Professional Documents

Culture Documents

Pneumatics Exercises 13

Pneumatics Exercises 13

Uploaded by

KhamilleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pneumatics Exercises 13

Pneumatics Exercises 13

Uploaded by

KhamilleCopyright:

Available Formats

Exercise 13: Crushing of drinks cans

Training aims • To familiarise yourself with the design and mode of operation of a pressure

sequence valve.

• To be able to design pressure-dependent control systems.

Problem definition In a recycling plant drinks cans are to be crushed into a block for space-saving

storage. The pressing operation is to be triggered by means of a pushbutton. The

return stroke can be triggered by a pushbutton. The pressing operation is to start

only if sufficient pressure is available.

Parameters • The retracted end position is the initial position of the pressing cylinder.

• The pressing operation is to start only if the system pressure is above 6 bar

(600 kPa).

• The return stroke can be triggered manually since, depending on material load,

the pressing cylinder does not reach the forward end position.

Project task 1. Complete the pneumatic circuit diagram for the crushing of cans.

2. Carry out the assembly.

3. Check the assembled circuit.

4. Describe the mode of operation of the circuit.

5. Compile an equipment list.

© Festo Didactic GmbH & Co. KG • 541088 A-87

Exercise 13: Crushing of drinks cans

Positional sketch

Tin can press

1. A pressure sequence valve is to switch upon reaching the preset pressure and to

release compressed air for the circuit. The circuit must not function below a

pressure of 4.5 bar (450 kPa).

2. It should not be possible to commence the pressing operation via a start button

unless the pressing cylinder is in the upper end position. The pressing cylinder is

to move up to the forward end position or a stop predefined by the material.

3. The return stroke is to be triggered by means of a limit switch or pushbutton.

Note

The required protective grid is not shown.

Additional exercises • What errors can occur during the assembly and tubing up of the circuit?

• What is the effect of such errors? Describe these.

A-88 © Festo Didactic GmbH & Co. KG • 541088

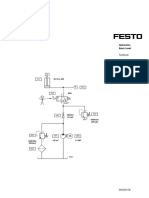

Exercise 13: Crushing of drinks cans

Exercise 13: Crushing of drinks cans

Name:

Function of a pressure sequence valve

12 1 3

Symbol of a pressure sequence valve

3 2 1 12

Schematic representation of a pressure sequence valve

– Describe the function of a pressure sequence valve.

© Festo Didactic GmbH & Co. KG • 541088 A-89

Exercise 13: Crushing of drinks cans

Exercise 13: Crushing of drinks cans

Name:

Completing the pneumatic circuit diagram

– Complete the circuit diagram below.

1A1

1B1 1B2

1V6 1 1 1V7

2 2

1V5 4 2

14 12

5 3

1

1V4 2

1V3 2

1 1/3

1 1/3

1B1 2 1S1 1S2 1B2

2 2 2

1 3 1 3 1 3 1 3

1V2 2

12 1 3

1V1

1 3

Pneumatic circuit diagram

A-90 © Festo Didactic GmbH & Co. KG • 541088

Exercise 13: Crushing of drinks cans

Exercise 13: Crushing of drinks cans

Name:

Compiling the equipment list

Apart from the circuit diagram, comprehensive project documentation also requires

an equipment list.

– Compile the equipment list by entering the required equipment in the table

below.

Quantity

Equipment list

© Festo Didactic GmbH & Co. KG • 541088 A-91

Exercise 13: Crushing of drinks cans

Exercise 13: Crushing of drinks cans

Name:

Completing additional exercises

– What errors can occur during the assembly and tubing up of the circuit?

– What is the effect of such errors? Describe these.

