able to spot gross errors & prevent unsafe

testing & overpressurization of systems & components.

SAEP-1160,

Section 8

Bullet Item 2

Test Manifold & Appurtanances (Piping, Fittings, Hoses)

C1

Pressure testing manifolds were separately pressure tested to at least

1.2 times system test pressure. (Manifold Test Report/Cert)

SAES-A-004

Para 5.5.4

C2

Pressure rating or design of test manifold components* (isolation valves,

pipe nipples, fittings) exceed system test pressure by 20%.

See Safety Note 1 in Remarks for isolation valves

G.I.-2.102,

Para. 5.1.5.5

C3

Manifold Arrangement Drawings attest to the following:

A) Fabrication was per code construction with component details listed

such as Class, size, schedule, type isolation valve, etc.

B) Maximum Safe Test Pressure Rating based on limiting factor.

C) Each test manifold is identified with a unique number (certificate)

D) Shows actual arrangement including hose configuration used

Note 1: Manifold permanent marking (unique ID #, pressure rating) is

legible, traceable & certified (Engineering support docs).

G.I.-2.102,

Para. 5.1.2.5

C4

Manifolds proposed for use on projects without detailed code

construction certification (Engineering calcs & Inspection) must be

evaluated for fitness and safety. Provide necessary details and support

test manifolds with any necessary calculations (SIS sheet) and the

appropriate visual Inspection and any necessary NDE.

Note: Unknown piping schedules can be determined by using a UT

Thickness meter. Weld quality is verified by VT or RT.

G.I.-2.102,

Para. 5.1.5.5

C5

A blow down valve of adequate pressure rating is installed to

depressurize the system safely (easily accessible to operator).

G.I.-2.102,

Para. 5.1.5.3

C6

Test piping pressure tested to at least 20 percent above test

pressure of the system under test. (Exception: Final connection

between test manifold and system under test may be tested to

maximum system test pressure only if a higher test pressure is

impractical.)

G.I.-2.102,

Section 5.1.5

C7

Paddles or spectacle blinds & other fabricated test items used to

isolate test sections are at least the same code class rating of systems

under test or are supported by appropriate code calcs. See Remarks,

Critical Safety Note 2

SAES-A-004

Para. 7.3

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

SAES-A-004,

Para. 5.6.1

QR NUMBER

Page 2 of 5

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2010)

Rev 4

31-Mar-10

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation

DATE APPROVED

SAIC-A-2011

PROJECT TITLE

31-Aug-11

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

Test Relief Valve(s)

D1

Relief valve is located in the system under test and near the test pump

with Isolation valves on the inlet and outlet of the relief valve sealed open

during the test. (SAEP-1160, Bullet Item # 3)

G.I.-2.102,

Para. 5.5

D2

Relief valve(s) of adequate capacity (*SIS Sheet & Calcs available) are

set to relieve at 5%* above the hydrotest pressure.

*Note: Test pressures less than 85% of SMYS can have relief valves

set at 10% above test pressure. Verify SIS sheets calcs.

SAES-A-004

Para 5.5.1

D3

Relief valve(s) are tested, dated, and tagged (as valid) for a period of one

week for project pressure tests. Stickers are legible & valid.

SAES-A-004

Para 5.5.1

Pressure Gages and Recorders

E1

A minimum of two pressure gages are required for test systems, with

accuracy within 5% of one another.

Note 1: When large systems are tested, Inspection personnel will

determine the need for additional gages.

Note 2: Elevation changes (hydrostatic head considerations) & hot

weather create pressure testing problems with frequent popping of relief

valves. For this reason, gage accuracy within 2% is best.

Note 3: Careful handling of delicate instruments like test gages is

practiced by test crews. No gage damage or mishandling is found.

SAES-A-004

Para 8.1.5.4

E2

Pressure gages and pressure recorders are calibrated within (1) month

prior to test. Stickers applied indicate latest calibration date.

