A694 16

A694 16

Uploaded by

Esteban CastellanoCopyright:

Available Formats

A694 16

A694 16

Uploaded by

Esteban CastellanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

A694 16

A694 16

Uploaded by

Esteban CastellanoCopyright:

Available Formats

Designation: A694/A694M − 16

Standard Specification for

Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings,

Valves, and Parts for High-Pressure Transmission Service1

This standard is issued under the fixed designation A694/A694M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A106/A106M Specification for Seamless Carbon Steel Pipe

1.1 This specification covers forged or rolled steel pipe for High-Temperature Service

flanges, forged fittings, valves, and parts suitable for use with A381 Specification for Metal-Arc-Welded Steel Pipe for Use

high-strength transmission-service pipe. Included are flanges, With High-Pressure Transmission Systems

fittings, and similar parts ordered either to dimensions specified A707/A707M Specification for Forged Carbon and Alloy

by the purchaser or to ASME or MSS dimensional standards Steel Flanges for Low-Temperature Service

referenced in Section 2. A788/A788M Specification for Steel Forgings, General Re-

quirements

1.2 Several grades of material, based on minimum yield A961/A961M Specification for Common Requirements for

strength requirements, are covered, as indicated in Table 1. Steel Flanges, Forged Fittings, Valves, and Parts for

1.3 Supplementary Requirements are provided. Supplemen- Piping Applications

tary Requirement S1 is provided for use when purchaser 2.3 ASME Standards:

approval is required for repair welding.

ASME B 16.5 Steel Pipe Flanges and Flanged Fittings3

1.4 This specification is expressed in both inch-pound units ASME B 16.9 Steel Butt-Welding Fittings3

and in SI units. However, unless the order specifies the ASME B 16.11 Forged Steel Fittings, Socket Welding and

applicable “M” specification designation (SI units), the mate- Threaded3

rial shall be furnished to inch-pound units. ASME B 16.47 Large Diameter Steel Flanges3

1.5 The values stated in either SI units or inch-pound units 2.4 MSS Standards:4

are to be regarded separately as standard. Within the text, the MSS SP-44 Standard for Steel Pipe Line Flanges

SI units are shown in brackets. The values stated in each MSS SP-75 Specification for High-Test Welding Fittings

system are not exact equivalents; therefore, each system must MSS SP-97 Integrally Reinforced Forged Branch Outlet

be used independently of the other. Combining values from the Fittings

two systems may result in nonconformance with the standard.

2.5 API Standard:

2. Referenced Documents 5L Specification for Line Pipe5

2.1 In addition to those reference documents listed in 3. Ordering Information

Specification A961/A961M, the following list of standards

--`,``,,,,`,``,``,```,`,,,```,`-`-`,,`,,`,`,,`---

apply to this specification: 3.1 It is the purchaser’s responsibility to specify in the

2.2 ASTM Standards: 2 purchase order all ordering information necessary to purchase

A53/A53M Specification for Pipe, Steel, Black and Hot- the needed material. In addition to the ordering guidelines in

Dipped, Zinc-Coated, Welded and Seamless Specification A961/A961M, orders should include the follow-

ing information:

3.1.1 Additional requirements (see 8.1 and 11.1).

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting

3

Materials for Piping and Special Purpose Applications. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved May 1, 2016. Published May 2016. Originally International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

approved in 1974. Last previous edition approved in 2014 as A694/A694M – 14. www.asme.org.

4

DOI: 10.1520/A0694_A0694M-16. Available from Manufacturers Standardization Society of the Valve and Fittings

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM hq.com.

5

Standards volume information, refer to the standard’s Document Summary page on Available from American Petroleum Institute (API), 1220 L. St., NW,

the ASTM website. Washington, DC 20005-4070, http://www.api.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Licensee=US mvd from 2458000 (007- subacct/5940240030, User=Castellano, Esteban

No reproduction or networking permitted without license from IHS Not for Resale, 05/03/2018 13:06:24 MDT

A694/A694M − 16

TABLE 1 Tensile Requirements 5.2.1 Material for forgings shall consist of ingots or blooms,

Grade Yield Strength (0.2 % Tensile Strength, Elongation in 2 billets, slabs, or bars of forged or rolled form and cut to the

Offset), min, ksi [MPa] min, ksi [MPa] in. or 50 mm, required length by a suitable process.

min %

5.2.2 The finished product shall be a forging as defined in

F42 42 [290] 60 [415] 20

F46 46 [315] 60 [415] 20 the Terminology section of Specification A788/A788M.