A-92 © Festo Didactic GmbH & Co. KG • 541088

You might also like

- Worksheets Electropneumatics Basic LevelDocument128 pagesWorksheets Electropneumatics Basic LevelNur SyimahNo ratings yet

- Furnace Door Control Hydraulic TaskingDocument4 pagesFurnace Door Control Hydraulic TaskingAbdul Aziz Abdul Rahim100% (1)

- Control Valves and Actuators TrainingDocument12 pagesControl Valves and Actuators TrainingKK100% (1)

- Hni Investors Mobile NumbersDocument53 pagesHni Investors Mobile NumbersRakesh Jain100% (2)

- تجارب مخبر الهيدروليك طالبDocument150 pagesتجارب مخبر الهيدروليك طالبjndalyfrasNo ratings yet

- SMC Pneumate-200 PDFDocument8 pagesSMC Pneumate-200 PDFUnknownNo ratings yet

- Lab 3: Pneumatic Control Practical: List Down The Steps Taken To Solve Given Scenarios From Exercise 1 To Exercise 6Document12 pagesLab 3: Pneumatic Control Practical: List Down The Steps Taken To Solve Given Scenarios From Exercise 1 To Exercise 6Ng Kah FeiNo ratings yet

- Pneumatics Vs HydraulicsDocument19 pagesPneumatics Vs HydraulicsGebBerhe100% (1)

- Air Line Equipment: For Quality Compressed AirDocument114 pagesAir Line Equipment: For Quality Compressed AirCastañeda ValeriaNo ratings yet

- ThermocouplesDocument21 pagesThermocouplesdhineshpNo ratings yet

- Festo Troubleshooting and Maintenance in PneumaticsDocument2 pagesFesto Troubleshooting and Maintenance in PneumaticsYousef AlkabbaniNo ratings yet

- Festo Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Document66 pagesFesto Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Parinpa Ketar100% (1)

- 纯液压技术 英文版讲义 PDFDocument236 pages纯液压技术 英文版讲义 PDFWeeLun TanNo ratings yet

- Pneumatic Systems: Module 2: Direct and Indirect Control in Electro-PneumaticsDocument19 pagesPneumatic Systems: Module 2: Direct and Indirect Control in Electro-PneumaticsĐiệp NgọcNo ratings yet

- Process Automation Festo Product OverviewDocument20 pagesProcess Automation Festo Product Overviewlue-ookNo ratings yet

- Lab Report 2: BTM 2243 Fluid Power TechnologyDocument5 pagesLab Report 2: BTM 2243 Fluid Power TechnologyIbrahim AdhamNo ratings yet

- Advanced Electropnuematics Its ApplicationsDocument30 pagesAdvanced Electropnuematics Its ApplicationssaruNo ratings yet

- VAD Variable Area Desuperheaters: Desuperheater OverviewDocument6 pagesVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaNo ratings yet

- SKEM 3742 Electro Hydraulic LabsheetDocument6 pagesSKEM 3742 Electro Hydraulic Labsheetcikgu_relaNo ratings yet

- De Super HeaterDocument2 pagesDe Super HeatergateauxboyNo ratings yet

- Unit 2: Load Sensing, Pressure Compensated Hydraulic SystemsDocument19 pagesUnit 2: Load Sensing, Pressure Compensated Hydraulic SystemsMohammed KhalidNo ratings yet

- Hydraulics & Pneumatics: Introduction To Electro-PneumaticsDocument67 pagesHydraulics & Pneumatics: Introduction To Electro-PneumaticsSAMUEL MAKATANENo ratings yet

- 4 PLCDocument31 pages4 PLCThakur Dhananjay PratapNo ratings yet

- Chapter 4 - Pneumatic ValvesDocument78 pagesChapter 4 - Pneumatic ValvesPhaM TruoNg QuoC VuNo ratings yet

- Signalling Device SymbolDocument1 pageSignalling Device Symbolnooruddinkhan1No ratings yet

- Fluid Power Ass. 2Document5 pagesFluid Power Ass. 2gebremariam birkieNo ratings yet

- Poster in Pneumatic From Hamiti Festo DidacticDocument1 pagePoster in Pneumatic From Hamiti Festo DidacticHAMIT100% (4)

- Fisher l2 Liquid Level Controllers en 135074Document16 pagesFisher l2 Liquid Level Controllers en 135074GOKUL PRASADNo ratings yet

