Technical Data Sheet For Control Valve

Technical Data Sheet For Control Valve

Uploaded by

alinor_tnCopyright:

Available Formats

Technical Data Sheet For Control Valve

Technical Data Sheet For Control Valve

Uploaded by

alinor_tnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Technical Data Sheet For Control Valve

Technical Data Sheet For Control Valve

Uploaded by

alinor_tnCopyright:

Available Formats

Contractor: Engineering: Project: Client:

NAWARA PROJECT

(PIPELINE)

Contract n°: OTP/PP/189 OMV/BIMS EPCC PPL

Job n° : P13IT02472

Contractor doc. n°: Engineering doc. n°: Sheet Class Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 1 of 5 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

TECHNICAL DATA SHEET FOR CONTROL VALVE

000 17/03/2015 Issue for Use/Construction FPA MBO BFU

C02 02/03/2015 Issue for Approval FPA MBO BFU D

C01 19/12/2014 Issue for Review FPA MBO BFU C

Rev. Date REVISION TITLE PREPARED CHECKED APPROVED Rev. Status

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File Name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

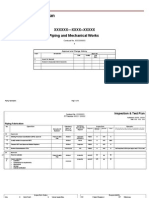

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 2 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

INDEX FOR SHEETS AND REVISIONS

SHEET

DENOMINATION DATE OF LAST REV. REVISION

N°

1 Cover 02/03/2015 C01 C02

2 Index 02/03/2015 C01 C02

3 General Notes 02/03/2015 C01 C02

4 NG0-324-PCV-0621 - Pressure control valve at Propane metering skid outlet 02/03/2015 C01 C02

5 NG0-323-PCV-0721 - Pressure control valve at Butane metering skid outlet 02/03/2015 C01 C02

6

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 3 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

GENERAL NOTES

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 4 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

CONTROL VALVE

VALVE TAG NUMBER : NG0-324-PCV-0621 REFERENCE SPEC. NO.: NAWPPL-BIMS-NPPL-000-CI-SPE-00005

1 Location/P&ID NAWPPL-BIMS-0F04-324-PR-PID-00003 63 MFR. (*) Model (*)

2 Service pressure control at propane metering skid outlet 64 Pneumatic diaphragm piston others

3 Haz. area class. Zone 2, Gas Group IIB, Temperature Class T3 65 Style sprg. opposed double act. air spr.

4 Ambient temp. -0.2°C min. 46.2°C max. 66 Area (*)

5 Allowable sound pressure level 85 dB(A) 67 Reqd. Travel (mm) / angle (°) (*) / (*)

6 Pipe identification No. NG0-6"-LP-324-0019-B51-V 68 Supply press. (*) min. (*) max.

ACTUATOR (*)

PROCESS DATA RELEVANT FOR CONTROL VALVE SELECTION

7 DN /Rating 6" / 300# (In) 6" / 300# (Out) 69 Bench range (*)

8 Pipe wall thickness (Out) 7.11 mm 70 Action modulating on-off others

9 Pipe material ASTM A 333 Gr. 6 71 Air connection size and thread (*)

10 Pipe insulation thermal acoustic 72 Case material/finish/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002

11 Pipe corrosion allow. 1 mm 73 Actuator orientation Vertical

12 Pipe connection (note 3) 4" 74 Other actuator elect. hydraulic manual

13 Pipe design pressure/temperature 44 barg / 85 °C 75

14 Process fluid Propane 76 Handwheel

15 Upstream condition liquid vapour gas 77

16 Min. Norm. Max. Unit 78 Tag. No. MFR. (*) Model (*)

17 Flow rate 20023 20030 58000 kg/h 79 Input signal pneumatic (0.2-1 barg) electric (4-20 mA)

18 Inlet pressure P1 33.91 33.91 25 barg 80 Action direct reverse

19 Outlet pressure P2 10 (note 4) 23 23 barg 81 Style single act. double act.

POSITIONER (*)

