Fabricated Tee Strainers: Features Options

Fabricated Tee Strainers: Features Options

Uploaded by

mombarreCopyright:

Available Formats

Fabricated Tee Strainers: Features Options

Fabricated Tee Strainers: Features Options

Uploaded by

mombarreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fabricated Tee Strainers: Features Options

Fabricated Tee Strainers: Features Options

Uploaded by

mombarreCopyright:

Available Formats

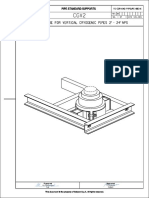

FABRICATED TEE STRAINERS

Model 150/300/600TFSBW Steel

Model 150/300/600TFSSBW Stainless Steel

FEATURES OPTIONS

SCREENS: 1/8" perforated type 304 stainless steel on sizes 2" to 24". ● Standard in sizes 2" through 24". Larger sizes available. Consult

Other perforations, meshes and materials are available factory

upon request ● Dimensions can be modified to suit customer requirements

● End connections available in RF flanges, RTJ flanges or buttweld.

CONSTRUCTION: Standard units are fabricated with weld-neck ● Various body and screen materials and coatings are available.

flanges in standard pressure classes up to 600 lb. ● Special screen open area ratios

Other flange styles and welded connections are ● Quick-opening cover

available per your specifications ● Cover lifting davits

● Upstream and downstream screen supports allow for bi-directional flow

CODES: Fabricated to ASME B31.1, ASME B31.3 and/or ASME ● Reduced inlets and outlets

Section VIII , Div. 1. Latest Revision ● Self-Flushing assembly

● Vent and pressure differential connections

PRESSURE AND TEMPERATURE RATINGS

Maximum Design Pressure

Model Body Material Low Temperature Limit – M.D.M.T

M.A.W.P. at 100ºF

150TFSBW Carbon Steel 285 psig -20 ºF

150TFSSBW / 150TFSS6BW 304 / 316 Stainless Steel 275 psig -20 ºF (Optional -425 °F available)

150TFSSLBW / 150TFSSL6BW 304L / 316L Stainless Steel 230 psig -20 ºF (Optional -425 °F available)

300TFSBW Carbon Steel 740 psig -20 ºF

300TFSSBW / 300TFSS6BW 304 / 316 Stainless Steel 720 psig -20 ºF (Optional -425 °F available)

300TFSSLBW / 300TFSSL6BW 304L / 316L Stainless Steel 600 psig -20 ºF (Optional -425 °F available)

600TFSBW Carbon Steel 1480 psig -20 ºF

600TFSSBW / 600TFSS6BW 304 / 316 Stainless Steel 1440 psig -20 ºF (Optional -425 °F available)

600TFSSLBW / 600TFSSL6BW 304L / 316L Stainless Steel 1200 psig -20 ºF (Optional -425 °F available)

All models will be designed to the maximum design pressure unless alternative design conditions are specified. In some cases a cost savings may result if lower

design conditions are acceptable.

Lower and higher M.D.M.T rating is available upon request.

Colton has a policy of continuous product research and improvement and reserves the right to change design and specifications without notice