- Relay Based Electropneumatics BucengDocument76 pagesRelay Based Electropneumatics BucengDEATH WISHNo ratings yet

- Valves 4Document78 pagesValves 4Gurmeet MehmaNo ratings yet

- Chap 5Document26 pagesChap 5Fernando CespedesNo ratings yet

- Festo Electropneumatics Advanced Level IIDocument1 pageFesto Electropneumatics Advanced Level IIAbhinav ChaudharyNo ratings yet

- Hydropower PlantDocument9 pagesHydropower Plantmebratu AssefaNo ratings yet

- Unit 4& 5Document9 pagesUnit 4& 5hariharanbook0% (1)

- Chapter 7 - Hydraulic Operation Circuit and ApplicationDocument19 pagesChapter 7 - Hydraulic Operation Circuit and ApplicationMuhammad AbdullahNo ratings yet

- 1.push Button and Switches 2Document35 pages1.push Button and Switches 2Mahadzir Bin Mat Rabi'No ratings yet

- Me8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeDocument12 pagesMe8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeArul Prakasam GNo ratings yet

- The Pneumatics Installation Guide: Festo Worldwide WWW - FestoDocument216 pagesThe Pneumatics Installation Guide: Festo Worldwide WWW - FestorzezniccNo ratings yet

- 2020-MC-274 System 2Document17 pages2020-MC-274 System 2David James100% (1)

- Proportional Control For Set Point Change (Servo Problem) Proportional Control For Load Change (Regulatory Problem)Document19 pagesProportional Control For Set Point Change (Servo Problem) Proportional Control For Load Change (Regulatory Problem)Imran UnarNo ratings yet

- Fluid CircuitsDocument189 pagesFluid CircuitsM.Saravana Kumar..M.E100% (1)

- Simbologia PDFDocument1 pageSimbologia PDFMartin Abraham Perez UriasNo ratings yet

- Industrial Electric RelayDocument26 pagesIndustrial Electric Relaysyed muazzam shah putraNo ratings yet

- Hydraulic Trainings For Axial Piston UnitsDocument29 pagesHydraulic Trainings For Axial Piston UnitsrpenaviscontiNo ratings yet

- PLC Based Water Bottle Filling and Caping SystemDocument4 pagesPLC Based Water Bottle Filling and Caping SystemSajid BashirNo ratings yet

- Basic Pneumatic AutomationDocument15 pagesBasic Pneumatic AutomationAngela Jenkins100% (1)

- Pneumatic LogicDocument27 pagesPneumatic LogicEliasNo ratings yet

- Explanations To Hydraulic DiagramDocument7 pagesExplanations To Hydraulic Diagramsunil singhNo ratings yet

- Multiactuator CircuitsDocument38 pagesMultiactuator CircuitsMeda AdimurthyNo ratings yet

- Design and Analysis of Hydraulic CircuitsDocument12 pagesDesign and Analysis of Hydraulic Circuitssharafudheen_sNo ratings yet

- Basic Pneumatics: Module 5: Double Acting CylinderDocument14 pagesBasic Pneumatics: Module 5: Double Acting Cylinderاحمد السيدNo ratings yet

- Friction Clutches-Study MaterialDocument11 pagesFriction Clutches-Study MaterialAnvesh HegdeNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Pneumatics ElectropneumaticsDocument44 pagesPneumatics ElectropneumaticswanNo ratings yet

- Kilian Tablet Press Replacement Parts CatalogDocument40 pagesKilian Tablet Press Replacement Parts CatalogIndependent TradingNo ratings yet

- DanielGwapo PDFDocument144 pagesDanielGwapo PDFalexisNo ratings yet

- Hydraulic Symbols TutorialDocument17 pagesHydraulic Symbols TutorialEric SamNo ratings yet

- Advanced PneumaticsDocument76 pagesAdvanced PneumaticsFranklin BosiNo ratings yet

- tp101 enDocument131 pagestp101 enJorge AvellanedaNo ratings yet

- MA2000 Manual EU MLDocument26 pagesMA2000 Manual EU MLmoumenmagdy220No ratings yet

