HDS Reactor Model

Uploaded by

pcyadav8HDS Reactor Model

Uploaded by

pcyadav8Journal of Petroleum Science Research (JPSR)

Two Dimensional Dynamic Modeling of

Hydrodesulphurization Reactor

Peyman Mahinsa1,2, Mohammad Taghi Sadeghi2, Hamid Ganji1*, Saeed Shokri1

1

Process Development Division, Research Institute of Petroleum Industry, Tehran, IRAN

Faculty of Chemical Engineering, Iran University of Science and Technology, Tehran, IRAN

ganjih@ripi.ir

Abstract- In this research a pseudo-homogeneous twodimensional model was proposed to describe the dynamic

behavior of a fixed-bed pilot-plant hydrodesulphurization

reactor. The catalyst pellet used in this reactor was Co-Mo/Al2O3.

At first, using the experimental data, a power law kinetic model

was developed for hydrodesulphurization reaction. Then a

pseudo-homogeneous two-dimensional dynamic model was

proposed to describe the concentration profile in the reactor bed.

The simulation obtained with the proposed dynamic model

showed good agreement with experimental data and the sulfur

concentration error in the reactor outlet was 3.8 percent

compared to the experimental data. Two dimension modeling

revealed that the radial variation of sulfur concentration is more

in the reactor inlet than the outlet, but in general the

concentration profile can be considered in one dimension.

Unsteady reactor modeling showed that the transition time was

higher in the reactor outlet and estimated to be 11667 seconds.

Keywords- Hydrotreating reactor, Dynamic Modeling, Two

Dimension

I. INTRODUCTION

Hydrodesulphurization (HDS) is an important process in

oil industry. The HDS process is essential to obtain fuels with

improved quality and low polluting compounds and it is

usually conducted in a fixed-bed catalytic reactor either in

single gas-phase flow or two phases (gas and liquid) [1-3] and

usually a trickle-flow regime may occur. In the trickle flow

regime, the liquid reactant flows downward through the

reactor in the form of thin laminar film droplets around the

solid catalyst [4-6]. Modeling and simulation are commonly

applied in the design, performance analysis, optimization, and

scale-up of HDS reactors. More papers in modeling and

simulation are in steady state but reliable three-phase reactor

modeling and simulation should be based on dynamic

heterogeneous models, which can be used not only for scaleup, start-up and operability studies, but also to obtain a

meaningful continuity path to the steady state of the reactor,

since dynamic models provide a realistic description of the

transient states of three-phase reactors [7, 8]. The study of the

dynamic behavior of the three phase reactor also helps

designing the best control system in order to obtain a safe,

efficient and profitable operation. Although the dynamic

models are more complicated to formulate and to solve, they

should be preferred over steady-state models because the

numerical solution strategy of dynamic models is more robust

than the solution of steady-state models [9-12].

Numerous papers have been published on steady state

modeling of hydrotreating reactors. However, studies on

dynamic modeling of such reactors are reported less in the

open literature among which the two dimensional models are

rarely reported. Julcour et. al.[13] investigated the dynamic of

the three phase up-flow fixed bed reactor using a nonisothermal heterogeneous model. They compared a simplified

model with an extended one and concluded that the diffusion

of hydrocarbons is not limiting agent so that the simplified

model predicts accurately the reactor transient behavior.

Hastaoglue and Jibril[12] modeled the transient gas-solid

reactions in a fixed-bed reactor and applied to HDS reaction

with the Langmuir-Hinshelwood mechanism. They validated

the model through a comparison of experimental data from

naphtha HDS pilot plant. Mederos et. al[14] investigated a

dynamic heterogeneous one-dimensional model of trickle-bed

hydrotreating

reactor.