Tel: 1-888-300-9155 Fax: 1-888-300-9160 www.COLTONIND.com info@coltonind.com

BULLETIN STR720-1

FABRICATED TEE STRAINERS

STYLE 1 STYLE 2 STYLE 3

DIMENSIONS AND WEIGHTS FOR SERIES 150T

DIMENSIONS

Size A B C D E Weight

mm in mm in mm in mm in mm in mm in kg lbs

50 2 254 10 127 5 146 5-3/4 279 11 318 12-1/2 13 28

80 3 311 12-1/4 172 6-3/4 179 7-1/16 349 13-3/4 387 15-1/4 24 52

100 4 362 14-1/4 210 8-1/4 205 8-1/16 413 16-1/4 467 18-3/8 36 79

125 5 425 16-3/4 248 9-3/4 237 9-5/16 489 19-1/4 549 21-5/8 48 105

150 6 464 18-1/4 286 11-1/4 257 10-1/8 540 21-1/4 606 23-5/8 64 140

200 8 559 22 356 14 308 12-1/8 660 26 737 29 104 230

250 10 635 25 432 17 348 13-11/16 762 30 851 33-1/2 148 325

300 12 737 29 508 20 400 15-3/4 889 35 991 39 227 500

350 14 813 32 559 22 441 17-3/8 991 39 1092 43 322 710

400 16 864 34 610 24 468 18-7/16 1067 42 1168 46 390 860

450 18 965 38 686 27 552 20-9/16 1194 47 1308 51-1/2 465 1025

500 20 1051 41-11/32 762 30 568 22-3/8 1305 51-3/8 1432 56-3/8 613 1350

600 24 1168 46 864 34 632 24-7/8 1473 58 1600 63 953 2100

DIMENSIONS AND WEIGHTS FOR SERIES 300T

DIMENSIONS

Size A B C D E Weight

mm in mm in mm in mm in mm in mm in kg lbs

50 2 267 10-1/2 127 5 156 6-1/8 292 11-1/2 330 13 19 42

80 3 330 13 172 6-3/4 194 7-5/8 368 14-1/2 406 16 33 72

100 4 381 15 210 8-1/4 222 8-3/4 432 17 486 19-1/8 57 125

125 5 445 17-1/2 248 9-3/4 257 10-1/8 508 20 568 22-3/8 73 160

150 6 483 19 286 11-1/4 278 10-15/16 559 22 625 24-5/8 102 225

200 8 578 22-3/4 356 14 330 13 679 26-3/4 756 29-3/4 159 350

250 10 667 26-1/4 432 17 381 15 794 31-1/4 883 34-3/4 225 495

300 12 768 30-1/4 508 20 435 17-1/8 921 36-1/4 1022 40-1/4 347 765

350 14 845 33-1/4 559 22 476 18-3/4 1022 40-1/4 1124 44-1/4 465 1025

400 16 902 35-1/2 610 24 508 20 1105 43-1/2 1207 47-1/2 599 1320

450 18 1003 39-1/2 686 27 562 22-1/8 1232 48-1/2 1346 53 772 1700

500 20 832 32-3/4 762 30 606 23-7/8 1086 42-3/4 1213 47-3/4 1022 2250

600 24 1200 47-1/4 864 34 670 26-3/8 1505 59-1/4 1632 64-1/4 1544 2340

Tel: 1-888-300-9155 Fax: 1-888-300-9160 www.COLTONIND.com info@coltonind.com

BULLETIN STR720-1

FABRICATED TEE STRAINERS

STYLE 1 STYLE 2 STYLE 3

DIMENSIONS AND WEIGHTS FOR SERIES 600T

DIMENSIONS

Size A B C D E Weight

mm in mm in mm in mm in mm in mm in kg lbs

50 2 286 11-1/4 127 5 175 6-7/8 311 12-1/4 349 13-3/4 24 52

80 3 349 13-3/4 172 6-3/4 213 8-3/8 387 15-1/4 425 16-3/4 45 100

100 4 425 16-3/4 210 8-1/4 257 10-1/8 476 18-3/4 530 20-7/8 86 190

125 5 489 19-1/4 248 9-3/4 295 11-5/8 552 21-3/4 613 24-1/8 134 295

150 6 533 21 286 11-1/4 321 12-5/8 610 24 676 25-5/8 166 365

200 8 635 25 356 14 379 14-15/16 737 29 813 32 263 580

250 10 749 29-1/2 432 17 445 17-1/2 876 34-1/2 965 38 409 900

300 12 832 32-3/4 508 20 489 19-1/4 984 38-3/4 1086 42-3/4 522 1150

350 14 902 35-1/2 559 22 527 20-3/4 1080 42-1/2 1181 46-1/2 672 1480

400 16 978 38-1/2 610 24 572 22-1/2 1181 46-1/2 1283 50-1/2 885 1950

450 18 1067 42 686 27 622 24-1/2 1295 51 1410 55-1/2 1112 2450

500 20 1156 45-1/2 762 30 673 26-1/2 1410 55-1/2 1537 60-1/2 1430 3150

600 24 1283 50-1/2 864 34 749 29-1/2 1588 62-1/2 1715 67-1/2 2088 4600

Notes:

● Dimensions shown are for flanged and butt-weld strainers. Dimensions can be modified to suit customer requirements