SAES-A-004

Para 8.1.5.2

E3

Avoid the following typical examples of poor practices:

Testing equipment with the test gauge located at the bottom of the

equipment reading the test pressure,including the head of test water

G.I.-2.102,

Sec.4 &

SAES-A-004,

Para 5.3

E4

All gages have a range such that the test pressure is within 30% to 80%

of the full range.

SAES-A-004

Para 8.1.5.3

Temperature Gages and Recorders (When Required, ie: 24-hr Recorded Tests)

F1

Bubble Leak Test (associated with Pneumatic strength/service test)

surface metal temperatures shall be recorded and compatible with test

methods (including test solution used to detect leaks).

Note: ASME V, Art 10, Man. App. 1, Table 1-1021 requires surface metal

temp measurements during testing (detailed in procedure). Record

maximum (direct sun) & minimum test temperatures.

SAES-A-004

Para 5.6.3

F2

Thermocouples are installed to obtain accurate pipe metal temperature

measurements and to determine the acceptance of the pressure test

where pressure variations due to test water temperature changes occur,

such as in cross-country pipelines.

SAES-L-150,

Para. 11.3

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS: Critical Safety Note 1: Surveys of test manifolds used on projects have resulted in many findings of inadequate ratings for isolation

valves. Test manifolds for testing specific pressure rating Classes require isolation valves of the next higher class. Example: Manifolds for testing Class

300 # systems require Class 600 # isolation valves as a general rule. For Pressure tests against closed seats follow the 110% rule for safe test

pressure calculation. See ASME B16.34, Para 7.2 as applicable. Also, this same requirement must be carefully considered when determining test

pressures where an isolation valve serves as a test boundary limit and the valve seat will be pressurized. Ensure system test pressures are reduced to

110% as applicable and show the valve seat as the test "limiting factor".

Safety Note 2: Fabricated test implements of proper

code construction receive inspection and properly identification/marking for pressure rating, inspection acceptance/fitness (Insp Ok, initial, date). Never

allow uninspected non-code test implement use or those that are unfit for testing (deteriorated, damaged, heavily corroded). Unsafe/unfit test

implements found are reported/removed ASAP from Company Projects.

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (14-Dec-2009)

2. GI-2.102, Saudi Aramco General Instruction-Pressure Testing Safely, (28 October, 2008)

3. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (1-Nov-2008)

4. Pro Forma Contract Schedule Q (Project Specific)

5. SAEP-1160 (2-Aug-2009)

Contractor / Third-Party

Construction Representative*

Saudi Aramco

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

T&I Witnessed

QC Record Reviewed

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Work Verified

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 3 of 5

Work Verified

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2010)

Rev 4

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation

SAIC NUMBER

SAIC-A-2011

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

MECH-

Attachment 1 - SAEP-1160 Test Pkg Minimum Requirements

Page 4 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2010)

Rev 4

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pressure Test Preparation

SAIC NUMBER

SAIC-A-2011

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

MECH-

Attachment 2 - Component Safeguard Summary

Note: This Summary Checklist has been developed with concurrence of CSD

1. INSTALL THESE COMPONENTS IN LINE ONLY AFTER THOROUGH FLUSHING:

Soft seated valves & control valves (SAES-A-004, Para. 8.1.3)

2. INSTALL THESE COMPONENTS IN LINE AFTER FLUSHING & TEST COMPLETION (ON REINSTATEMENT):

Components in new piping systems which interfere with filling, venting, draining or flushing shall not be installed until after line

flushing and pressure testing are completed. This includes Procedures/Test Package Instruction or details about specific component

care as listed below (SAES-A-004, Para 8.1.4):

a) Orifice plates -- Flow nozzles -- Sight glasses (incl. vessel trim) -- Venturies -- Meters (positive displacement, turbine)

b) In-line equipment (as determined by Proponent) includes valve care (corrosion, cleaning, lay-up considerations). A list shall be

obtained by Contractor from COMPANY relative to Component Safeguards. Contractor shall request specific instruction for specific

component safeguards from Company (Proponent, SAPMT, SA Inspection)