20 Temperature T1 12.4 12.4 50 °C 82 Characteristic linear MFR.STD.

21 Inlet density ρ or M 517.4 516.5 452.8 kg/m3 83 Digital comunication HART

22 Specific gravity 0.52 0.52 0.45 84 Electric connection ISO M20 Air connection (*)

23 Viscosity 0.11 0.11 0.08 cP 85 Enclosure material low copper aluminium, epoxy coated

24 Vapour pressure Pv 7.1 7.1 17.6 bara 86 Enclosure mechanical protection IP 66

25 Critical pressure Pc 42.82 bara 87 Accessories bypass gauges

26 Ratio of specific heats k 1.6 88 Reduction of haz. Ex-ia explos.-proof

27 Compressibility factor Z 0.11 89 Tag. No. MFR. Model

28 Max. Shutoff ΔP 34 bar 90 Switch type mech. proximity pneumatic

POS. IND. SWITCH (*)

29 Air supply 4.5 barg min. 10.5 barg max. 91 Contact type SPST SPDT DPDT Namur

30 Power failure pos. open closed hold 92 Switching pos. closed % travel open

31 Calculations MFR data 93 Switching acting make break

32 Min. Norm. Max. 94 Contact rating Contact material

SUPPLIER (note (1) , (*))

33 CV 6.57 9.74 71.21 CV= 95 Reduction of haz. intrin. safe explos.-proof

34 % travel 10.2 14.6 63 96 Enclosure mechanical protection Enclosure material

35 FLP FLP= 97 Electric conn. (n°/size)

36 FD FD= 98 Integral indicator

37 σ σMR= 99 Tag. No. MFR. Model

38 xT 100 Valve style two way three way four way

39 Mach n°/ outlet velocity (m/s) 1.32 m/s 1.32 m/s 4.4 m/s 101 Coil de-energ.: ctrl. valve open closed hold

SOLENOID VALVE (*)

40 Sound pressure level (dB(A)) 82 < 70 < 70 102 Air connection Port size

41 MFR (*) Model (*) 103 Reset automatic manual

42 Body type single seat globe 104 Body/Trim material

43 Flow direction to close 105 Mechanical protection Electric connection

44 Pressure rating 300# 106 Reduction of haz. intrin. safe explos.-proof

45 Nominal size 4" 107 Coil supply nominal voltage (U) UMIN : UMAX :

46 End conn. flg. flgless welded thd. 108 Coil insulation class / max consumption /

47 Flange face finish RF 125Ra 109

VALVE BODY ASSEMBLY (*)

48 Valve face to face dimension (*) 110 Air set MFR. (*) Model (*) connect:¼" NPT-F

49 End extensions required (xx mm) not required 111 with filter with gauge

50 Bonnet style std. ext bellows 112 Transducer MFR. Model

51 Body/bonnet matl. CS ASTM A350 LF2 / ASTM A352 LCB 113

52 Trim standard low noise anti cavitation (*) 114

53 Characteristic linear eq. percent 115 Booster MFR. Model

OTHERS (*)

54 Plug / ball / disc matl. AISI 316 + STELLITE 116

55 Guide / seat matl. AISI 316 / AISI 316 + STELLITE 117 Lockup MFR. Model

56 Stem matl. AISI 316 118

57 Seat style metal soft seat 119 Position transmitter MFR. Model

58 Trim coating 120

59 Leakage specification/ class ANSI FCI 70-2 / IV 121 Stem travel indicator

60 Packing type low emission normal 122 Tubing & fittings 10 mm OD Matl. SS

61 Packing matl. PTFE 123

62 External coat painting/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002 124

NOTES

(*) Information to be supplied or to be confirmed by Manufacturer

(1) Manufacturer is required to provide his valve calculation sheet according to ISA S 75-01 (engineering calculation sheet is attached for preliminary valve sizing purpose)

(2) Valve shall be supplied completely assembled with actuator and all the accessories requested on this data sheet.

