ER-56.03 (Skid Design and Fabrication)

ER-56.03 (Skid Design and Fabrication)

Uploaded by

NicolasCopyright:

Available Formats

ER-56.03 (Skid Design and Fabrication)

ER-56.03 (Skid Design and Fabrication)

Uploaded by

NicolasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ER-56.03 (Skid Design and Fabrication)

ER-56.03 (Skid Design and Fabrication)

Uploaded by

NicolasCopyright:

Available Formats

The contents of this document are proprietary and confidential.

They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

ENGINEERING REFERENCE manufacture in part or in whole without written permission from Ariel Corporation.

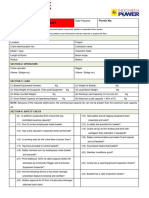

Skid Design and Fabrication

A skid/package mechanical analysis is required to provide a properly engineered system to

the end user. The Packager or a third party conducts the analysis for all unproven driver-

/compressor combinations. This is especially critical for projects such as:

• Any first of a driver and/or compressor combination.

• Any first of a frame class.

• Offshore platforms.

• FPSO installations.

• Pile-mounted skids.

NOTE: The Packager must retain any supporting calculations made by the Packager and/or

consultant. The Packager must consider dynamic as well as static forces. Combined Rod

Load and Unbalanced Forces and Couples data are available within the Ariel Performance

Program.

Package Design Requirements

1. The skid/pedestal should transmit shaking forces to the foundation and provide adequate structural

support with proper tie-down under piping, and other critical components.

2. Provide sufficient skid stiffness and strength so the compressor mounts flat without bending or twist-

ing the compressor frame, crosshead guide, or cylinder. All frame and crosshead guide mounting

points should be supported by full depth cross members.

3. When installing equipment to the skid, ensure all mounting points are flat and parallel to compressor

feet to avoid angular and parallel soft foot and facilitate ER-82 compliance. The mounting method

depends heavily on packager ability to duplicate skid flatness at installation. Methods to mount the

frame to the skid include:

• Grouted sole plates

• Grout chocks

• Careful rail or full bed grouting

• Welded steel chocks

NOTE: Flatness and parallelism can be difficult to achieve using this method. It is recom-

mended to machine steel chocks after welding to avoid angular soft foot, which requires

the use of step shims or re-machining in the field. Step shims create point loading and

will not provide adequate contact between the foot and chock.

• Threaded adjustable chocks

NOTE: Though threaded adjustable chocks have been used with success under smaller

frame classes, they are not permitted under JGC:D:F:Z:U:B:V and KBZ:U:B:V frames.

Keep in mind the compressor frame is to be the stationary component of the alignment

train.

4. Provide compressor hold down bolting in accordance with ER-26. Bolt lengths extending through

only the compressor foot and I-beam flange are typically insufficient to prevent loosening.

For the most recent edition of this document, visit www.arielcorp.com.

Page 3, "Head End Support Required Features", 4th bullet: "Attach the vertical support of the 14 018882 12-20-13

HES to a full depth skid beam flange so it is directly supported by the web of the beam. Gussets 13 019052 10-21-13

17 are required between the skid beam flanges directly beneath the HES vertical supports." was

"Attach the vertical support of the HES to the skid beam web section, not to the flange. Gussets

12

11

018694

015759

1-25-13

9-21-12

17

16

201600689

201600207

7-21-16

6-1-16

are required between the beam flanges." 10 016437 3-4-11 15 019638 12-8-14

VER. DESCRIPTION VER. ECN DATE VER. ECN DATE

Page 1 of 3 VER. 17 ER-56.03

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

ENGINEERING REFERENCE manufacture in part or in whole without written permission from Ariel Corporation.

5. Support crosshead guide feet not only to provide vertical support, but also to prevent horizontal

movement perpendicular to the piston rod. Attaching any support to the deck plate alone is insuf-

ficient. Ariel recommends A-frame supports attached directly to a full depth skid member. Ariel

offers crosshead guide supports for JGW and larger frames. Use of threaded adjustable chocks to

support the crosshead guides requires a careful mechanical study to validate their use.

6. JGH:E:K:T 2-throw frames with pipeline cylinders, all JGC:D and larger 2-throw frames,

and all JGF frames require a full width compressor pedestal (wide enough to include the

guide support mounting feet) to control unbalanced forces and couples. Ariel recommends

a reinforced concrete-filled pedestal of common height and use of Ariel crosshead guide supports.

7. Each crosshead guide deflects an amount relative to the weight of the cylinder mounted on that

throw. See the Ariel Performance Program for estimated crosshead guide foot deflection. This

estimate accounts only for cylinder weight. Account for the weight of attached bottles and piping if

correcting after bottle mounting. For JGR:J:W and smaller frames, cylinder weight will not deflect

the guide, but bottle weight still requires consideration. After mounting the frame and torquing the

frame mounting bolts, shim the crosshead guide to achieve zero deflection when the guide support

bolts are tightened. Loosen the guide support bolts, lift the cylinder, then add shims equaling the

deflection value as calculated by the Ariel Performance Program to the shim pack under the

crosshead guide to level it. Tighten guide support bolts per ER-63. Out of spec crosshead running

clearances may indicate incorrect guide shimming. Except for KBZ:U frames, shim crosshead

guides between the guide feet and the support; shim KBZ:U guides under the support. On JGZ:U

frames equipped with long two-compartment (L2) crosshead guide extensions, use the outboard

feet under the guide extension to support the guide. Leave feet under the guide unsupported.