3. INSTALL THESE COMPONENTS (EXCLUDED FROM PRESSURE TEST) ON FINAL REINSTATEMENT:

Note: The following list defines the equipment that shall be excluded from the in-situ pressure testing of the tested system. Also,

other unlisted sensitive equipment or as designated by SA Inspector can be added (SAES-A-004-Para 8.2):

a) Rotating machinery, such as pumps, turbines and compressors;

b) Strainers and filter elements

c) Pressure relieving devices, such as rupture disks and pressure relief valves;

d) Locally mounted indicating pressure gauges, where the test pressure will exceed their scale range;

e) Equipment that cannot be drained (This includes valve cavities. See Valve Care below).

f) Instrument Devices.

g) Other unlisted sensitive equipment (propose exclusion in test package)

h) Equipment designated by Saudi Aramco Inspector (Approves procedures that list specific equipment in scope)

CSD VALVE SAFEGUARDS & CARE (TYPICAL FOR AMBIENT LAY-UP)

Valve Field Hydrotest Practice (separate from line/system testing) assures adequate preservation as listed below. Valves or

other equipment that are field tested prior to installation in a pipeline, plant, or other facility are likely to experience corrosion

damage if this is not performed with adequate diligence and precautions.

a) The following applies to valve trims Type 1, 4, 6, 7, 8, and 8A and all solid Type 400 SS (13 CR) valves.

b) Plan prior field testing of valves to minimize the length of time between test and installation in the system.

c) All critical isolation valves that are tested shall be tested with water containing less than 50 ppm chlorides. The water shall

contain 0.5% by weight (5 grams per liter) Cortec VpCI 609. (Note:Chemical cost would be about $0.30 per liter. VpCI 609 is

biodegradable so there are no problems with its use. (See Environmental Protection Dept.)

d) After hydrotesting, gate valves will have their gates raised to allow full draining of water. Allow adequate drainage time. All

traces of visible water shall be removed from the valve body and seat area. Blow dry with clean compressed air.

e) Apply manufacturer approved lubricant plus 10% Cortec VpCI-329 (SAP 1000173887) added to all interior critical surfaces such

as seal areas. Ball valves shall be full operated to distribute inhibited lubricant between ball and body.

Constructed Piping Hydrotest Practice (Valve Safeguards)

a) Hydrotest plans for constructed field equipment shall be designed to minimize exposure of valves to hydrotest water. Unless it is

absolutely unavoidable, critical isolation valves (Field Hydrotested) shall be installed after completion of hydro.

b) Piping systems shall be thoroughly flushed before hydrotesting to remove wind-blown sand, construction debris, and any other

foreign matter. Flushing water shall be the same quality as the hydrotest water. Hydrotest shall be performed immediately after

flushing or the line shall be properly layed-up per SAES-A-007 Procedures (30-day rule).

c) If any 400 series (13 CR) trimmed valves are pre-installed & hydrotested in the line, utilize test gaskets and thoroughly drain test

water immediately after the test. Where complete draining is impossible (no valve body drain plug), valves shall be removed

immediately after test, dried with clean compressed air and re-lubricated before "ambient" lay-up. Ensure that there is no

debris in the seat area.

d) Any 400 series (13 CR) trimmed valves that are pre-installed and hydrotested in the line, and that have body or seat drains and

are in place when field pipework is hydrotested shall be treated with Cortec VpCI 609 by blowing into all possible valve injection

locations immediately after completion of the hydrotest and draining of all water.

e) Any 400 series (13Cr) trimmed valves that are pre-installed welded-in-place shall be liberally coated with inhibited lubricant

before final welding into the line.

f) Safeguards for 300 series (316 SS, etc) trimmed valves require similar care to assure complete cavity draining. Corrosion

inhibitors used shall be approved by CSD.