They

considered

the

hydrodesulphurization,

hydrodenitrogenation

and

hydrodearomatization reactions and axial changes in

concentration, partial pressure and temperature profiles were

obtained with time. Chen and Ring[15] considered a pseudo

homogeneous two dimensional reactor model of a fixed-bed

hydrotreater and studied concentration and temperature

profiles. Their model considered the heat conduction in the

thermowell to predict the temperature difference between the

thermowell and the catalytic bed. They concluded that if this

difference is too high and ignored, could cause errors in the

interpretation of pilot plant data. Mederos and Ancheyta [2]

developed a dynamic heterogeneous one-dimensional model

to predict the behavior of trickle-bed hydrotreating reactor

with co-current and counter-current operation. They

concluded that counter-current mode can have great potential

to be used for deep hydrodesulfurization of oil fractions since

it minimizes the inhibiting effect of some products in reactor

zones where these species tend to concentrate in concurrent

operation.

This paper reports experimental work and simulation

results on the steady-state and dynamic behavior of a fixedbed pilot-plant HDS reactor.

II. EXPERIMENTAL SECTION

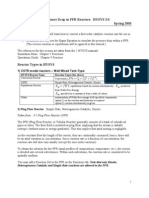

The experiments were done in an isothermal pilot-plant

reactor. The schematic diagram of the pilot plant setup is

shown in fig. 1.

Fig 1. Schematic diagram of the pilot plant setup

JPSR Vol. 1, Iss. 2, Jul. 2012 PP. 32-35 http://www.jpsr.org American V-King Scientific Publishing

- 32 -

Journal of Petroleum Science Research (JPSR)

The unit has been operated at temperature range of 340380 C and pressure range of 48-60 bar. Feed volumetric flow

rate was 60-260

. The reactor length and internal diameter

were 200 and 1.9 cm respectively and the catalytic bed length

catalyst.

was 35 cm which was filled with CoMo/

Above and below catalyst bed were packed with glass beads

to provide a uniform gas and liquid flow.

Hydrodesulfurization unit needs two different kinds of feeds.

One for activation that consists of Dimethyl disulfide,

hydrogen sulfide and carbon disulfide and other is used for

separation of sulfur.

III. MATHEMATICAL MODEL

The reactor which has been used in pilot plant was

operated isothermally. In this research we considered a

pseudo-homogeneous two-dimensional model with axial

convective and radial dispersion of mass. The dynamic mass

balance equation in the catalyst bed is

C

(1)

a type of weight residual method (WRM) for elliptic PDE

with two spatial domains. The orthogonal collocation is

applied on both domains to yield a set of algebraic equations

[16-18].

IV. RESULTS

A. Kinetics Evaluation

The following power law rate equations were considered

for sulfur conversion although other expressions are available:

HDS

(2)

Where i=S, H2S, H2

1.

2.

Isothermal reactor

Plug flow regime

Equation 4 can be written as:

C .T

(3)

.T

It was assumed that all holes of catalyst pellet were filled

with liquid.

A. Model initial and boundary conditions and solution

For steady state and dynamic modeling it is necessary to

define initial and boundary conditions. The initial and

boundary conditions for liquid and solid phases are

summarized in tables 1 and 2 respectively.

TABLE 1 INITIAL CONDITIONS

Condition

z=0

0rR

0<z<

0rR

z= B

0rR

Liquid phase

Solid phase

64402.1 exp

CS .

(7)

B. Steady State Results

The reactor governing equations have to be solved

simultaneously to obtain sulfur axial concentration profile. Fig.

2 shows how sulfur concentration decreases in the liquid

phase through the reactor.

120

100

80

60

40

20

0.05

0.1

0.15

0.2

Length of reactor (m)

0.25

0.3

0.35

Fig 2. Sulfur axial concentration profile in liquid phase (feed rate: 140 cc/hr ,

P=50 bars inlet temperature=632.15 K)

Liquid phase

Solid phase

z=0

0rR

z= B

0rR

r=0

0<z< B

r=R

0<z< B

HDS

0

0

TABLE 2 BOUNDRY CONDITIONS

condition

(6)

LHSV

Kinetics parameters were obtained using Eq. 6 and fitting

experimental data where the following kinetics equation was

obtained with linear regression of 98.7 percent:

Concentration of sulfur (Mol/m3)

Were Cf and CP are sulfur concentration at reactor inlet

and outlet respectively.