F48 48 [330] 62 [425] 20 5.2.3 Hot working shall be sufficient to develop a wrought

F50 50 [345] 64 [440] 20 structure throughout the part.

F52 52 [360] 66 [455] 20

F56 56 [385] 68 [470] 20 5.2.4 Flanges shall not be machined directly from plate nor

F60 60 [415] 75 [515] 20 from solid bar stock.

F65 65 [450] 77 [530] 20

F70 70 [485] 82 [565] 18 5.3 Heat Treatment:

5.3.1 All items shall be heat treated. Heat treatment of

carbon steel and high-strength low-alloy steel may consist of

normalizing, normalizing-and-tempering, or quenching-and-

4. General Requirements tempering. Heat treatment of alloy steel may consist of

normalizing and precipitation heat treatment or quenching and

4.1 Product furnished to this specification shall conform to precipitation heat treatment.

the requirements of Specification A961/A961M, including any 5.3.2 The tempering temperature shall be at least 1000 °F

supplementary requirements that are indicated in the purchase [540 °C]. The precipitation heat treatment of the alloy steel

order. Failure to comply with the general requirements of shall be in the range from 1000 to 1225 °F [540 to 665 °C].

Specification A961/A961M constitutes nonconformance with

this specification. In case of conflict between the requirements 6. Chemical Composition

of this specification and Specification A961/A961M, this 6.1 A chemical heat analysis in accordance with Specifica-

specification shall prevail. tion A961/A961M shall be made and conform to the require-

ments as to chemical composition prescribed in Table 2.

5. Manufacture

6.2 High-strength low-alloy steels shall be of specified alloy

5.1 Melting Process: element composition, with the elements covered in 6.1 re-

5.1.1 The steel shall be made by any of the following stricted within the limits prescribed therein as may be neces-

processes: open hearth, electric furnace, or basic oxygen. The sary to ensure weldability and specified minimum tensile

steel shall be fully deoxidized. properties. When high-strength low-alloy steel is furnished,

5.1.2 The steel shall be carbon steel, high-strength low-alloy appropriate procedures are required for field welding.

steel, or alloy steel, as agreed upon between the manufacturer

and purchaser. Analysis of the steel used, including all alloying 6.3 Alloy steel shall conform to the requirements for Grade

elements listed in Table 2, shall be reported by the manufac- L 5 of Specification A707/A707M.

turer to the purchaser. The steel shall be suitable for field 7. Tensile Requirements

welding (as established by the purchaser) to other fittings,

valve materials and flanges, and to pipe manufactured under 7.1 The material shall conform to the requirements as to

the following ASTM specifications: Specification A53/A53M, tensile properties prescribed in Table 1, when tested in accor-

Specification A106/A106M, Specification A381, and API dance with the mechanical testing requirements of Specifica-

Standard 5L pipe, as well as to fittings manufactured under tion A961/A961M.

MSS SP-75. 7.2 The tension test specimen shall be obtained from a

5.2 Manufacturing Practice: production forging, or from an integral prolongation represen-

tative of the hub location of a flange, or the heaviest cross

section of a fitting, valve, or other part within the scope of this

--`,``,,,,`,``,``,```,`,,,```,`-`-`,,`,,`,`,,`---

specification. Alternatively, the test specimen may be taken

TABLE 2 Chemical Requirements from a separately forged test block which has been taken from

Composition, % the same heat of steel as the production forgings, and which has

Heat Analysis been reduced by forging in a manner similar to that for the

Carbon, max 0.30 forgings it represents.