8. Provide sufficient skid stiffness to prevent twisting due to torque reaction between the driver and

compressor. Provide enough stiffness so shipment or relocation minimally affects driver/compressor

alignment. Always check and correct coupling alignment after package relocation.

9. Every installed compressor package has several mechanical natural frequencies (MNF), usually in

scrubber/bottle/cylinder system groupings. Each frequency is a function of the stiffness and mass of

the entire system, including the foundation or deck.

If the system first MNF is within the operating speed range or twice the operating speed range of the

package, resonant vibration occurs. Ensure the first MNF of the skid package mounted on the user

foundation or deck is either less than 0.8 times the minimum compressor operating speed, or more

than 2.4 times the maximum operating speed. Coordinate with the foundation or deck designer.

Although not recommended, to tune a major cylinder MNF between 1 and 2 times the operating fre-

quency, maintain the cylinder MNF above 1.5 times operating frequency. The high excitation of 1

times compressor forces combined with low level amplification up to 1.5 times the operating fre-

quency can cause excessive vibration.

Forward maximum/minimum speed and normal operating speed range to the end user along with a

caution to examine off-skid structure, piping, instrumentation, and equipment for resonance.

10. Provide skid beams with gussets at anchor bolt locations. Anchor bolt locations should also be sup-

ported internally by cross members.

11. Well-designed crosshead guide supports provide high axial (parallel to the crankshaft) and vertical

stiffness that usually eliminate the need for head end cylinder supports (HES). If a mechanical ana-

lysis predicts interference with a cylinder/guide combination MNF in the operating speed range,

HES may be recommended. Use HES to supplement well-designed crosshead guide supports.

• The mechanical analysis provider should provide detail drawings of the cylinder support of appro-

priate stiffness to shift the MNF.

• It is a good practice to design provisions for HES into a skid, even if HES are not recommended. It

is relatively inexpensive to fabricate and correctly install HES if considered in the design phase.

Page 2 of 3 VER. 17 ER-56.03

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

ENGINEERING REFERENCE manufacture in part or in whole without written permission from Ariel Corporation.

• HES require careful adjustment and may hinder maintenance access. Improperly adjusted HES

can cause high stress on cylinders and fabricated process piping that can result in failure.

• HES are also recommended for vertical support of cylinders weighing over 10,000 lbs.

• Some cylinders have a small pad on the bottom of the head end of the cylinder. This can be used

when only vertical support is required.

• New pipeline and large bore cylinders have an external bolt circle specifically designed for mount-

ing HES. Consult the cylinder outline drawings for details. On cylinders without the external bolt

circle feature, Ariel recommends "clamp" style supports. Clamp style supports grip the flange of

the head end head or clearance pocket. For clamp style HES, it is critical to machine the inside dia-

meter of the clamp to a very tight tolerance to provide as much contact area as possible.

Head End Support Required Features

• HES must be adjustable to avoid cylinder stress. Adjust HES with the compressor at operating tem-

perature.

• HES must be very stiff vertically and as stiff as possible parallel with the crankshaft.

• HES must not be excessively stiff horizontally (parallel with the rod). They are not intended to restrain

rod load forces.

• Attach the vertical support of the HES to a full-depth skid beam flange so it is directly supported by the

web of the beam. Gussets are required between the skid beam flanges directly beneath the HES ver-

tical supports.

NOTE: Supports that use gas containment bolting to attach to the cylinder require Ariel

approval.

Head End Support Adjustment

Adjust the HES with the system heat-soaked and immediately after adjusting the bottle supports in

accordance with the start up checklist and the maintenance schedule. Shim or otherwise adjust the sup-

port to hold the current position of the cylinder.

NOTE: Piston rod runout and crosshead running clearance checks will confirm guide/cyl-

inder alignment has not been compromised.

Page 3 of 3 VER. 17 ER-56.03

You might also like

- Ibm Base Professional 6.0.1 User Guide PDF50% (2)Ibm Base Professional 6.0.1 User Guide PDF1,624 pages

- ER-56-03 EN Packager Standards Skid Design and FabricationNo ratings yetER-56-03 EN Packager Standards Skid Design and Fabrication4 pages

- Pipe Insulation Finding The Optimal Thickness Oct15 - EPNo ratings yetPipe Insulation Finding The Optimal Thickness Oct15 - EP5 pages

- Weight Calculation of Butt Weld Pipe FittingsNo ratings yetWeight Calculation of Butt Weld Pipe Fittings1 page