(3) Pipe provided with concentric reductions and connections to suit valve body/size connection

(4) Minimum operating pressure to be confirmed by SNDP

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 5 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

CONTROL VALVE

VALVE TAG NUMBER : NG0-323-PCV-0721 REFERENCE SPEC. NO.: NAWPPL-BIMS-NPPL-000-CI-SPE-00005

1 Location/P&ID NAWPPL-BIMS-0F05-323-PR-PID-00003 63 MFR. (*) Model (*)

2 Service pressure control at butane metering skid outlet 64 Pneumatic diaphragm piston others

3 Haz. area class. Zone 2, Gas Group IIB, Temperature Class T3 65 Style sprg. opposed double act. air spr.

4 Ambient temp. -0.2°C min. 46.2°C max. 66 Area (*)

5 Allowable sound pressure level 85 dB(A) 67 Reqd. Travel (mm) / angle (°) (*) / (*)

6 Pipe identification No. NG0-4"-LB-323-0019-B41-V 68 Supply press. (*) min. (*) max.

ACTUATOR (*)

PROCESS DATA RELEVANT FOR CONTROL VALVE SELECTION

7 DN /Rating 4" / 300# (In) 4" / 300# (Out) 69 Bench range (*)

8 Pipe wall thickness (Out) 6.02 mm 70 Action modulating on-off others

9 Pipe material ASTM A 106 Gr. B 71 Air connection size and thread (*)

10 Pipe insulation thermal acoustic 72 Case material/finish/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002

11 Pipe corrosion allow. 1 mm 73 Actuator orientation Vertical

12 Pipe connection (note 3) 3" 74 Other actuator elect. hydraulic manual

13 Pipe design pressure/temperature 44 barg / 85 °C 75

14 Process fluid Butane 76 Handwheel

15 Upstream condition liquid vapour gas 77

16 Min. Norm. Max. Unit 78 Tag. No. MFR. (*) Model (*)

17 Flow rate 20023 20057 28000 kg/h 79 Input signal pneumatic (0.2-1 barg) electric (4-20 mA)

18 Inlet pressure P1 33.74 33.74 16.5 barg 80 Action direct reverse

19 Outlet pressure P2 7.8 (note 4) 14.5 14.5 barg 81 Style single act. double act.

POSITIONER (*)

20 Temperature T1 11.7 11.7 50 °C 82 Characteristic linear MFR.STD.

21 Inlet density ρ or M 583.5 581.4 533.6 kg/m3 83 Digital comunication HART

22 Specific gravity 0.58 0.58 0.53 84 Electric connection ISO M20 Air connection (*)

23 Viscosity 0.19 0.19 0.13 cP 85 Enclosure material low copper aluminium, epoxy coated

24 Vapour pressure Pv 1.94 1.94 5.87 bara 86 Enclosure mechanical protection IP 66

25 Critical pressure Pc 37.52 bara 87 Accessories bypass gauges

26 Ratio of specific heats k 1.4 88 Reduction of haz. Ex-ia explos.-proof

27 Compressibility factor Z 0.1 89 Tag. No. MFR. Model

28 Max. Shutoff ΔP 36.2 bar 90 Switch type mech. proximity pneumatic

POS. IND. SWITCH (*)

29 Air supply 4.5 barg min. 10.5 barg max. 91 Contact type SPST SPDT DPDT Namur

30 Power failure pos. open closed hold 92 Switching pos. closed % travel open

31 Calculations MFR data 93 Switching acting make break

32 Min. Norm. Max. 94 Contact rating Contact material

SUPPLIER (note (1) , (*))

33 CV 5.98 6.95 31.54 CV= 95 Reduction of haz. intrin. safe explos.-proof

34 % travel 17.9 20.4 59.4 96 Enclosure mechanical protection Enclosure material

35 FLP FLP= 97 Electric conn. (n°/size)

36 FD FD= 98 Integral indicator

37 σ σMR= 99 Tag. No. MFR. Model

38 xT 100 Valve style two way three way four way

39 Mach n°/ outlet velocity (m/s) 2.1 m/s 2.1 m/s 3.2 m/s 101 Coil de-energ.: ctrl. valve open closed hold

SOLENOID VALVE (*)

40 Sound pressure level (dB(A)) 81 73 < 70 102 Air connection Port size

41 MFR (*) Model (*) 103 Reset automatic manual

42 Body type single seat globe 104 Body/Trim material

43 Flow direction to close 105 Mechanical protection Electric connection

44 Pressure rating 300# 106 Reduction of haz. intrin. safe explos.-proof

45 Nominal size 3" 107 Coil supply nominal voltage (U) UMIN : UMAX :

46 End conn. flg. flgless welded thd. 108 Coil insulation class / max consumption /

47 Flange face finish RF 125Ra 109

VALVE BODY ASSEMBLY (*)

