0 ratings0% found this document useful (0 votes)

23 viewsF Rictional Head Loss Affecting Pipeline Diametre With Different Material

F Rictional Head Loss Affecting Pipeline Diametre With Different Material

Uploaded by

SswahyudiThis document calculates the frictional head loss for gas flowing through polyethylene, steel, and steel pipes of different diameters. It provides the pipe diameters, gas flow rate, pipe roughness values, kinematic viscosity of gas, Reynolds numbers, relative pipe roughness, friction factors from Moody diagrams, and frictional head loss per meter calculated using the Darcy-Weisbach formula. The frictional head loss was highest for the 4 inch steel pipe at 0.209 m and lowest for the 6 inch steel pipe at 0.124 m.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

F Rictional Head Loss Affecting Pipeline Diametre With Different Material

F Rictional Head Loss Affecting Pipeline Diametre With Different Material

Uploaded by

Sswahyudi0 ratings0% found this document useful (0 votes)

23 views3 pagesThis document calculates the frictional head loss for gas flowing through polyethylene, steel, and steel pipes of different diameters. It provides the pipe diameters, gas flow rate, pipe roughness values, kinematic viscosity of gas, Reynolds numbers, relative pipe roughness, friction factors from Moody diagrams, and frictional head loss per meter calculated using the Darcy-Weisbach formula. The frictional head loss was highest for the 4 inch steel pipe at 0.209 m and lowest for the 6 inch steel pipe at 0.124 m.

Original Description:

formulas

Original Title

Hydraulic Calculation2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document calculates the frictional head loss for gas flowing through polyethylene, steel, and steel pipes of different diameters. It provides the pipe diameters, gas flow rate, pipe roughness values, kinematic viscosity of gas, Reynolds numbers, relative pipe roughness, friction factors from Moody diagrams, and frictional head loss per meter calculated using the Darcy-Weisbach formula. The frictional head loss was highest for the 4 inch steel pipe at 0.209 m and lowest for the 6 inch steel pipe at 0.124 m.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views3 pagesF Rictional Head Loss Affecting Pipeline Diametre With Different Material

F Rictional Head Loss Affecting Pipeline Diametre With Different Material

Uploaded by

SswahyudiThis document calculates the frictional head loss for gas flowing through polyethylene, steel, and steel pipes of different diameters. It provides the pipe diameters, gas flow rate, pipe roughness values, kinematic viscosity of gas, Reynolds numbers, relative pipe roughness, friction factors from Moody diagrams, and frictional head loss per meter calculated using the Darcy-Weisbach formula. The frictional head loss was highest for the 4 inch steel pipe at 0.209 m and lowest for the 6 inch steel pipe at 0.124 m.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

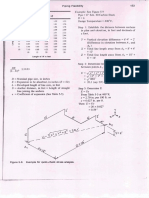

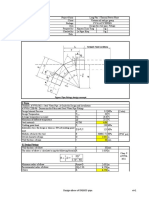

Frictional Head Loss Affecting Pipeline Diametre with Different Material

Pipeline Data

Polyethylene Pipeline Diameter

Steel Pipeline Diameter

D1 := 5 in

D2 := 6 in

D3 := 4 in

m

Gas Flowrate in Pipeline

v1 := 3.5

Polyethylene Pipe Roughness

1 := 5 10- 6

Steel Pipe Roughness

Kinematic Viscosity of Gas

2 := 3 10- 4

:= 3 10- 5

Friction Head Loss Calculation for Polyethylene Pipe

Reynolds number calculation

v1 D 1

Re1 :=

Re1 = 1.482

104

kg

Relative Pipe Roughness Calculation

1

1

= 3.937 10- 5

D1

m

Friction factor for Polyethylene Pipe Based on moody diagram

f1 := 0.02796

( )

Friction Head Loss each meter length using Darcy-Weisbach Formula

N s

2

Hf 1

( v1 )

:= -f

2

1 2 g D = -0.138

1

Friction Head Loss Calculation for Steel Pipe

Reynolds number calculation

v1 D 2

Re2 :=

Re2 = 1.778 104

kg

Relative Pipe Roughness Calculation

2

1

= 1.969 10- 3

D2

m

Friction factor for Polyethylene Pipe Based on moody diagram

f2 := 0.03031

( v1 )

:= -f

Friction Head Loss each meter length using Darcy-Weisbach Formula

Hf 2

2 2 g D = -0.124

2

Friction Head Loss Calculation for Steel Pipe

Reynolds number calculation

v1 D 3

Re3 :=

Re3 = 1.185 104

kg

Relative Pipe Roughness Calculation

D3

= 2.953 10- 3

Friction factor for Polyethylene Pipe Based on moody diagram

f3 := 0.03402

( v1 )