Manganese, max 1.60

Phosphorus, max 0.025

7.2.1 The test specimen shall represent all forgings from the

Sulfur, max 0.025 same heat and heat treatment load whose maximum thick-

Silicon 0.15–0.35 nesses do not exceed the thickness of the test forging or blank

CopperA

NickelA

by more than 1⁄4 in. [6 mm].

ChromiumA 7.3 The axis of the tension test sample shall be located in the

MolybdenumA

VanadiumA test forging, or prolongation so as to represent mid-wall of the

Columbium (Niobium)A flange hub, or mid-wall of the thickest cross section of the

BoronA valve, fitting, or other part.

A

All elements listed in Table 2 shall be reported. Where no composition limit is

listed, values are to be reported but no limits apply except as covered in 6.3. 7.4 The axis of the tension test specimen shall be oriented

parallel to the direction of maximum forging work for fittings,

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Licensee=US mvd from 2458000 (007- subacct/5940240030, User=Castellano, Esteban

No reproduction or networking permitted without license from IHS Not for Resale, 05/03/2018 13:06:24 MDT

A694/A694M − 16

valves, and other parts, except for flanges when the specimen 11. Rejection and Rehearing

shall be oriented in the tangential direction. 11.1 The purchaser shall comply with the requirements of

7.5 One tension test shall be taken from each heat in each Specification A961/A961M.

heat treatment load, and shall be representative of the largest

flange hub, or valve or fitting wall thickness in the load. 12. Certification

7.6 When heat treatment is done either continuous or batch 12.1 See Specification A961/A961M.

type furnaces in which the working zones are controlled to 12.2 The test report shall include the following:

within 6 25 °F [6 14 °C] of the required heat treatment 12.2.1 Chemical analysis results, Section 6 (Table 2).

temperature, and when the furnace is equipped with function- 12.2.2 Tensile properties, Section 7 (Table 1), report the

ing recording pyrometers such that complete heat treatment yield strength and tensile strength, in ksi [MPa], elongation and

records are available, then one tension test from each heat shall reduction in area, in percent,

be required instead of from each heat in each heat treatment

12.2.3 Type heat treatment, 7.6,

load. However, this provision is limited to forgings with heat

12.2.4 Any supplementary testing required by the purchase

treated weights not exceeding 10 000 lb [4540 kg], and the test

order.

forging must accompany a production charge.

8. Surface Finish, Appearance, and Corrosion Protection 13. Product Marking

8.1 The forgings and fittings shall conform to the require- 13.1 In addition to marking requirements of Specification

ments of Specification A961/A961M. A961/A961M, the following additional marking requirements

shall apply:

9. Repair by Welding

13.1.1 Forgings repaired by welding shall be marked with

9.1 Repair by Welding of Injurious Defects—Repair of the letter “W” following the ASTM designation.

injurious defects shall be permitted at the discretion of the

13.2 Bar Coding—In addition to the requirements in 13.1

manufacturer in accordance with Specification A961/A961M.

and 13.1.1, bar coding is acceptable as a supplemental identi-

9.1.1 Deposited weld metal shall be capable of meeting all

fication method. The purchaser may specify in the order a

mechanical properties upon heat treatment.

specific bar coding system to be used. The bar coding system,

9.1.2 All forgings to be repaired by welding shall be repair

if applied at the discretion of the supplier, should be consistent

welded prior to heat treatment.

with one of the published industry standards for bar coding. If

10. Retests used on small parts, the bar code may be applied to the box or

10.1 If any of the results of the tension tests of any lot do not a substantially applied tag.

conform to the requirements specified, the manufacturer may

reheat treat such lots, but not more than twice, except with the 14. Keywords

approval of the purchaser, on the basis of satisfactory metal- 14.1 high strength low alloy steel; pipe fittings, steel; piping

lurgical evidence that the cause of failure is curable and the applications; pressure containing parts; steel flanges; steel

quality of the material is satisfactory. forgings, alloy; steel forgings, carbon; steel valves

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall apply only when specified by the purchaser in the

inquiry, contract, and order:

S1. Special Flanges

S1.1 Flanges shall meet the requirements of MSS SP-44,

including the chemical requirements, carbon equivalency, and

impact testing limitations.