48 Valve face to face dimension (*) 110 Air set MFR. (*) Model (*) connect:¼" NPT-F

49 End extensions required (xx mm) not required 111 with filter with gauge

50 Bonnet style std. ext bellows 112 Transducer MFR. Model

51 Body/bonnet matl. CS ASTM A216 WCB 113

52 Trim standard low noise anti cavitation (*) 114

53 Characteristic linear eq. percent 115 Booster MFR. Model

OTHERS (*)

54 Plug / ball / disc matl. AISI 316 + STELLITE 116

55 Guide / seat matl. AISI 316 / AISI 316 + STELLITE 117 Lockup MFR. Model

56 Stem matl. AISI 316 118

57 Seat style metal soft seat 119 Position transmitter MFR. Model

58 Trim coating 120

59 Leakage specification/ class ANSI FCI 70-2 / IV 121 Stem travel indicator

60 Packing type low emission normal 122 Tubing & fittings 10 mm OD Matl. SS

61 Packing matl. PTFE 123

62 External coat painting/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002 124

NOTES

(*) Information to be supplied or to be confirmed by Manufacturer

(1) Manufacturer is required to provide his valve calculation sheet according to ISA S 75-01 (engineering calculation sheet is attached for preliminary valve sizing purpose)

(2) Valve shall be supplied completely assembled with actuator and all the accessories requested on this data sheet.

(3) Pipe provided with concentric reductions and connections to suit valve body/size connection

(4) Minimum operating pressure to be confirmed by SNDP

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

You might also like

- Omniscan Techniques For Crack SizingDocument31 pagesOmniscan Techniques For Crack Sizingalinor_tnNo ratings yet

- ISO 6520 Defects Overview PDFDocument27 pagesISO 6520 Defects Overview PDFalinor_tn80% (5)

- ISO 50001 NotesDocument21 pagesISO 50001 NotesLevi Mecca100% (1)

- 31 38 01 31-P6000CFP-000-PV - C PDFDocument5 pages31 38 01 31-P6000CFP-000-PV - C PDFmanojballaNo ratings yet

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDocument251 pages000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnNo ratings yet

- 000 ZA E 09411 Punch List ProcedureDocument17 pages000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Oerlikon ManualDocument255 pagesOerlikon Manualapoorva singhNo ratings yet

- Microscope ActivityDocument5 pagesMicroscope ActivityJulie GerberNo ratings yet

- Globe Valve1 DatasheetDocument1 pageGlobe Valve1 DatasheetobumuyaemesiNo ratings yet

- 50 190 RC e 03100Document6 pages50 190 RC e 03100ThirukkumaranBalasubramanianNo ratings yet

- Norsok MDS TableDocument2 pagesNorsok MDS TableerstendrainNo ratings yet

- Mto Check List1Document4 pagesMto Check List1vipul gandhi100% (1)

- VDS (Valve Data Sheet)Document1 pageVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Check Valve DatasheetDocument4 pagesCheck Valve DatasheetSeptian FirdausNo ratings yet

- ELT-01-EP-TS-0005 - Specification For Manual Valve - R0Document20 pagesELT-01-EP-TS-0005 - Specification For Manual Valve - R0jorgekarlosprNo ratings yet

- What Is A Flushing RingDocument6 pagesWhat Is A Flushing RingFarooqNo ratings yet

- Final-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815Document80 pagesFinal-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815KalaiYarasan100% (1)

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- 903-10004-SPC-M-001 Piping Material SpecificationDocument15 pages903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNo ratings yet

- 4.3.10 Data Sheet For Air Release ValveDocument3 pages4.3.10 Data Sheet For Air Release Valvevenka07No ratings yet

- Chemical Injection Skids - FinalDocument2 pagesChemical Injection Skids - Finallethanhcong228No ratings yet

- Material Requisition For Flexible Hose - Rev0Document5 pagesMaterial Requisition For Flexible Hose - Rev0altipatlarNo ratings yet