:= -f

Friction Head Loss each meter length using Darcy-Weisbach Formula

Hf 3

3 2 g D = -0.209

3

You might also like

- Pipe Line Flexibility Manual CalculationDocument20 pagesPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Ameron Calculation Manual For Bondstand GRE Pipe SystemsDocument16 pagesAmeron Calculation Manual For Bondstand GRE Pipe Systemsgbuckley9630No ratings yet

- AWWA C208 Elbow enDocument4 pagesAWWA C208 Elbow enjaimecneto1No ratings yet

- Experiment 12 Fluid Friction 1Document4 pagesExperiment 12 Fluid Friction 1Shahid KhanNo ratings yet

- Fluida Minggu Ke-3: Oleh: Siti NurhasanahDocument16 pagesFluida Minggu Ke-3: Oleh: Siti NurhasanahDesrizal ANo ratings yet

- Celerity of Exposed Steel Pipes:-: (A) For A Pipe Anchored at The Upper End and Without Expansion JointsDocument5 pagesCelerity of Exposed Steel Pipes:-: (A) For A Pipe Anchored at The Upper End and Without Expansion JointsRajashekar.PNo ratings yet

- Aspecte HidrauliceDocument31 pagesAspecte HidrauliceFlorentina SuduNo ratings yet

- AWWA C208 Elbow enDocument4 pagesAWWA C208 Elbow enEkhtor AcostaNo ratings yet

- Pipe SizingDocument19 pagesPipe SizingroyalcomNo ratings yet

- Pip SizingDocument26 pagesPip SizingSatpal SinghNo ratings yet

- Pressure Loss in Vacuum Lines With Water Vapour: The Diagram in Fig. 1, Is Calculat-Ed From The FormulaDocument2 pagesPressure Loss in Vacuum Lines With Water Vapour: The Diagram in Fig. 1, Is Calculat-Ed From The FormulaEsther Valladares NuñezNo ratings yet

- Steam Pipeline SizingDocument25 pagesSteam Pipeline SizingniteshchouhanNo ratings yet

- Pipeline Design-HydrotestDocument19 pagesPipeline Design-HydrotestFaridah ZahraNo ratings yet

- Heat Loss Insulated PipeDocument32 pagesHeat Loss Insulated PipeDougMooreNo ratings yet

- Questions - SteamDocument44 pagesQuestions - SteamMaxmore KarumamupiyoNo ratings yet

- Roughness Coefficient & Piping Schedule No22Document18 pagesRoughness Coefficient & Piping Schedule No22Joon EeoNo ratings yet

- Ductile Iron Piping PDFDocument9 pagesDuctile Iron Piping PDFsmani170100% (1)

- Pipes and Pipe Sizing - International Site For Spirax SarcoDocument19 pagesPipes and Pipe Sizing - International Site For Spirax Sarcokarthikraja21100% (1)

- Assignment LabDocument19 pagesAssignment LabHidayah HumairaNo ratings yet

- App DDocument26 pagesApp DgerardomediavillaepnNo ratings yet

- 5 - Hydro Power PlantsDocument73 pages5 - Hydro Power Plants2003_335100% (1)

- 3.3 Design Considerations: 3.3.1 Codes, Standards and SpecificationsDocument7 pages3.3 Design Considerations: 3.3.1 Codes, Standards and SpecificationsUmar KidaNo ratings yet

- Friction Loss Along A Pipe: ME 337 Fluid Mechanics LabDocument14 pagesFriction Loss Along A Pipe: ME 337 Fluid Mechanics LabOk SokNo ratings yet

- Prediction of Pressure Drop For Tubulent Flow in 90 BendsDocument3 pagesPrediction of Pressure Drop For Tubulent Flow in 90 BendsNakkolopNo ratings yet

- Figure: Pipe Fittings Design Concept I. Datas: 1 1 PD R D+ 2 3 2tf PDDocument2 pagesFigure: Pipe Fittings Design Concept I. Datas: 1 1 PD R D+ 2 3 2tf PDNobitaKunNo ratings yet

- Energy EquationDocument4 pagesEnergy EquationAnonymous VA3KeEwzNo ratings yet

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Pipes Technical InformationDocument20 pagesPipes Technical InformationSreenubabu KandruNo ratings yet

- Energy Loses in PipesDocument6 pagesEnergy Loses in PipesrianrureNo ratings yet

- Elbow and Bend Fluid Mechanics ReportDocument13 pagesElbow and Bend Fluid Mechanics ReportPira CsonNo ratings yet

- FLuid FlowDocument13 pagesFLuid FlowDuncoh Dun100% (1)

- Analytical Calculation of Automatic Sprinkler Fire Extinguishing System (Sfes)Document20 pagesAnalytical Calculation of Automatic Sprinkler Fire Extinguishing System (Sfes)IRJMETS JOURNALNo ratings yet