Using Eq. 2, the effectiveness factor can be calculated with

the following equation:

(5)

In which three kinetics parameters ( , E, n) were

unknown and to calculate them two basic assumptions were

considered:

(4)

exp

Where i=S, N, A

For catalyst pellets:

kCS

The numerical method chosen to solve the developed

partial differential equations is orthogonal collocation method,

The results reveal that there exists good agreement with

experimental data and the sulfur concentration error in the

reactor outlet was 3.8 percent compared to the experimental

data and conversion was 99 percent. The partial pressure of

H2S in gas phase increases smoothly along the reactor bed as

shown in Fig 3. But the H2S concentration at the liquid phase

increases and then decreases (Fig. 4). This phenomenon can

be interpreted by mass transfer resistances. When the H2S

concentration in the liquid phase increases, the driving force

of mass transfer from liquid to gas phase increases

accordingly. This decreases the H2S concentration in liquid

phase.

JPSR Vol. 1, Iss. 2, Jul. 2012 PP. 32-35 http://www.jpsr.org American V-King Scientific Publishing

- 33 -

Journal of Petroleum Science Research (JPSR)

-7

x 10

Sulfur Concentration (mol/m3)

Partial Pressure H2S (MPa)

3.5

3

2.5

2

1.5

1

0.5

0

0

0.05

0.1

0.15

0.2

Length of reactor (m)

0.25

0.3

0.35

1.12

1.1

1.08

0

0.2

80

0.8

C. Dynamic Simulation

Figure 6 shows the variation of sulfur concentration at

initial part of the catalytic bed (8.75 cm) and also at the

reactor outlet with time. It was observed that the transition

time was higher in the reactor outlet and estimated to be

11667 seconds

60

50

40

30

20

10

0

0

0.05

0.1

0.15

0.2

Length of reactor (m)

0.25

0.3

0.35

0.16

17.4

0.14

0.1

0.06

0.04

0.02

0.2

0.4

0.6

0.8

0.4

0.6

0.8

Dimensionless Radius (r/R)

A

8.2

8.15

8.1

8.05

0.2

Dimensionless Radius (r/R)

B

6.2

6.15

20

30

40

50

60

Dimensionless Time

70

80

90

100

0.08)

V. CONCLUSIONS

A mathematical reactor model has been developed to

numerically simulate the steady-state and dynamic behavior of

a pilot-plant hydrotreater. The pilot plant reactor has been

operated isothermally. Simulation results revealed suitable

agreement with the pilot-plant experimental data. Simulation

results indicated that the axial sulfur concentration decreases

in the liquid phase while the hydrogen sulfide partial pressure

increases smoothly in the gas phase. Hydrogen sulfide

concentration in the liquid phase increases first and then

decreases. The reason of this behavior can be interpreted by

mass transfer driving force from liquid to gas phase which

increases when the H2S Concentration in liquid phase

increases. Two dimension modeling result indicated that there

is not much radial concentration variation and one

dimensional approach can be considered. Dynamic simulation

results proved that the transition time to steady state increases

when reach to the reactor outlet.

Nomenclature

6.1

= Molar concentration of component i in the liquid phase,

6.05

6

0

10

time is

17.1

8

0

reactor outlet

0.08

Fig 6. Sulfur concentration at 8.75 cm and the reactor outlet as a function of

time (Feed rate: 140 cc/hr, P=50 bars inlet temperature=632.15 K, Dimension

17.2

17

0

Z=8.75 CM

0.12

0

0

17.3

Sulfur Concentration (mol/m3)

0.6

70

Radial sulfur concentration profiles were obtained at

various axial sections of the reactor (Fig.5). Note that the

radial variation of sulfur concentration decrease when

approach the end of reactor.