- Steam Trap Datasheet TLV Type P65SRNDocument2 pagesSteam Trap Datasheet TLV Type P65SRNAnonymous ThzA9zNo ratings yet

- LTJ-PGAS-GTLT-EN-DS-001 Buffer Tank Data SheetDocument15 pagesLTJ-PGAS-GTLT-EN-DS-001 Buffer Tank Data SheetsswahyudiNo ratings yet

- Iit MumbaiDocument243 pagesIit MumbaiYogesh JagdaleNo ratings yet

- Barred Tee DatasheetDocument3 pagesBarred Tee DatasheetBiginch67% (3)

- Piping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionDocument20 pagesPiping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionSami ThirunavukkarasuNo ratings yet

- GP410118 - Chemical Feed EquipmentDocument29 pagesGP410118 - Chemical Feed EquipmentIlham Husnul Abid100% (1)

- Data Sheet Ko Drum 43-401Document14 pagesData Sheet Ko Drum 43-401sokrat sebti100% (1)

- L&T Double Block and Bleed Plug ValvesDocument12 pagesL&T Double Block and Bleed Plug Valvesvijay10484No ratings yet

- Title / Link To Download Bidding DocumentDocument24 pagesTitle / Link To Download Bidding Documentarjun SinghNo ratings yet

- Design Criteria For Mechanical Equipment 4S. 4300 SAI S0003 ISGP G00000 ...Document28 pagesDesign Criteria For Mechanical Equipment 4S. 4300 SAI S0003 ISGP G00000 ...vydani100% (1)

- Section VIII Div. 1 - UG-119 PDFDocument1 pageSection VIII Div. 1 - UG-119 PDFEsapermana RiyanNo ratings yet

- Pig Launcher Data Sheet 91303 - 8 InchDocument4 pagesPig Launcher Data Sheet 91303 - 8 InchSina100% (1)

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BDocument7 pagesPE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7No ratings yet

- Equipment Design BasisDocument4 pagesEquipment Design BasisAnjani GantiNo ratings yet

- A0Y0Y7 - Appendix E1 - Engineering Piping SpecificationsDocument40 pagesA0Y0Y7 - Appendix E1 - Engineering Piping SpecificationsDipesh YadavNo ratings yet

- Barred TeesDocument1 pageBarred TeesAdvis100% (1)

- Spec For Process StrainerDocument11 pagesSpec For Process StrainerHarish GundaNo ratings yet

- Pressure Vessel RulesDocument15 pagesPressure Vessel Rulesnirmal100% (1)

- TN10 Critical Line List SampleDocument2 pagesTN10 Critical Line List Sampleyulianus_srNo ratings yet

- Specification For Piping DesignDocument57 pagesSpecification For Piping DesignZainuddin CIENo ratings yet

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- Control ValvesDocument2 pagesControl ValvesJuan Pablo MarvalNo ratings yet

- Technical Specification For PipesDocument13 pagesTechnical Specification For PipesRahul GangulyNo ratings yet

- SEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev ADocument15 pagesSEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev AShanu kumarNo ratings yet

- Engineering Design Basis Static EqptDocument52 pagesEngineering Design Basis Static EqptRajesh OwaiyarNo ratings yet

- Allowable Nozzle LoadsDocument6 pagesAllowable Nozzle Loads김동하No ratings yet

- Piping Material Specification Pipe Class: A1ADocument8 pagesPiping Material Specification Pipe Class: A1AShreesh SharmaNo ratings yet

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Easyflex Flexible Hose DatasheetDocument2 pagesEasyflex Flexible Hose DatasheetzassssNo ratings yet

- Ball Valve Data Sheet: Item Requirement NotesDocument1 pageBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiNo ratings yet

- DBB Datasheet WHRP PDFDocument48 pagesDBB Datasheet WHRP PDFRajendraNo ratings yet

- Piping Class CompletoDocument638 pagesPiping Class CompletoEduardo Rueda100% (1)

- Autopipe Vessel Guide Pages 6-10Document5 pagesAutopipe Vessel Guide Pages 6-10fiuto_rights_1404802No ratings yet