--`,``,,,,`,``,``,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Licensee=US mvd from 2458000 (007- subacct/5940240030, User=Castellano, Esteban

No reproduction or networking permitted without license from IHS Not for Resale, 05/03/2018 13:06:24 MDT

A694/A694M − 16

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this specification since the last issue,

A694/A694M – 14, that may impact the use of this specification. (Approved May 1, 2016)

(1) Added new chemical requirements to Table 2, deleted some

inappropriate references, revised 5.1.2 and S1.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

--`,``,,,,`,``,``,```,`,,,```,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

4Licensee=US mvd from 2458000 (007- subacct/5940240030, User=Castellano, Esteban

No reproduction or networking permitted without license from IHS Not for Resale, 05/03/2018 13:06:24 MDT

You might also like

- WoodPlans Online - Crown Molding BoxesDocument9 pagesWoodPlans Online - Crown Molding BoxesЧедомир Арнаут100% (10)

- ITP - Fencing and Gates Installation Works - MAB1Document24 pagesITP - Fencing and Gates Installation Works - MAB1Vasilica Barbarasa100% (2)

- Astm A105 2021Document5 pagesAstm A105 2021Pedrito Calapucha100% (2)

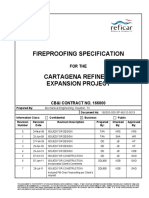

- Fireproofing SpecificationDocument48 pagesFireproofing SpecificationEsteban Castellano100% (12)

- Kahlwax 7304 - Synthetic Candelilla Wax Substitute - KahlWaxDocument2 pagesKahlwax 7304 - Synthetic Candelilla Wax Substitute - KahlWaxhelmiriniaNo ratings yet

- Carbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceDocument4 pagesCarbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceNasrin AkhondiNo ratings yet

- Astm A961 A 961M - 12Document8 pagesAstm A961 A 961M - 12Behrouz NaeimiNo ratings yet

- Astm A352Document5 pagesAstm A352depeche1modeNo ratings yet

- Astm A234 PDFDocument9 pagesAstm A234 PDFJuan Hernández Hernández100% (1)

- A350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Document6 pagesA350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Yilia WangNo ratings yet

- 02 Samss 011Document31 pages02 Samss 011Nicu Man100% (1)

- Astm G 48Document9 pagesAstm G 48nisha_khanNo ratings yet

- ASTM B564 (2011) - Standard Specification For Nickel Alloy ForgingsDocument11 pagesASTM B564 (2011) - Standard Specification For Nickel Alloy Forgingsanoop100% (1)

- Astm A358Document8 pagesAstm A358Dyna Mafikasari100% (2)

- Astm A420a420m-16Document6 pagesAstm A420a420m-16arcadiosco100% (1)

- Astm-A707 CS As LTS PDFDocument5 pagesAstm-A707 CS As LTS PDFGoutam Kumar DebNo ratings yet

- 16 Astm - A350-A350mDocument10 pages16 Astm - A350-A350mFYNo ratings yet

- Astm A860Document5 pagesAstm A860julian2282254No ratings yet

- Astm A350Document8 pagesAstm A350nse mcx100% (1)

- Astm A707Document5 pagesAstm A707Shanib Mohammed SiddiqueNo ratings yet

- Astm B366Document9 pagesAstm B366NaOHita100% (1)

- Astm A105Document5 pagesAstm A105ahmad0% (1)

- A333 - 18 PDFDocument8 pagesA333 - 18 PDFRamyMoustafaNo ratings yet

- Astm A262-98Document16 pagesAstm A262-98Nadhira100% (1)

- Astm A961-21Document9 pagesAstm A961-21bdr85100% (1)

- ASTM A403 - A403M-22bDocument11 pagesASTM A403 - A403M-22b1965karanfil6100% (1)

- Astm A707 PDFDocument5 pagesAstm A707 PDFCristian OtivoNo ratings yet

- Astm A420 - A420mDocument7 pagesAstm A420 - A420msajjad shafieiNo ratings yet

- B466 PDFDocument6 pagesB466 PDFKikin K. Permata100% (1)