Sulfur Concentration (mol/m3)

0.4

Dimensionless Radius (r/R)

D

Fig 5. Sulfur radial concentration profile in liquid phase at various bed

sections (feed rate: 140 cc/hr , P=50 bars, inlet temperature=632.15 K ,

A=0.25 Z, B=0.5 Z, C=0.75 Z, D=Z)

Fig 4. H2S concentration profile in liquid phase

Sulfur Cincentration(mol/m3)

1.14

Sulfur Concentration (Mol/m3)

Concentration of H2S (Mol/m3)

Fig 3. Partial pressure of H2S in gas phase

1.16

0.2

0.4

0.6

Dimensionless Radius (r/R)

C

0.8

= Molar concentration of component i inside the solid

filled with liquid phase,

= Catalyst particle diameter, m

JPSR Vol. 1, Iss. 2, Jul. 2012 PP. 32-35 http://www.jpsr.org American V-King Scientific Publishing

- 34 -

Journal of Petroleum Science Research (JPSR)

,

= Effective diffusivity of component i inside a porous

catalyst,

= Molecular hydrogen

= Mass axial dispersion coefficient of liquid phase,

= Mass radial dispersion coefficient of liquid phase,

LHSV= Liquid hourly space velocity, (

n= Reaction Order

P= Reactor Pressure, (MPa)

r= Radial reactor coordinate, (m)

= Radius of particle, (m)

=Rate of reaction j per unit of catalyst mass in the liquid

phase,

t= Time, s

= Dimensionless Time

z= Axial reactor coordinate, m

Greek Letters

= Catalyst bed void fraction or catalyst bed porosity

= Catalyst particle porosity

= Catalyst bulk (or bed) density,

= Density at process conditions of f phase,

= Catalyst effectiveness factor of reaction j in the liquid

phase

Subscripts

App= Apparent

= Hydrogen sulfide

L= Liquid phase

S= solid phase, inside catalyst pellet

= Apparent reaction rate constant

f= Phase (gas, liquid or solid)

REFERENCES

[1] Vishwakarma, S. K.(2007) Sonochemical and Impregnated Co-W/Al O Catalysts:Performances and Kinetic Studies on Hydrotreatment of

2 3 Gas Oil.

Light

[2] Mederos, F.S., Ancheyta, J. (2007) Mathematical modeling and

simulation of hydrotreating reactors: Cocurrent versus countercurrent

operationsApplied Catalysis A: General 332 (1) ,821.

[3] Ramachandran, P. A., Chaudhari, R. V. Three pPhase Catalytic Reactors;

Gordon and Breach Science Publishers Inc.: London, 1983.

[4] Doraiswamy, L.K., Sharma, M.M. (1984) Heterogeneous Reactions:

Analysis, Examples, and Reactor Design; John Wiley & Sons: New York,

1984; Vol. 2, 374 pp.

[5] Bhaskar, M., Valavarasu, G. (2002) Meenakshisundaram, A., Balaraman,

K. S. Application of a Three Phase Heterogeneous Model to Analyse the

Performance of a Pilot Plant Trickle Bed Reactor. Pet. Sci. Technol., 20

(3&4): 251268.

[6] Froment, G.F., Depauw, G.A., Vanrysselberghe, V. (1994) Kinetic

Modeling and Reactor Simulation in Hydrodesulfurization of Oil

Fractions. Ind. Eng. Chem. Res., 33 (12): 29752988.

[7] Fabin S. Mederosa Ignacio Elizalde, Jorge Ancheyta, Steady-State and

Dynamic Reactor odels for Hydrotreatment of Oil Fractions: A Review,

Mxico, 2009.

[8] Tarhan, M.O. (1983) Catalytic Reactor Design. McGraw-Hill: New York;

372 pp.

[9] Chen, J., Ring, Z., Dabros, T. (2001) Modeling and Simulation of a

Fixed-Bed Pilot-Plant Hydrotreater. Ind. Eng. Chem. Res., 40 (15):

32943300.

[10] Warna , J., Salmi, T. (1996) Dynamic Modelling of Catalytic Three

Phase Reactors. Comput. Chem. Eng., 20 (1): 3947.

[11] Salmi, T., Warna , J., Toppinen, S., Ronnholm, M., Mikkola, J.P.

(2000) Dynamic

Modelling of Catalytic Three-Phase Reactors for

Hydrogenation and Oxidation Processes. Braz. J. Chem. Eng., 17 (47):

10231035.