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument4 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- General Specification For Air-Conditioning, Refrigeration, Ventilation and Central Monitoring & Control SystemDocument3 pagesGeneral Specification For Air-Conditioning, Refrigeration, Ventilation and Central Monitoring & Control SystemjackwpsoNo ratings yet

- Technical Data Sheet For Temperature TransmitterDocument38 pagesTechnical Data Sheet For Temperature Transmitteralinor_tn100% (1)

- Nawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesDocument18 pagesNawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesWalid KhelfaNo ratings yet

- NAWPPL-BIMS-NPPL-000-HS-PRO-00009 - C01 - Tagging & Isolation ProcedureDocument8 pagesNAWPPL-BIMS-NPPL-000-HS-PRO-00009 - C01 - Tagging & Isolation ProcedureMoaatazz NouisriNo ratings yet

- Nawppl-Bims-Nppl-000-Co-Mst-00001-000 - Method of Statement For Pipeline Route Site VisitDocument34 pagesNawppl-Bims-Nppl-000-Co-Mst-00001-000 - Method of Statement For Pipeline Route Site VisitWalid KhelfaNo ratings yet

- Nawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test SpecificationDocument44 pagesNawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test Specificationradhwen chammakhi100% (1)

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- 000-ZA-E-09413 Construction Progress Meas ProcDocument12 pages000-ZA-E-09413 Construction Progress Meas Procalinor_tnNo ratings yet

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocument32 pagesHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (2)

- IDS For Fiber Optic CableDocument5 pagesIDS For Fiber Optic Cablealinor_tnNo ratings yet

- Nawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping SupportsDocument21 pagesNawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping Supportsalinor_tnNo ratings yet

- Pipeline Welding Visual Inspection ReportDocument8 pagesPipeline Welding Visual Inspection Reportalinor_tn0% (1)

- WPS MS 01C Rev. 0Document1 pageWPS MS 01C Rev. 0alinor_tnNo ratings yet

- Work Method Statement For De-Watering Drying and Purging After HydrotestDocument12 pagesWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnNo ratings yet

- ESAB - PipelinesDocument65 pagesESAB - PipelinesLigia114100% (2)

- 000 ZA E 09403 SITE NC MNGMT ProcedureDocument11 pages000 ZA E 09403 SITE NC MNGMT Procedurealinor_tn100% (1)

- Technical Data Sheet For Temperature TransmitterDocument38 pagesTechnical Data Sheet For Temperature Transmitteralinor_tn100% (1)

- Pipeline Hydrotest ProcedureDocument78 pagesPipeline Hydrotest Procedurealinor_tn100% (2)

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- MLE System SubSystem SheduleDocument29 pagesMLE System SubSystem Shedulealinor_tnNo ratings yet

- Welders MatrixDocument1 pageWelders Matrixalinor_tn100% (2)

- Sample Test Pack - Piping HydrotestDocument96 pagesSample Test Pack - Piping Hydrotestalinor_tn75% (4)

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDocument11 pagesIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tn100% (1)

- Raw Gas Pipeline - Alignment Sheet N.407Document1 pageRaw Gas Pipeline - Alignment Sheet N.407alinor_tn100% (1)

- PT-MT Kurs NotuDocument300 pagesPT-MT Kurs NotuBahadir TekinNo ratings yet

- General Procedure For AUTDocument19 pagesGeneral Procedure For AUTalinor_tn100% (2)

- Piping Codes (41-45)Document42 pagesPiping Codes (41-45)Brenda Davis100% (2)

- TeknosDocument76 pagesTeknosMartin LafonNo ratings yet

- Erection Manual-Pc PipingDocument219 pagesErection Manual-Pc Pipingalinor_tn100% (2)

- Jacobs Standard Specification - Piping Fabrication and ErectionDocument19 pagesJacobs Standard Specification - Piping Fabrication and Erectionalinor_tn100% (1)

- Piping Notes 1Document47 pagesPiping Notes 1sanjay421100% (1)

- ASME CalculationDocument25 pagesASME Calculationalinor_tn100% (1)

- Inspection Plan For Crane PDFDocument3 pagesInspection Plan For Crane PDFalinor_tnNo ratings yet