- Astm B443 PDFDocument8 pagesAstm B443 PDFMohammad ShamimNo ratings yet

- Astm A182Document15 pagesAstm A182Joffre ValladaresNo ratings yet

- A182 PDFDocument19 pagesA182 PDFالGINIRAL FREE FIRE100% (3)

- Astm A352-A352m-06-1Document5 pagesAstm A352-A352m-06-1Kishor JadhavNo ratings yet

- 24 Astm A815Document8 pages24 Astm A815FYNo ratings yet

- ASTM A860, 2018 Standard Specification For Wrought High-Strength Ferritic Steel Butt-Welding FittingsDocument5 pagesASTM A860, 2018 Standard Specification For Wrought High-Strength Ferritic Steel Butt-Welding FittingsArcadio DuranNo ratings yet

- Astm A530 A530m-18Document9 pagesAstm A530 A530m-18Rafa Pontón RNo ratings yet

- ASTM SA-370, Standard Test Methods and Definitions For Mecha PDFDocument61 pagesASTM SA-370, Standard Test Methods and Definitions For Mecha PDFSunny SaparNo ratings yet

- Astm A694, A694mDocument3 pagesAstm A694, A694mMike DukasNo ratings yet

- Astm A333 PDFDocument8 pagesAstm A333 PDFrams789No ratings yet

- Asme B16.9 2018aDocument41 pagesAsme B16.9 2018aWUMING100% (1)

- Astm B444Document3 pagesAstm B444Ratnakar PatilNo ratings yet

- Titanium and Titanium Alloy Forgings: Standard Specification ForDocument7 pagesTitanium and Titanium Alloy Forgings: Standard Specification ForjenishjsNo ratings yet

- Astm A999Document12 pagesAstm A999Gustavo FreitasNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Marcos Carrero0% (1)

- Astm A961-21Document9 pagesAstm A961-21psytembeNo ratings yet

- Asme 36.10MDocument26 pagesAsme 36.10MAlberto darian100% (1)

- A999a999m 17Document12 pagesA999a999m 17AFQBAVQ2EFCQF31FNo ratings yet

- List AWSDocument14 pagesList AWSRafiqKuNo ratings yet

- Astm A 694Document4 pagesAstm A 694Alexander MonroyNo ratings yet

- A234A234M − 14Document9 pagesA234A234M − 14myenas87No ratings yet

- A420m 14Document6 pagesA420m 14Plinio LavinasNo ratings yet

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument10 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceNagLakshmananNo ratings yet

- Invalid / Ungültig: Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument8 pagesInvalid / Ungültig: Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceMauricio RecalcattiNo ratings yet

- Astm A234-2015Document9 pagesAstm A234-2015Sam WeberNo ratings yet

- A 234 A 234M Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument8 pagesA 234 A 234M Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceILSEN N. DAETNo ratings yet

- Astm A234Document8 pagesAstm A234Hamza Ali KhanNo ratings yet

- Astm 105Document5 pagesAstm 105JOSEPH REFUERZONo ratings yet

- ASTM A105 2005 - Cast Steel ForgingsDocument5 pagesASTM A105 2005 - Cast Steel Forgingskunle oladapoNo ratings yet

- A234wpb 2013 EditionDocument9 pagesA234wpb 2013 EditionptubesindiaNo ratings yet

- Astm A105Document5 pagesAstm A105Ali ArsalanNo ratings yet

- Astm 105 ADocument5 pagesAstm 105 Apaty_cm2No ratings yet

- Astm A420-A420m 2010Document6 pagesAstm A420-A420m 2010Lucas IglesiasNo ratings yet

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Comparison of Astm Specifications and SIMILAR Standards PDFDocument1 pageComparison of Astm Specifications and SIMILAR Standards PDFRoberto_PrrNo ratings yet

- Afety Nstructions: EnglishDocument25 pagesAfety Nstructions: EnglishEsteban CastellanoNo ratings yet

- Piping Material Combination - Piping StudyDocument2 pagesPiping Material Combination - Piping StudyEsteban Castellano100% (1)