[12] Hastaoglu, M.A., Jibril, B.E. (2003) Transient Modeling of

Hydrodesulfurization in a Fixed- Bed Reactor. Chem. Eng. Comm., 190

(2): 151170.

[13] Julcour C., Chaudhari R. V., Lelann J M., Wilhelm A. M., Delmas H. ,

Dynamic modeling of three phase upflow fixed-bed reactor including

pore diffusion, Chem. Eng. And Proc., 41(2002)311-320.

[14] Mederos F. S., Rodriguoz J., Ancheyta J., and Arce E., Dynamic

modeling and simulation of catalytic hydrotreating reactor, Energy &

Fuels, 20(2006)936-945.

[15] Chen, J., Ring, Z., Dabros, T. (2001) Modeling and Simulation of a

Fixed-Bed Pilot-Plant Hydrotreater. Ind. Eng. Chem. Res., 40 (15):

32943300.

[16] Villadsen, J., Michelsen, M.L., (1978) Solutions of Differential Equations

Models by Polynomial Approximation. Prentice-Hall, Inc., New Jersey.

[17] Hilfebrand, F., (1965) Method of Applied Mathematics, second ed.,

Prentice-Hall, Inc., New Jersey.

[18] Mickley, H.S., Sherwood, T.K., Reed, C.E. (1990) Applied Mathematics

in Chemical Engineering, second ed., McGraw-Hill, Delhi.

B= Referred to reactor catalytic bed

JPSR Vol. 1, Iss. 2, Jul. 2012 PP. 32-35 http://www.jpsr.org American V-King Scientific Publishing

- 35 -

You might also like

- Mathematical Modelling of A Hydrocracking Reactor For Triglyceride Conversion To Biofuel: Model Establishment and ValidationNo ratings yetMathematical Modelling of A Hydrocracking Reactor For Triglyceride Conversion To Biofuel: Model Establishment and Validation11 pages

- Methanol Synthesis From Syngas in A Slurry ReactorNo ratings yetMethanol Synthesis From Syngas in A Slurry Reactor2 pages

- Catalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 2003No ratings yetCatalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 200330 pages

- En Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessNo ratings yetEn Analysis of Thermal Efficiency Limit of Steam Methane Reforming Process8 pages

- Energy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering CollegeNo ratings yetEnergy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering College32 pages

- Process Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 4No ratings yetProcess Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 421 pages

- Modeling and Simulation of Methanation Catalytic Reactor in Ammonia PlantNo ratings yetModeling and Simulation of Methanation Catalytic Reactor in Ammonia Plant8 pages

- Propane Dehydrogenation in Modified Membrane Porous ReactorNo ratings yetPropane Dehydrogenation in Modified Membrane Porous Reactor7 pages

- Modeling and Simulation of A Hydrocracking UnitNo ratings yetModeling and Simulation of A Hydrocracking Unit18 pages

- Chemical Plant Design For The Production of Ammonia Through Haldor Topsoe Process Route: Simulation Using Plant Design Management SystemNo ratings yetChemical Plant Design For The Production of Ammonia Through Haldor Topsoe Process Route: Simulation Using Plant Design Management System9 pages

- Biodiesel Plant Optimisation Study by Using Aspen-HYSYS Process SimulatorNo ratings yetBiodiesel Plant Optimisation Study by Using Aspen-HYSYS Process Simulator5 pages

- Chapter 2 - Fundamentals of Fixed-Bed ReactorsNo ratings yetChapter 2 - Fundamentals of Fixed-Bed Reactors21 pages

- Fixed-Bed Reactor Modeling For Methanol To Dimethyl Ether (DME)100% (2)Fixed-Bed Reactor Modeling For Methanol To Dimethyl Ether (DME)37 pages

- ENCH 609 Presentation Group G2 (Sulfinol)No ratings yetENCH 609 Presentation Group G2 (Sulfinol)21 pages

- Isocracking - Hydrocracking For Superior Fuels and Lubes ProductionNo ratings yetIsocracking - Hydrocracking For Superior Fuels and Lubes Production9 pages

- ADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDFNo ratings yetADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDF29 pages

- Fluidized Bed For Catalytic Polymerization100% (1)Fluidized Bed For Catalytic Polymerization41 pages

- 40 Tcbiomass2019 Presentation David Dayton PDFNo ratings yet40 Tcbiomass2019 Presentation David Dayton PDF20 pages

- Methane Syngas Methanol MicroprocessingNo ratings yetMethane Syngas Methanol Microprocessing14 pages

- Design of A New, 100,000 Metric Ton Per Year, Cumene Production FacilityNo ratings yetDesign of A New, 100,000 Metric Ton Per Year, Cumene Production Facility4 pages

- Modeling of Trickle Bed Reactor For Hydrotreating of Vacuum Gas Oils: Effect of Kinetic Type On Reactor ModelingNo ratings yetModeling of Trickle Bed Reactor For Hydrotreating of Vacuum Gas Oils: Effect of Kinetic Type On Reactor Modeling6 pages

- Modeling Residue Hydroprocessing in A Multi-Fixed-Bed Reactor SystemNo ratings yetModeling Residue Hydroprocessing in A Multi-Fixed-Bed Reactor System11 pages

- Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsFrom EverandMultiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsNo ratings yet

- Computational Pharmaceutics: Application of Molecular Modeling in Drug DeliveryFrom EverandComputational Pharmaceutics: Application of Molecular Modeling in Drug DeliveryDefang OuyangNo ratings yet

- Modeling of Fixed Bed Catalytic Reactors: Computers & Chemical Engineering December 1985No ratings yetModeling of Fixed Bed Catalytic Reactors: Computers & Chemical Engineering December 198512 pages

- Generac Doosan 22.0 Liter V12 Diesel 22.0DTA Generator Engine Parts ManualNo ratings yetGenerac Doosan 22.0 Liter V12 Diesel 22.0DTA Generator Engine Parts Manual63 pages

- Consolidated Punchlist - OM - r3 - 5feb19No ratings yetConsolidated Punchlist - OM - r3 - 5feb192 pages

- Power System Studies - CT&VT Sizing Calculation - LeafletNo ratings yetPower System Studies - CT&VT Sizing Calculation - Leaflet6 pages

- catalog-series-353-integral-pilot-ss-dual-stage-asco-apac-en-9666258No ratings yetcatalog-series-353-integral-pilot-ss-dual-stage-asco-apac-en-96662583 pages

- Mechanical Technology PAT GR 12 2024 (Automotive) EngNo ratings yetMechanical Technology PAT GR 12 2024 (Automotive) Eng48 pages

- Barometer Is Used To Measure Atmospheric PressureNo ratings yetBarometer Is Used To Measure Atmospheric Pressure14 pages

- HL-01A Hydrogen Liquefaction - A Review of The Fundamental Physic, Engineering Practice and FutureNo ratings yetHL-01A Hydrogen Liquefaction - A Review of The Fundamental Physic, Engineering Practice and Future42 pages

- As GROVE - Physics and Technology of Semiconductor DevicesNo ratings yetAs GROVE - Physics and Technology of Semiconductor Devices198 pages

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsNo ratings yetShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & Recommendations2 pages

- Main Switchboard: Burma Shipyard Hull No.No ratings yetMain Switchboard: Burma Shipyard Hull No.27 pages

- EN DX140W-7 DX160W-7 Brochure D4600863 04-2023No ratings yetEN DX140W-7 DX160W-7 Brochure D4600863 04-202328 pages

- AMNS Boldrocchi ENDA 5800 SO2, NO, CO, Co2, O2 DrawingNo ratings yetAMNS Boldrocchi ENDA 5800 SO2, NO, CO, Co2, O2 Drawing7 pages

- Fintech and Sustainable Development Assessing The ImplicationsNo ratings yetFintech and Sustainable Development Assessing The Implications90 pages