- Group4 Tourismpolicy Quiz 1Document4 pagesGroup4 Tourismpolicy Quiz 1kiaraaurin26No ratings yet

- Shell Pakistan Financial ManagementDocument24 pagesShell Pakistan Financial ManagementMohsyn SyedNo ratings yet

- Pickling & PasatativationDocument11 pagesPickling & PasatativationS.MANIMARANNo ratings yet

- Areas of Triangles, Parallelograms, Sectors and Segments Area of TriangleDocument4 pagesAreas of Triangles, Parallelograms, Sectors and Segments Area of Trianglebigmike459No ratings yet

- Navarez Bsais 4 y1 3 Project 3Document4 pagesNavarez Bsais 4 y1 3 Project 3ashleyjoymacabentaNo ratings yet

- Our Kitchen Is A Lab PicklesDocument9 pagesOur Kitchen Is A Lab PicklesJoana RitaNo ratings yet

- Spare Parts RequisitionDocument2 pagesSpare Parts Requisitionyasinyou143No ratings yet

- Virlix DrugDocument2 pagesVirlix DrugMsOrangeNo ratings yet

- Drotaverine: Solution For Injection - 40 MG / 2 MLDocument1 pageDrotaverine: Solution For Injection - 40 MG / 2 MLZarbakht AliNo ratings yet

- Sustainable Business Models-Canvas For Sustainability, Evaluation Method, and Their Application To Additive Manufacturing in Aircraft MaintenanceDocument22 pagesSustainable Business Models-Canvas For Sustainability, Evaluation Method, and Their Application To Additive Manufacturing in Aircraft Maintenanceakshita ramdasNo ratings yet

- 9 World War II in Kiribati: Sam HighlandDocument4 pages9 World War II in Kiribati: Sam HighlandkemalNo ratings yet

- Computer Aided Design of Non-Standard Elliptical Gear DrivesDocument11 pagesComputer Aided Design of Non-Standard Elliptical Gear Driveseng_pedro3421No ratings yet

- Frenic4600fm5ecatalog24d1 e 0035dDocument28 pagesFrenic4600fm5ecatalog24d1 e 0035dhoang van tuyenNo ratings yet

- Tennis Court - CentComDocument4 pagesTennis Court - CentComEppNo ratings yet

- Baumann Primordial CosmologyDocument77 pagesBaumann Primordial CosmologyLillyOpenMindNo ratings yet

- Movement of Substances Across A Plasma Membrane in Living OrganismsDocument1 pageMovement of Substances Across A Plasma Membrane in Living Organismsboloqpiau boloqbokNo ratings yet

- Postalb 16-Synthesis of Sudan 1Document2 pagesPostalb 16-Synthesis of Sudan 1edcalumpitNo ratings yet

- Commented Research Proposal @GTSDocument13 pagesCommented Research Proposal @GTSMahedere TebebeNo ratings yet

- Egypt Balance of PaymentDocument7 pagesEgypt Balance of PaymentBram DirgantaraNo ratings yet

- Digital USB Driver Installation Guide R5.0Document26 pagesDigital USB Driver Installation Guide R5.0elkinfgh0417No ratings yet

- Biryani Encompasses A Heritage of Classical South Asian CuisineDocument3 pagesBiryani Encompasses A Heritage of Classical South Asian CuisineMD RafianNo ratings yet

- Concept of Measurement-1Document83 pagesConcept of Measurement-1Pratheesh JpNo ratings yet

- Pastoral PaperDocument32 pagesPastoral Paperkurios33No ratings yet

- Case No. 9 Ramos v. Director of Lands (Full Text and Digest)Document10 pagesCase No. 9 Ramos v. Director of Lands (Full Text and Digest)Victoria AlexanderNo ratings yet

- Acer Aspire 4935 Compal La 4492p Kal90 Kalh0 Laptop Schematics Diagram PDFDocument52 pagesAcer Aspire 4935 Compal La 4492p Kal90 Kalh0 Laptop Schematics Diagram PDFOgan AltrkyNo ratings yet

- KVLDocument5 pagesKVLAliNo ratings yet

- P. 7-Comprehension-NotesDocument29 pagesP. 7-Comprehension-NotessharifniolaNo ratings yet