● Drains and differential tappings are optional

● Weights shown are for flanged end strainers only

ORDERING CODES

ANSI STRAINER CONNECTION BODY COVER CONSTRUCTION

STYLE

CLASS TYPE TYPE MATERIAL TYPE TYPE

Example: 150 T F S B W 1

150 T - Tee F – Flanged S – Carbon Steel B – Bolted W - Welded 1

300 RTJ – Ring Joint SS – 304 Stainless Steel D – Bolted Cover With Davit 2

600 BW – Butt-weld SS6 – 316 Stainless Steel H – Swing Bolt Hinged Cover 3

G - Grooved SSL – 304L Stainless Steel

TC – Tri-Clamp SS6L – 316L Stainless Steel

(Other materials are available

upon request)

Colton has a policy of continuous product research and improvement and reserves the right to change design and specifications without notice

Tel: 1-888-300-9155 Fax: 1-888-300-9160 www.COLTONIND.com info@coltonind.com

BULLETIN STR720-1

You might also like

- Service - Manual - SAMSUNG 0 - 20130109-1Document110 pagesService - Manual - SAMSUNG 0 - 20130109-1Georom Instal100% (1)

- Inspection and Test PlanDocument10 pagesInspection and Test Planixotee100% (1)

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 pageData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanNo ratings yet

- FORD Injector ProgrammingDocument5 pagesFORD Injector Programmingmanutec100% (1)

- Herl PDF Catalog 120926Document302 pagesHerl PDF Catalog 120926John Gordon-Smith100% (1)

- Piles Design Calc PDFDocument15 pagesPiles Design Calc PDFMukhlish Akhatar100% (4)

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- VBO - Triple Offset Butterfly ValveDocument14 pagesVBO - Triple Offset Butterfly ValveFabio Peres de Lima100% (1)

- Horizontal End Suction Pump Din 24255: GU, GUM Series 50Hz/60HzDocument8 pagesHorizontal End Suction Pump Din 24255: GU, GUM Series 50Hz/60HzAwwalin Bocah IlangNo ratings yet

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerAnonymous 0OizFXUONo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document5 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- Rhozeta: Structural Design Calculation Sheet For Block of Duplex FOR MR & Mrs Adokiye Precious CharlesDocument1 pageRhozeta: Structural Design Calculation Sheet For Block of Duplex FOR MR & Mrs Adokiye Precious CharlesEze NonsoNo ratings yet

- Butterfly ValveDocument6 pagesButterfly ValveRomisamomNo ratings yet

- 3 Way Ball ValvesDocument17 pages3 Way Ball ValvesSagar Bhosale100% (1)

- Inner Scraper Self-Cleaning FiltersDocument1 pageInner Scraper Self-Cleaning FiltersCarlos BarriosNo ratings yet

- 15-Produced Water Injection CoolerDocument1 page15-Produced Water Injection CoolerLe vuNo ratings yet

- Sa 423Document6 pagesSa 423Widya widyaNo ratings yet

- One Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsDocument3 pagesOne Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsMainuddin AliNo ratings yet

- Data Sheet For Globe ValveDocument4 pagesData Sheet For Globe ValveShaaban Noaman100% (1)

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- Pressure. Pressure and Temperature Ratings For Steel Pipe Flanges and Flanged Fittings. ANSI B16.5Document45 pagesPressure. Pressure and Temperature Ratings For Steel Pipe Flanges and Flanged Fittings. ANSI B16.5vyrgoNo ratings yet

- Composited Lined Butterfly Valves (Series BFVSC)Document12 pagesComposited Lined Butterfly Valves (Series BFVSC)AgustinaDeWinneNo ratings yet

- 03CA2SAE: Specification Piping Material ClassDocument7 pages03CA2SAE: Specification Piping Material Classabhishek186186No ratings yet

- Specification For Eye Wash & Safety ShowerDocument5 pagesSpecification For Eye Wash & Safety ShowerAnkit MaheshwariNo ratings yet

- Lokring Fitting Guide Rev1Document7 pagesLokring Fitting Guide Rev1John DryNo ratings yet

- Diaphragm ValveDocument1 pageDiaphragm ValveS AMNo ratings yet

- Sandborn Roofs System BrochureDocument5 pagesSandborn Roofs System BrochurezafarbadalNo ratings yet

- DS-50-0804.02-6000-004 Rev D2 Non Slam Check Valve PDFDocument2 pagesDS-50-0804.02-6000-004 Rev D2 Non Slam Check Valve PDFjhon smithNo ratings yet