Page 5 of 5

You might also like

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (2)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Method Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemDocument10 pagesMethod Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemRagu Rajan100% (1)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (5)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Introduction To iRICDocument277 pagesIntroduction To iRICtri radinal saputraNo ratings yet

- Pike Perch Farming in The NetherlandsDocument4 pagesPike Perch Farming in The NetherlandsAini ZahraNo ratings yet

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- SAIC-A-2020 Rev 2Document3 pagesSAIC-A-2020 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- SAIC-A-2009 Rev 0Document3 pagesSAIC-A-2009 Rev 0philipyapNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Saic A 2013Document6 pagesSaic A 2013jerinNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- SAIC-A-2015 Rev 7Document8 pagesSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- 32 Samss 027Document30 pages32 Samss 027naruto256No ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- SATIP-F-001-01 Fired Heaters Field InstallationDocument3 pagesSATIP-F-001-01 Fired Heaters Field InstallationhossamalsherbinyNo ratings yet

- Saep 1161Document51 pagesSaep 1161Anonymous 4IpmN7OnNo ratings yet

- SAIC-L-2074 Rev 0Document1 pageSAIC-L-2074 Rev 0philipyapNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Satr-W-2020Document1 pageSatr-W-2020Joni Carino SuniNo ratings yet

- Saep 1630Document10 pagesSaep 1630faisalqr100% (1)

- Saudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 NdeDocument3 pagesSaudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 Ndenadeem shaikhNo ratings yet

- !indx SaipDocument2 pages!indx Saipimrankhan22No ratings yet

- 2019 Saes W 016Document18 pages2019 Saes W 016smdriyazbashaNo ratings yet

- 00 Saip 06Document4 pages00 Saip 06Selvakpm06No ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- 1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Document2 pages1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Anonymous S9qBDVkyNo ratings yet

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 pageSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapNo ratings yet

- SAIC-A-2007 Rev 3Document12 pagesSAIC-A-2007 Rev 3imrankhan22No ratings yet

- 175 010800Document3 pages175 010800Abu Anas M.Salaheldin100% (1)

- S.A.E.P. - 1145Document20 pagesS.A.E.P. - 1145silvrsurfr637No ratings yet

- SAIC-K-4041 Rev 7Document2 pagesSAIC-K-4041 Rev 7shahzadaNo ratings yet

- 1 Scope: SAEP-302Document8 pages1 Scope: SAEP-302nasirNo ratings yet

- 01 Samss 039 PDFDocument14 pages01 Samss 039 PDFMohamed Soliman100% (1)

- 34 Samss 619Document14 pages34 Samss 619naruto256No ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- Resume Atif Fashion DesignerDocument2 pagesResume Atif Fashion DesignerRipper AgeNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- 175 043000Document1 page175 043000Fahad AhmadNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saep 1144Document23 pagesSaep 1144Amit shahNo ratings yet

- Saep 308Document19 pagesSaep 308brecht1980No ratings yet

- SAIC-A-2013 Rev 0Document2 pagesSAIC-A-2013 Rev 0philipyapNo ratings yet

- SAIC-A-2023 Rev 0Document2 pagesSAIC-A-2023 Rev 0philipyapNo ratings yet

- SAIC-A-2011 Rev 6 Pressure TestDocument8 pagesSAIC-A-2011 Rev 6 Pressure Testpookkoya thangalNo ratings yet

- SAIC-A-2015 Rev 2Document9 pagesSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saic A 2011Document10 pagesSaic A 2011tayyab aliNo ratings yet

- SAIC-A-2010 Rev 0Document3 pagesSAIC-A-2010 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 pagesRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- 07 Atmospheric Foam Concentrate Storage TanksDocument3 pages07 Atmospheric Foam Concentrate Storage TanksmbloexNo ratings yet

