Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Uploaded by

neilCopyright:

Available Formats

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Uploaded by

neilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Uploaded by

neilCopyright:

Available Formats

STRUX® Clinch Studs and Nuts

Optimal Performance in Thin Sheet and Aluminum Sheet Applications

Acument® Global Technologies has developed a line of products to meet the increasing demand for

fastener attachment in a wide range of steel and aluminum sheet applications. Our STRUX® line of

clinch fasteners provides an external or internal thread in sheet metal stack-ups where welding is

impossible or undesirable.

®

STRUX Clinch Studs – External Threads

Cost-effective, high performance alternative to other staked or welded products.

STRUX® Clinch Nuts – Internal Threads

A unique configuration offers unmatched performance and reliability when compared to competitive

clinch products.

One Of A Kind Performance

Features Benefits

º Heat treated to SAE grades, ISO classes or to your own º Greater strength

specifications º May replace larger diameter, conventional weld or other

Studs: ISO 898-1 (metric), SAE J1199 (metric); non-heat treated studs

SAE J429 (inch)

Nuts: ISO 898-2 (metric); SAE J995 (inch)

º Displacement lobes and Retaining Groove º Resist push-out and rotation during service

º Can be used where welding is impossible or º Eliminates hazardous welding operations

undesirable, such as joining dissimilar materials, º Reduced potential for corrosion

pre-coated sheets and high strength sheet materials º Provides a cleaner appearance than welded fasteners

º Improved centerline-to-centerline tolerances compared to

weld studs and nuts

º Unlike spot welding, joints can be created in-die with º Lowers in-place costs

clinch fasteners and automated installation equipment º Maximizes assembly flexibility

º Can be installed after the painting or coating process º Changes and damage to the application materials are

without aesthetic damage minimized

º Unlike welding, clinch fasteners do not create a heat º No distortion due to excessive heat

zone in the materials during installation

º Easy installation º Increased production rates when used in a progressive die

º Improved product and joint integrity

º Allows simple visual inspection º Joints do not require destructive testing to determine

installed strength

Efficient Installation Options

Installation of STRUX® fasteners can be achieved by using mechanical or hydraulic presses, whether your application

calls for manual installation or fully automated in-line/in-die systems. Most equipment capable of feeding rivets, weld

®

fasteners or conventional clinch fasteners will install STRUX fasteners.

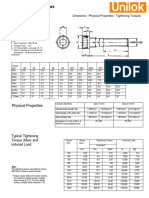

STRUX® Studs Dimensional & Performance Data† – Metric Sizes (all dimensions shown in millimeters)

Approx*

Approx* Unsupported

Mat Recommended Staking Approx* Torsional

Thread S C D K Thick Hole Size Force Pushout Resistance

Size 0.07 0.13 0.25 Max Min Min Max kN kN Nm

1.5 1.0 13.3 1.04 4.80

M4 x 0.7 4.61 1.40 7.75 4.68 4.78

2.3 1.5 16.9 2.27 5.01

1.5 1.0 13.3 1.09 4.00

M5 x 0.8 5.61 1.75 8.75 5.68 5.78

2.3 1.5 16.5 2.22 10.73

1.5 1.0 20.2 1.42 7.69

M6 x 1.0 6.61 2.10 11.00 2.3 1.5 6.68 6.78 25.8 2.56 15.22

3.4 2.3 26.7 4.78 15.22

2.3 1.5 35.6 2.40 26.78

M8 x 1.25 8.61 2.80 15.25 3.4 2.3 8.68 8.78 42.3 6.09 40.06

4.6 3.0 45.4 9.06 40.06

3.4 2.3 66.7 5.92 60.49

M10 x 1.5 10.61 3.50 19.75 10.68 10.78

4.6 3.0 73.4 8.82 84.80

3.4 2.3 73.4 7.26 81.14

M12 x 1.75 12.61 3.80 20.00 12.68 12.78

4.6 3.0 77.8 13.91 124.25

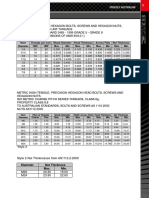

STRUX® Nuts Dimensional & Performance Data† – Metric Sizes (all dimensions shown in millimeters)

Approx*

Approx* Unsupported

Mat Recommended Staking Approx* Torsional

Thread S C D K Thick Hole Size Force Pushout Resistance

Size 0.07 0.19 0.13 Max Min Min Max kN kN Nm

M4 x 0.7 7.13 3.19 10.16 1.5 1.5 7.20 7.30 13.3 0.91 6.19

1.5 1.5 26.7 1.04 12.00

M5 x 0.8 7.61 4.19 11.30 7.68 7.78

1.9 1.9 30.2 1.68 21.32

1.5 1.5 38.7 1.39 18.85

M6 x 1.0 8.61 4.71 14.10 1.9 1.9 8.68 8.78 40.0 2.57 21.04

2.3 2.3 42.3 3.22 32.52

1.5 1.5 44.5 1.53 21.17

M8 x 1.25 10.61 5.93 16.64 1.9 1.9 10.68 10.78 48.9 2.41 41.94

2.3 2.3 57.8 4.58 54.23

2.3 2.3 53.4 4.16 57.21

M10 x 1.5 13.09 7.20 18.42 13.16 13.26

3.4 3.4 57.8 4.28 65.65

2.3 2.3 108.3 4.75 75.39

M12 x 1.75 15.61 9.61 23.88 15.68 15.78

3.4 3.4 109.0 7.66 124.32

NOTES FOR BOTH STRUX® STUDS AND NUTS:

Other sizes up through M16 available upon request.