- Mechanical Engineering DepartmentDocument7 pagesMechanical Engineering Departmentحسين عمريNo ratings yet

- Applied Fluid Mechanics Objective: Volume Flow Rate Method II-A: No Minor LossesDocument15 pagesApplied Fluid Mechanics Objective: Volume Flow Rate Method II-A: No Minor LossesMara TorresNo ratings yet

- Triangular Pit CalculationDocument14 pagesTriangular Pit CalculationmathiNo ratings yet

- F.M.H.M.PR.8,9,10 PracticalDocument15 pagesF.M.H.M.PR.8,9,10 PracticalnitinmiskeNo ratings yet

- Single Phase Flow Line SizingDocument21 pagesSingle Phase Flow Line SizingvictorvikramNo ratings yet

- Presentation 2Document16 pagesPresentation 2Eslam ShorbasiNo ratings yet

- Energy Loses in Pipes PDFDocument6 pagesEnergy Loses in Pipes PDFAlexander MugabeNo ratings yet

- Viscous Flow in Viscous Flow in Duct DuctDocument19 pagesViscous Flow in Viscous Flow in Duct DuctMuhammad Amni FitriNo ratings yet

- Full Experiment 3Document33 pagesFull Experiment 3Nnitesh PalaNo ratings yet

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenNo ratings yet

- Rclect5 11Document24 pagesRclect5 111man1bookNo ratings yet

- Lab - Session - 03 (1) FM 46Document7 pagesLab - Session - 03 (1) FM 46Areeba MujtabaNo ratings yet

- Pump Station Check ListDocument2 pagesPump Station Check ListGerhard HornNo ratings yet

- M6 CV RC G 007 (R2)Document89 pagesM6 CV RC G 007 (R2)ksshashidharNo ratings yet

- Abaco Di Moody-Scabrezza (P 6-10, Fig 6-9 e Tab 6-1)Document1 pageAbaco Di Moody-Scabrezza (P 6-10, Fig 6-9 e Tab 6-1)UmbybotNo ratings yet

- Design CalculationsDocument31 pagesDesign CalculationsmrnaeemNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- 20" Mol Replacement Project: Data Sheet PipelineDocument7 pages20" Mol Replacement Project: Data Sheet PipelineAdvisNo ratings yet

- New Spirolite PipeDocument39 pagesNew Spirolite PipeMario LunaNo ratings yet

- Total Head Calculation of Pipe Line and Pump StationDocument7 pagesTotal Head Calculation of Pipe Line and Pump Stationthakur_raghabNo ratings yet

- Din 11851 Edited VersionDocument22 pagesDin 11851 Edited VersionSenthilKumarShanmughamNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Instruments Index RO Plant YTMDocument8 pagesInstruments Index RO Plant YTMSswahyudiNo ratings yet

- PCV 02Document1 pagePCV 02SswahyudiNo ratings yet

- BOLOK Thermodynamic Characteristic Curves of Condensing TurbineDocument19 pagesBOLOK Thermodynamic Characteristic Curves of Condensing TurbineSswahyudiNo ratings yet

- Electric Valve Actuator (DZW)Document14 pagesElectric Valve Actuator (DZW)Sswahyudi100% (1)

- CuprionDocument93 pagesCuprionSswahyudiNo ratings yet

- Tnu TT 10 Pro DWG 003 AllDocument9 pagesTnu TT 10 Pro DWG 003 AllSswahyudiNo ratings yet

- Manual Book TurbinDocument130 pagesManual Book TurbinSswahyudiNo ratings yet

- PL O Tfqdu - Ot : L"Dcoej, Q ) S?: Po P./JDocument14 pagesPL O Tfqdu - Ot : L"Dcoej, Q ) S?: Po P./JSswahyudiNo ratings yet

- Catalog PDFDocument85 pagesCatalog PDFSswahyudiNo ratings yet

- Digest SchaniderDocument56 pagesDigest SchaniderSaka AdityaNo ratings yet

- Basic Design and Engineering Package PDFDocument164 pagesBasic Design and Engineering Package PDFSswahyudi100% (6)

- A2 - Open, Pre Cabled Motor Starters - P - EN (Dgcat)Document22 pagesA2 - Open, Pre Cabled Motor Starters - P - EN (Dgcat)SswahyudiNo ratings yet

- ABB Thermal and Electronic Overload RelaysDocument40 pagesABB Thermal and Electronic Overload RelaysVicktor GranadosNo ratings yet

- Research Article: Cathodic Protection of Pipeline Using Distributed Control SystemDocument8 pagesResearch Article: Cathodic Protection of Pipeline Using Distributed Control SystemSswahyudiNo ratings yet