- Mathematical Modelling of A Hydrocracking Reactor For Triglyceride Conversion To Biofuel: Model Establishment and ValidationMathematical Modelling of A Hydrocracking Reactor For Triglyceride Conversion To Biofuel: Model Establishment and Validation

- Methanol Synthesis From Syngas in A Slurry ReactorMethanol Synthesis From Syngas in A Slurry Reactor

- Catalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 2003Catalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 2003

- En Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessEn Analysis of Thermal Efficiency Limit of Steam Methane Reforming Process

- Energy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering CollegeEnergy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering College

- Process Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 4Process Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 4

- Modeling and Simulation of Methanation Catalytic Reactor in Ammonia PlantModeling and Simulation of Methanation Catalytic Reactor in Ammonia Plant

- Propane Dehydrogenation in Modified Membrane Porous ReactorPropane Dehydrogenation in Modified Membrane Porous Reactor

- Chemical Plant Design For The Production of Ammonia Through Haldor Topsoe Process Route: Simulation Using Plant Design Management SystemChemical Plant Design For The Production of Ammonia Through Haldor Topsoe Process Route: Simulation Using Plant Design Management System

- Biodiesel Plant Optimisation Study by Using Aspen-HYSYS Process SimulatorBiodiesel Plant Optimisation Study by Using Aspen-HYSYS Process Simulator

- Fixed-Bed Reactor Modeling For Methanol To Dimethyl Ether (DME)Fixed-Bed Reactor Modeling For Methanol To Dimethyl Ether (DME)

- Isocracking - Hydrocracking For Superior Fuels and Lubes ProductionIsocracking - Hydrocracking For Superior Fuels and Lubes Production

- ADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDFADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDF

- Design of A New, 100,000 Metric Ton Per Year, Cumene Production FacilityDesign of A New, 100,000 Metric Ton Per Year, Cumene Production Facility

- Modeling of Trickle Bed Reactor For Hydrotreating of Vacuum Gas Oils: Effect of Kinetic Type On Reactor ModelingModeling of Trickle Bed Reactor For Hydrotreating of Vacuum Gas Oils: Effect of Kinetic Type On Reactor Modeling

- Modeling Residue Hydroprocessing in A Multi-Fixed-Bed Reactor SystemModeling Residue Hydroprocessing in A Multi-Fixed-Bed Reactor System

- Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsFrom EverandMultiphase Catalytic Reactors: Theory, Design, Manufacturing, and Applications

- Computational Pharmaceutics: Application of Molecular Modeling in Drug DeliveryFrom EverandComputational Pharmaceutics: Application of Molecular Modeling in Drug Delivery

- Modeling of Fixed Bed Catalytic Reactors: Computers & Chemical Engineering December 1985Modeling of Fixed Bed Catalytic Reactors: Computers & Chemical Engineering December 1985

- Generac Doosan 22.0 Liter V12 Diesel 22.0DTA Generator Engine Parts ManualGenerac Doosan 22.0 Liter V12 Diesel 22.0DTA Generator Engine Parts Manual

- Power System Studies - CT&VT Sizing Calculation - LeafletPower System Studies - CT&VT Sizing Calculation - Leaflet

- catalog-series-353-integral-pilot-ss-dual-stage-asco-apac-en-9666258catalog-series-353-integral-pilot-ss-dual-stage-asco-apac-en-9666258

- Mechanical Technology PAT GR 12 2024 (Automotive) EngMechanical Technology PAT GR 12 2024 (Automotive) Eng

- HL-01A Hydrogen Liquefaction - A Review of The Fundamental Physic, Engineering Practice and FutureHL-01A Hydrogen Liquefaction - A Review of The Fundamental Physic, Engineering Practice and Future

- As GROVE - Physics and Technology of Semiconductor DevicesAs GROVE - Physics and Technology of Semiconductor Devices

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & Recommendations

- AMNS Boldrocchi ENDA 5800 SO2, NO, CO, Co2, O2 DrawingAMNS Boldrocchi ENDA 5800 SO2, NO, CO, Co2, O2 Drawing

- Fintech and Sustainable Development Assessing The ImplicationsFintech and Sustainable Development Assessing The Implications