- Merichem LPGDocument65 pagesMerichem LPGEsteban Castellano100% (1)

- 400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Document22 pages400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Esteban CastellanoNo ratings yet

- Sistema de Control 2Document98 pagesSistema de Control 2Esteban CastellanoNo ratings yet

- Reference Drawings Revisions Project Info. NotesDocument1 pageReference Drawings Revisions Project Info. NotesEsteban CastellanoNo ratings yet

- Pakil LagunaDocument14 pagesPakil LagunaLhowell LipitNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Scie 7 Q1 Module-5 EditedF v3Document24 pagesScie 7 Q1 Module-5 EditedF v3Mercy MangaoilNo ratings yet

- PEERLESS Cadenas de GradoDocument2 pagesPEERLESS Cadenas de GradosmilingotokoNo ratings yet

- Sir - Tds .Siropol 7440 LV. No3Document3 pagesSir - Tds .Siropol 7440 LV. No3Yousef LotfyNo ratings yet

- 10 Magnetic Effect of Electric CurrentDocument2 pages10 Magnetic Effect of Electric CurrentNihal RaoNo ratings yet

- UPDATE B Associate Fabric Manufacturing Weaving Mill List 2022 23Document40 pagesUPDATE B Associate Fabric Manufacturing Weaving Mill List 2022 23prasenjitpandit4No ratings yet

- Electrodes Hilchrome 308rDocument1 pageElectrodes Hilchrome 308rManu NistorNo ratings yet

- 1.0 Title: Shield Metal Arc Welding (SMAW)Document13 pages1.0 Title: Shield Metal Arc Welding (SMAW)Exo NadiNo ratings yet

- 3.5 Geotechnical Work (Class G) PDFDocument4 pages3.5 Geotechnical Work (Class G) PDFMohd AzwanNo ratings yet

- Flexible Connector - Union TypeDocument1 pageFlexible Connector - Union TypeKABIR CHOPRANo ratings yet

- PAROC Hvac Mat AluCoat en GBDocument2 pagesPAROC Hvac Mat AluCoat en GBDiogo EstevesNo ratings yet

- MS SCI PS Unit 1 Chapter 2 Nature of MatterDocument30 pagesMS SCI PS Unit 1 Chapter 2 Nature of Mattermohamed shaabanNo ratings yet

- Ultratech Xtralite Autoclaved Aerated Concrete Aac BlockDocument9 pagesUltratech Xtralite Autoclaved Aerated Concrete Aac BlockkhajahusNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- Product Catalogue 2019nov Digital SM Eng 0Document26 pagesProduct Catalogue 2019nov Digital SM Eng 0Rezoanul HaqueNo ratings yet

- SV 1Document3 pagesSV 1Arjun GuptaNo ratings yet

- Study Bipolar and CniDocument4 pagesStudy Bipolar and CniGaneshNo ratings yet

- GFRG Panels PDFDocument7 pagesGFRG Panels PDFMHd SaeeNo ratings yet

- Chemistry by Ashwani Ohri: Electronegativity and Miscl. QuestionsDocument3 pagesChemistry by Ashwani Ohri: Electronegativity and Miscl. QuestionsSavvy GuptaNo ratings yet

- Proplast RC50 - TDSDocument2 pagesProplast RC50 - TDSAhmed AbuoelnagaNo ratings yet

- CBSE XI Text BooksDocument160 pagesCBSE XI Text Booksmsk5in100% (1)

- H12 M-10 H12 MV-10: Data SheetDocument4 pagesH12 M-10 H12 MV-10: Data SheetDirceu ValadaresNo ratings yet

- 91 Club New Hack Mod ApkDocument8 pages91 Club New Hack Mod Apkgautamamgautamam14100% (1)

- Electrical Anti CorrosionDocument4 pagesElectrical Anti CorrosionEstika SulistiyantoNo ratings yet

- Welding BasicsDocument5 pagesWelding BasicsJohn TualaNo ratings yet

- Copper Alloy C67500Document10 pagesCopper Alloy C67500Kapil HarchekarNo ratings yet