- Optimized Sponge Iron Making ProcessDocument10 pagesOptimized Sponge Iron Making Processawneet_semc100% (1)

- Shubunkin GoldfishDocument10 pagesShubunkin GoldfishSwarna RekhaNo ratings yet

- Bio Methane Into The Gas Grid A Guide For ProducersDocument24 pagesBio Methane Into The Gas Grid A Guide For ProducersAhmet DarelNo ratings yet

- 3 The - Biochemical - CycleDocument3 pages3 The - Biochemical - CycleKynthel KyellNo ratings yet

- Lecturenote - 1628442650hs-II, Lecture On Ch-1Document35 pagesLecturenote - 1628442650hs-II, Lecture On Ch-1sent T100% (1)

- REACT Report On Fenimore LandfillDocument49 pagesREACT Report On Fenimore LandfillLouis C. HochmanNo ratings yet

- SS3 2ND Term Geography E-NotesDocument25 pagesSS3 2ND Term Geography E-Notespalmer okiemuteNo ratings yet

- 464 - Rural and Urban Regional Planning (EMT 425) - NotesDocument73 pages464 - Rural and Urban Regional Planning (EMT 425) - NotesJason VillagomezNo ratings yet

- Plumbing Key AnswerDocument7 pagesPlumbing Key AnswerStanley Scott ArroyoNo ratings yet

- Detail of Clean Out: Vertical To Horizontal Cleanout Floor Cleanout Ceiling CleanoutDocument1 pageDetail of Clean Out: Vertical To Horizontal Cleanout Floor Cleanout Ceiling CleanoutAlbert GalagNo ratings yet

- Preparation of Ester Derivatives of Fatty Acids For GC AnalysisDocument27 pagesPreparation of Ester Derivatives of Fatty Acids For GC Analysism_m_hamedi3866No ratings yet

- Chapter 10 ReportDocument22 pagesChapter 10 Reporthello whelloNo ratings yet

- USAID/Nigeria Seeking Applications For Small Town WASH ActivityDocument3 pagesUSAID/Nigeria Seeking Applications For Small Town WASH ActivityjosefNo ratings yet

- Landscape Water Efficiency Guide PDFDocument51 pagesLandscape Water Efficiency Guide PDFbhupsjangir100% (1)

- Anarock - Mumbai RedefinedDocument52 pagesAnarock - Mumbai RedefinedVilom OzaNo ratings yet

- Region VDocument15 pagesRegion VTrista MagdaraogNo ratings yet

- Water Purification in Natural SystemsDocument3 pagesWater Purification in Natural SystemsColdWinterKid25% (4)

- RR-0209 Mold TestingDocument5 pagesRR-0209 Mold TestingbamboobuckNo ratings yet

- Minor ElementsDocument50 pagesMinor ElementsnaldsonNo ratings yet

- Environmental Science HandoutDocument10 pagesEnvironmental Science HandoutChrisel Calibo RaineNo ratings yet

- Ten Plumbing Safety TipsDocument2 pagesTen Plumbing Safety TipsSamantha Meril PandithaNo ratings yet

- Manual 803, 1003, 1103, 1303Document68 pagesManual 803, 1003, 1103, 1303Snehasis DespandeNo ratings yet

- Reverse Osmosis Desalination Plant in Nuweiba City (Case Study)Document16 pagesReverse Osmosis Desalination Plant in Nuweiba City (Case Study)RonaldNo ratings yet

- Lecture 4Document7 pagesLecture 4Dheeraj BudhlakotiNo ratings yet

- 2 Related Topics Automatic IrrigationDocument13 pages2 Related Topics Automatic IrrigationSftvsn Giovanni TandogNo ratings yet

- Boracay Foundation Inc v. Province of AklanDocument23 pagesBoracay Foundation Inc v. Province of AklanCareenNo ratings yet