Underhead shape and dimensions controlled by manufacturer to meet performance requirements.

*Tests conducted in low carbon steel with a maximum hardness of Rockwell B70.

†Performance data shown are typical results obtained under laboratory conditions. It is recommended that each application be tested individually for precise values.

For performance in materials other than steel, individual testing is a requirement. This data is not to be considered a specification. Contact an Acument® Global

Technologies applications engineer for assistance.

4366 Old US 31 North

Rochester, IN 46975

(574) 223-3131

acument.com

acumentnorthamerica.com

STRUX® and Acument® are trademarks of Acument® Intellectual Properties, LLC.

©2006-11 Acument® Intellectual Properties, LLC. F1051Rev._06/02/11

You might also like

- 3S HSE MS Docs Master ListDocument1 page3S HSE MS Docs Master ListSreekumar80% (5)

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (5)

- Sperre LL2 77 CompressorDocument1 pageSperre LL2 77 CompressorTanay ShahNo ratings yet

- Bolt Torque - Specifications - UsDocument2 pagesBolt Torque - Specifications - UsMudang ObingNo ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- Screw LoadsDocument2 pagesScrew LoadsserkanNo ratings yet

- RAMSET-DynaBolt PlusDocument2 pagesRAMSET-DynaBolt PlusPatrick Kelly FontanillaNo ratings yet

- An Engineer and ToolmakerDocument6 pagesAn Engineer and ToolmakerNaveen RaghavanNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringDocument2 pagesRamset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringBrian ChmeisseNo ratings yet

- PT Bar Product Datasheet Mar2016Document14 pagesPT Bar Product Datasheet Mar2016J. Fernando RodriguesNo ratings yet

- SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASDocument5 pagesSS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASHithish ReddyNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- Datasheet Rigid CouplingDocument6 pagesDatasheet Rigid Couplingaras aliNo ratings yet

- Mechanical Bolt Torque TableDocument7 pagesMechanical Bolt Torque TablesitehabNo ratings yet

- Socket Head Cap ScrewDocument4 pagesSocket Head Cap ScrewsarbiniNo ratings yet

- PT Bar Systems Brochure 17.05.29Document8 pagesPT Bar Systems Brochure 17.05.29SACHINNo ratings yet

- HayDocument8 pagesHayMinh Tâm TrầnNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Wedge Wire Screens - Techincal Info - Screen SystemsDocument5 pagesWedge Wire Screens - Techincal Info - Screen SystemsChris HdezNo ratings yet

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelNo ratings yet

- Is 19781982Document5 pagesIs 19781982Padakandla SumanNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Sizing Steel Sections For BeamsDocument25 pagesSizing Steel Sections For BeamsAnonymous ujfx6mNo ratings yet

- Coupling Forged Steel Astm A105 Class 3000 SWDocument1 pageCoupling Forged Steel Astm A105 Class 3000 SWWilliam DelgadoNo ratings yet

- Draka PVCDocument4 pagesDraka PVCapi-3803155No ratings yet

- Screw Torque A2Document1 pageScrew Torque A2adi325325No ratings yet

- 08 ScrewDocument10 pages08 ScrewJuanGómezNo ratings yet

- Style E485-1Document5 pagesStyle E485-1Ummes AhmedNo ratings yet

- Hank BushesDocument18 pagesHank Bushess bNo ratings yet

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- Metric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.PDocument2 pagesMetric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.Pdinesh panchalNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- Page 0075Document1 pagePage 0075nasermohjunaid9No ratings yet

- Gripwell - 9688 HexsertDocument1 pageGripwell - 9688 HexsertmaringopiyukNo ratings yet

- Codo 90Document1 pageCodo 90RoLopNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- Metric DIN 93 SpecDocument5 pagesMetric DIN 93 SpecJhon Edison Posada MuñozNo ratings yet

- Metric DIN 7980 SpecDocument4 pagesMetric DIN 7980 SpecGowtham VenkatNo ratings yet

- Dextra: System DescriptionDocument10 pagesDextra: System DescriptionHiba SolimanNo ratings yet

- Victaulic Quick Vic Rigid CouplingsDocument7 pagesVictaulic Quick Vic Rigid Couplingsionut cerneaNo ratings yet

- Hexagon Head Bolts/Screws: Metric Series-DimensionsDocument7 pagesHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryNo ratings yet

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainPanthNo ratings yet

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 pageForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- We 505Document3 pagesWe 505nguyễn mạnhNo ratings yet

- Style 807NDocument7 pagesStyle 807NUmmes AhmedNo ratings yet

- RawrblmspecDocument1 pageRawrblmspecTakis ApostolidesNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Examples of ConductorsDocument16 pagesExamples of ConductorsJubert PerezNo ratings yet