- ASTM A707 GR L5 CL4Document6 pagesASTM A707 GR L5 CL4Ruben Dario Espinoza VasquezNo ratings yet

- CPVC Price ListDocument8 pagesCPVC Price ListYashwanth GowdaNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Air Release VacuumDocument7 pagesAir Release VacuumsudjonoNo ratings yet

- Flame Arrester Installation and Maintenance Instructions ForDocument3 pagesFlame Arrester Installation and Maintenance Instructions Forhk168No ratings yet

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocument2 pagesCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaNo ratings yet

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Document3 pages(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaNo ratings yet

- TECO Commercial Split TypeDocument23 pagesTECO Commercial Split TypeFerdinand FernandezNo ratings yet

- GA Drawing SLOP TankDocument2 pagesGA Drawing SLOP TankMathivanan AnbazhaganNo ratings yet

- Stainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Document1 pageStainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Senthil KumarNo ratings yet

- Fully Welded Ball Valve 2500 - Cross Sectional DrawingDocument4 pagesFully Welded Ball Valve 2500 - Cross Sectional DrawingJorge GarciaNo ratings yet

- Welded Pipes - API 5L Grade X65 PSL 2Document2 pagesWelded Pipes - API 5L Grade X65 PSL 2Minh TrungNo ratings yet

- QR4798 16x12 600# HTF - DWGDocument1 pageQR4798 16x12 600# HTF - DWGjasama100% (1)

- Ref. Code For Partition Plate TEMA (RCB-9.13) Nominal Pass Partition Plate Thickness As Per Table Rcb-9.131 Nominal Size Carbon Steel Alloy MatrialDocument5 pagesRef. Code For Partition Plate TEMA (RCB-9.13) Nominal Pass Partition Plate Thickness As Per Table Rcb-9.131 Nominal Size Carbon Steel Alloy MatrialbytestefNo ratings yet

- Gauge Accessories - Syphons TypeDocument2 pagesGauge Accessories - Syphons Typecasio662No ratings yet

- Sa 980 P 11434 Cs Swing Check Valve Rev. t02Document3 pagesSa 980 P 11434 Cs Swing Check Valve Rev. t02altipatlar100% (1)

- 02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Document1 page02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Roman Ugarte0% (1)

- VMS GailDocument129 pagesVMS GailManjunatha V100% (1)

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- SPE 76-002 (2006) Flange MaterialsDocument6 pagesSPE 76-002 (2006) Flange Materials김창배100% (1)

- 0708-Q-CC-004 Pipe Stress Calculation From KO Drum To Flare Rev ADocument9 pages0708-Q-CC-004 Pipe Stress Calculation From KO Drum To Flare Rev AElias EliasNo ratings yet

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- Stripper InfoDocument30 pagesStripper Infonedian_2006No ratings yet

- Datasheet DBB Ball ValvesDocument1 pageDatasheet DBB Ball ValvesVivi Oktavianti100% (1)

- How To Select Your Dosing SetDocument2 pagesHow To Select Your Dosing SetGrundfosEgyptNo ratings yet

- PIP VEDTA003 Atmospheric Storage Tank Data SheetDocument7 pagesPIP VEDTA003 Atmospheric Storage Tank Data SheetPRESIDENCIA SEVIGEANo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Static MixerDocument1 pageStatic Mixeraras aliNo ratings yet

- Iplex UPVC Pipes and Fittings CatalogueDocument18 pagesIplex UPVC Pipes and Fittings Cataloguemanoj thankachan100% (1)

- Simplex Basket StrainerDocument42 pagesSimplex Basket StrainerShaisthaNo ratings yet

- Duplex StrainersDocument1 pageDuplex StrainersBossman Instruments TechnologyNo ratings yet

- Fabricated Basket Strainers: Features OptionsDocument3 pagesFabricated Basket Strainers: Features OptionsmusaveerNo ratings yet

- 25 SP650 1 MS Series SeparatorsDocument2 pages25 SP650 1 MS Series SeparatorsLa Ode AdhanNo ratings yet

- Fabricated "Y" Strainers: Features OptionsDocument2 pagesFabricated "Y" Strainers: Features OptionsGourav SharmaNo ratings yet