- Witch Hunters Errata PDFDocument6 pagesWitch Hunters Errata PDFLorenzo SaldenNo ratings yet

- Environmental ArtDocument19 pagesEnvironmental Artnina_quijanoNo ratings yet

- CG Zenith PDFDocument84 pagesCG Zenith PDFSu NisanthNo ratings yet

- Introduction To Earth Systems ScienceDocument13 pagesIntroduction To Earth Systems ScienceRain VicenteNo ratings yet

- SufismTaoism PDFDocument251 pagesSufismTaoism PDFStochastic Rhythm100% (1)

- The Great Cloud of BlessingsDocument5 pagesThe Great Cloud of BlessingsSiegfried Schwaiger100% (1)

- Module 5 Capacity PlanningDocument56 pagesModule 5 Capacity Planningwintoday01100% (14)

- CkyDocument1 pageCkykhalishaNo ratings yet

- Homework 6 SolutionsDocument14 pagesHomework 6 SolutionsAE ENo ratings yet

- Hsmarine Tugs and WorkboatsDocument3 pagesHsmarine Tugs and WorkboatsBoruida MachineryNo ratings yet

- ASSESSMENT - Mock Assessment OverviewDocument4 pagesASSESSMENT - Mock Assessment OverviewDet LaurenteNo ratings yet

- Mma Ripped Fight MindsetDocument26 pagesMma Ripped Fight MindsetJulio OlmedoNo ratings yet

- Luluk Handayani - PPTDocument14 pagesLuluk Handayani - PPTLuluk handayaniNo ratings yet

- Active Learning For Hyperspectral Image Classification A Comparative ReviewDocument23 pagesActive Learning For Hyperspectral Image Classification A Comparative ReviewAdduru U G SankararaoNo ratings yet

- DR R SakthivelDocument14 pagesDR R SakthivelRam PrasathNo ratings yet

- Olek Kulik AnimalityDocument14 pagesOlek Kulik AnimalityMaja LežaićNo ratings yet

- Concrete Pump Pipe CatalogDocument7 pagesConcrete Pump Pipe CatalogSiddhi SparesNo ratings yet

- Cardiology USMLE 2CK (Cardio Clinical Care) Flashcards - MemorangDocument4 pagesCardiology USMLE 2CK (Cardio Clinical Care) Flashcards - MemorangMohamed Abbas0% (2)

- First Quarter Summative TestDocument12 pagesFirst Quarter Summative TestFlorence Lizardo Liwanag100% (1)

- C242 - Flexible - Pavements-Shellharbour CouncilDocument21 pagesC242 - Flexible - Pavements-Shellharbour CouncilstefpanNo ratings yet

- Slab Design ComputationDocument1 pageSlab Design ComputationgertjaniNo ratings yet

- CTD Module 4 - SafetyDocument113 pagesCTD Module 4 - SafetyacbgdvNo ratings yet

- Gen Subj 2Document199 pagesGen Subj 2Stabin MathewNo ratings yet

- Pressure Relief Valve, Direct Operated: RE 25402, Edition: 2016-07, Bosch Rexroth AGDocument20 pagesPressure Relief Valve, Direct Operated: RE 25402, Edition: 2016-07, Bosch Rexroth AGRafael Pérez PupoNo ratings yet

- Republic of The Marshall Islands: Implementation Plan For Marine Air Pollutant Emission Control AreasDocument1 pageRepublic of The Marshall Islands: Implementation Plan For Marine Air Pollutant Emission Control AreasHarman SandhuNo ratings yet

- Cara Kerja PlungerDocument4 pagesCara Kerja PlungerGaLih Pancaran SentirNo ratings yet

- Sensual Meditation LoveDocument143 pagesSensual Meditation LoveMamas Matriarch100% (1)

- Review 2 Mid Test SMT 2 FF5Document3 pagesReview 2 Mid Test SMT 2 FF5Zulfan FirdausiNo ratings yet

- YoDocument40 pagesYoMiguel Martinez AlmendrosNo ratings yet