- 6991 1726 01 Elemex Catalogue English LR Tcm795-1785111Document44 pages6991 1726 01 Elemex Catalogue English LR Tcm795-1785111Jacky_LEOLEONo ratings yet

- Tuberias SCHDocument1 pageTuberias SCHrussoliNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- 9greens Wire New Rates 8 OctDocument14 pages9greens Wire New Rates 8 OctTejas AgrawalNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- Expanded Metals PDFDocument3 pagesExpanded Metals PDFMichael MirandaNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- SLB Dowel CementPlugs PDFDocument27 pagesSLB Dowel CementPlugs PDFMohamed MahmoudNo ratings yet

- List - Approved Prequalified SubsDocument42 pagesList - Approved Prequalified SubsJAGUAR GAMINGNo ratings yet

- Topographic Map of JoppaDocument1 pageTopographic Map of JoppaHistoricalMapsNo ratings yet

- Ford OBD-II Tren de Potencia P0102 - P0812 PDFDocument37 pagesFord OBD-II Tren de Potencia P0102 - P0812 PDFJoséCevallosNo ratings yet

- Current Affairs Q&A PDF Free - October 2018Document41 pagesCurrent Affairs Q&A PDF Free - October 2018Chandra Shekhar Prasad100% (1)

- Negotiations Between Apple and SamsungDocument5 pagesNegotiations Between Apple and SamsungAnonymous 8x1sqf100% (1)

- Ijest NG Vol3 No7 pp1 14Document14 pagesIjest NG Vol3 No7 pp1 14Harsh PatelNo ratings yet

- WendingmcDocument39 pagesWendingmcVoskula ShivakrishnaNo ratings yet

- Preffered Classroom Management Styles and Academic Performance of Senior High School Students in UPHSLDocument15 pagesPreffered Classroom Management Styles and Academic Performance of Senior High School Students in UPHSLVin Nicole Salazar RevillaNo ratings yet

- Planta de Tratamiento de Agua Esquema Eléctrico Del Sistema de Automatización. SidorDocument279 pagesPlanta de Tratamiento de Agua Esquema Eléctrico Del Sistema de Automatización. SidorEdgar MartinezzNo ratings yet

- ETC012 - Device Driver Development To Accessing SDMMC Card Using SPI On LPC2148Document3 pagesETC012 - Device Driver Development To Accessing SDMMC Card Using SPI On LPC2148Vinay FelixNo ratings yet

- Com - OPENCMX STM3210D SchematicDocument1 pageCom - OPENCMX STM3210D Schematicfetk52No ratings yet

- TEX RT335 EspecificacionesDocument4 pagesTEX RT335 EspecificacionesPizarro AndresNo ratings yet

- Application For Allotment of Permanent Retirement Account Number (PRAN)Document4 pagesApplication For Allotment of Permanent Retirement Account Number (PRAN)pushparaviNo ratings yet

- 5 ResearchDocument3 pages5 Researchapi-257746864No ratings yet

- ECE 482 Homework Assignment #1 Solution Fall Semester 2012 Prof. N. ShanbhagDocument2 pagesECE 482 Homework Assignment #1 Solution Fall Semester 2012 Prof. N. ShanbhagkourseNo ratings yet

- AA1164 3-Way NFB Switch Mod PDFDocument1 pageAA1164 3-Way NFB Switch Mod PDFjosemfcNo ratings yet

- BOOMDocument28 pagesBOOMDatNo ratings yet

- सार्वजनिक सडक ऐन, २०३१ (मिति २०७४ साल कार्तिक मसान्तसम्म भएका संशोधन समेत मिलाइएको)Document14 pagesसार्वजनिक सडक ऐन, २०३१ (मिति २०७४ साल कार्तिक मसान्तसम्म भएका संशोधन समेत मिलाइएको)Hariram RimalNo ratings yet

- Speaker Electrical Model IMPORTANTDocument6 pagesSpeaker Electrical Model IMPORTANTaudioblohmNo ratings yet

- Python (Programming Language) - Simple English Wikipedia, The Free EncyclopediaDocument17 pagesPython (Programming Language) - Simple English Wikipedia, The Free EncyclopediaGsts che dgNo ratings yet

- Control EnggDocument3 pagesControl EnggCinthya Indradewi DadimesaNo ratings yet

- Guidelines On Fabrication of Steel Structure ofDocument3 pagesGuidelines On Fabrication of Steel Structure ofsamirbendre1No ratings yet

- Concrete Mix Design Moisture Adjustment ProceduresDocument6 pagesConcrete Mix Design Moisture Adjustment ProceduresM HAFEEZ RAJA0% (1)

- Lloyd Industries Inc.: ApplicationDocument1 pageLloyd Industries Inc.: ApplicationdbaillonNo ratings yet

- Final LCSMDocument9 pagesFinal LCSMDavid BabaganovNo ratings yet

- Tron Sart20Document2 pagesTron Sart20muhamad syameer bin rusliNo ratings yet

- Fasson: MZ2050 MZ0037Document3 pagesFasson: MZ2050 MZ0037Praveen KumarNo ratings yet