- Intrinsically Safe ValvesDocument7 pagesIntrinsically Safe ValvesmombarreNo ratings yet

- TIMSA Elements of Insulation DesignDocument6 pagesTIMSA Elements of Insulation DesignmombarreNo ratings yet

- Thermosetting PolymerDocument3 pagesThermosetting PolymermombarreNo ratings yet

- Astm f1470Document5 pagesAstm f1470mombarre100% (2)

- Curing Agents For Epoxy ResinsDocument10 pagesCuring Agents For Epoxy ResinsmombarreNo ratings yet

- Gao Et Al 2007 Anal ChemDocument7 pagesGao Et Al 2007 Anal ChemmombarreNo ratings yet

- The Misunderstanding of Memes: Biography of An Unscienti C Object, 1976-1999Document30 pagesThe Misunderstanding of Memes: Biography of An Unscienti C Object, 1976-1999mombarreNo ratings yet

- Gkc03 Checklist For FireproofingDocument4 pagesGkc03 Checklist For Fireproofingmombarre100% (1)

- Wall UnitDocument172 pagesWall UnitsamsibaniNo ratings yet

- 1224 Threading Machine - Operator's Manual PDFDocument71 pages1224 Threading Machine - Operator's Manual PDFAlberto Flores FrancoNo ratings yet

- 10863624Document88 pages10863624GhjNo ratings yet

- Parts Taskalfa 8000iDocument115 pagesParts Taskalfa 8000igkalman_2100% (2)

- RC411 Operator Manual: Instructions For The UserDocument14 pagesRC411 Operator Manual: Instructions For The UserAbdul KhaliqNo ratings yet

- EPB-TBM WorkingPhaseDocument3 pagesEPB-TBM WorkingPhaseLyndaNo ratings yet

- IAC PAC Power Plant BarhDocument19 pagesIAC PAC Power Plant BarhMohammad AtaullahNo ratings yet

- B.Tech 3-1 R16Document18 pagesB.Tech 3-1 R16Pranay PNo ratings yet

- ReclinerDocument20 pagesReclinersiddhifurniturehubNo ratings yet

- 2000 International Building Code® VIIDocument6 pages2000 International Building Code® VIIAsyraf ZailudinNo ratings yet

- 350 SX-F CAIROLI 2012: Spare Parts Manual: EngineDocument28 pages350 SX-F CAIROLI 2012: Spare Parts Manual: EnginecharlesNo ratings yet

- Add: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Document4 pagesAdd: 3B Ming Huang Industry, Wujin District, Changzhou, Jiangsu, China, 213100Vinícius MartinezNo ratings yet

- 125HBL-8-4 Parker Brass Hose BarbDocument14 pages125HBL-8-4 Parker Brass Hose BarbMROstop.comNo ratings yet

- Fan Uc Manuals 1785Document135 pagesFan Uc Manuals 1785SAMSUNG J1ACENo ratings yet

- Flow PakDocument12 pagesFlow PakAnonymous mZODBTHjUNo ratings yet

- 02 Engine Electronics IPOs PDFDocument44 pages02 Engine Electronics IPOs PDFgeorge_mudura167% (3)

- 0 Introduction To CE5108Document7 pages0 Introduction To CE5108Dicky DjayadiNo ratings yet

- DSR 2010-11Document285 pagesDSR 2010-11bolsamirNo ratings yet

- IACS Liquiefied Gas Cargo and Process PipingDocument8 pagesIACS Liquiefied Gas Cargo and Process Pipingmohammed ramzi CHAHBINo ratings yet

- Bearing GardDocument2 pagesBearing Gardmember1000No ratings yet

- Reinforced Concrete Box CulvertDocument64 pagesReinforced Concrete Box Culvertkhraieric16No ratings yet

- Boquillas AbbDocument16 pagesBoquillas Abbjtcool74No ratings yet

- Analysis of Subsynchronous Resonance in Power Systems: Printed BookDocument1 pageAnalysis of Subsynchronous Resonance in Power Systems: Printed BookRaturi DeepankarNo ratings yet

- HydropowerDocument24 pagesHydropowerHari KrishnanNo ratings yet

- Filter Systems Component Information (Combined) PDFDocument157 pagesFilter Systems Component Information (Combined) PDFwilson chacon0% (1)