- API Standard 618 - Reciprocating Compressors For Petroleum, Chemical, and Gas Industry ServicesNo ratings yetAPI Standard 618 - Reciprocating Compressors For Petroleum, Chemical, and Gas Industry Services8 pages

- Anexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design CriteriaNo ratings yetAnexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design Criteria64 pages

- Standards Manager Web Standards List Standards Manager Web Standards List PIP-Process Industry Practices PIP-Process Industry PracticesNo ratings yetStandards Manager Web Standards List Standards Manager Web Standards List PIP-Process Industry Practices PIP-Process Industry Practices10 pages

- Water Tank Support Structure Design - RISA Tutorial ExampleNo ratings yetWater Tank Support Structure Design - RISA Tutorial Example13 pages

- NIOEC-SP-00-53 (0) : Layout and SpacingNo ratings yetNIOEC-SP-00-53 (0) : Layout and Spacing15 pages

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)No ratings yetDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)3 pages

- API 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryNo ratings yetAPI 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As Necessary3 pages

- Contractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationNo ratings yetContractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump Station1 page

- Design of Pin Connections Between Steel MembersNo ratings yetDesign of Pin Connections Between Steel Members14 pages

- Foundation Manual: State of California Department of Transportation Engineering Service Center Division of Structures100% (2)Foundation Manual: State of California Department of Transportation Engineering Service Center Division of Structures529 pages

- Fabrication Tolerances: Api-Rp-2A (December 2000)No ratings yetFabrication Tolerances: Api-Rp-2A (December 2000)2 pages

- Structural Analysis and Design Modification of The Compressor Skid of Helium Liquifier Plant IJERTV2IS110897No ratings yetStructural Analysis and Design Modification of The Compressor Skid of Helium Liquifier Plant IJERTV2IS1108976 pages

- Pressure Vessels: Horizontal On Two Saddles - DesignNo ratings yetPressure Vessels: Horizontal On Two Saddles - Design20 pages

- Pipeline Stress Analysis With Caesar II PDF100% (1)Pipeline Stress Analysis With Caesar II PDF16 pages

- Client: Project: Location: BY: Date:: API RP-2FB Blast CalculationsNo ratings yetClient: Project: Location: BY: Date:: API RP-2FB Blast Calculations33 pages

- Pvp2010-25092-Lower Bound Buckling Load of A Floating Roof PontoonNo ratings yetPvp2010-25092-Lower Bound Buckling Load of A Floating Roof Pontoon9 pages

- NRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor BoltsNo ratings yetNRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor Bolts4 pages

- Civil Legend: Mechanical Legend Pipe and Fitting Symbols General Structural Notes100% (1)Civil Legend: Mechanical Legend Pipe and Fitting Symbols General Structural Notes1 page

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasNo ratings yetASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & Gas14 pages

- Pipeline Wrapping and Coating SpecificationNo ratings yetPipeline Wrapping and Coating Specification9 pages

- "Lifting - Lug" - Lifting Lug Analysis: Program Description100% (3)"Lifting - Lug" - Lifting Lug Analysis: Program Description3 pages

- Flange Spreader: Parts List and Operating Instructions ForNo ratings yetFlange Spreader: Parts List and Operating Instructions For6 pages

- SHERWOOD 17000 27000 Pump Series Technical GuideNo ratings yetSHERWOOD 17000 27000 Pump Series Technical Guide6 pages

- A DIY'ers Definitive Guide to Building a Custom Volkswagen TrikeFrom EverandA DIY'ers Definitive Guide to Building a Custom Volkswagen TrikeNo ratings yet

- 7A. Man Basket Daily Checklist - PTW ProcedureNo ratings yet7A. Man Basket Daily Checklist - PTW Procedure2 pages

- Optimization Principles: 7.1.1 The General Optimization ProblemNo ratings yetOptimization Principles: 7.1.1 The General Optimization Problem13 pages

- Penerapan Metode Just in Time Terhadap Efisiensi Biaya Bahan Baku PT Harmonize Invitation (Jira) KualiNo ratings yetPenerapan Metode Just in Time Terhadap Efisiensi Biaya Bahan Baku PT Harmonize Invitation (Jira) Kuali19 pages

- CFM56 5B SB Rev 72-0922 TSN.03 R 20200117No ratings yetCFM56 5B SB Rev 72-0922 TSN.03 R 202001178 pages

- Setting The Standard: For Electronic Theodolites WorldwideNo ratings yetSetting The Standard: For Electronic Theodolites Worldwide2 pages

- Metix - A Global Leader in Electric Smelter SolutionsNo ratings yetMetix - A Global Leader in Electric Smelter Solutions27 pages

- ISO 7241-1 A Interchange: Dimensions (Female NPT, Valved)No ratings yetISO 7241-1 A Interchange: Dimensions (Female NPT, Valved)1 page

- SH RH QH RH : 2.642 M/s Critical Velocity (V)No ratings yetSH RH QH RH : 2.642 M/s Critical Velocity (V)4 pages

- Triple Effect Evaporators Heating Surface AreaNo ratings yetTriple Effect Evaporators Heating Surface Area2 pages